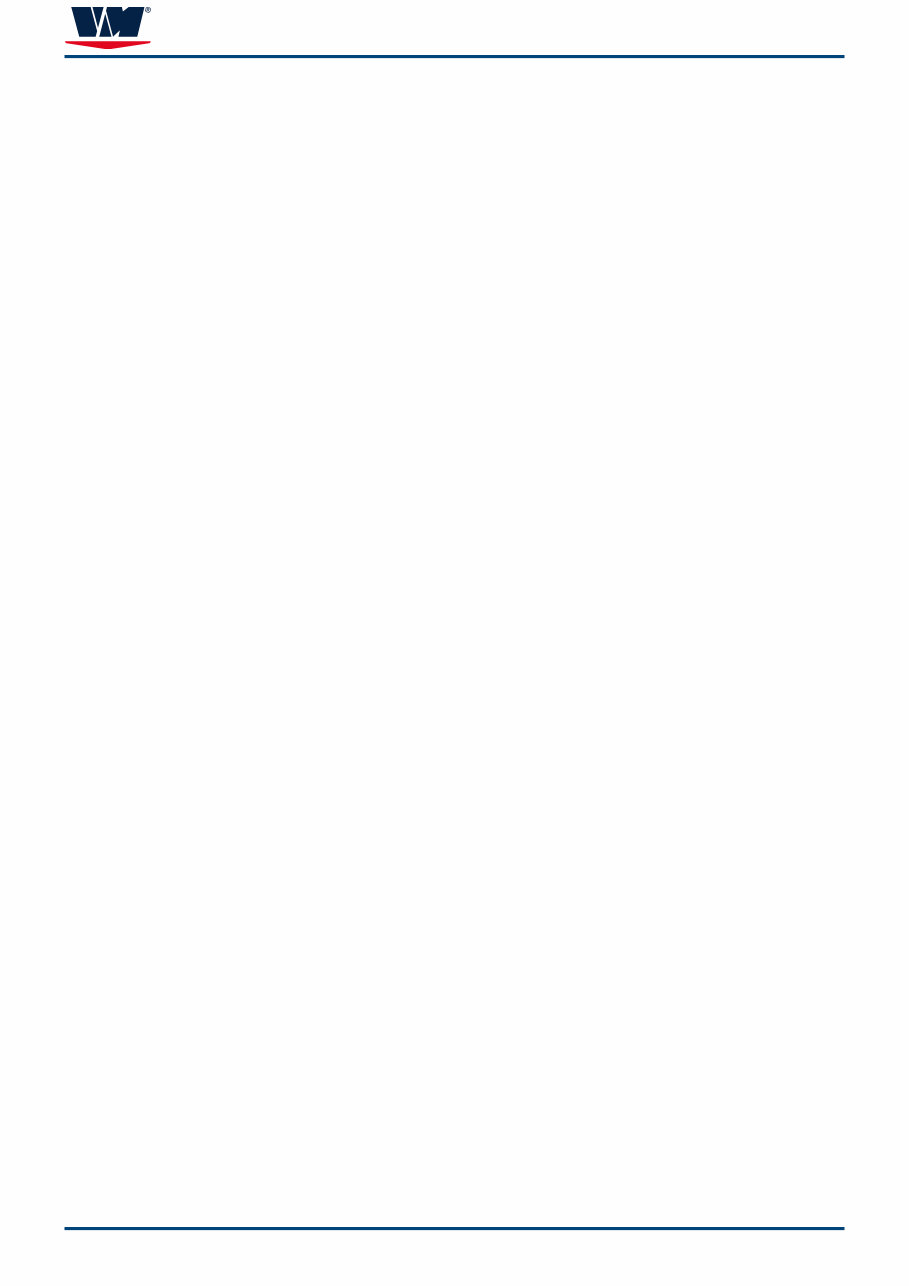

VM Motori R 750 Series Common Rail Diesel Engine Complete Workshop Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

