Wisconsin Engine Repair Manual for TJD,THD,TH engines

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

WISCONSIN

MODE~ W2-880

TJD, THD, TH

REPAIR

]~CORP.

FOREWORD

Good operation anda planned maintenance program as outlined in this manual are vital in

obtaining maximum engine performance andlong engine life. Theinstructions on the following

pages have been written with this in mind,to give the operatora better understanding of the

various problems which may arise, andthe manner in which these problems can best be solved

or avoided.

The operator is cautioned againstthe useof anyparts, other than genuine Wis-Con Total Power

Corp.parts, for replacement or repair. These parts have been engineered and tested for their

particular job, and the useof any other parts may result in unsatisfactory performance and short

engine life. Wis-Con Total Power Corp. distributors and dealers, because of their close factory

relations, canrender the best and most efficient service.

THE LIFE OF YOUR ENGINE DEPENDS ON THE CARE IT RECEIVES.

The MODEL, SPECIFICATION and SERIAL NUMBER of your engine must be given when

ordering parts. The MODEL and SPECIFICATION number are on the name plate. The SERIAL

NUMBER is stamped either on the crankcase or the engine’s identification tag.

Copy the MODEL, SPECIFICATION and SERIAL NUMBER in the spaces provided below so

that it will be available when ordering parts.

MODEL SPECIFICATION

SERIAL NUMBER

To insure prompt and accurate service, the following informationmust also be given:

1. State EXACTLY the quantity of eachpart andpart number.

2. State definitely whether parts are to be shipped by express, freight or parcel post.

3. State the exactmailing address.

IMPORTANT

READTHESE INSTRUCTIONS CAREFULLY

All pointsof operation and maintenance have been covered as carefully as possible,but if further

information is required, send inqt,~iries to the factoryfor prompt attention.

When writing to the factory, ALWAYS GIVE THEMODEL, SPECIFICATION AND SERIAL

NUMBER of the enginereferred to.

Starting and Operating New Engines

Careful breaking-in of a new engine will greatly increase its life and result in troublefree operation.

A factory test is not sufficient to establish the polished bearing surfaces, which are so necessary

to the proper performance and long life of an engine.These can only be obtained by runninga

new engine carefully and under reduced loadsfor a short time.

¯ Be surethe engine is filled to the proper level with a good quality engine oil.

¯ For proper procedures to follow when breaking-in a new engine, see’Testing Rebuilt Engine’.

The various bearing surfaces in a new engine have not been glazed, asthey will be with continued

operation, and it is in this period of "running in" that specialcaremust be exercised, otherwise

the highly desired glaze will neverbe obtained. A new bearing surface that has once been

damaged by carelessness will be ruined forever.

IMPORTANT SAFETY NOTICE

Proper repair is important to the safe and reliable operation of an engine. This Repair Manual

outlines basic recommended procedures, some of whichrequire special tools, devicesor work

methods.

Improper repair procedures canbe dangerous and could result in injury or death.

READAND UNDERSTAND ALL SAFETY PRECAUTIONS AND

WARNINGS BEFORE PERFORMING REPAIRS ON THIS ENGINE

Warning labels have also been put on the engines to provide instructions and identify specific

hazards which, if not heeded, couldcause bodily injury or death to youor other persons. These

labels identify hazards which may not be apparentto a trained mechanic. Thereare many

potential hazards for an untrained mechanic and there is no way to label the engine againstall

such hazards. These warnings in the RepairManual andon the engine are indentified by this

symbol:

z WARNING

Operations that may result only in engine damage are identified in the RepairManual by this

symbol:

&CAUTION

Wis-Con Total Power Corp. cannot anticipate every possible circumstance that mightinvolve

a potential hazard; therefore,the warnings in this manual are not all inclusive. If a procedure,

tool, device orwork method not specifically recommended by Wis-Con Total PowerCorp., Industrial

Product Divisionis used, you must satisfy yourselfthat it is safe for you and others.You should

also ensure that the engine will not be damaged or made unsafe by the procedures youchoose.

