Perkins 1103 and 1104,2490/1500 manual collection

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Perkins 1103 &1104 Series

WORKSHOP MANUAL

Disassembly and Assembly

3 and 4 cylinder, naturally aspirated, and turbocharged

diesel engines for agricultural and industrial use

Publication SENR9779-00

© Proprietary information of Perkins Engines Company Limited 2004, all rights reserved.

The information is correct at the time of print.

Published by Technical Publications.

Perkins Engines Company Limited, Peterborough, PE1 5NA, England

Important Safety Information

Most accidents that involve product operation, maintenance and repair are caused by failure to

observe basic safety rules or precautions. An accident can often be avoided by recognizing potentially

hazardous situations before an accident occurs. A person must be alert to potential hazards. This

person should also have the necessary training, skills and tools to perform these functions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and

could result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you have

read and understood the operation, lubrication, maintenance and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard

warnings are not heeded, bodily injury or death could occur to you or to other persons.

The hazards are identified by the “Safety Alert Symbol” and followed by a “Signal Word” such as

“DANGER”, “WARNING” or “CAUTION”. The Safety Alert “WARNING” label is shown below.

The meaning of this safety alert symbol is as follows:

Attention! Become Alert! Your Safety is Involved.

The message that appears under the warning explains the hazard and can be either written or

pictorially presented.

Operations that may cause product damage are identified by “NOTICE” labels on the product and in

this publication.

Perkins cannot anticipate every possible circumstance that might involve a potential hazard. The

warnings in this publication and on the product are, therefore, not all inclusive. If a tool, procedure,

work method or operating technique that is not specifically recommended by Perkins is used,

you must satisfy yourself that it is safe for you and for others.You should also ensure that the

product will not be damaged or be made unsafe by the operation, lubrication, maintenance or

repair procedures that you choose.

The information, specifications, and illustrations in this publication are on the basis of information that

was available at the time that the publication was written. The specifications, torques, pressures,

measurements, adjustments, illustrations, and other items can change at any time. These changes can

affect the service that is given to the product. Obtain the complete and most current information before

you start any job. Perkins dealers or Perkins distributors have the most current information available.

When replacement parts are required for this

product Perkins recommends using Perkins

replacement parts.

Failure to heed this warning can lead to prema-

ture failures, product damage, personal injury or

death.