R 750

VM Order Number 42431133F

Edition 7 - 03/2010

Workshop Manual

Engine Family R750

R754EU4 R756EU4 R756IE3 R754EU5 R756EU5

R Common Rail Injection System

750 Unitary Displacement

4 (no. of cylinders) 4 x x 4 x

6 (no. of cylinders) x 6 6 x 6

Turbocharged yes yes yes yes yes

I (Intercooler) yes yes yes yes yes

EU4 - Emissions

Certification

EURO 4

EC/EPA Stage3A

EURO 4

EC/EPA Stage3A

x x x

E3 - Emissions

Certification

x x EC/EPA Stage3A x x

EU5 - Emissions

Certification

x x x

EURO 5

EC/EPA Stage3B

EURO 5

EC/EPA Stage3B

R 750

SECTIONS

INTRODUCTION ...................................................................................................................... 6

HANDLING PRECAUTIONS FOR ELECTRIC CIRCUITS ...................................................... 8

SERVICE MANUAL - UPDATING .......................................................................................... 13

GENERAL INFORMATION ..................................................................................................... 16

MAINTENANCE ...................................................................................................................... 18

REMOVAL AND INSTALLATION ........................................................................................... 50

FASTENER TIGHTENING SPECIFICATIONS ....................................................................... 51

SPECIAL TOOLS.................................................................................................................... 52

TIMING SIDE........................................................................................................................... 56

EXHAUST SIDE ...................................................................................................................... 83

FLYWHEEL SIDE.................................................................................................................... 91

BASIC ENGINE...................................................................................................................... 100

ENGINE BLOCK .................................................................................................................... 134

ENGINE BLOCK .................................................................................................................... 135

INJECTION SIDE ................................................................................................................... 151

ENGINE ELECTRICAL .......................................................................................................... 169

ENGINE CONTROL ............................................................................................................... 173

LABOUR TIME GUIDE .......................................................................................................... 190

ELECTRICAL SYSTEM ......................................................................................................... 197

R 750

3

SUMMARY

INTRODUCTION ...................................................................................................................... 6

MODELS COVERED ....................................................................................................................................... 6

R 754 AND 756 EU4/EU5 COMMON RAIL INDUSTRIAL ENGINES ARE APPLIED TO VEHICLES OF THE

ROAD, SUCH AS ROAD SWEEPERS AND TRUCKS. R 756 IE3 ARE APPLIED TO VEHICLES NOT OF THE

ROAD, AGRICULTURAL AND LIFTING APPLICATION. ................................................................................. 6

NOTICE TO USERS OF THIS MANUAL ......................................................................................................... 6

REPLACEMENT PARTS .................................................................................................................................. 7

CLEANLINESS AND CARE OF PRODUCT .................................................................................................... 7

HANDLING PRECAUTIONS FOR ELECTRIC CIRCUITS ...................................................... 8

ENGINE ELECTRONIC CONTROL UNIT ....................................................................................................... 8

PRECAUTIONS FOR ARC WELDING............................................................................................................. 12

SERVICE MANUAL - UPDATING .......................................................................................... 13

GENERAL INFORMATION ..................................................................................................... 16

INTRODUCTION .............................................................................................................................................. 16

HOW TO ORDER THIS MANUAL.................................................................................................................... 16

ENGINE SERIAL NUMBER AND ENGINE PLATE IDENTIFICATION............................................................. 16

MAINTENANCE ...................................................................................................................... 18

ENGINE SPECIFICATIONS ............................................................................................................................. 18

MAINTENANCE INTERVALS .......................................................................................................................... 24

MAINTENANCE SCHEDULE - R750 EURO 4 - IE3 ....................................................................................... 24

MAINTENANCE SCHEDULE - R750 EURO 5 ................................................................................................ 25

ENGINE EXTERNAL VIEWS ........................................................................................................................... 26

ENGINE OIL .................................................................................................................................................... 30

COOLANT ........................................................................................................................................................ 35

AIR FILTER ELEMENT .................................................................................................................................... 38

FUEL SYSTEM ................................................................................................................................................ 41

FUEL FILTER ................................................................................................................................................... 42

ALTERNATOR BELT / POLY - V (SERPENTINE) ........................................................................................... 44

DIESEL PARTICULATE FILTER (DPF) - R 750 EURO 4................................................................................. 46

DIESEL PARTICULATE FILTER (DPF) - R 750 EURO 5................................................................................. 48

EXTENDED STORAGE ................................................................................................................................... 49

