EG-244

LUBRICATIONSYSTEM

DESCRIPTION

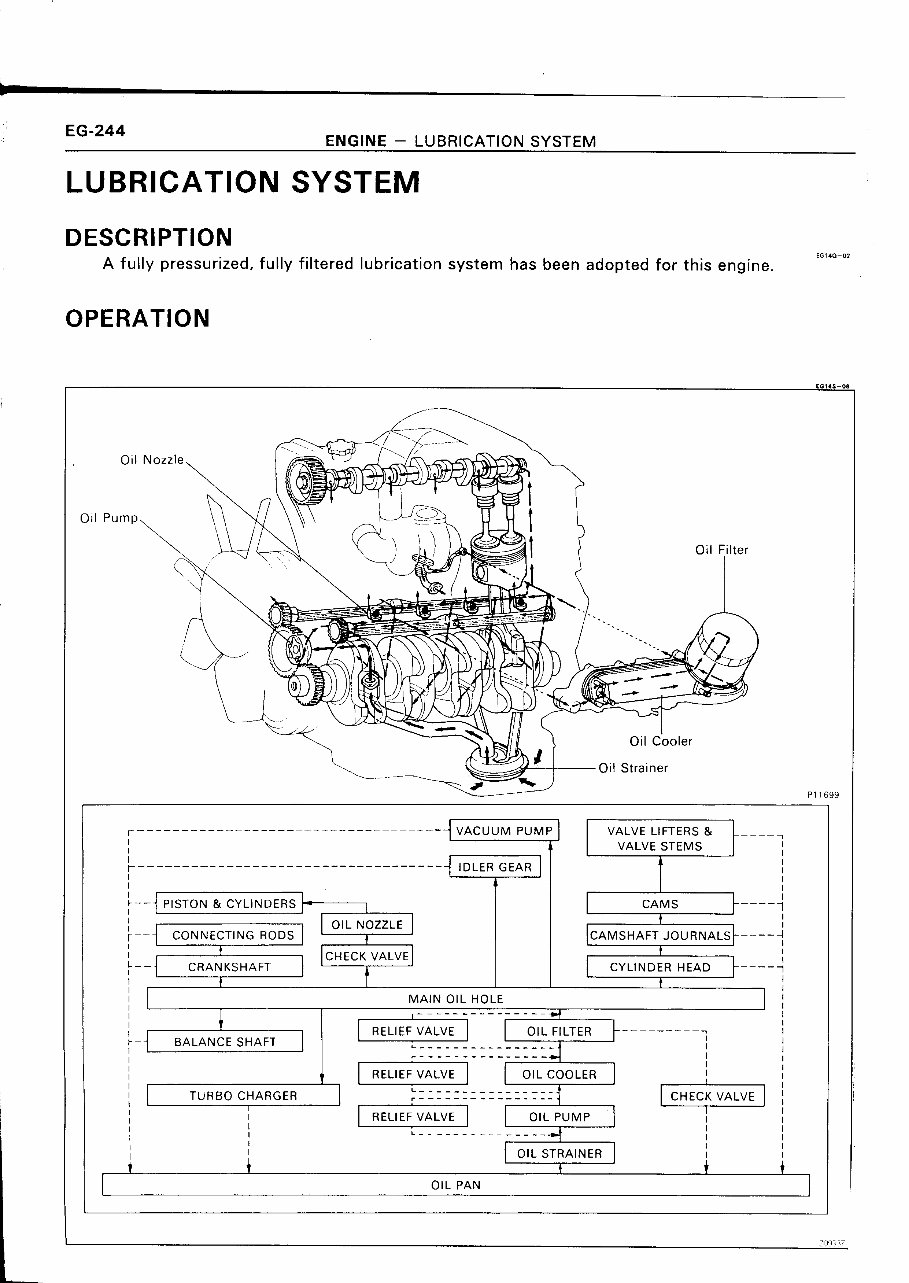

Afullypressurized,fullyfilteredlubricationsystemhasbeenadoptedforthisengine

.

OPERATION

ENGINE -

LUBRICATIONSYSTEM

EG 140-02

EG14S-0S

P11699

r

VACUUMPUMP VALVELIFTERS&

____~

VALVESTEMS

IDLERGEAR

--- PISTON&CYLINDERS CAMS

i

r --

OILNOZZLE

CONNECTINGRODS } CAMSHAFTJOURNALS

CHECKVALVE

--- CRANKSHAFT

CYLINDERHEAD -- --7

F

i

MAINOILHOLE

RELIEFVALVE OILFILTER ~

r-

i

BALANCESHAFT

I

----------------

RELIEFVALVE OILCOOLER

i TURBOCHARGER ~CHECK VALVE

i

RELIEFVALVE OILPUMP

j OILSTRAINER

OILPAN

ENGINE - LUBRICATIONSYSTEM

EG-245

Apressurefeedinglubricationsystemhasbeenadoptedtosupplyoiltothemovingpartsofthis

engine

.Thelubricationsystemconsistsofanoilpan,oilpump,oilfilterandotherexternalparts

OILPUMP

Theoilpumppumpsupoilfromtheoilpanandsendsitunderpressuretothevariouspartsofthe

engine

.Anoilstrainerismountedinfrontoftheinlettotheoilpumptoremoveimpurities .The

oilpumpitselfisatrochoidtypepump,whichusesadriverotorandadriveninsidethepump

body .Whenthedriverotorrotates,thedrivenrotorrotatesinthesamedirection .Theaxisofthe

driverotorshaftisdifferentfromthecenterofthedrivenrotor,sowhenbothrotorsrotate,the

spacebetweenthe2rotorschanges .Oilisdrawninwhenthespacewidensandisdischarged

whenthespacebecomesnarrow

.

OILPRESSUREREGULATOR(RELIEFVALVE)

Athighenginespeeds,theengineoilsuppliedbytheoilpumpexceedsthecapacityoftheengine

toutilizeit .Forthatreason,theoilpressureregulatorwor stopreventanoversupplyofoil .

Duringnormaloilsupply,acoilspringandvalve

eepthebypassclosed,butwhentoomuchoil

isbeingfed,thepressurebecomesextremelyhigh,overpoweringtheforceofthespringand

openingthevalve .Thisallowstheexcessoiltoflowthroughthevalveandreturntotheoilpan .

