Subaru Robin EY15, EY20, EY28 Engine Full Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

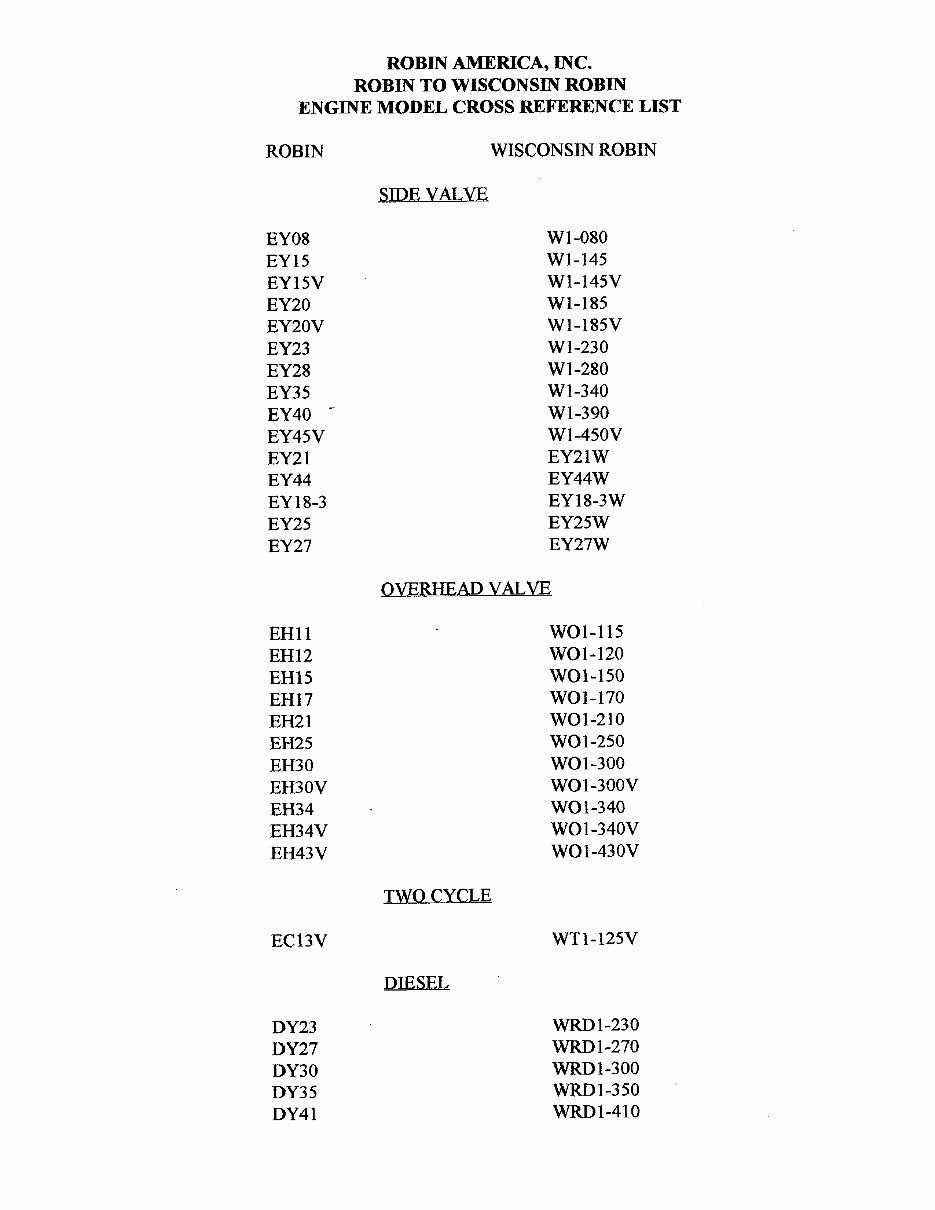

ROBIN AMERICA, INC.