REMOVAL AND INSTALLATION ........................................................................................... 50

FASTENER TIGHTENING SPECIFICATIONS ....................................................................... 51

SPECIAL TOOLS.................................................................................................................... 52

TIMING SIDE........................................................................................................................... 56

TIMING GEARS ............................................................................................................................................... 57

OIL PUMP ........................................................................................................................................................ 60

CRANKSHAFT GEAR ...................................................................................................................................... 65

HYDRAULIC PUMP IDLER GEAR (BETWEEN THE CRANKSHAFT AND CAMSHAFT GEARS) ................. 66

INJECTION PUMP IDLER GEAR (BETWEEN THE CAMSHAFT AND INJECTION PUMP GEARS) ............. 69

HYDRAULIC PUMP GEAR ASSEMBLY .......................................................................................................... 70

BELT TENSIONER - (AUTOMATIC TYPE) ...................................................................................................... 74

BELT TENSIONER BRACKET ......................................................................................................................... 75

IDLER PULLEYS.............................................................................................................................................. 76

CRANKSHAFT HUB AND PULLEY ................................................................................................................. 77

WATER PUMP AND PULLEY .......................................................................................................................... 80

TIMING GEAR COVER .................................................................................................................................... 81

FRONT OIL SEAL ............................................................................................................................................ 82

EXHAUST SIDE ...................................................................................................................... 83

TURBOCHARGER ........................................................................................................................................... 83

EGR COOLER ................................................................................................................................................. 84

INTAKE THROTTLE / EGR VALVE & PROPER ACTUATORS ...................................................................... 86

EXHAUST MANIFOLD ..................................................................................................................................... 89

INTAKE MANIFOLD ......................................................................................................................................... 90

R 750

4

FLYWHEEL SIDE.................................................................................................................... 91

CRANKSHAFT END PLAY (AXIAL CLEARANCE) .......................................................................................... 91

FLYWHEEL ...................................................................................................................................................... 92

FLYWHEEL RING GEAR ................................................................................................................................. 95

FLYWHELL HOUSING ..................................................................................................................................... 96

REAR MAIN BEARING CARRIER ................................................................................................................... 98

THRUST WASHERS ........................................................................................................................................ 98

REAR MAIN BEARING ................................................................................................................................... 99

REAR OIL SEAL............................................................................................................................................... 99

CPS TARGET WHEEL BOLT ........................................................................................................................... 99

BASIC ENGINE...................................................................................................................... 100

CYLINDER HEAD GASKET............................................................................................................................. 100

CYLINDER HEAD ............................................................................................................................................ 101

TORQUE PROCEDURE AFTER THE FIRST 20-30 MINUTES OF OPERATION........................................... 104

EXPANSION PLUGS ....................................................................................................................................... 105

CYLINDER HEAD END SPACER .................................................................................................................... 105

VALVE GUIDES ............................................................................................................................................... 106

VALVE SEATS .................................................................................................................................................. 108

VALVE SEAT RECONDITIONING ................................................................................................................... 109

VALVES ............................................................................................................................................................ 110

VALVE SPRINGS ............................................................................................................................................. 112

ROCKER ARM ................................................................................................................................................. 113

VALVE LIFTERS .............................................................................................................................................. 115

VALVE PUSH RODS ........................................................................................................................................ 117

FRACTURED CONNECTING ROD ................................................................................................................. 118

REMOVAL ........................................................................................................................................................ 118

BROACHED CONNECTING ROD ................................................................................................................... 122

REMOVAL ........................................................................................................................................................ 122

PISTON ............................................................................................................................................................ 126

OIL PAN & OIL PICKUP ................................................................................................................................... 131

OIL PICKUP ..................................................................................................................................................... 131

OIL PRESSURE RELIEF VALVE ..................................................................................................................... 132

ENGINE BLOCK .................................................................................................................... 134

CRANKCASE ................................................................................................................................................... 134

ENGINE BLOCK .................................................................................................................... 135

LINER ............................................................................................................................................................... 135

CAMSHAFT...................................................................................................................................................... 138

CAMSHAFT BEARINGS ................................................................................................................................. 141

FRONT JOURNAL CAMSHAFT BUSHING ..................................................................................................... 142