IMPORTANT: The information, specifications and illustrations in this manual are based

on informationthat was available at the time it was published.The specifications,

torques, pressures of operation, measurements, adjustments, illustrations and other

items can change at any time. These changes can affect the service given to the product.

Get the complete and most current information before starting any job. For parts,

service, or information, contact Wis-Con Total Power Corp., Memphis, Tennessee.

/ WARNING

Mostsub-systems usedin conjunction with Wis-Con Total Power Corp. industrial engines

including (but not limited to) radiators, hoses, fans, fuel tanks,fuel lines or otherfuel system

components, batteries, electrical connections or other electrical components, clutches, trans-

missions, hydraulic pumps and generators, are not supplied by Wis-Con Total Power Corp.

These items are provided by the manufacturer of the end item in which the engine is used.

Some of the dangers associatedwith servicing such items are generally mentioned in this

manual; however, the appropriate handbooks and safety instructions provided by the manufac-

turer of the end item should always be consulted prior to the undertaking of anyworkon sub-

systems attached to the engine, to avoid any hazards inherent to thesesub-systems.

Read and observe all individual safety warnings as youusethis manual to operate, service or

repair your engine.

Always exercise caution whenever working with an engine or any associated system.

Injuries may be caused by lack of care when working with, or near, moving parts, hot parts,

pressurized systems, electrical equipment, or fuel systems.

Always weareye andhearing protection when working on or near engines.

Improper attire such as loose clothing,ties, rings, soft shoes or bare feet could be hazardous and

should be avoided when servicing engines.

Use or serviceof the engine (includingthe use of modified parts or materials) not in accordance

with manufacturer’s specifications could damage your engine or cause personal injury.

/ WARNING

Some equipment andmaterials usedin the overhaul or maintenance of an engine such as

machine tools, electrical equipment, compressed air, solvents, gasoline or other fuels may be

dangerous andcan cause injury. Always observe safety precautions.

ooo

111

Safety

Precautions

¯ Never fill fuel tank while engine is running or hot;

avoid the possibility of spilled fuel causing a fire.

¯ Always refuel slowly to avoid spillage.

¯ When starting engine, maintain a safe distance from

moving parts of equipment.

¯ Do not start engine with clutch engaged.

¯ Do not spin hand crank when starting. Keep crank-

ing components clean and free from conditions

which might cause the crank jaw to bind and not re-

lease properly. Oil periodically to prevent rust.

¯

Never run engine with governor disconnected, or op-

erate at speeds in excess of 3600 R.P.M. load.

Do not operate engine in a closed building unless

the exhaust is piped outside. This exhaust contains

carbon monoxide, a poisonous, odorless and invi-

sible gas, which if breathed causes serious illness

and possible death.

Never make adjustments on machinery while it is

connected to the engine, without first removing the

ignition cables from the spark plugs. Turning the

machinery over by hand during adjusting or cleaning

might start the engine and machinery with it, caus-

ing serious injury to the operator.

¯

Precaution is the best insurance agvinst accidents.

Keep this book handy at all times, fami-

liarize yourself with the operating instructions.

CONTENTS

Air Cleaners ....................................................................

10

Dry .Element (Tri-Phase) Air Cleaner .......................

11

Dry Type Air Cleaner ................................................

11

Oil Bath Air Cleaner .................................................

10

Alternator -- Flywheel ...................................................

17

Battery Ignition -- Distributor .......................................

14

Breather -- Crankcase ....................................................

11

Carburetor Adjustment ....................................................

12

Carburetor Service

Walbro Model LMH-33 .............................................

37

Walbro Model LUB ...................................................

35

Walbro Model WHG-53 ............................................

39

Zentih Model 68-7 ..................................................... 33

Clutch Adjustment ..........................................................

19

Clutch Power Take-off ...................................................

19

Clutch Reduction Unit Adjustment ................................

20

Compression -- Restoring ..............................................

17

Cooling ............................................................................. 8

Disassembly and Reassembly .........................................

22

Accessories ................................................................

22

Camshaft ....................................................................