ROBIN TO WISCONSIN ROBIN

ENGINE MODEL CROSS REFERENCE LIST

ROBIN

EY08

EY15

EY 15V

EY20

EY2OV

EY23

EY28

EY3 5

EY40 -

EY45V

EY2 1

EY44

EY 18-3

EY25

EY27

EH11

EH12

EH15

EH17

EH21

EH25

EH30

EH30V

EH34

EH34V

EH43V

EC13V

DY23

DY27

DY30

DY3 5

DY4 1

WISCONSIN ROBIN

SIDE VALVE

W 1-080

W1-145

W1-145V

W1-185

W1-185V

W1-230

W 1-280

W 1-340

W 1-390

Wl-45OV

EY21W

EY44W

EY18-3W

EY25W

EY27W

OVERHEAD VALVE

WO1-115

wo1-120

WO1-150

WO1-170

wo1-210

WOl-250

WO 1-300

WO1-300V

WO1-340

WO 1 -340V

WO 1-43 OV

TWO CYCLE

WT1-125V

DIESEL

WRD 1-230

WRD 1-270

-1-300

WRD1-350

WRD1-410

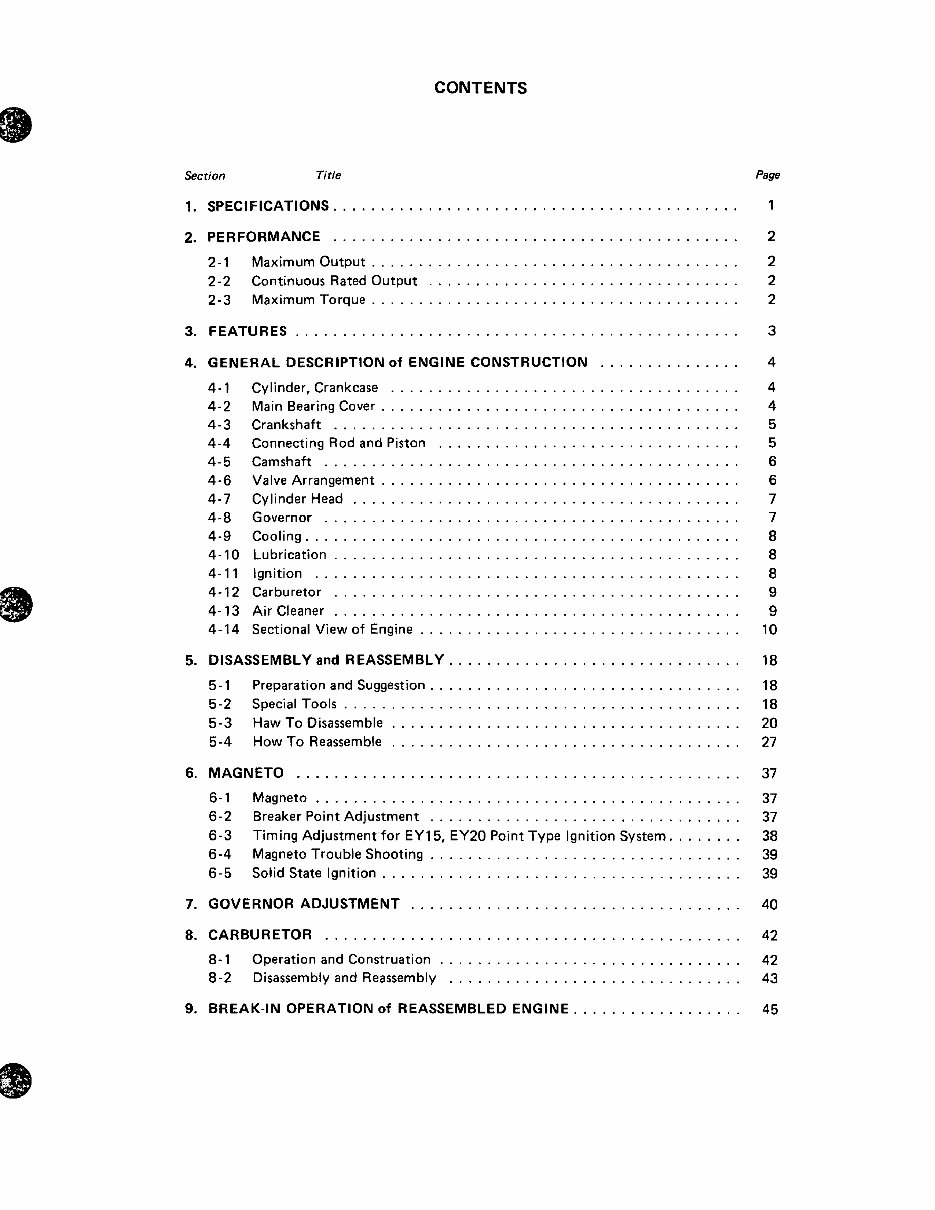

CONTENTS

Section Title Page

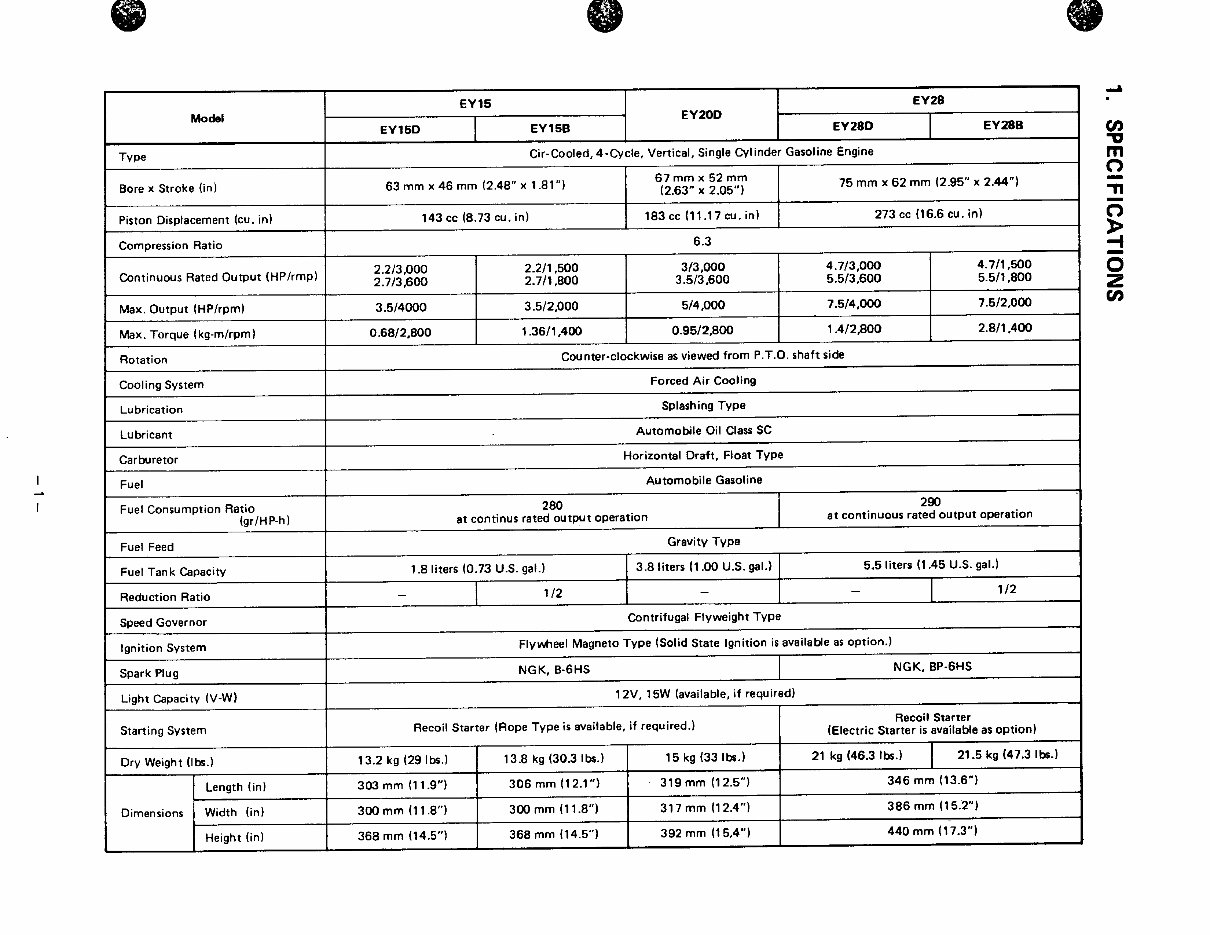

1 . SPECIFICATIONS ...........................................

2 . PERFORMANCE ...........................................

2- 1 Maximum Output .......................................

2-2 Continuous Rated Output .................................

2-3 Maximum Torque .......................................

3 . FEATURES ...............................................

4 . GENERAL DESCRIPTION of ENGINE CONSTRUCTION ...............

4- 1

4-2

4-3

4-4

4-5

4-6

4-7

4-8

4-9

4-10

4-1 1

4-12

4- 13

4-14

Cylinder. Crankcase .....................................

Main Bearing Cover ......................................

Crankshaft ...........................................

ConnectingRodandPiston ................................

Camshaft ............................................

Valve Arrangement ......................................

Cylinder Head .........................................

Governor ............................................

Cooling ..............................................

Lubrication ...........................................

Ignition .............................................

Carburetor ...........................................

Air Cleaner ...........................................

Sectional View of Engine ..................................

5 . DISASSEMBLY and REASSEMBLY ...............................

5-1 Preparation and Suggestion .................................

5-2 Special Tools ..........................................

5-3 Haw To Disassemble .....................................

5-4 How To Reassemble .....................................

6 . MAGNETO ...............................................

6-1 Magneto .............................................

6-2 Breaker Point Adjustment .................................

6-3 Timing Adjustment for EY15. EY20 Point Type Ignition System ........

6-4 Magneto Trouble Shooting .................................

6-5 Solid State Ignition ......................................

7 . GOVERNORADJUSTMENT ...................................

8 . CARBURETOR ............................................

8- 1 Operation and Construation ................................

8-2 Disassembly and Reassembly ...............................

9 . BREAK-IN OPERATION Of REASSEMBLED ENGINE ................