OILFILTER

Theoilfilterisafullflowtypefilterwithareliefvalvebuiltintothepaperfilterelement

.Particles

ofmetalfromwear,airbornedirt,carbonandotherimpuritiescangetintotheoilduringuseand

couldcauseacceleratedwearorseizingifallowedtocirculatethroughtheengine .Theoilfilter,

integratedintotheoilline,removestheseimpuritiesastheoilpassesthroughit .Thefilteris

mountedoutsidetheenginetosimplifyreplacementofthefilterelement .Areliefvalveisalso

includedaheadofthefilterelementtorelievethehighoilpressureincasethefilterelement

becomescloggedwithimpurities .Thereliefvalveopenswhentheoilpressureoverpowersthe

forceofthespring

.Oilpassingthroughthereliefvalvebypassestheoilfilterandflowsdirectly

intothemainoilholeintheengine

.

EG-246

PREPARATION

SST(SPECIALSERVICETOOLS)

RECOMMENDEDTOOLS

EQUIPMENT

Oilpressuregauge

Precisionstraightedge

Torquewrench

LUBRICANT

SSM(SPECIALSERVICEMATERIALS)

ENGINE - LUBRICATIONSYSTEM

EG14U-06

EGI4V-02

EG14W-O6

EGI4X-07

EG14V-04

08826 - 00080 Sealpac ingorequivalent

Oilpan

08833 -

00080

Adhesive1344,

Oilpressuresendergauge

THREEBOND1344,

LOCTITE242orequivalent

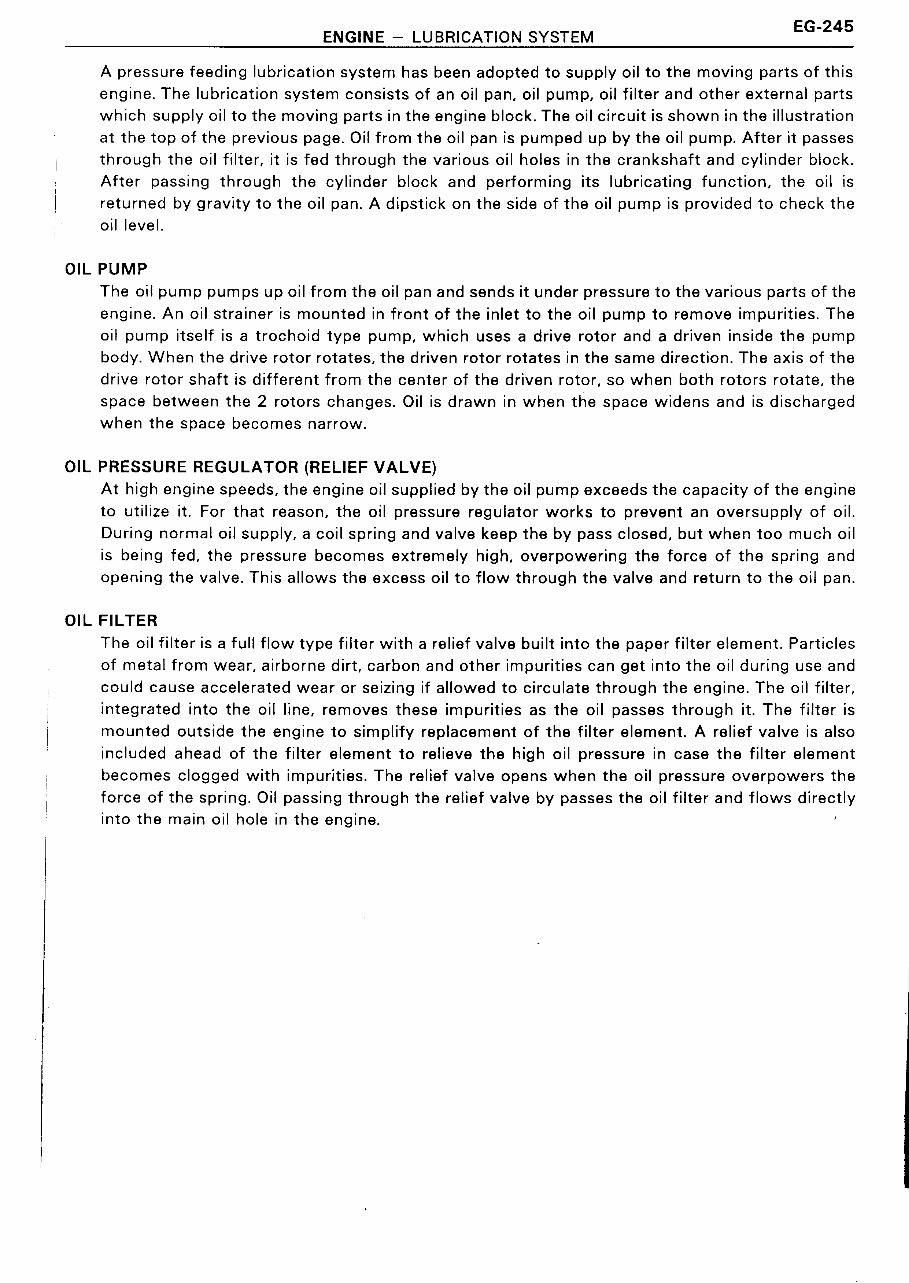

Item

Capacity

Classification

Engineoil

APIgradeCDorbetter

Dryfill

Drainandrefill

w/Oilfilterchange

w/oOilfilterchange

8 .5liters(9

.0USqts,7 .5Imp .qts)

8 .0liters(8 .5USqts,7

.0Imp .qts)

7 .3liters(7 .7USqts,6 .4Imp .qts)