PISTON COOLING JETS (OIL SPRAY NOZZLES) ......................................................................................... 143

CRANKSHAFT ................................................................................................................................................. 144

CRANKSHAFT FRONT MAIN BEARING ........................................................................................................ 150

INJECTION SIDE ................................................................................................................... 151

INJECTION FUEL SYSTEM............................................................................................................................. 151

ELECTRICAL SENSORS ................................................................................................................................ 152

LOW PRESSURE SYSTEM REQUIREMENTS............................................................................................... 156

HIGH PRESSURE PUMP ................................................................................................................................ 157

INJECTOR........................................................................................................................................................ 160

RAIL ................................................................................................................................................................. 162

HIGH PRESSURE FUEL COMPONENTS TIGHTENING PROCEDURE........................................................ 163

OIL FILTER HOUSING ..................................................................................................................................... 164

OIL DELIVERY PIPE TO ROCKER ARM ......................................................................................................... 165

ROCKER ARM COVER ................................................................................................................................... 166

COOLANT MANIFOLD .................................................................................................................................... 166

THERMOSTATIC VALVE ................................................................................................................................ 167

VACUUM PUMP............................................................................................................................................... 168

R 750

5 Introduction

ENGINE ELECTRICAL .......................................................................................................... 169

ALTERNATOR .................................................................................................................................................. 169

ALTERNATOR PULLEY ................................................................................................................................... 169

VOLTAGE REGULATOR .................................................................................................................................. 172

ALTERNATOR BRACKET ................................................................................................................................ 172

STARTER ......................................................................................................................................................... 172

ENGINE CONTROL ............................................................................................................... 173

DIAGNOSTIC TROUBLE CODES “EURO 4” .................................................................................................. 173

DIAGNOSTIC TROUBLE CODES “EURO 5” .................................................................................................. 179

LABOUR TIME GUIDE .......................................................................................................... 190

KEY TO DEFINITIONS..................................................................................................................................... 190

ELECTRICAL SYSTEM ......................................................................................................... 197

ELECTRICAL SCHEMATIC DIAGRAMS ........................................................................................................ 197

ENGINE WIRING HARNESS ........................................................................................................................... 199

INSTALLATION ELECTRIC DIAGRAM ............................................................................................................ 203

R 750

6 Introduction

MODELS COVERED

R 754 and 756 EU4/EU5 common rail industrial engines are applied to vehicles of the road, such as road swee-

pers and trucks. R 756 IE3 are applied to vehicles not of the road, agricultural and lifting application.

NOTICE TO USERS OF THIS MANUAL

Throughout this publication, Dangers, Warnings and Cautions (accompanied by the International HAZARD Sym-

bol ) are used to alert the mechanic to special instructions concerning a particular service or operation that

may be hazardous if performed incorrectly or carelessly. OBSERVE THEM CAREFULLY!

These safety alerts alone cannot eliminate the hazards that they signal. Strict compliance to these special instruc-

tions when performing the service, plus common sense operation, are major accident prevention measures.

DANGER

DANGER—indicates an imminently hazardous situation that, if not avoided, will result in death or serious

injury.

WARNING

WARNING—indicates a potentially hazardous situation that, if not avoided, could result in death or se-

rious injury.

CAUTION

CAUTION—indicates a potentially hazardous situation that, if not avoided, may result in minor or modera-

te injury or property damage. It may also be used to alert against unsafe practices.

This manual has been written and published by the Service Department of VM Motori to aid our dealers’ mechani-

cs and company service personnel when servicing the products described herein. We reserve the right to make

changes to this manual at any time and without prior notice in accordance with the Company’s policy of

constant product improvement.

COPYRIGHT © 2007 July, VM Motori S.p.A.

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system or transmitted, in any form, whether electronic or mechanical, or by photocopying, recording or other

means without prior permission in writing of VM Motori.

Published by VM Motori, from whom further copies may be obtained through your normal literature ordering pro-

cedure (refer to front page to identify the order number).