1

3

4

4

4

5

5

6

6

7

7

8

8

8

9

9

10

18

18

18

20

27

37

37

37

38

39

39

40

42

42

43

45

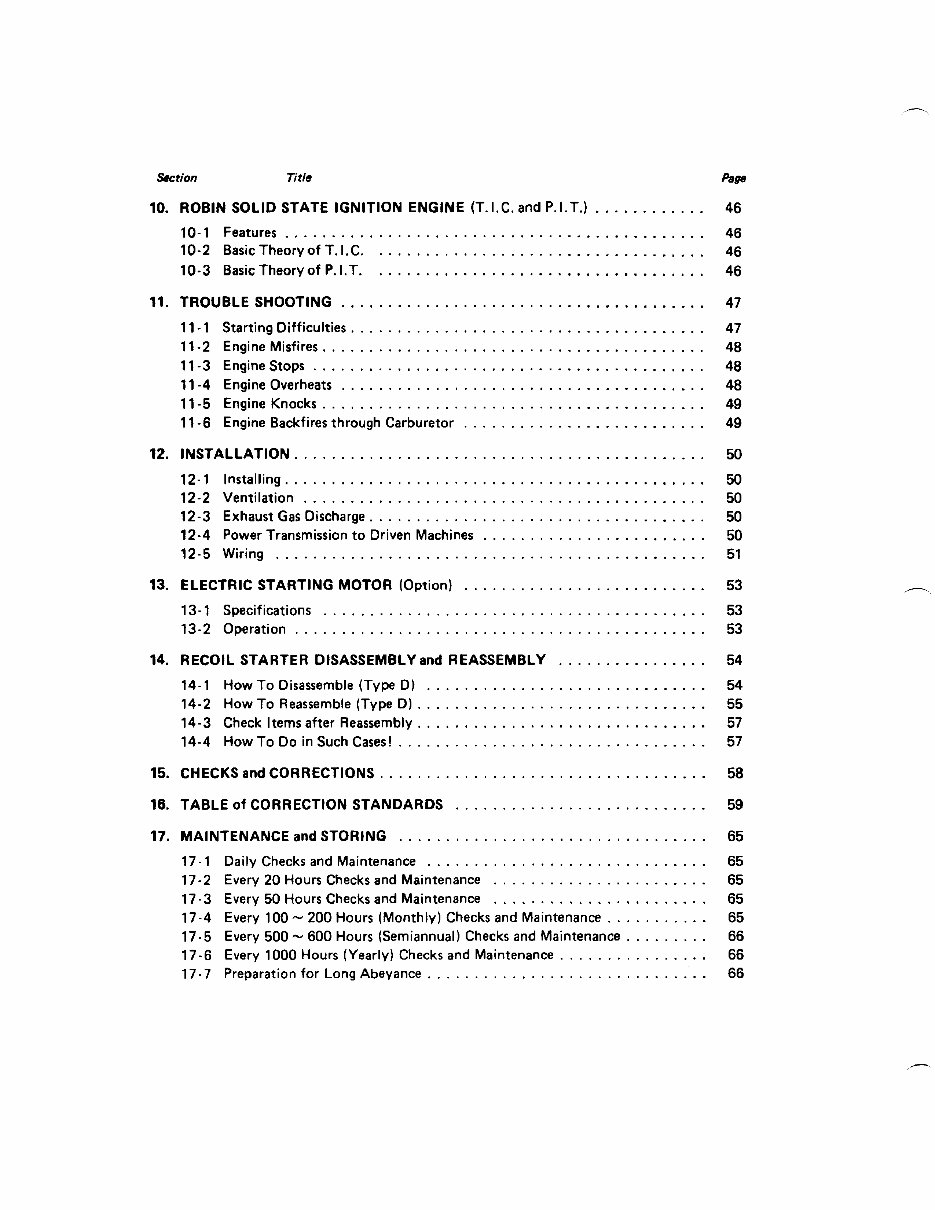

Section Title pese

10 . ROBIN SOLID STATE IGNITION ENGINE (T.I.C. and P.I.T.) ............ 46

10-1 Features ............................................. 46

10-2 Basic Theory of T . I.C. ................................... 46

10-3 Basic Theory of P . I.T. ................................... 46

11 . TROUBLE SHOOTING ....................................... 47

11 . 1 Starting Difficulties ...................................... 47

11 -2 Engine Misfires ......................................... 48

1 1-3 Engine Stops .......................................... 48

11 -4 Engine Overheats ....................................... 48

11 -6 Engine Backfires through Carburetor .......................... 49

12 . INSTALLATION ............................................ 50

12-1 Installing ............................................. 50

12-2 Ventilation ........................................... 50

12-3 Exhaust Gas Discharge .................................... 50

12-4 Power Transmission to Driven Machines ........................ 50

12-5 Wiring .............................................. 51

13 . ELECTRIC STARTING MOTOR (Option) .......................... 53

13- 1 Specifications ......................................... 53

13-2 Operation ............................................ 53

11-5 Engine Knocks ......................................... 49

14 . RECOIL STARTER DISASSEMBLY and REASSEMBLY ................ 54

14-1 How To Disassemble (Type D) .............................. 54

14-2 How To Reassemble (Type D) ............................... 55

14-3 Check Items after Reassembly ............................... 57

14-4 How To Do in Such Cases! ................................. 57

15 . CHECKS and CORRECTIONS ................................... 58

16 . TABLE of CORRECTION STANDARDS ........................... 59

17 . MAINTENANCE and STORING .................................

17-1 Daily Checks and Maintenance ..............................

17-2 Every 20 Hours Checks and Maintenance .......................

17-3 Every 50 Hours Checks and Maintenance .......................

17-4 Every 100 - 200 Hours (Monthly) Checks and Maintenance ...........

17-5 Every 500 - 600 Hours (Semiannual) Checksand Maintenance .........

17-6 Every 1000 Hours (Yearly) ChecksandMaintenance ................

17- 7 Preparation for Long Abeyance ..............................

65

65

65

65

65

66

66

66

.