09200-00010 EngineAdjustKit

---~,Q

09905-00013 SnapRingPliers

09032-00100 OilPanSealCutter

09228-10001 OilFilterWrench

ENGINE - LUBRICATIONSYSTEM

OILPRESSURECHECK

EG-247

EG35A-01

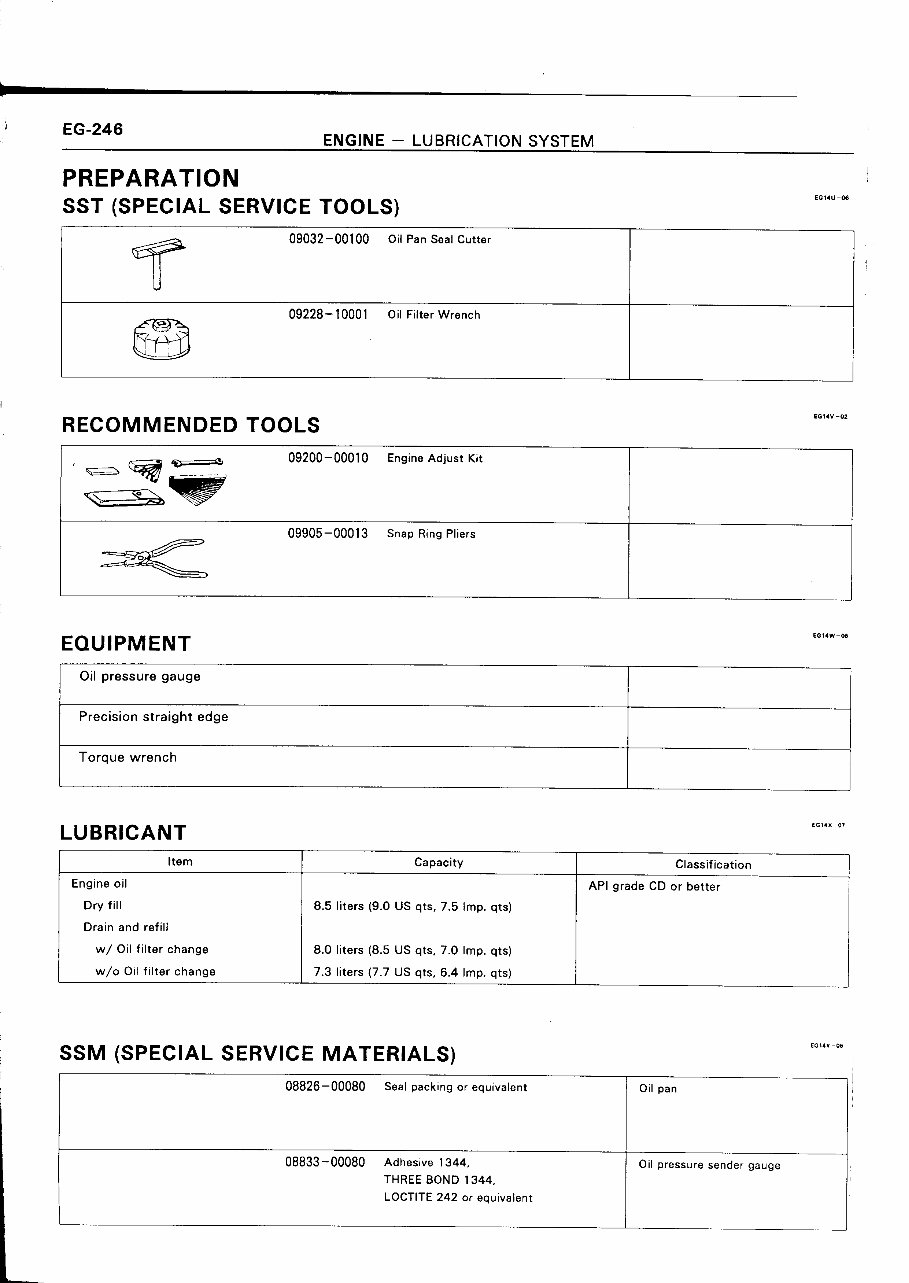

1 . CHECKENGINEOILQUALITY

Chec

theoilfordeterioration,entryofwater,dis-

coloringorthinning .

Ifthequalityisvisiblypoor,replacetheoil .

Oilgrade :

APIgradeCDorbetter

Recommendedviscosity

:

Refertoillustration

2 .

CHECKENGINEOILLEVEL

Theoillevelshouldbebetweenthe"L"and"F"mar

s

onthedipstic .

Iflow,chec forlea ageandaddoilupto"F"mar

.