3

Table of Contents

Table of Contents

Disassembly and Assembly Section

Fuel Priming Pump - Remove and Install .............. 4

Fuel Filter Base - Remove and Install .................... 5

Fuel Injection Lines - Remove ............................... 6

Fuel Injection Lines - Install ................................... 7

Fuel Injector Cover - Remove and Install ................ 8

Fuel Injection Pump - Remove (Delphi DP210) ...... 8

Fuel Injection Pump - Remove (Bosch EPVE for the

1104 engines only) .............................................. 10

Fuel Injection Pump - Install (Delphi DP210) ........ 11

Fuel Injection Pump - Install (Bosch EPVE for the

1104 engines only) .............................................. 13

Fuel Injector - Remove ......................................... 14

Fuel Injector - Install ............................................ 15

Turbocharger - Remove ........................................ 16

Turbocharger - Install ............................................ 17

Exhaust Manifold - Remove and Install ............... 18

Exhaust Elbow - Remove and Install (Option for Four

Cylinder Engines Only) ....................................... 20

Inlet and Exhaust Valve Springs - Remove and

Install ................................................................... 21

Inlet and Exhaust Valves - Remove and Install ..... 23

Inlet and Exhaust Valve Guides - Remove and

Install ................................................................... 26

Inlet and Exhaust Valve Seat Inserts - Remove and

Install ................................................................... 28

Engine Oil Filter Base - Remove and Install ........ 30

Engine Oil Cooler - Remove ................................. 34

Engine Oil Cooler - Install ..................................... 36

Engine Oil Relief Valve - Remove and Install (Engine

Oil Pump) ............................................................ 37

Engine Oil Relief Valve - Remove and Install

(Balancer Unit for the 1104 engines only) ........... 39

Engine Oil Pump - Remove (Engines Without a

Balancer) ............................................................. 40

Engine Oil Pump - Install (Engines Without a

Balancer) ............................................................. 40

Water Pump - Remove ......................................... 41

Water Pump - Disassemble ................................. 42

Water Pump - Assemble ...................................... 43

Water Pump - Install ............................................. 45

Water Temperature Regulator - Remove and Install

............................................................................. 46

Flywheel - Remove ............................................... 48

Flywheel - Install ................................................... 49

Crankshaft Rear Seal - Remove ........................... 50

Crankshaft Rear Seal - Install ............................... 50

Crankshaft Wear Sleeve (Rear) - Remove ............ 52

Crankshaft Wear Sleeve (Rear) - Install ............... 53

Flywheel Housing - Remove and Install ............... 53

Crankshaft Pulley - Remove and Install ............... 55

Crankshaft Front Seal - Remove ........................... 55

Crankshaft Front Seal - Install .............................. 56

Crankshaft Wear Sleeve (Front) - Remove ........... 57

Crankshaft Wear Sleeve (Front) - Install ............... 58

Front Cover - Remove and Install ......................... 58

Gear Group (Front) - Remove ............................... 59

Gear Group (Front) - Install ................................... 61

Idler Gear - Remove and Install ............................ 63

Housing (Front) - Remove ..................................... 68

Housing (Front) - Install ........................................ 69

Accessory Drive - Remove and Install ................. 70

Crankcase Breather - Remove and Install ........... 72

Valve Mechanism Cover - Remove and Install ..... 74

Rocker Shaft and Pushrod - Remove ................... 76

Rocker Shaft - Disassemble ................................ 77

Rocker Shaft - Assemble ..................................... 77

Rocker Shaft and Pushrod - Install ....................... 78

Cylinder Head - Remove ....................................... 79

Cylinder Head - Install .......................................... 81

Lifter Group - Remove and Install ......................... 84

Camshaft - Remove and Install ............................ 85

Camshaft Gear - Remove and Install ................... 86

Camshaft Bearings - Remove and Install ............ 86

Engine Oil Pan - Remove and Install ................... 87

Balancer - Remove (Some 1104 Engines Only) ... 90

Balancer - Install (Some 1104 Engines Only) ....... 91

Piston Cooling Jets - Remove and Install ............. 92

Pistons and Connecting Rods - Remove .............. 93

Pistons and Connecting Rods - Disassemble ....... 94

Pistons and Connecting Rods - Assemble ........... 95

Pistons and Connecting Rods - Install .................. 96

Connecting Rod Bearings - Remove .................... 98

Connecting Rod Bearings - Install ........................ 98

Crankshaft Main Bearings - Remove .................... 99

Crankshaft Main Bearings - Install (Crankshaft in

Position) ............................................................ 101

Crankshaft - Remove .......................................... 103

Crankshaft - Install .............................................. 105

Crankshaft Gear - Remove and Install ............... 108

Bearing Clearance - Check ................................. 109

Glow Plugs - Remove and Install ....................... 110

V-Belts - Remove and Install .............................. 111

Fan - Remove and Install ................................... 112

Fan Drive - Remove and Install .......................... 113

Alternator - Remove ............................................ 113

Alternator - Install ................................................ 114

Electric Starting Motor - Remove and Install ..... 114

Vacuum Pump - Remove and Install (Some 1104

engines only) ..................................................... 115

Hydraulic Pump (Steering) - Remove ................. 116

Hydraulic Pump (Steering) - Install ..................... 116

Index Section

Index ................................................................... 117

4

Disassembly and Assembly Section

Disassembly and Assembly

Section

i01939024

Fuel Priming Pump - Remove

and Install

Removal Procedure

Start By:

a. Remove the assembly of the filter case and the

fuel filter element. Refer to this Disassembly and

Assembly Manual, “Fuel Filter Base - Remove

and Install”.

Note: There is an option for the three cylinder

engine. The fuel priming pump and the fuel filter

can be installed onto the application rather than

onto the engine. If this is the case, refer to the

appropriate OEM information as well as this text.

Note: Put identification marks on all fuel hose

assemblies and on all tube assemblies for

installation purposes. After being disconnected,

plug all fuel hose assemblies and plug all tube

assemblies. This helps prevent fluid loss, and

this helps to keep contaminants from entering the

system.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compartment or disassembling any compo-

nent containing fluids.

Dispose of all fluids according to local regulations and

mandates.