28

Camshaft Gear ...........................................................

25

Carburetor and Manifold ...........................................

24

Connecting Rod and Piston .......................................

25

Crankshaft and Main Bearing Plate..........................

27

Cylinder Block .......................................................... 27

Cylinder Head ............................................................ 24

Engine Base ............................................................... 25

Flywheel and Shroud .................................................

23

Fuel Tank ...................................................................

24

Gear Cover ................................................................

24

House Panels .............................................................

22

Oil Pump ...................................................................

25

PistonRing and Rod Clearance Chart .......................

26

Piston Rings ...............................................................

26

Valve Tappets ............................................................

28

Valves and Seat Inserts .............................................

27

Distributor and Generator Maintenance .........................

15

Electric Wiring Circuits ..................................................

15

Electrical Wiring Diagrams ............................................

16

Firing Order .................................................................... 14

Flywheel Alternatorwith Solid State Regulation ...........

30

Fuel ................................................................................... 9

Fuel Filter ........................................................................

11

Fuel Pump & Priming ........................................................ 9

Fuel Pump Service .....................................................

~ .....

29

Gear Train --Timing Marks (Fig. 36) ...........................

25

General Information and Design ......................................

8

Governor Adjustment .....................................................

18

Governor Operation .....................................................

:.. 18

Horsepower .......................................................................

8

Ignition Switch ..................................................................

9

Ignition System .................................................................

8

Illustrations, Engine

Cross Section (TJD) ....................................................

6

Fan End View (W2-880) .............................................

5

Lubrication System (TJD) ...........................................

7

Power Unit Fan End View (TJD) ................................

4

Take-off View (TJD) ...................................................

3

Take-off View (W2-880) .............................................

5

Lubrication ........................................................................

8

Lubrication System ...........................................................

8

Magneto Breaker PointAdjustment ...............................

12

Magneto Ignition Spark ..................................................

12

Magneto Service

Fairbanks-Morse (Type FMX2B7E) .........................

42

Fairbanks-Morse (Type FMX 12B71) .......................

43

Wico Model XH-2D ..................................................

41

Magneto Timing .............................................................

13

Magneto Timing Diagram ..............................................

13

Maintenance Section .......................................................

10

Oil-- Grade of and Service Classification ......................

9

Oil Spray Nozzles ...........................................................

28

Reduction Gears ..............................................................

20

Rotation ............................................................................

8

Safety Precautions ............................................................

1

Safety Switch - High Temperature .................................

17

Solid State Ignition Distributors .....................................

16

Spark Plugs .....................................................................

17

Starting and Operating Instructions ..................................

8

Starting and Operating New Engines ................................

i

Starting Procedure ..........................................................

10

Stopping Engine ..............................................................

10

Storage of Engine forWinter ..........................................

20

Testing Rebuilt Engine ...................................................

22

Timing

Distributor Timing .....................................................

14

Magneto Timing ........................................................

13

Neon Lamp Timing ...................................................

15

Troubles -- Causes and Remedies .................................

20

Backfiring Through Carburetor .................................

22

Compression ..............................................................

21

Ignition ......................................................................

21

Knocking ...................................................................

22

Missing ...................................................................... 21

Overheating ...............................................................

22

Starting Difficulties - Fuel Mixture ...........................

21

S tops ..........................................................................

21

Surging or Galloping .................................................

21

Valves --Grinding ..........................................................

27

Valve Tappet Adjustment ...............................................

28

Warm-Up Period -- Overspeeding ................................