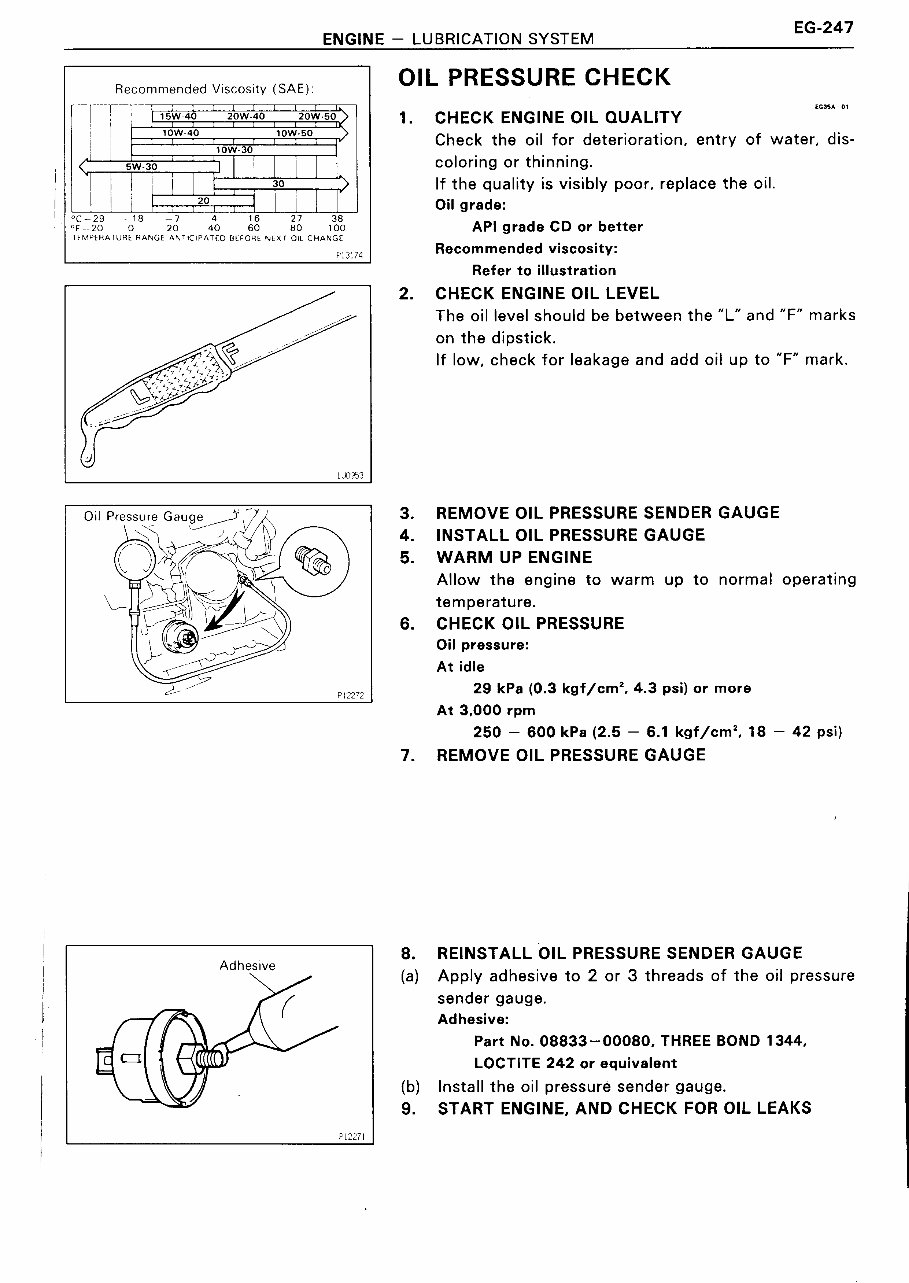

3 .

REMOVEOILPRESSURESENDERGAUGE

4 . INSTALLOILPRESSUREGAUGE

5 .

WARMUPENGINE

Allowtheenginetowarmuptonormaloperating

temperature .

6 . CHECKOILPRESSURE

Oilpressure :

Atidle

29 Pa(0 .3 gf/cm

2 , 4 .3psi)ormore

At3,000rpm

250 - 600

Pa(2 .5 - 6 .1 gf/cm 2, 18 - 42psi)

7 . REMOVEOILPRESSUREGAUGE

8 . REINSTALLOILPRESSURESENDERGAUGE

(a) Applyadhesiveto2or3threadsoftheoilpressure

sendergauge .

Adhesive :

PartNo . 08833-00080,

THREEBOND 1344,

LOCTITE242orequivalent

(b) Installtheoilpressuresendergauge

.

9 .

STARTENGINE,ANDCHECKFOROILLEAKS

RecommendedViscosity(SAE)

:

Pl - i

15W-40 20W40 20W50

10W40 tOW50

I 1OW30

5W-30

30

20 i ,

°C-29

- 18

-7

4

16 27

38

°F--20

0

20

40

60 80

100

TEMPERATURERANGEANTICIPATEDBEFORENEXT OILCHANGE

03174

ENGINE - LUBRICATIONSYSTEM

OILANDFILTERREPLACEMENT

EG177-03

CAUTION :

•

Prolongedandrepeatedcontactwithmineraloilwill

resultintheremovalofnaturalfatsfromthes in,

leadingtodryness,irritationanddermatitis .Inaddi-

tion,usedengineoilcontainspotentiallyharmful

contaminantswhichmaycauses

incancer .

•

Careshouldbeta

en,therefore,whenchanging

engineoiltominimizethefrequencyandlengthof

timeyours inisexposedtousedengineoil .Protec-

tiveclothingandglovesthatcannotbepenetrated

byoilshouldbeworn .Thes inshouldbethorought-

hlywashedwithsoapandwater,orusewater-less

handcleaner,toremoveanyusedengineoil .Donot

usegasoline,thinners,orsolvents .

•

Inordertopreservetheenvironment,usedoiland

usedoilfiltermustbedisposedofonlyatdesignated

disposalsites .

1 .

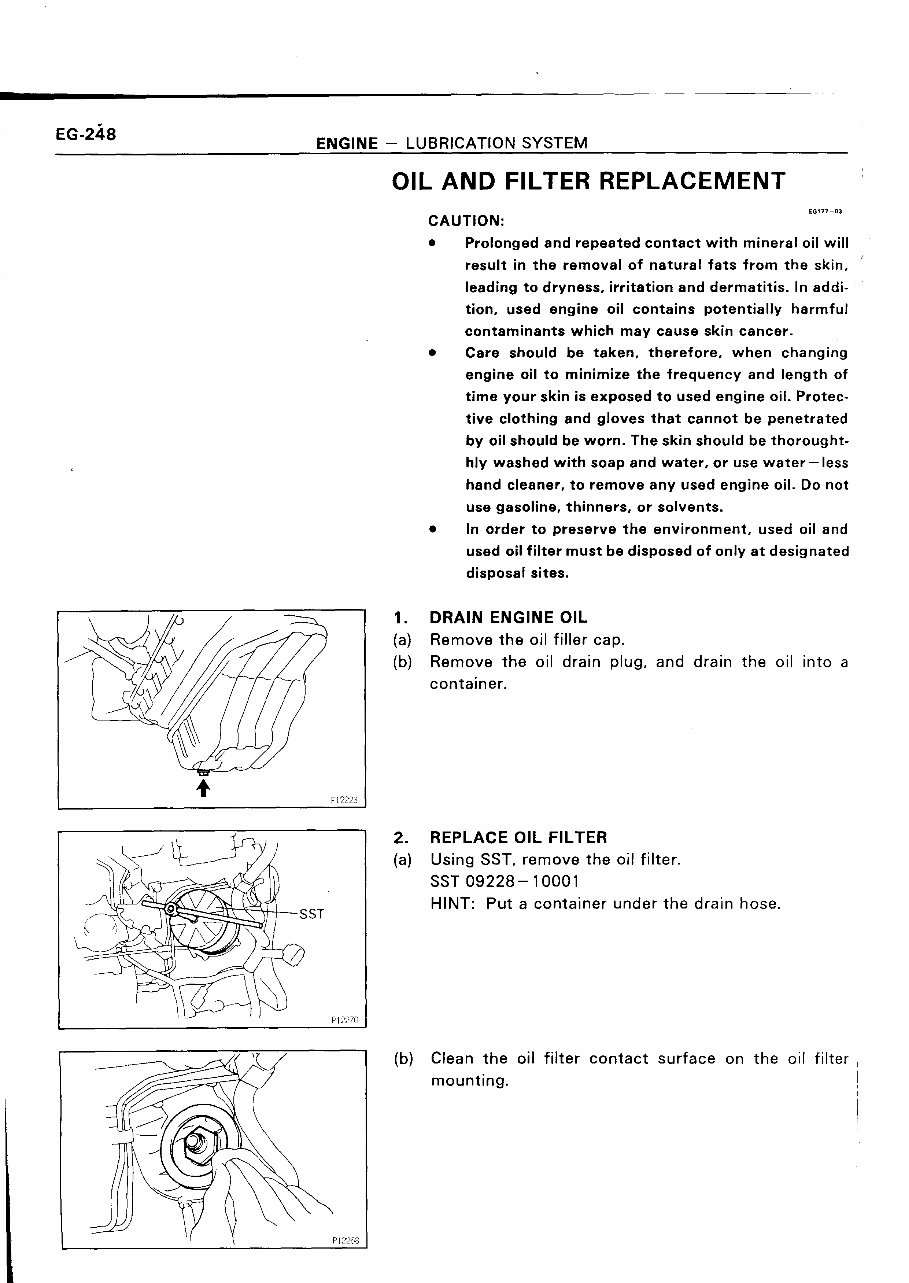

DRAINENGINEOIL

(a) Removetheoilfillercap .