A copy of this manual is available from VM Motori web site Customer Reserved Area “Extranet”

VM Motori S.p.A. - Service Department, Via Ferrarese 9 - 4404 Cento (FE) ITALY

Every reasonable effort is made to ensure that the VM Motori’s publications are accurate, but nothing

shown, described or referred to herein should be regarded as an infallible guide to the procedures, mate-

rials, specifications, dimensions, design or availability of any particular engine, nor does this publication

constitute an offer for the sale of any particular engine. No liability can be accepted by the VM Motori or

any Distributor or Dealer for any malfunction, damage, loss, injury or death caused by the use of incorrect

or misinterpreted information, omissions or errors that may have arisen during the preparation of this

workbook.

INTRODUCTION

It is assumed that these personnel are familiar with industrial product servicing procedures.

Furthermore, it is assumed that they have been trained in the recommended service

procedures of VM Motori Products, including the use of mechanics’ common hand tools and the special VM Motori

or recommended tools from other suppliers.

We could not possibly know of and advise the industrial trade of all conceivable procedures and of the possible

hazards and/or results of each method. Therefore, anyone who uses a service procedure and/or tool, which is not

recommended by the manufacturer, first must completely satisfy himself that neither his nor the products safety

will be endangered.

All information, illustrations and specifications contained in this manual are based on the

latest product information available at the time of publication. As required, revisions to this manual will be sent to

all dealers contracted by us to service these products.

Refer to dealer service bulletins, warranty, owner manuals and installation manuals for other pertinent information

concerning the products described in this manual.

Extranet area contained in VM Motori web site is another source of information.

R 750

7 Introduction

REPLACEMENT PARTS

Use of parts other than the recommended service re-

placement parts, will avoid the warranty on those parts

that are damaged as a result.

WARNING

When servicing the electrical, ignition and fuel sy-

stems, it is extremely important that all

components are properly installed and tightened. If

not, any electrical or ignition

component opening would permit sparks to ignite fuel

vapors from fuel system leaks, if

they existed.

CLEANLINESS AND CARE OF PRO-

DUCT

A VM Motori Product is a combination of many machi-

ned, honed, polished and lapped surfaces with tole-

rances that are measured in the thousands of a mm.

When any product component is serviced, care and

cleanliness are important.

Throughout this manual, it should be understood that

proper cleaning and protection of

machined surfaces and friction areas is a part of the

repair procedure. This is considered standard shop

practice even if not specifically stated.

Whenever components are removed for service, they

should be retained in order. At the

time of installation, they should be installed in the

same locations and with the same mating surfaces as

when removed.

Any time the intake or exhaust openings are expo-

sed during service they should be covered to protect

against accidental entrance of foreign material which

could enter the cylinders and cause extensive internal

damage when the engine is started.

It is important to note, during any maintenance proce-

dure replacement fasteners must have the same mea-

surements and strength as those removed. Numbers

on the heads of the metric bolts and on the surfaces of

metric nuts indicate their strength. American bolts use

radial lines for this purpose, while most American nuts

do not have strength markings.

Mismatched or incorrect fasteners can result in dama-

ge or malfunction, or possibly personal injury. There-

fore, fasteners removed should be saved for reuse

in the same locations whenever possible. Where the

fasteners are not satisfactory for reuse, care should be

taken to select a replacement that matches the origi-

nal.

Personnel should not work on or under an engine that

is suspended. Engines should be attached to work

stands, or lowered to ground as soon as possible.

R 750

Introduction

HANDLING PRECAUTIONS FOR ELECTRIC CIRCUITS

ENGINE ELECTRONIC CONTROL UNIT

WARNING

IN ORDER TO AVOID ECU DAMAGE PAY ATTENTION TO

THE FOLLOWING INSTRUCTIONS:

DO NOT CUT ENGINE VOLTAGE OFF DURING ENGINE

OPERATION

BEFORE CUT ENGINE VOLTAGE OFF THROUGH ELET-

TRICAL DEVICES (BREAKERS, SWITCH, ETC.) WAIT

FOR 30 SEC. AT LEAST SO THAT THE ECU CAN BE

CARRIED OUT THE “AFTER-RUN” PROCEDURE

DO NOT USE START BOOSTER TO LET START THE EN-

GINE

•

•

•

R 750

9 Introduction

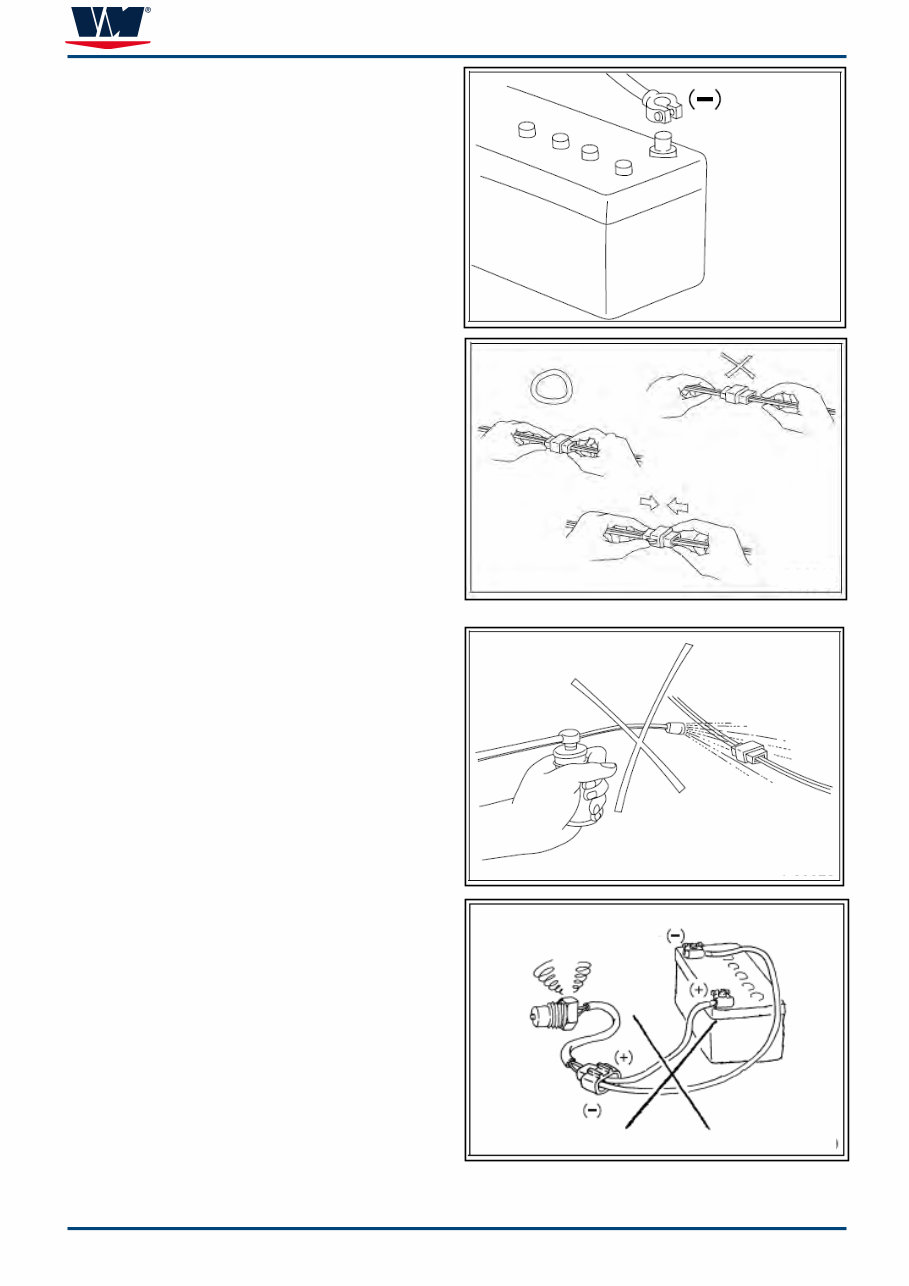

It should be kept in mind, while working on the product,

that the electrical systems are capable of violent and

damaging short circuits or severe electrical shocks.

When performing any work where electrical terminals

could possibly be grounded or touched by the mecha-

nic, the battery cables should be disconnected at the

battery.

Before working on the electrical system, disconnect

the (–) battery cable to prevent short circuits.

CAUTION

Make sure the starter switch and lighting switches are

OFF before disconnecting or connecting battery cable.

Semiconductor components may otherwise be dama-

ged.