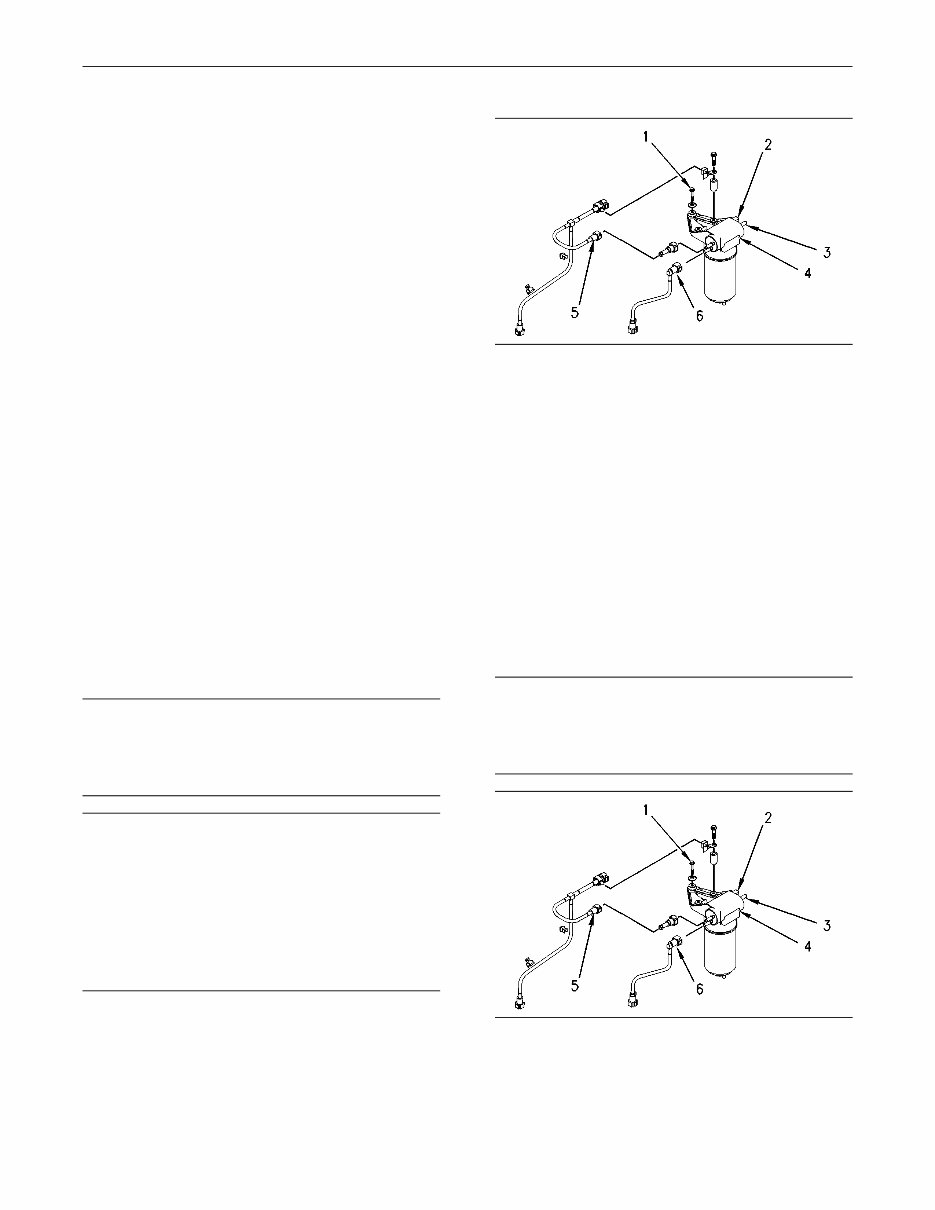

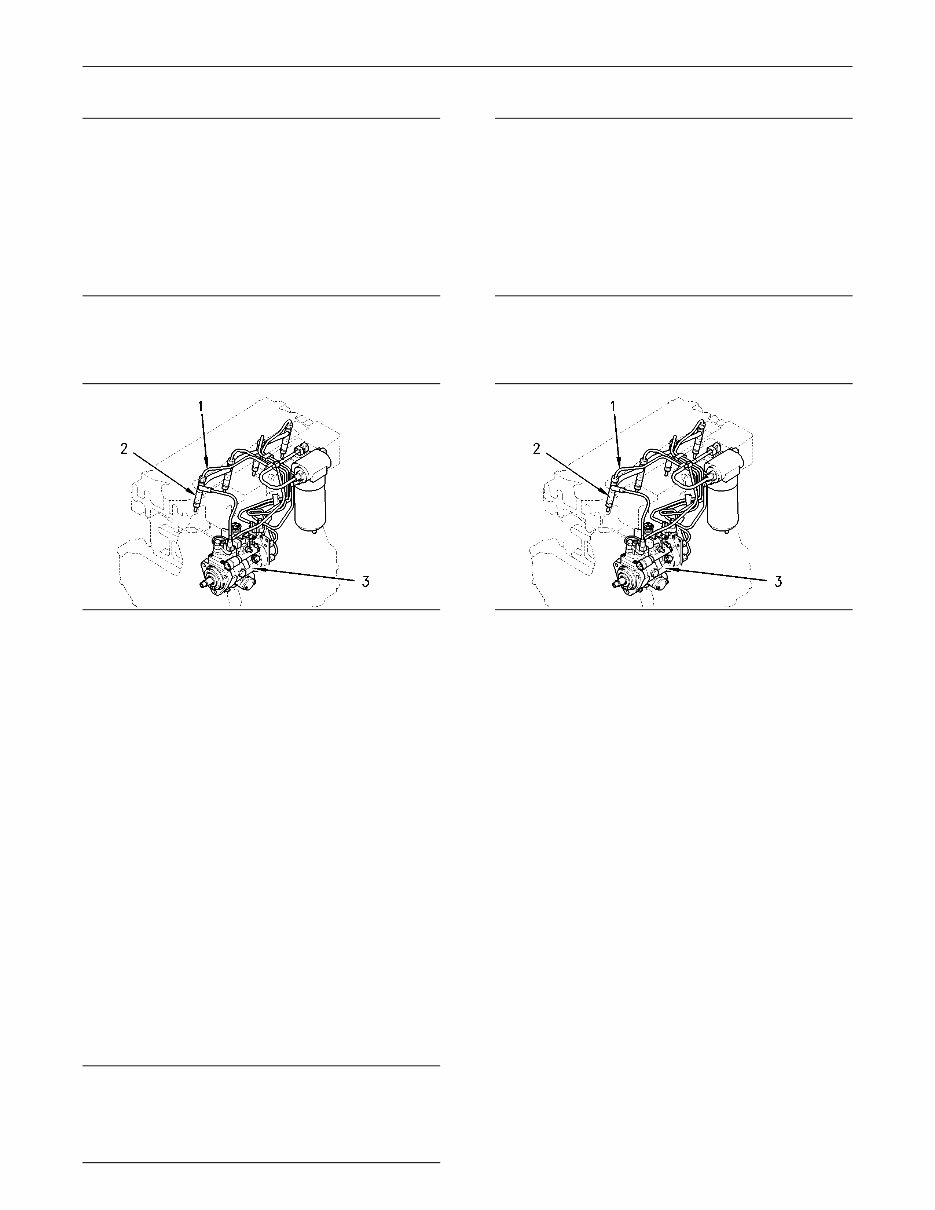

g00952432

Illustration 1

Typical example

1. Disconnect the tube assembly (5). Disconnect

the tube assembly (6). Install dust covers onto

the connectors for the fuel priming pump.

2. Disconnect the fuel return line from the connector

(3). Install a dust cover to the connector (3).

3. Disconnect the harness assembly from the

connector (2).

4. Support the fuel priming pump. Remove the

three setscrews (1) and discard the rubber

washers. Remove the fuel priming pump (4).

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

g00952432

Illustration 2

Typical example

1. Clean the external surfaces of the fuel priming

pump (4). Position the fuel priming pump (4) and

install the setscrews (1) and new rubber washers.

5

Disassembly and Assembly Section

2. Remove the dust covers from the fuel priming

pump. Remove the plugs from the tube

assemblies. Connect the tube assembly (5).

Connect the tube assembly (6).

3. Connect the fuel return line to the connector (3).

4. Connect the harness assembly to the connector

(2).