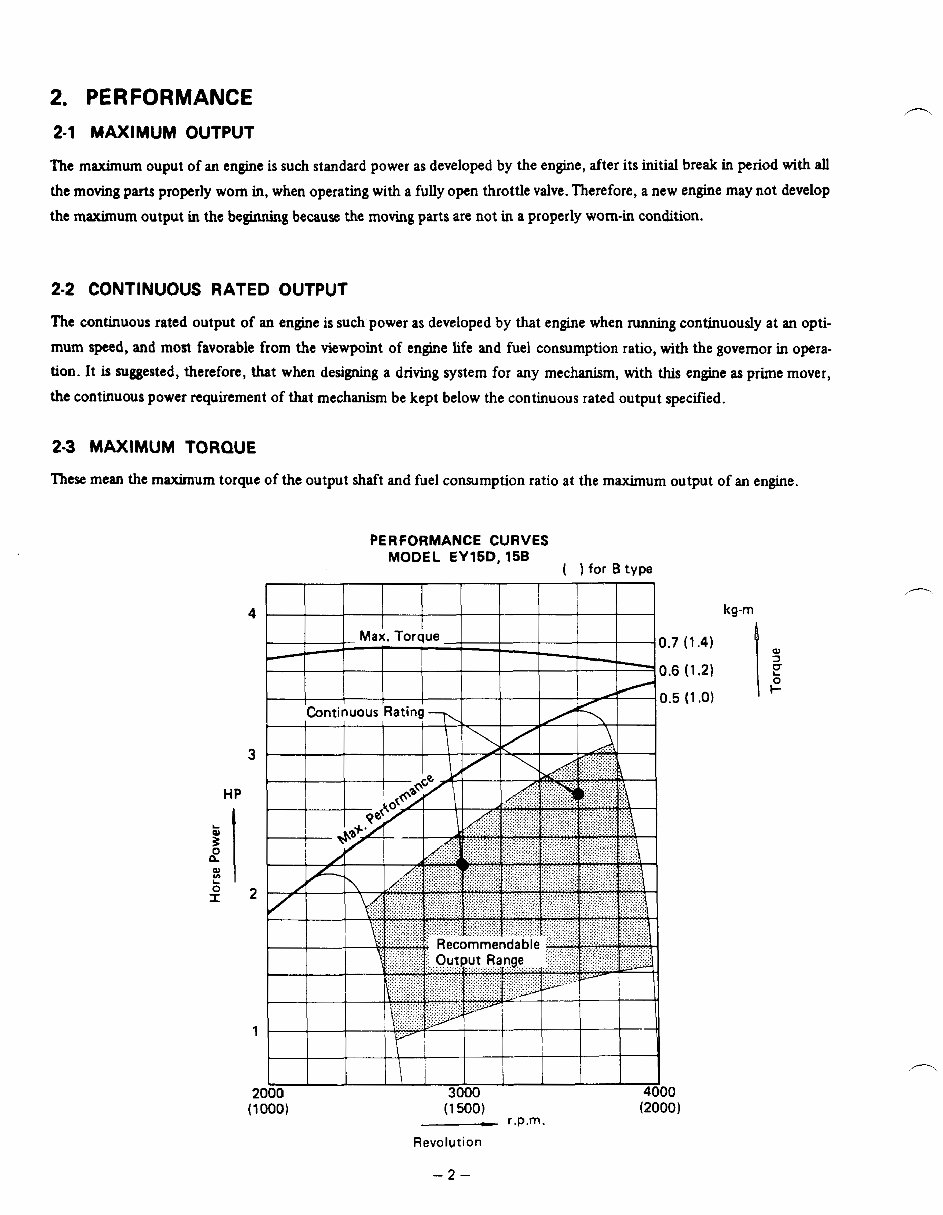

2. PERFORMANCE

2-1 MAXIMUM OUTPUT

The maximum ouput of an engine is such standard power as developed by the engine, after its initial break in period with all

the moving parts properly worn in, when operating with a fully open throttle valve. Therefore, a new engine may not develop

the maximum output in the beginning because the moving parts are not in a properly worn-in condition.

2-2 CONTINUOUS RATED OUTPUT

The continuous rated output of an engine is sudrpower as developed by that engine when running continuously at an opti-

mum speed, and most favorable from the viewpoint of engine life and fuel consumption ratio, with the governor in opera-

tion. It is suggested, therefore, that when designing a driving system for any mechanism, with this engine as prime mover,

the continuous power requirement of that mechanism be kept below the continuous rated output specified.

23 MAXIMUM TORQUE

These mean the maximum torque of the output shaft and fuel consumption ratio at the maximum output of an engine.

PERFORMANCE CURVES

MODEL EY15D, 15B

( 1 for B type

4

Ma;. Torque ~ 0.7

-

I I 7 0.6

HP

t i i

I \ I I I I I I

I

2000 3000 4000

(1 000) (1 500) (20001

r.p.m.

Revolution

kg-m

-2-

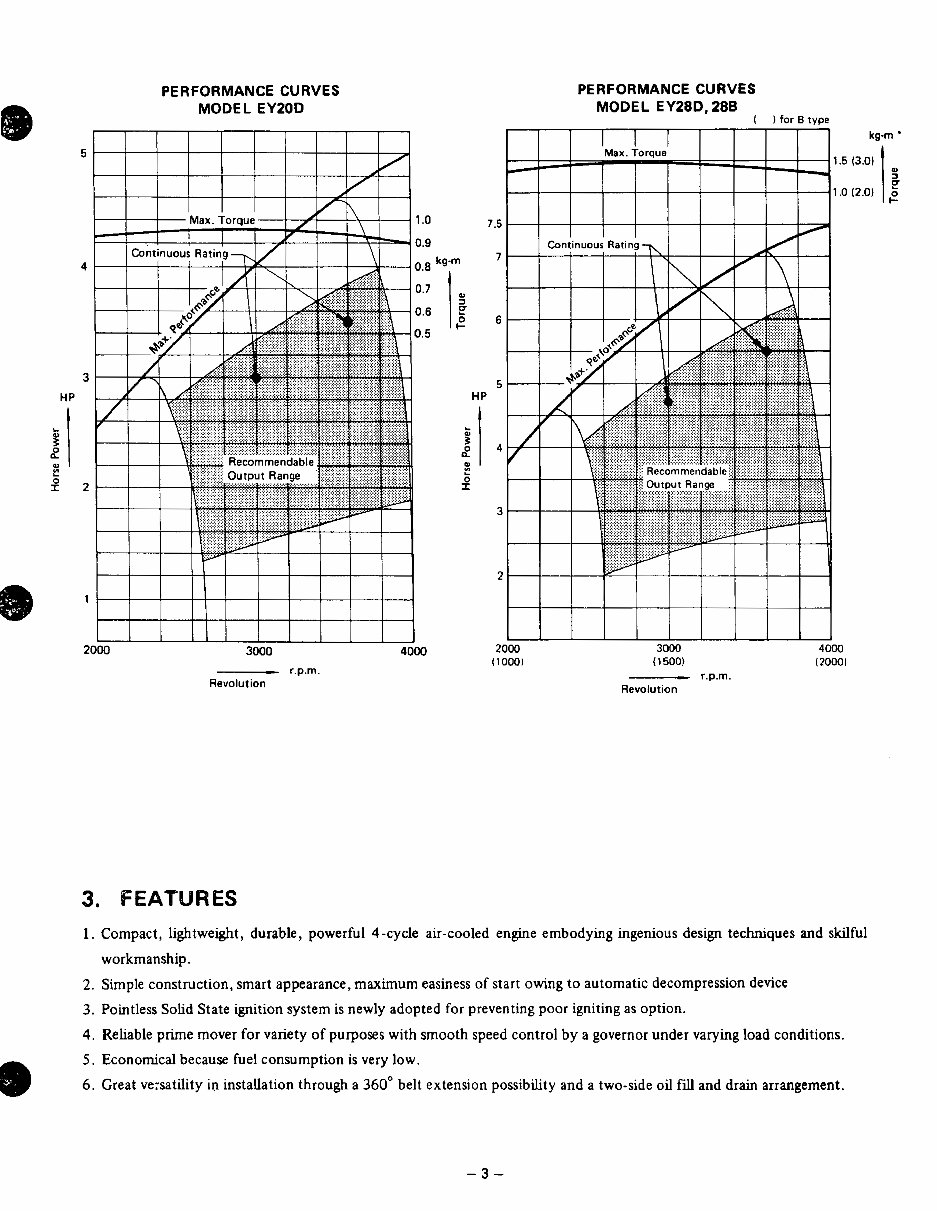

PERFORMANCE CURVES

MODEL EYZOD

5

Max. Toraue 1 .o

4

3

HP

L .