When separating connectors, grasp the connectors

themselves rather than the harnesses.To separate

locking connectors, first push them in the direction of

the arrows. To reconnect locking connectors, push

them together until they click.

Before washing the engine, cover electrical parts to

keep them dry. (Use plastic sheets or the like.) Keep

water away from harness connectors and sensors and

immediately wipe off any water that gets on them.

When applying a voltage to a part for inspection pur-

poses, check that the (+) and (–) cables are connected

properly then gradually increase the voltage from zero.

Do not exceed the specified voltage.

Remember that control units and sensors do not ne-

cessarily operate on the battery voltage.

CAUTION

R 750

0 Introduction

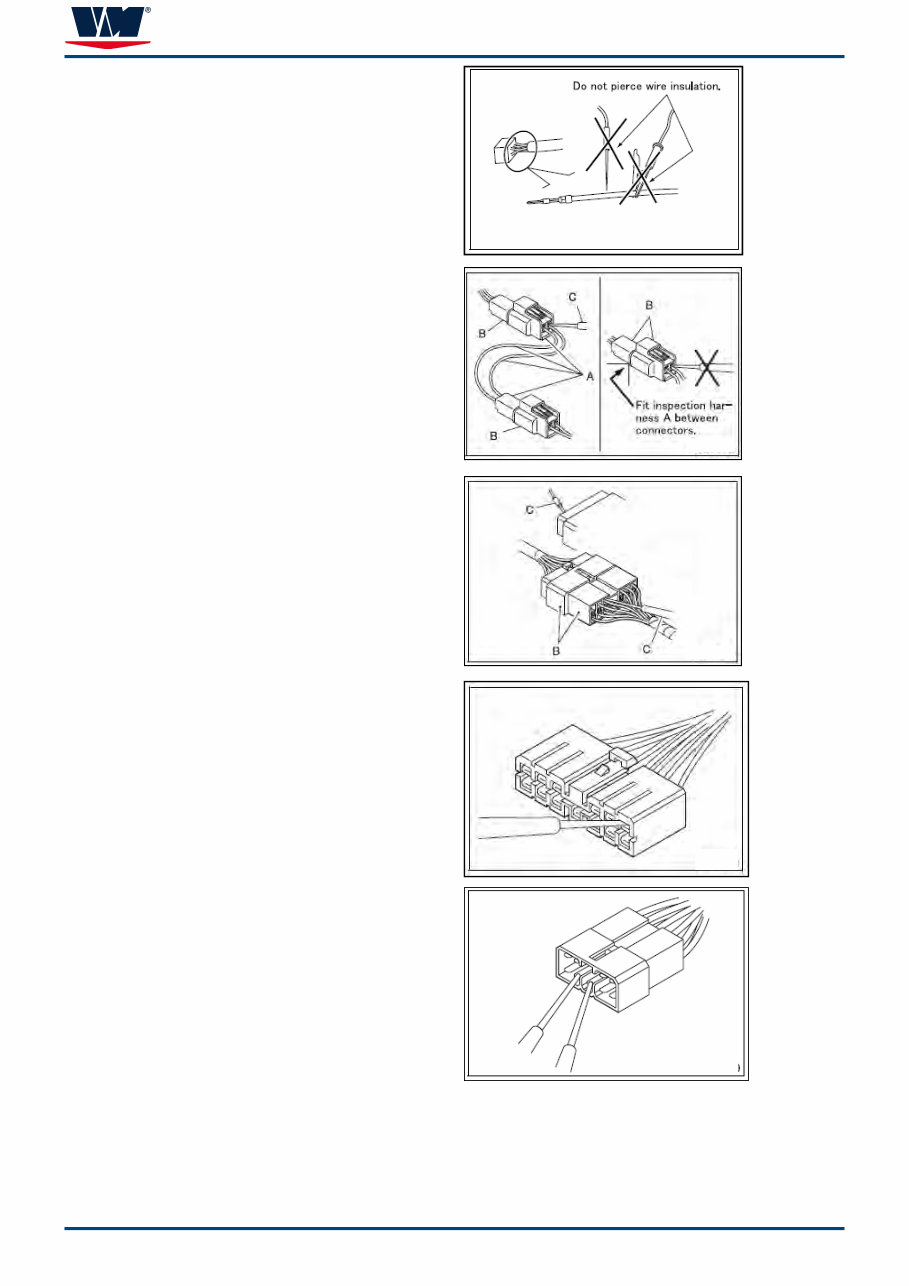

• Do not pierce wire insulation with test probes or

alligator clips when performing electrical inspections.