5. Remove the air from the fuel system. Refer to

the Operations and Maintenance Manual, “Fuel

System - Prime”.

i01939067

Fuel Filter Base - Remove and

Install

Removal Procedure

Note: There is an option for the three cylinder

engine. The fuel filter and the fuel priming pump

can be installed onto the application rather than

onto the engine. If this is the case, refer to the

appropriate OEM information as well to this text.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compartment or disassembling any compo-

nent containing fluids.

Dispose of all fluids according to local regulations and

mandates.

Note: The removal procedure is identical for the

four cylinder and the three cylinder engines. The

illustrations show the four cylinder engine.

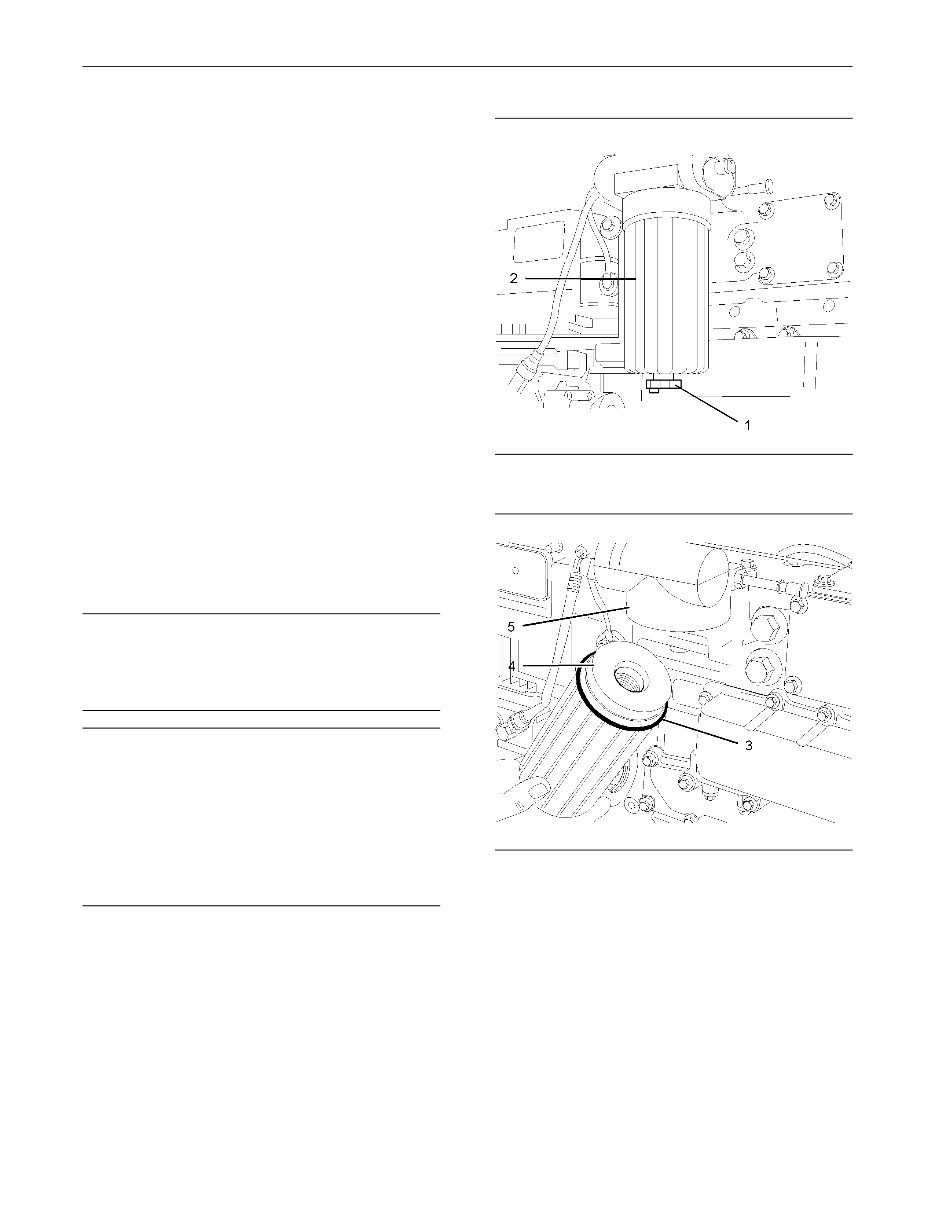

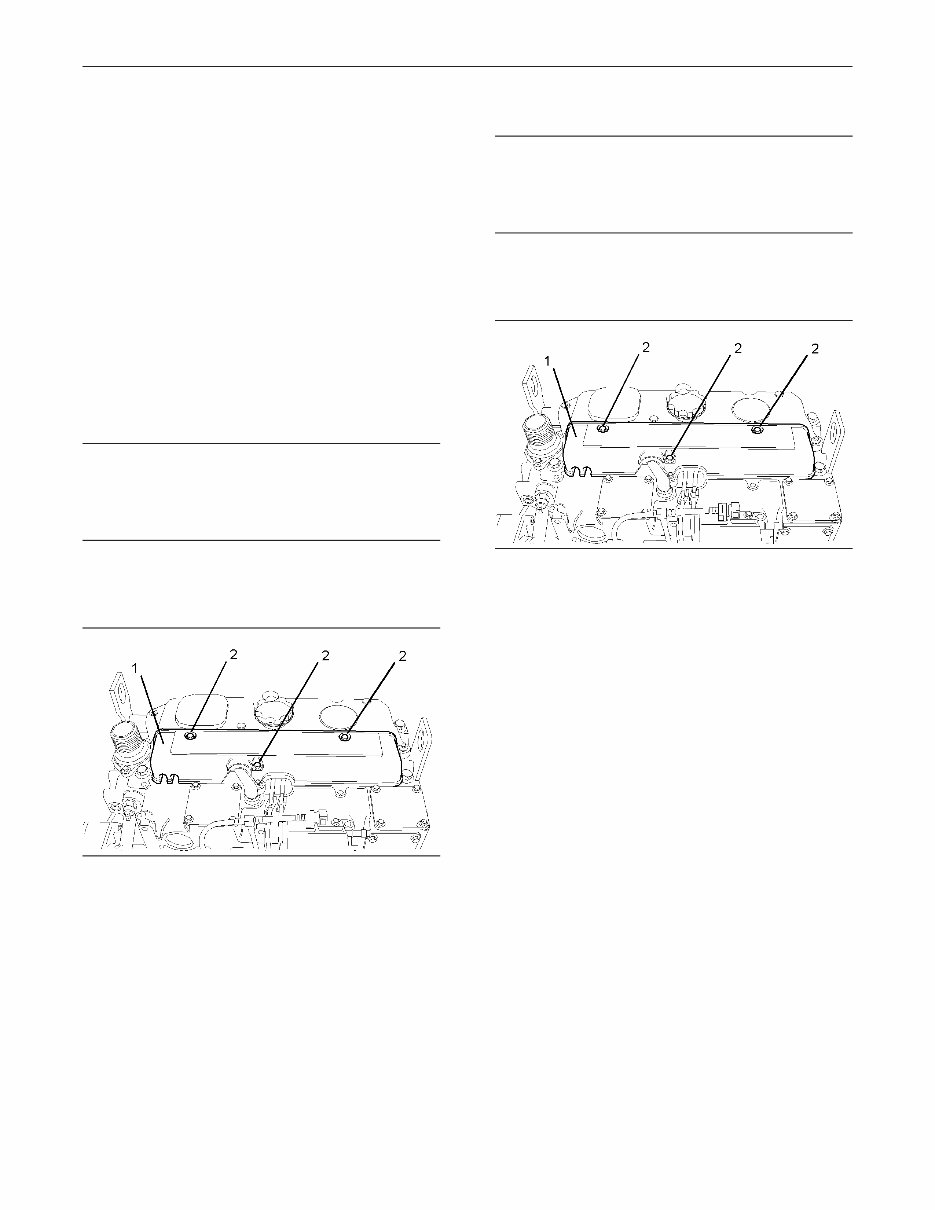

g01010637

Illustration 3

Typical example

g01010595

Illustration 4

Typical example

1. Place a suitable container below the filter in

order to collect the spilled fuel. Thoroughly clean

the outside surfaces of the fuel filter. Open the

drain (1) in order to drain the fuel from the filter.

2. Use a suitable strap wrench to loosen the filter

case (2). Remove the filter case (2) from the filter

head (5).

3. Push down against the spring pressure that is

applied to the filter element (4). Rotate the filter

element (4) counterclockwise in order to release

the filter element from the filter case (2).

4. Discard the filter element (4) and the O-ring (3).

6

Disassembly and Assembly Section

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: The installation procedure is identical for the

four cylinder and the three cylinder engines. The

illustrations show the four cylinder engine.