B

2 2

w

r

1

2000 3000 4000

Revolution

r.p.m.

2000

(1 000)

PERFORMANCE CURVES

MODEL EY28D, 288

I ) for B tvm

3000

( 15001

Revolution

r.p.rn.

4000

I20001

3. FEATURES

1. Compact, lightweight, durable, powerful 4-cycle air-cooled engine embodying ingenious design techques and skilful

workmanship.

2. Simple construction, smart appearance, maximum easiness of start owing to automatic decompression device

3. Pointless Solid State ignition system is newly adopted for preventing poor igniting as option.

4. Reliable prime mover for variety of purposes with smooth speed control by agovernor under varying load conditions.

5. Economical because fuel consumption is very low.

6. Great ve:satility in installation through a 360" belt extension possibihty and a two-side oil fill and drain arrangement.

-3-

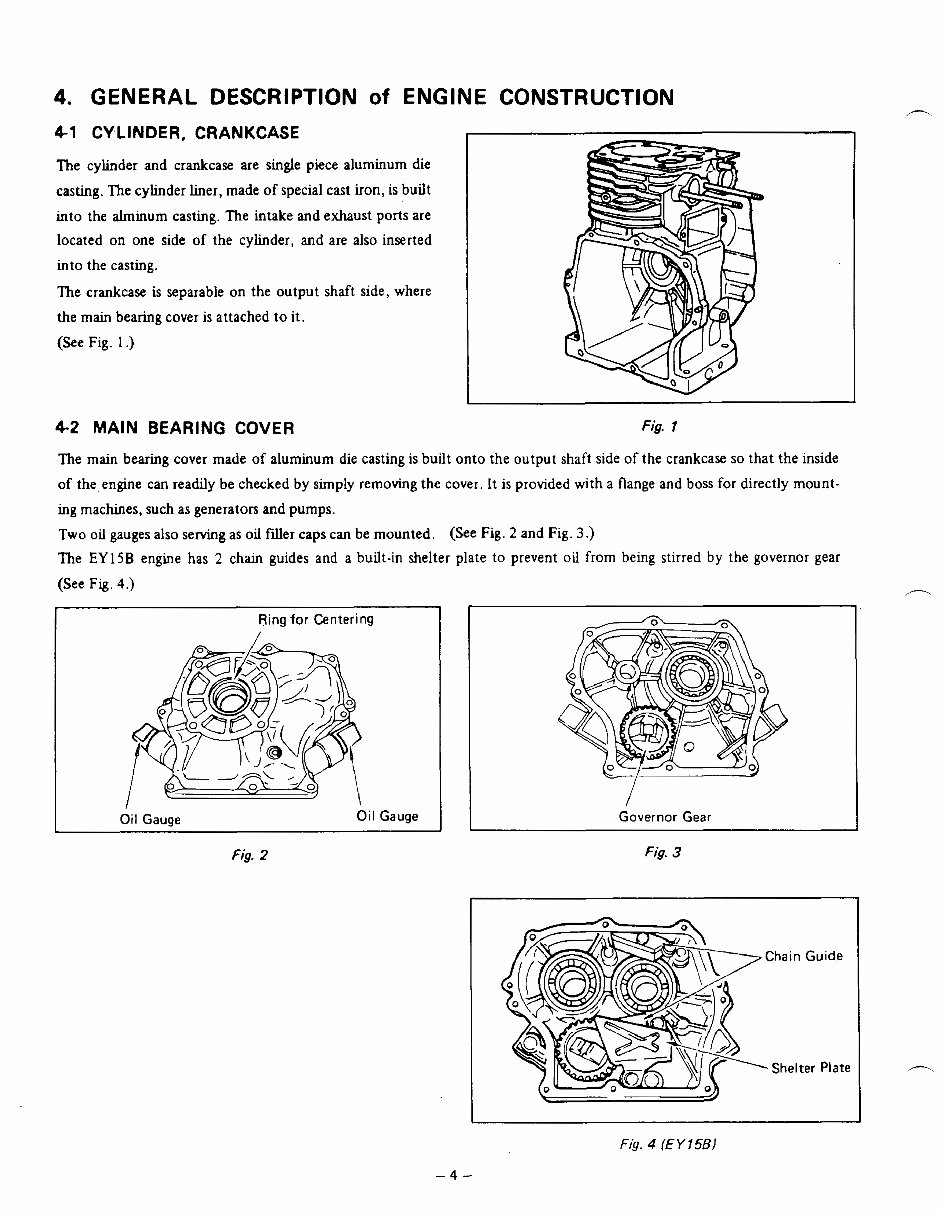

4. GENERAL DESCRIPTION of ENGINE CONSTRUCTION

4-1 CYLINDER, CRANKCASE

The cylinder and crankcase are single piece aluminum die

casting. The c y h d e r liner, made of special cast iron, is built

into the alminum casting. The intake and exhaust ports are

located on one side of the cyhder, and are also inserted

into the casting.