(b) Removetheoildrainplug,anddraintheoilintoa

container

.

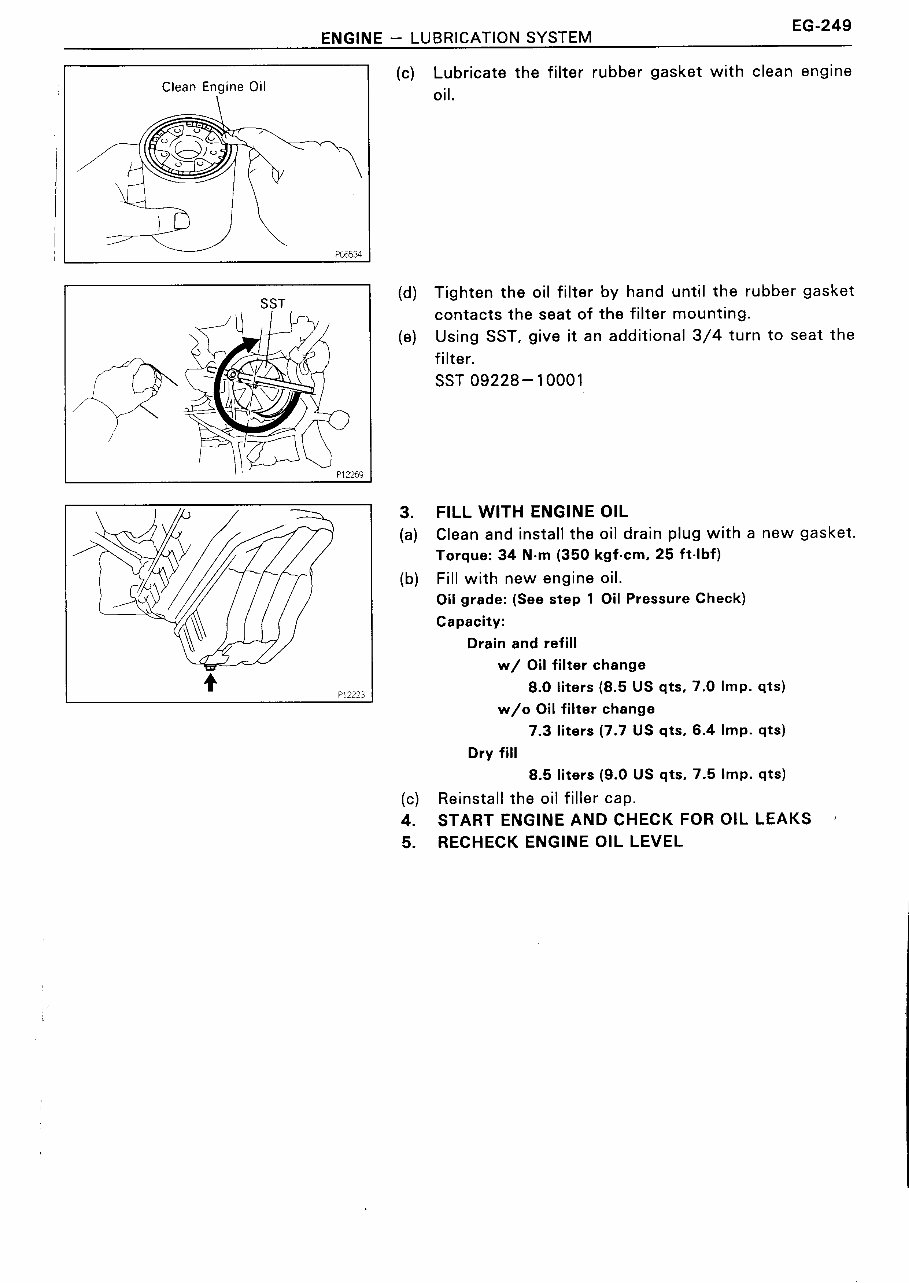

2 . REPLACEOILFILTER

(a) UsingSST,removetheoilfilter .

SST09228-10001

HINT :Putacontainerunderthedrainhose .

(b) Cleantheoilfiltercontactsurfaceontheoilfilter

mounting .

ENGINE - LUBRICATIONSYSTEM

EG-249

(c)

Lubricatethefilterrubbergas etwithcleanengine

oil .

(d)

Tightentheoilfilterbyhanduntiltherubbergas

et

contactstheseatofthefiltermounting

.

(e)

UsingSST,giveitanadditional3/4turntoseatthe

filter .

SST09228-10001

3 .

FILLWITHENGINEOIL

(a) Cleanandinstalltheoildrainplugwithanewgas

et .

Torque :34N .m(350 gf .cm,25ft

.lbf)

(b) Fillwithnewengineoil

.

Oilgrade :(Seestep1OilPressureChec

)

Capacity :

Drainandrefill

w/Oilfilterchange

8 .0liters(8 .5USqts,7

.0Imp .qts)

w/oOilfilterchange

7 .3liters(7 .7USqts,6 .4Imp .qts)

Dryfill

8 .5liters(9 .0USqts,7

.5Imp .qts)

(c)

Reinstalltheoilfillercap .

4 .

STARTENGINEANDCHECKFOROILLEAKS

5 .