g01010637

Illustration 5

Typical example

g01010595

Illustration 6

Typical example

1. Thoroughly clean the inside of the filter case (2)

and thoroughly clean the lower face of the filter

head (5).

2. Inspect the thread of a new filter element (4) in

order to ensure that the thread is not damaged.

Inspect the thread of the adapter in the filter

head (5) in order to ensure that the thread is not

damaged.

3. Inspect the condition of the spring and ensure

that the spring is correctly located within the

filter case (2).

4. Install the new filter element (4) into the filter

case (2). Push the filter element against the

spring pressure and rotate the filter element in

a clockwise direction in order to secure the filter

element within the filter case (2).

5. Lightly lubricate a new O-ring (3) with clean fuel

oil. Install the new O-ring (3) into the recess

within the filter case (2).

6. Close the drain (1).

7. Remove the air from the fuel system. Refer to

the Operations and Maintenance Manual, “Fuel

System - Prime”. Remove the suitable container

and dispose of the fuel that has drained as

waste.

i01939856

Fuel Injection Lines - Remove

Removal Procedure

Start By:

a. Remove the cover for the fuel injectors. Refer to

this Disassembly and Assembly Manual, “Fuel

Injector Cover - Remove and Install”.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

7

Disassembly and Assembly Section

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compartment or disassembling any compo-

nent containing fluids.

Dispose of all fluids according to local regulations and

mandates.

Note: The removal procedure is identical for four

cylinder and three cylinder engines. The illustration

shows the four cylinder engine.