Doing so can, particularly with the chassis harness,

hasten corrosion.

INSPECTION OF HARNESSES

INSPECTIONS WITH CONNECTORS FITTED TO-

GETHER

Waterproof connectors

• Connect an inspection harness and connector A

between the connectors B of the circuit to be ins-

pected. Perform the inspection by applying a test

probe C to the connectors of the inspection harness.

Do not insert the test probe C into the wire-entry sides

of the waterproof connectors since this would damage

their waterproof seals and lead to rust.

Non-waterproof connectors

Perform the inspection by inserting a test probe C into

the wireentry sides of the connectors. An extra-narrow

probe is required for control unit connectors, which are

smaller than other types of connector. Do not force a

regular-size probe into control unit connectors since

this would cause damage.

INSPECTIONS WITH CONNECTORS SEPARATED

Inspections on female terminals

Perform the inspection by carefully inserting a test pro-

be into the terminals. Do not force the test probe into

the terminals since this could deform them and cause

poor connections.

Inspections on male terminals

Perform the inspection by applying test probes directly

to the pins.

CAUTION .

• Be careful not to short-circuit pins together with the

test probes. With control unit connectors, short-cir-

cuiting of pins can cause damage to the control unit’s

internal circuitry.

When using a multimeter to check continuity, do not

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Viewed 42 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Thank you for considering this comprehensive Workshop Service Repair Manual for the VM Motori R 750 Series Common Rail Diesel Engine.

This manual is an invaluable resource covering every service and repair procedure necessary for professional mechanics and DIY enthusiasts alike.

Description:

- This manual enables significant cost savings by empowering you to perform your own repairs with its easy-to-follow, step-by-step instructions and detailed illustrations covering all aspects of servicing and repairs.

- Once acquired, this manual is yours to keep indefinitely. You have the flexibility to print individual pages, chapters, or the entire manual. Additionally, you can conveniently access it on your tablet or smartphone.

Models Covered:

- All models, engines, trim, and transmission types are comprehensively covered.

Contents:

- This high-quality manual encompasses all repair procedures from A to Z, ensuring that every repair and service procedure is thoroughly addressed.

Computer Requirements:

- This versatile manual is compatible with all PC and MAC computers, tablets, and mobile phones. The only software required is Adobe Reader, which is typically pre-installed on your computer or can be downloaded for free.

Delivery:

- Upon payment via Visa, MasterCard, or PayPal, the manual will be promptly emailed to the address provided during checkout, ensuring instant access.

Customer Satisfaction Guaranteed.

We're currently collecting product reviews for this item. In the meantime, here are some reviews from our past customers sharing their overall shopping experience.

4.5

Out of 5.0

Overall Rating

89%

of customers that buyfrom this merchant give

them a 4 or 5-Star rating.

Verified Buyer

November 13, 2025 by GORDON A. (New York, US)

“Repairs where made under the usage of the manual”

Verified Buyer

November 13, 2025 by Brock H. (US)

“Looks Like Right Manual”

Verified Buyer

November 13, 2025 by Jeffrey C. (US)

“Great!”

Verified Buyer

November 13, 2025 by Owen F. (US)

“Good”

Verified Buyer

November 13, 2025 by ENEST Z. (US)

“Grear”

Verified Buyer

November 13, 2025 by Wilder V. (US)

“Me parece genial”

Verified Buyer

November 13, 2025 by Mark S. (US)

“I took me about 2 min to find the manual I needed and download it.”

Verified Buyer

November 13, 2025 by Debra M. (US)

“This place rocks very helpful and it help me bring my baby back to life”

Verified Buyer

November 13, 2025 by James K. (United States)

“Just what I needed. Fair price. Thanks a lot for the help.”

Verified Buyer

November 13, 2025 by Alvin M. (United States)

“Our insurance provider requires that all maintenance be done to OEM standards. I used the site's chat feature to ask if this was the full factory manual. The agent confirmed it was. Good service, good manual.”