The crankcase is separable on the output shaft side, where

the main bearing cover is attached to it.

(See Fig. 1 .)

4-2 MAIN BEARING COVER Fig. 1

The main bearing cover made of aluminum die casting is built onto the output shaftside of the crankcase so that the inside

of the engine can readily be checked by simplyremoving the cover. It is provided with a flange and boss for directly mount-

ing machmes, such as generators and pumps.

Two oil gauges also serving as oil filler caps can be mounted. (See Fig. 2 and Fig. 3.)

The EY 15B engine has 2 chain guides and a built-in shelter plate to prevent oil from being stirred by the governor gear

(See Fig. 4.)

Ring for Centering

/

Oil Gauge Oil Gauge

Fig. 2

I

Governor Gear

Fig. 3

Chain Guide

- Shelter Plate

1

Fig. 4 (E Y 15B)

-4-

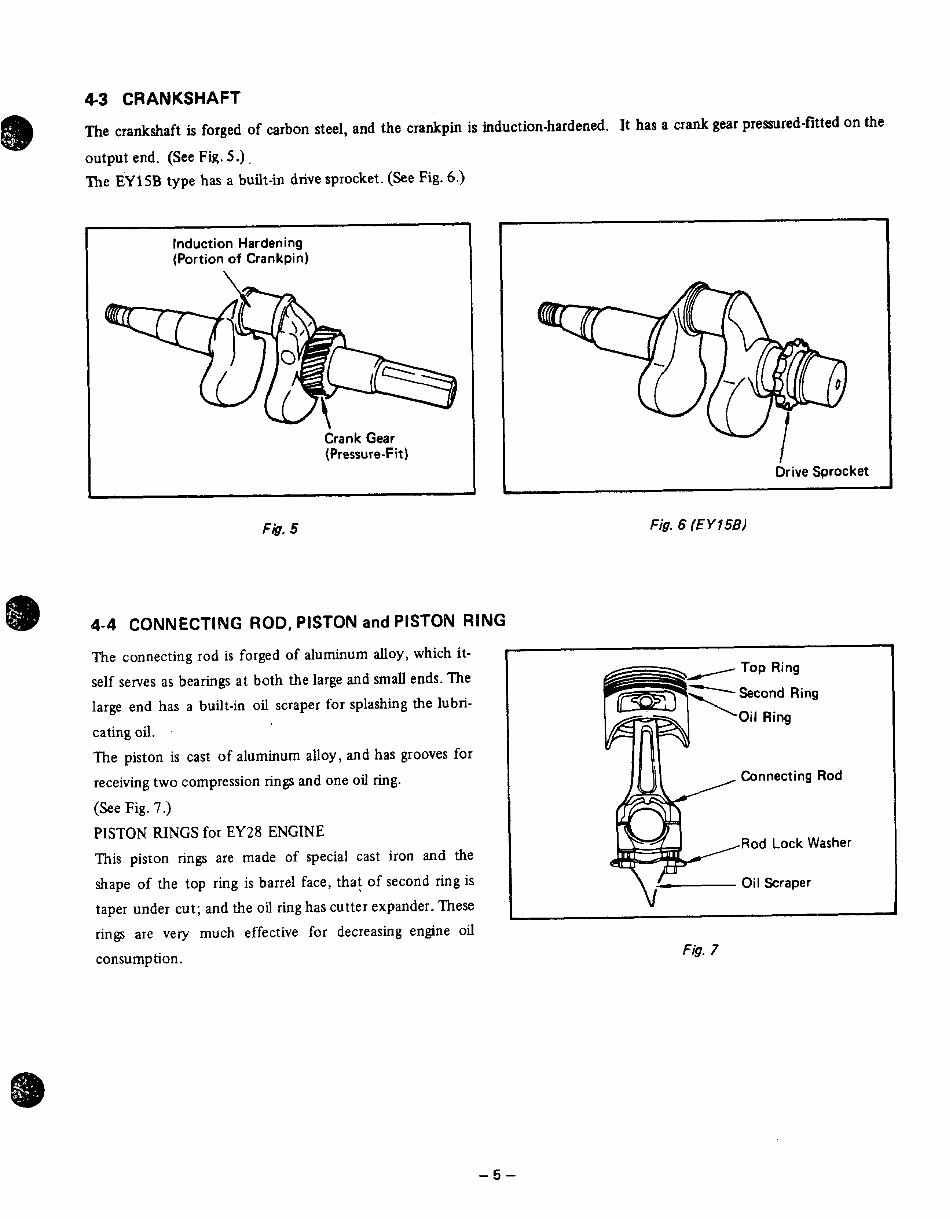

4-3 CRANKSHAFT

The crankshaft is forged of carbon steel, and the crankpin is induction-hardened. It has a crank gear premred-fitted on the

output end. (See Fig. 5.).

"he EY 15B type has a built-in drive sprocket. (See Fig. 6.)