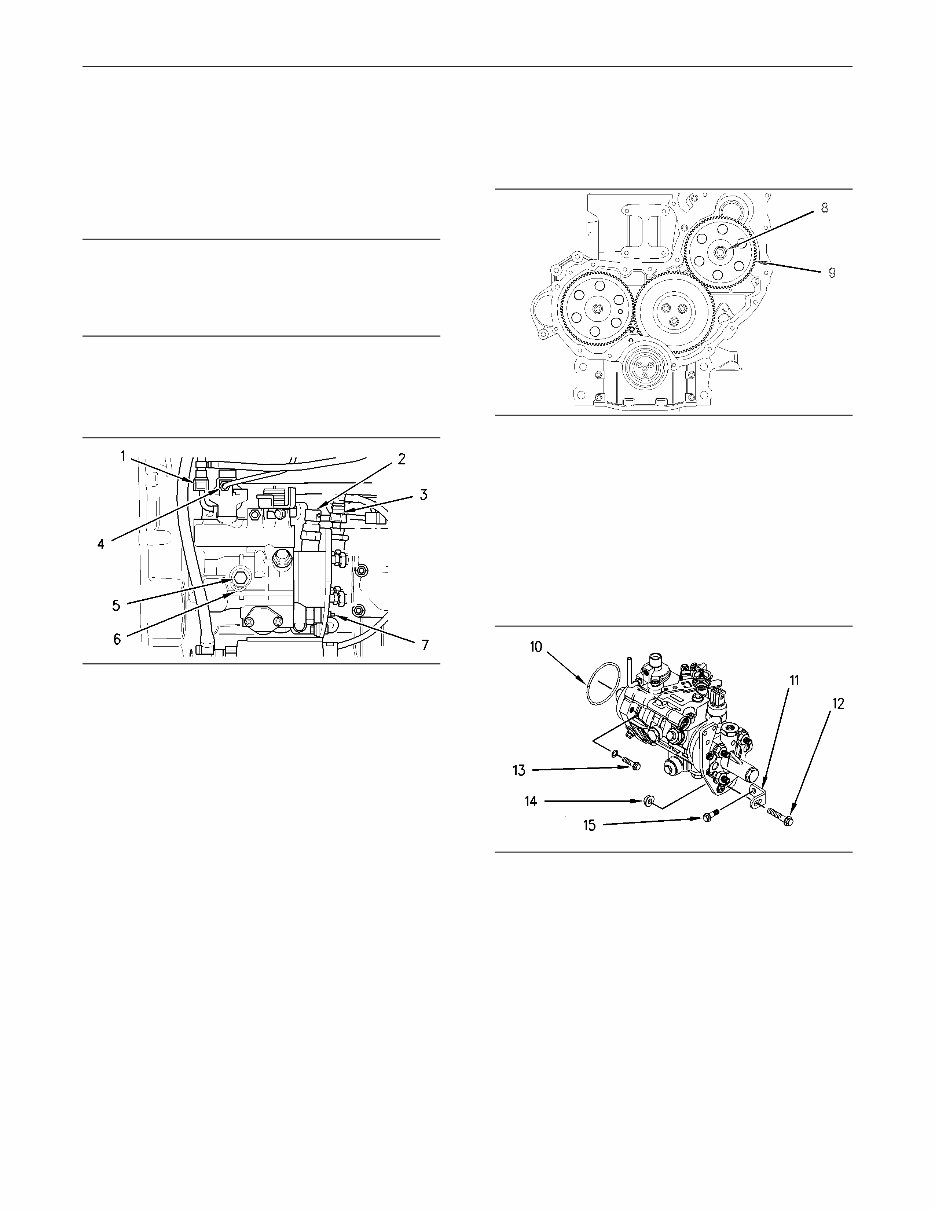

g00955826

Illustration 7

Typical example

1. Disconnect the fuel injection lines (1) at the fuel

injectors (2).

2. Disconnect the fuel injection lines (1) at the fuel

injection pump (3).

3. If it is necessary remove the clamps for the fuel

injection lines or loosen the clamps for the fuel

injection lines. Remove the fuel injection lines (1).

4. Install dust caps onto the ports of the fuel

injectors and onto the ports of the fuel injection

pump. Install dust caps onto both ends of the

fuel injection lines.

i01939857

Fuel Injection Lines - Install

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

NOTICE

Care must be taken to ensure that fluids are contained

during performance of inspection, maintenance, test-

ing, adjusting and repair of the product. Be prepared to

collect the fluid with suitable containers before open-

ing any compartment or disassembling any compo-

nent containing fluids.

Dispose of all fluids according to local regulations and

mandates.

Note: The installation procedure is identical for the

four cylinder and the three cylinder engines. The

illustration shows the four cylinder engine.

g00955826

Illustration 8

Typical example

1. Inspect the fuel injection lines (1) for wear and for

damage. Replace any fuel injection line (1) that

is worn or any fuel injection line that is damaged.

2. Loosely install the clamps for the fuel injection

lines (1).

3. Remove the dust caps from the fuel injection

pump (3) and from the fuel injectors (2). Remove

the dust caps from the fuel injection lines (1).

4. Loosely connect the nuts at both ends of the fuel

injection lines (1).

5. Ensure that each fuel injection line (1) does not

contact any other fuel injection line or any other

engine component. Tighten the fasteners for the

clamps for the fuel injection lines (1). Check that

the fuel injection lines (1) are still clear of other

components.

6. Tighten the fuel injection lines (1) at the fuel

injectors (2) to a torque of 30 N·m (22 lb ft).

7. Tighten the fuel injection lines (1) at the fuel

injection pump (3) to 30 N·m (22 lb ft).

8

Disassembly and Assembly Section

8. Remove the air from the fuel system. Refer to

the Operations and Maintenance Manual, “Fuel

System - Prime”.

End By:

a. Install the cover for the fuel injectors. Refer to

this Disassembly and Assembly Manual, “Fuel

Injector Cover - Remove and Install”.

i01940979

Fuel Injector Cover - Remove

and Install

Removal Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: The removal procedure is identical for the

four cylinder and the three cylinder engines. The

illustration shows the four cylinder engine.

g01011111

Illustration 9

Typical example

1. Thoroughly clean all of the outer surfaces of the

cover (1) for the fuel injectors.

2. Remove the setscrews (2) from the cover (1).

3. Remove the cover (1).

Installation Procedure

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

Note: The installation procedure is identical for the

four cylinder and the three cylinder engines. The

illustration shows the four cylinder engine.

g01011111

Illustration 10

Typical example

1. Thoroughly clean all of the inner surfaces of the

cover (1) for the fuel injectors.