RECHECKENGINEOILLEVEL

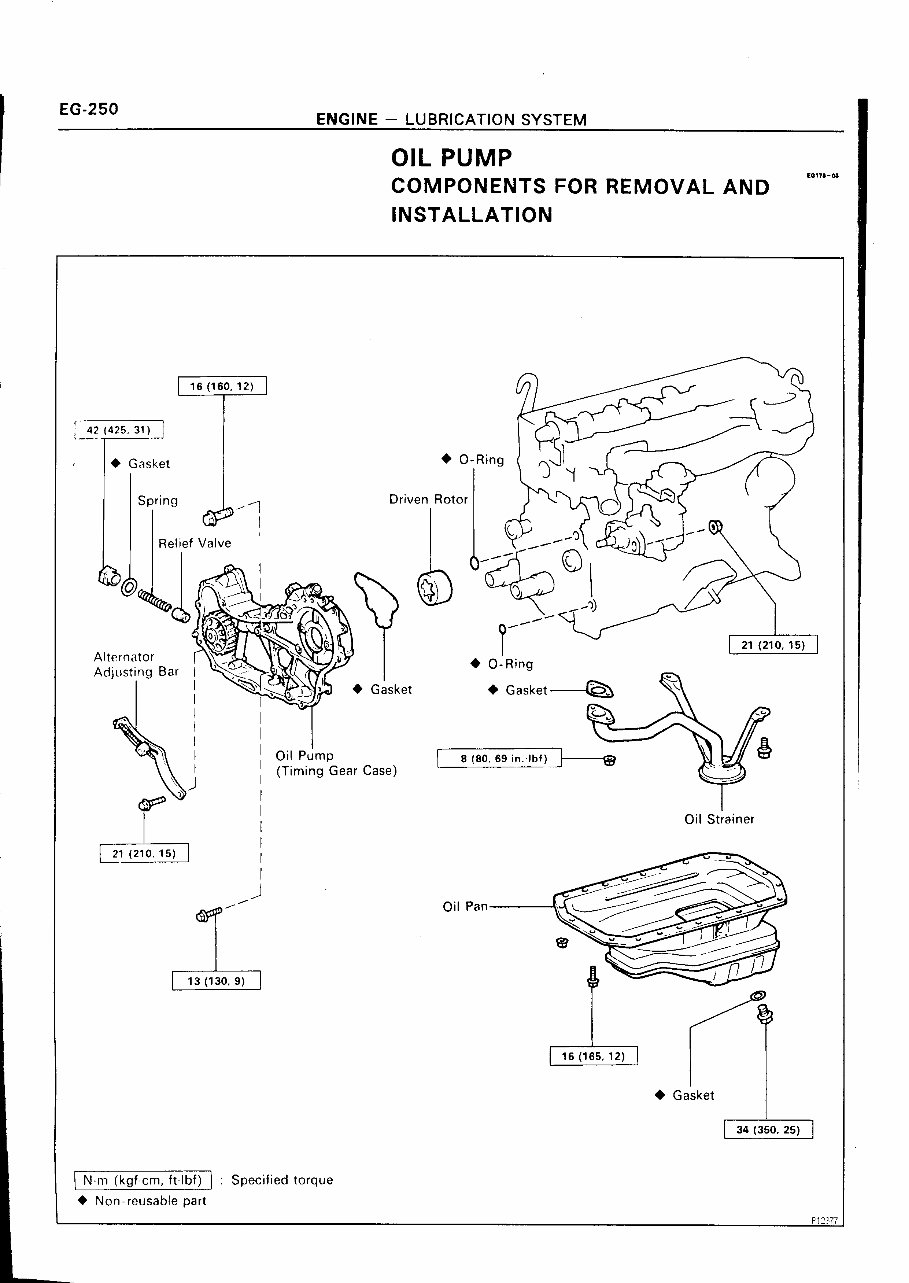

EG-250

ENGINE - LUBRICATIONSYSTEM

OILPUMP

COMPONENTSFORREMOVALAND

INSTALLATION

EG176-07

11 (210, 15)

16(160 .12)

N .m ( gf cm, ft lbf)

•

Non-reusablepart

13(130,9)

: Specifiedtorque

34(350,25)

P12377

ENGINE - LUBRICATIONSYSTEM

OILPUMPREMOVAL

(SeeComponentsforRemovalandInstallation)

HINT :Whenrepairingtheoilpump,theoilpanand

strainershouldberemovedandcleaned .

1 . DRAINENGINECOOLANT

2 . DRAINENGINEOIL

3 . REMOVEDRIVEBELT,FANANDWATERPUMP

PULLEY(Seestep2onpageEG-235)

4 . REMOVETIMINGBELT

(SeepageEG-32)

5 . REMOVETIMINGGEARS

(SeepageEG-41)

6 . REMOVEALTERNATORADJUSTINGBAR

(a) Removetheloc bolt .

(b) Removetheboltandadjustingbar .

7 . REMOVEALTERNATORANDALTERNATOR

BRACKET

(Seestep6onpageEG-235)

8 . REMOVEWATERPUMP

(Seestep6onpageEG-235)

9 . REMOVEOILLEVELSENSOR

(a) Disconncttheoillevelsensorconnector .

(b) Removethe4boltsandoillevelsensor .