10

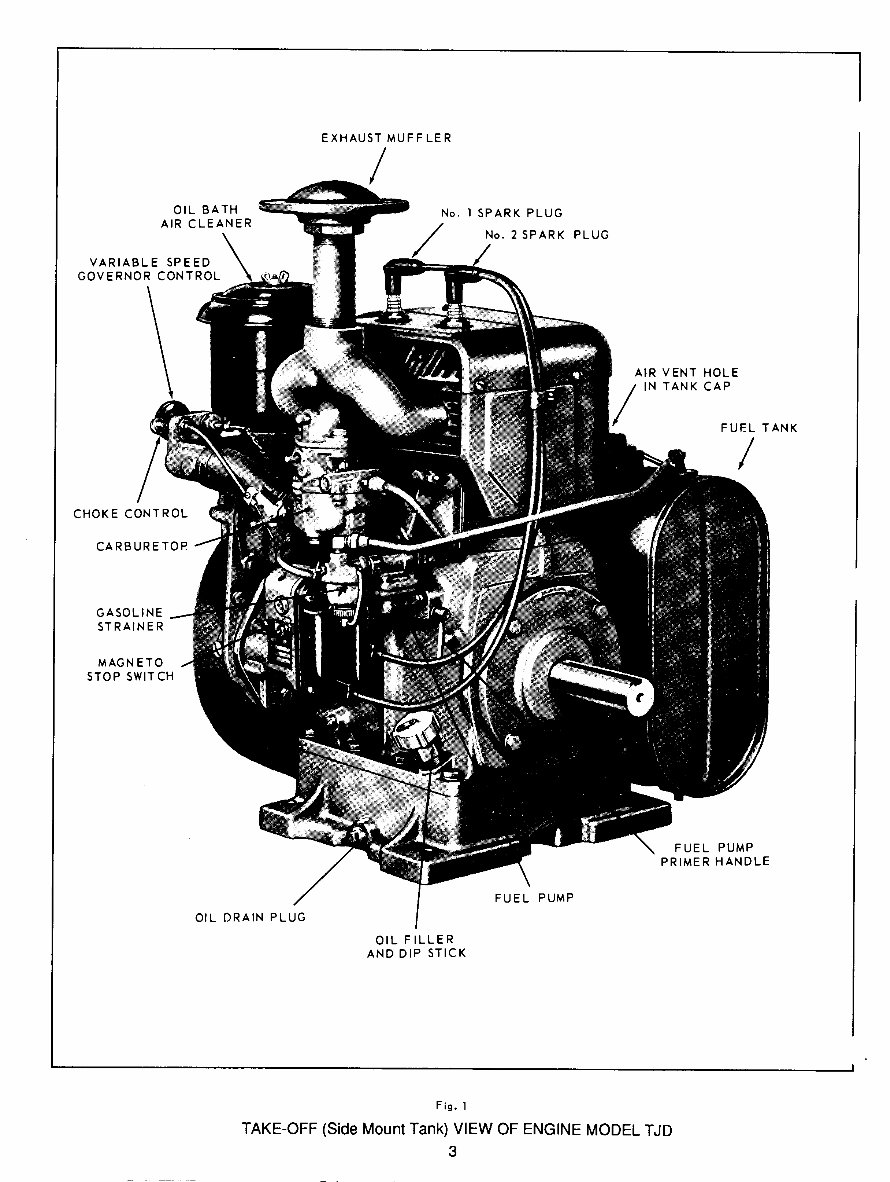

OIL BATH

AIR CLEANER

EXHAUST MUFFLER

/

No. 1 SPARK PLUG

No. 2 SPARK PLUG

AIR VENT HOLE

IN TANK CAP

FUEL TANK

/

CHOKE CONTROL

CARBURETOR

GASOLINE

STRAINER

MAGNETO

STOP SWITCH

OIL DRAIN PLUG

OIL FILLER

AND DIP STICK

FUEL PUMP

FUEL PUMP

PRIMER HANDLE

Fig. 1

TAKE-OFF (Side MountTank) VIEWOF ENGINE MODEL T,JD

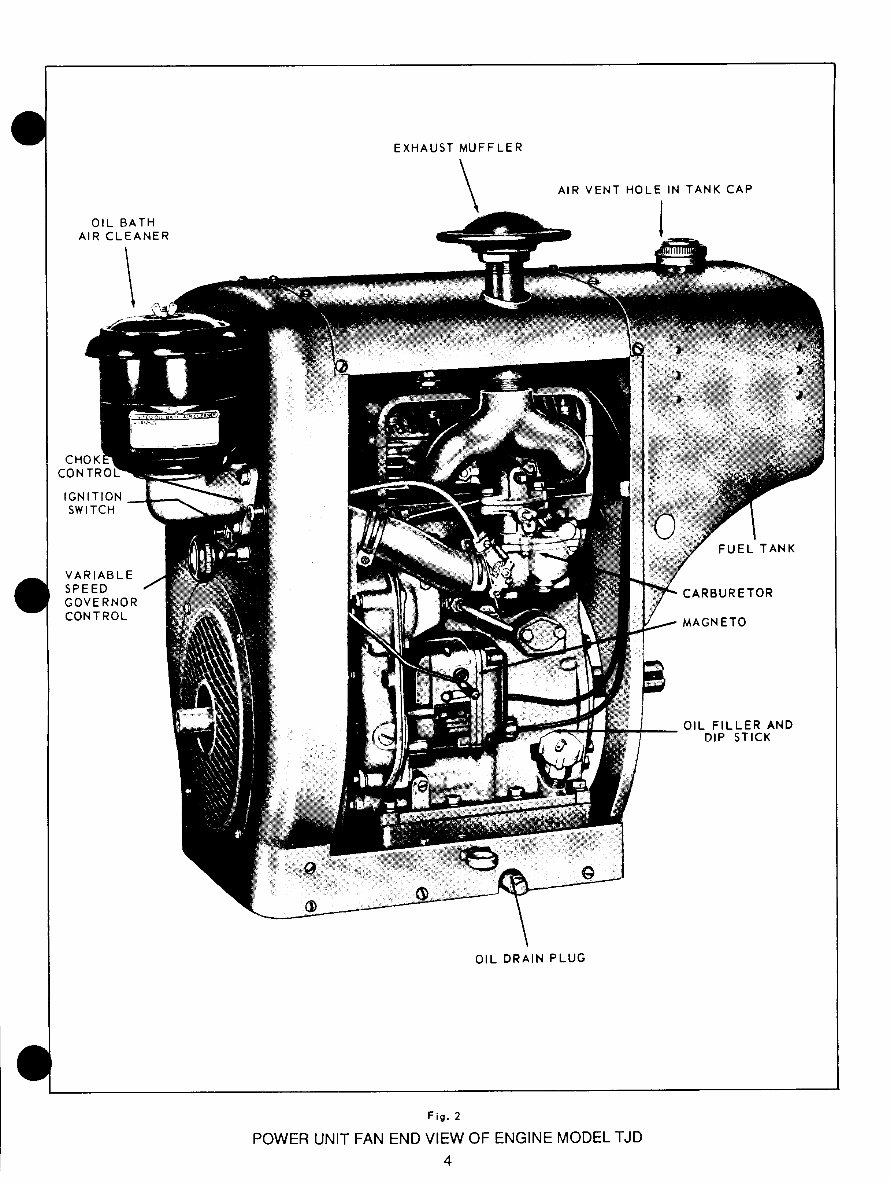

OIL BATH

AIR CLEANER

EXHAUST MUFFLER

AIR VENT HOLE

IN TANK CAP

1

CH

CONTRO

IGNITION