2. Install the cover (1).

3. Install the setscrews (2) for the cover (1). Tighten

the setscrews (2) to a torque of 9 N·m (7 lb ft).

i01940997

Fuel Injection Pump - Remove

(Delphi DP210)

Removal Procedure

Start By:

a. Remove the fuel injection lines. Refer to this

Disassembly and Assembly Manual, “Fuel

Injection Lines - Remove”.

b. Remove the crankshaft pulley. Refer to this

Disassembly and Assembly Manual, “Crankshaft

Pulley - Remove and Install”.

9

Disassembly and Assembly Section

c. Remove the front cover. Refer to this Disassembly

and Assembly Manual, “Front Cover - Remove

and Install”.

Note: The removal procedure is identical for the

four cylinder and the three cylinder engines. The

illustrations show the four cylinder engine.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

1. Ensure that the No. 1 cylinder is at top dead

center on the compression stroke. Refer to the

Testing and Adjusting Manual, “Finding Top

Center Position for No. 1 Piston”.

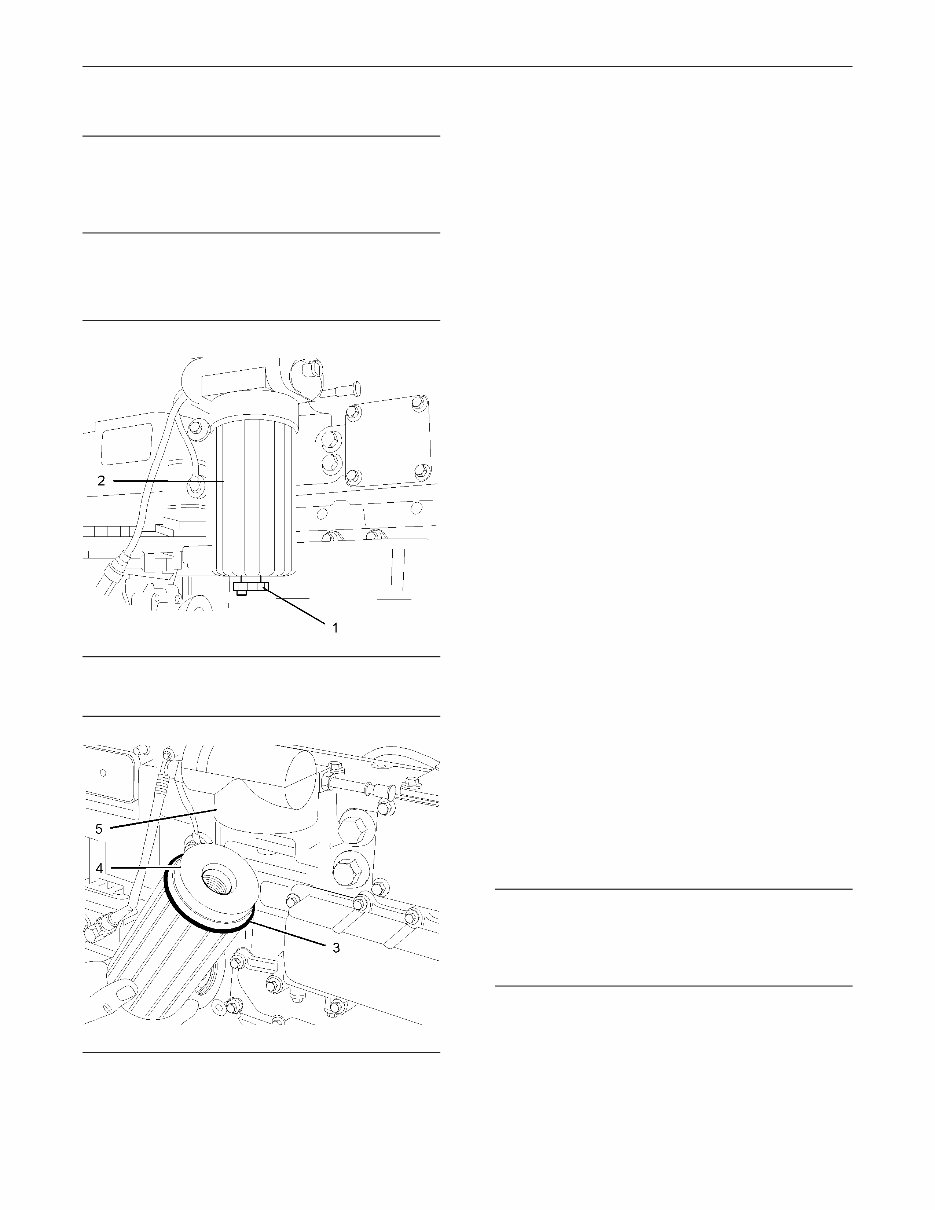

g00956204

Illustration 11

Typical example

2. Loosen the locking screw (5). Rotate the spacer

(6) in order to allow the locking screw (5) to

tighten against the shaft of the fuel injection

pump. Rotate the fuel injection pump gear in a

counterclockwise direction in order to remove

the backlash. Tighten the locking screw (5) to a

torque of 17 N·m (13 lb ft).

Note: The locking screw (5) must be tightened in

order to prevent the shaft of the fuel injection pump

from rotating. The shaft of the fuel injection pump

must not be rotated after the fuel injection pump

has been removed from the engine.

Note: Put identification marks on all fuel hose

assemblies and on all tube assemblies for

installation purposes. After being disconnected,

plug all fuel hose assemblies and plug all tube

assemblies with suitable plastic plugs. Also install

dust caps on all of the connectors on the fuel

injection pump. This helps prevent fluid loss, and

this helps to keep contaminants from entering the

system.

3. Disconnect the fuel return line (1). Disconnect the

tube assembly (4) from the fuel injection pump.