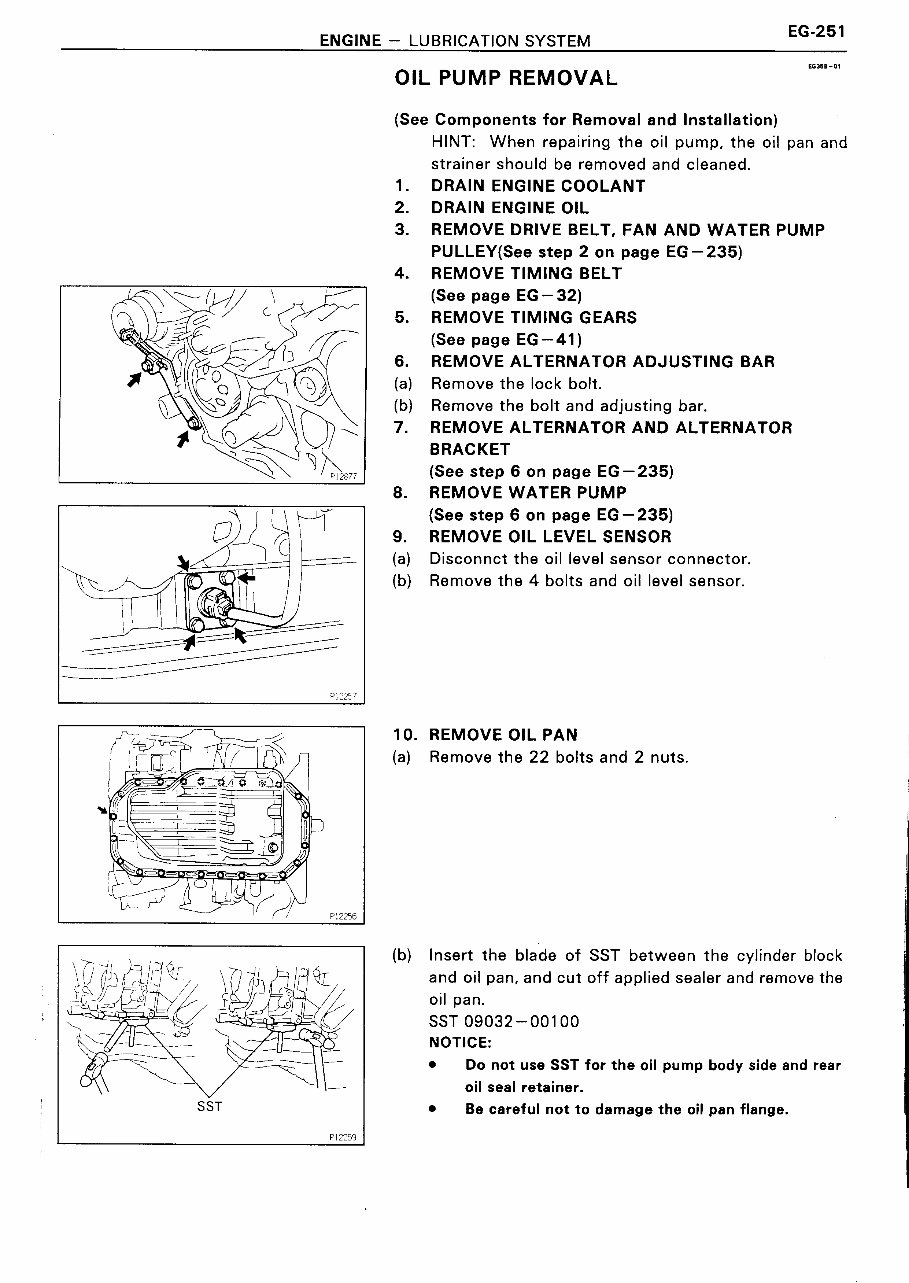

10 .REMOVEOILPAN

(a) Removethe22boltsand2nuts .

(b) InsertthebladeofSSTbetweenthecylinderbloc

andoilpan,andcutoffappliedsealerandremovethe

oilpan .

SST09032-00100

NOTICE :

•

DonotuseSSTfortheoilpumpbodysideandrear

oilsealretainer .

•

Becarefulnottodamagetheoilpanflange .

EG-251

EG35B-01

EG-252

ENGINE -

LUBRICATIONSYSTEM

11

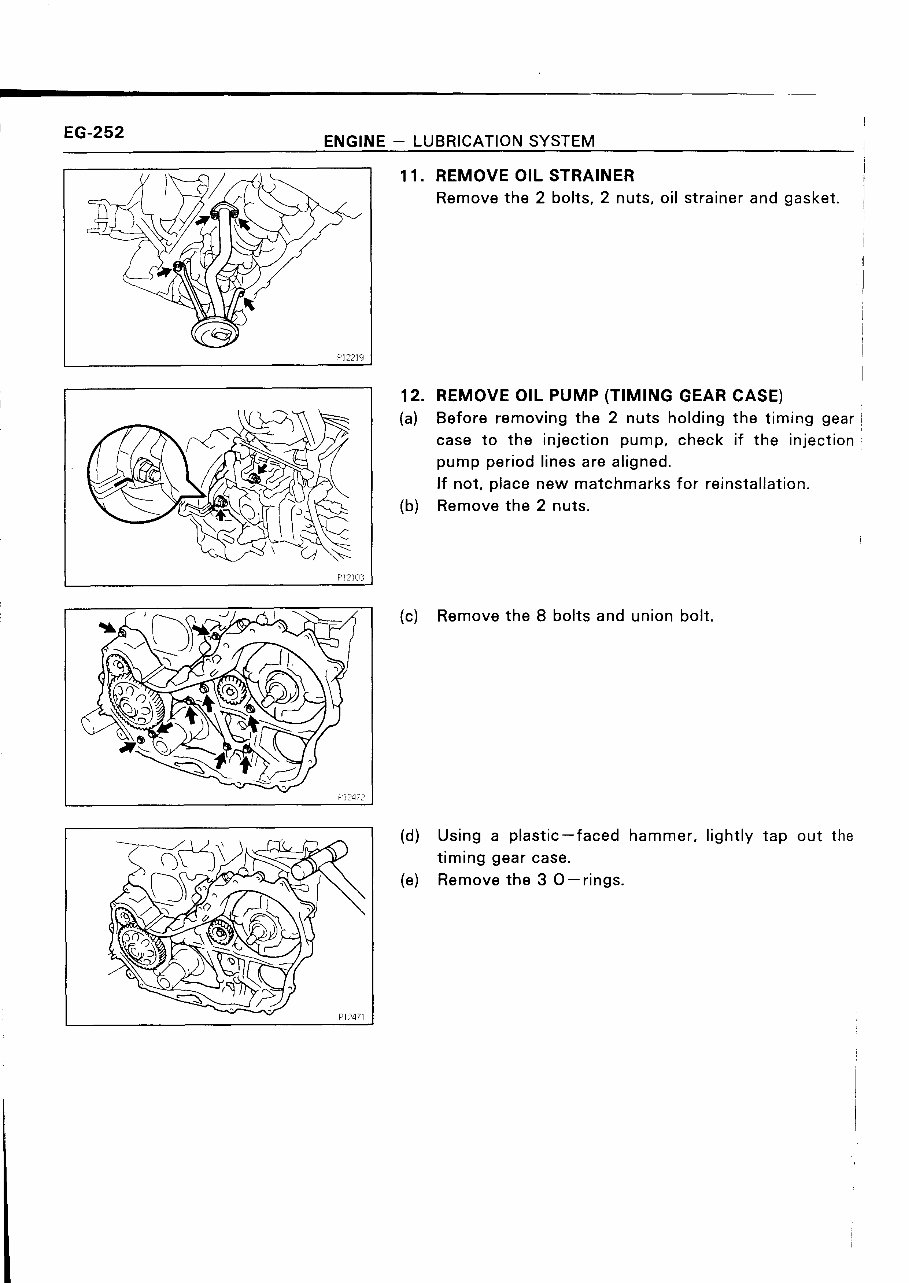

.REMOVEOILSTRAINER

Removethe2bolts,2nuts,oilstrainerandgas et .