Induction Hardening

(Portion of Crankpin)

Crank Gear

(Pressure-Fit)

Drive Sprocket

-

Fig. 5

Fig. 6 (E Y 158)

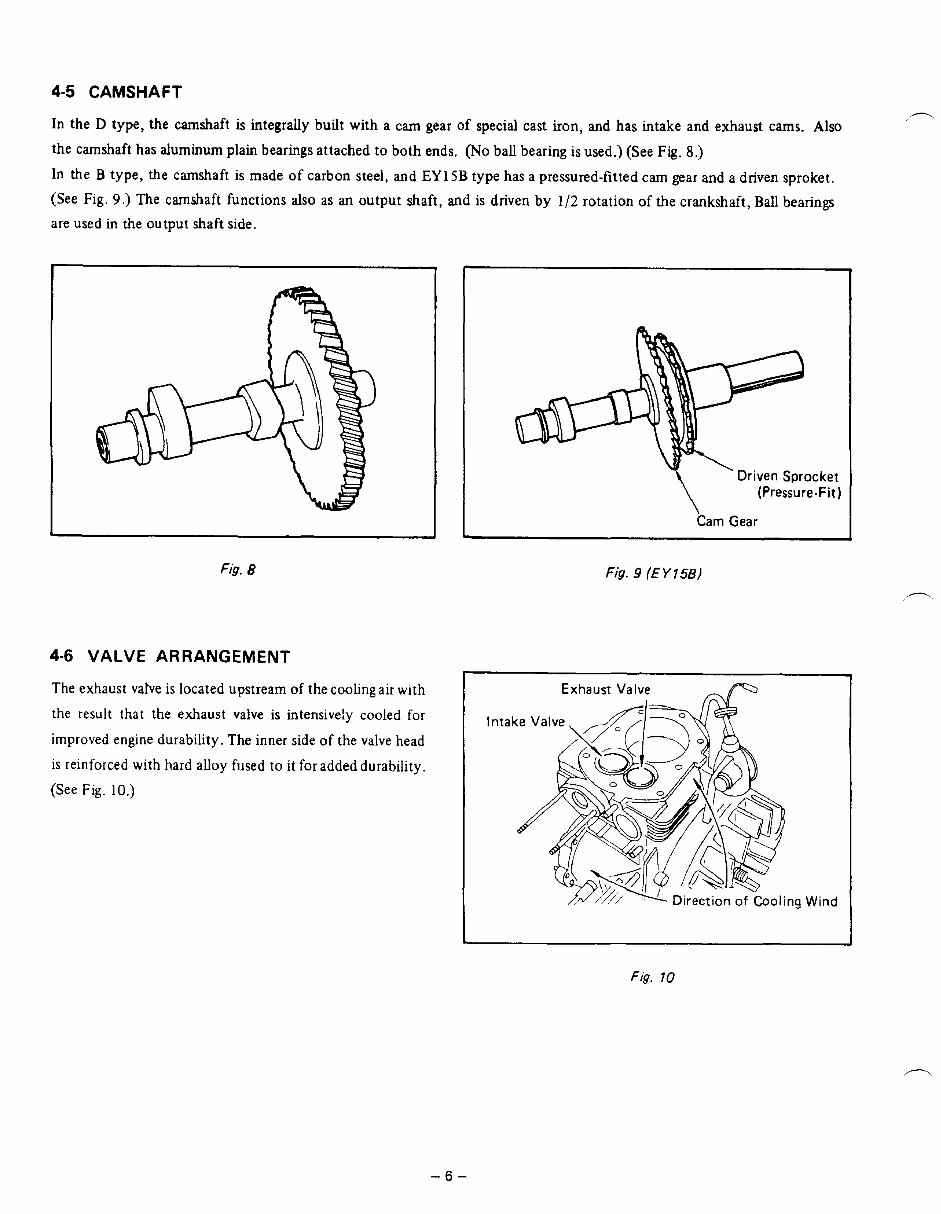

4-4 CONNECTING ROD, PISTON and PISTON RING

The connecting rod is forged of aluminum alloy, which it-

self serves as bearings at both the large and small ends. The

large end has a built-in oil scraper for splashing the lubri-

cating oil.

The piston is cast of aluminum alloy, and has grooves for

receiving two compression rings and one oil ring.

(See Fig. 7.)

PISTON RINGS for EY28 ENGINE

This piston rings are made of special cast iron and the

shape of the top ring is barrel face, that of second ring is

taper under cut; and the oil ring has cutter expander.These

rings are very much effective for decreasing engine oil

consumption.

Connecting Rod

Rod Lock Washer

Oil Scraper

1

Fig. 7

-5-

4-5 CAMSHAFT

In the D type, the camshaft is integrally built with a cam gear of special cast iron, and has intake and exhaust cams. Also

the camshaft has aluminum plain bearings attached to both ends. (No ball bearing is used.) (See Fig. 8.)

In the B type, the camshaft is made of carbon steel, and EYlSB type has a pressured-fitted cam gear and a driven sproket.

(See Fig. 9.) The camshaft functions also as an output shaft, and is driven by 1/2 rotation of the crankshaft, Ball bearings

are used in the output shaft side.

J

Fig. 8

4-6 VALVE ARRANGEMENT

The exhaust vahe is located upstream of the coolingair with

the result thattheexhaust valve is intensiveiy cooled for

improved engine durability. The inner side of the valve head

is reinforced with hard alloy fused to it for added durability.

(See Fig. 10.)

Driven Sprocket

(Pressure-Fit)

Cam Gear

Fig. 9 (E Y 156)

I Exhaust Valve

Direction of Cooling Wind

Fig. 70

-6-

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 54 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

- This full service and repair manual is a comprehensive factory workshop manual for Subaru Robin EY15, EY20, EY28 engines.

- It is available in PDF format for instant access on your computer, tablet, or smartphone.

- Professionally written, it covers all repair, servicing, and troubleshooting procedures with detailed photos and diagrams.

- Used by professional mechanics and technicians, it provides step-by-step instructions and highly detailed exploded diagrams and pictures for accurate completion of every job.

- You have the option to print out a single page or the entire manual.

- This manual can be used on multiple computers without any limitations or trial periods.

- There is no expiry date, renewal fee, or need to pay extra for continued use.

- It is fully compatible with Windows and MAC computers.

For more information, please click on the provided button.