SWITCH

VARIABLE

SPEED

GOVERNOR

CONTROL

FUEL TANK

CARBURETOR

MAGNETO

OIL FILLER AND

DIP STICK

OIL DRAIN PLUG

Fig. 2

POWEI~ UNIT FAN END VIEW OF ENGINE MODEL TJD

4

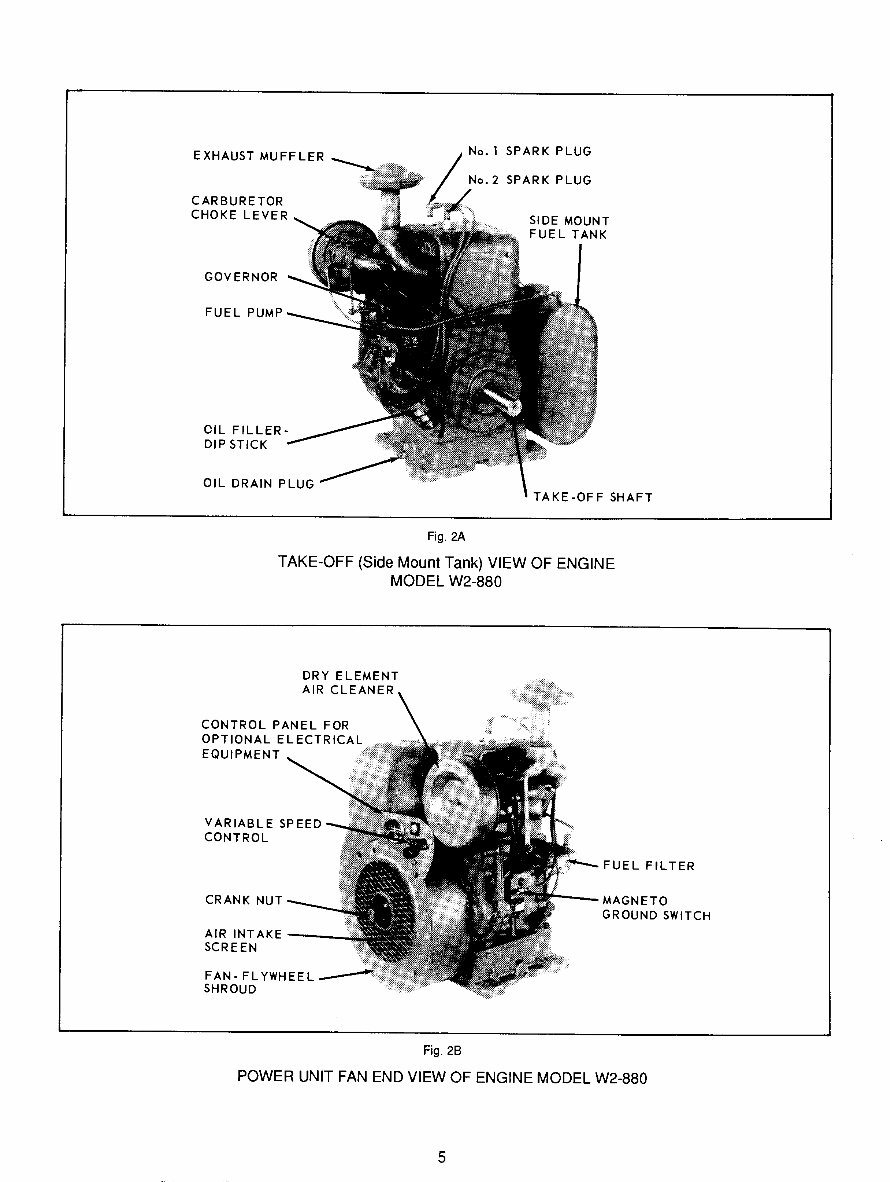

EXHAUST MUFFLER

CARBURETOR

CHOKE LEVER

No.l SPARK PLUG

No.2 SPARK PLUG

SIDE MOUNT

FUEL TANK

GOVERNOR

FUEL

OIL FILLERo

DIP STICK

OIL DRAIN PLUG

TAKE-OFF SHAFT

Fig. 2A

TAKE-OFF (Side MountTank) VIEW OF ENGINE

MODEL W2-880

DRY ELEMENT

AIR CLEANER

CONTROL PANEL FOR

OPTIONAL ELECTRICAL

EQUIPMENT

VARIABLE SPEED

CONTROL

CRANK NUT

AIRINTAKE

SCREEN

FAN-FLYWHEEL

SHROUD

FUEL FILTER

~NETO

GROUND SWITCH

Fig. 2B

POWER UNIT FAN ENDVIEW OF ENGINE MODEL W2-880

5

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

Viewed 48 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

The best manual available for these engines!

- File Format: .PDF

- Compatible: All Versions of Windows, Mac, and Linux

- Printable: Yes

- Downloadable: Instant High Speed

- Requirements: Adobe Reader