12 .REMOVEOILPUMP(TIMINGGEARCASE)

(a) Beforeremovingthe2nutsholdingthetiminggear

casetotheinjectionpump,chec iftheinjection

pumpperiodlinesarealigned .

Ifnot,placenewmatchmar sforreinstallation .

(b)Removethe2nuts .

(c) Removethe8boltsandunionbolt .

(d)Usingaplastic-facedhammer,lightlytapoutthe

timinggearcase .

(e) Removethe30-rings .

ENGINE - LUBRICATIONSYSTEM

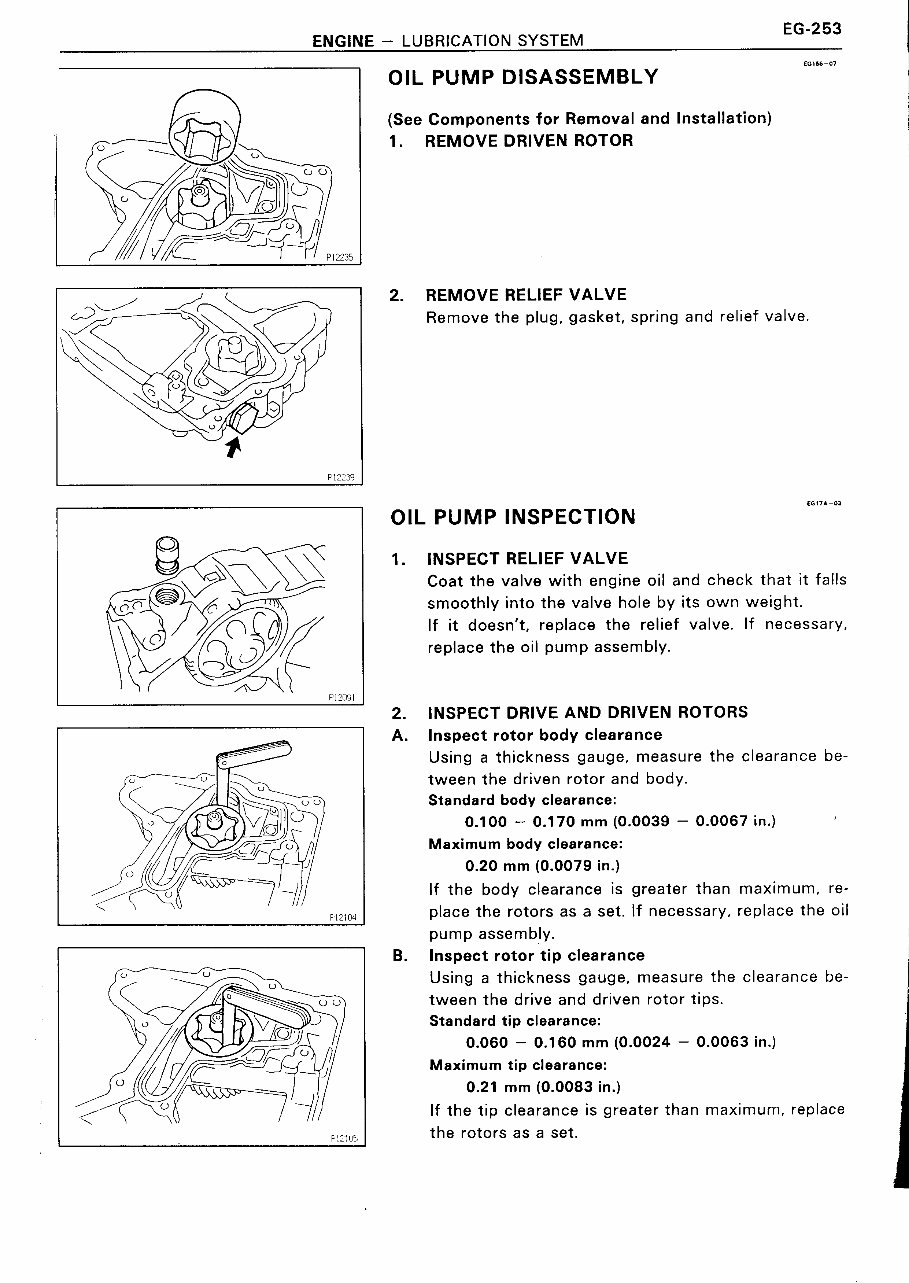

OILPUMPDISASSEMBLY

(SeeComponentsforRemovalandInstallation)

1 .

REMOVEDRIVENROTOR

2 .

REMOVERELIEFVALVE

Removetheplug,gas

et,springandreliefvalve .

OILPUMPINSPECTION

1 .

INSPECTRELIEFVALVE

Coatthevalvewithengineoilandchec thatitfalls

smoothlyintothevalveholebyitsownweight

.

Ifitdoesn't,replacethereliefvalve .Ifnecessary,

replacetheoilpumpassembly

.

2 . INSPECTDRIVEANDDRIVENROTORS

A . Inspectrotorbodyclearance

Usingathic

nessgauge,measuretheclearancebe-

tweenthedrivenrotorandbody .

Standardbodyclearance :

0 .100 - 0 .170mm(0 .0039 - 0

.0067in .)

Maximumbodyclearance :

0 .20mm(0 .0079in

.)

Ifthebodyclearanceisgreaterthanmaximum,re-

placetherotorsasaset

.Ifnecessary,replacetheoil

pumpassembly .

B . Inspectrotortipclearance

Usingathic nessgauge,measuretheclearancebe-

tweenthedriveanddrivenrotortips

.

Standardtipclearance :

0 .060 - 0 .160mm(0

.0024 - 0 .0063in .)

Maximumtipclearance :

0 .21mm(0 .0083in

.)

Ifthetipclearanceisgreaterthanmaximum,replace

therotorsasaset .

EG-253

EG166-07

EG17A-07

You're Reading a Preview

What's Included?

Lifetime Access

Access Contents & Bookmarks

Print one or all pages of your manual