4. Disconnect the fuel line (3).

5. Disconnect the harness assembly (2) from the

timing advance solenoid (7).

g01011369

Illustration 12

Typical example

6. Remove the nut (8) and the washer from the

shaft of the fuel injection pump.

7. Use a suitable puller in order to remove the fuel

injection pump gear (9).

Note: Do not pry the fuel injection pump gear (9)

from the shaft of the fuel injection pump.

g00956267

Illustration 13

8. Remove the nut (14). Remove the bolt (12).

9. If necessary, remove the setscrew (15) and the

bracket (11) from the cylinder block.

10. Remove the setscrews (13) in order to remove

the fuel injection pump.

11. Remove the fuel injection pump from the front

housing. Remove the O-ring (10) and discard the

O-ring from the fuel injection pump.

10

Disassembly and Assembly Section

i01941022

Fuel Injection Pump - Remove

(Bosch EPVE for the 1104

engines only)

Removal Procedure

Start By:

a. Remove the fuel injection lines. Refer to this

Disassembly and Assembly Manual, “Fuel

Injection Lines - Remove and Install”.

b. Remove the crankshaft pulley. Refer to this

Disassembly and Assembly Manual, “Crankshaft

Pulley - Remove and Install”.

c. Remove the front cover. Refer to this Disassembly

and Assembly Manual, “Front Cover - Remove

and Install”.

NOTICE

Keep all parts clean from contaminants.

Contaminants may cause rapid wear and shortened

component life.

1. Ensure that the No. 1 cylinder is at top dead

center on the compression stroke. Refer to the

Testing and Adjusting Manual, “Finding Top

Center Position for No. 1 Piston”.

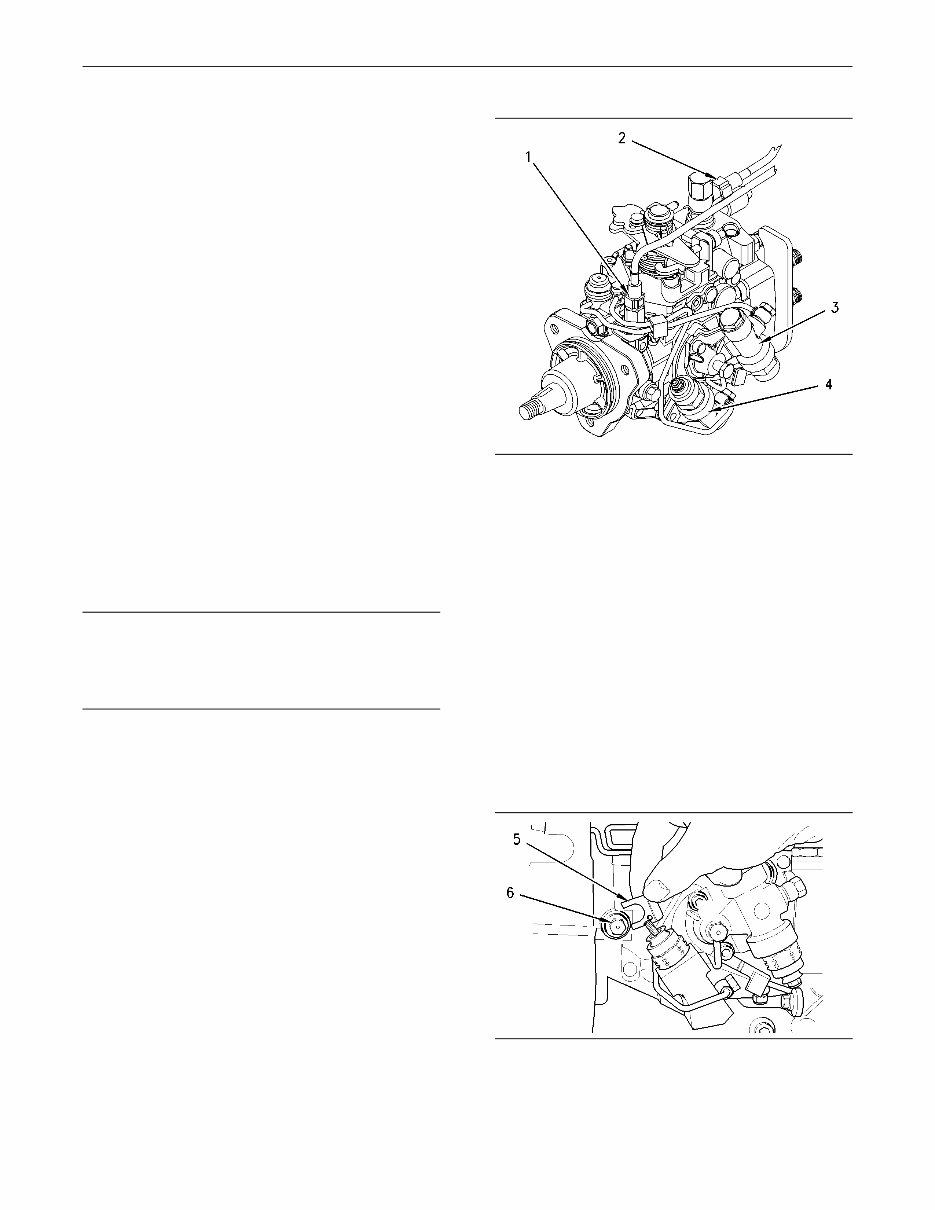

g00996409

Illustration 14

Note: Put identification marks on all fuel hose

assemblies and on all tube assemblies for

installation purposes. After being disconnected,

plug all fuel hose assemblies and plug all tube

assemblies with suitable plastic plugs. Also install

dust caps on all of the connectors on the fuel

injection pump. This helps prevent fluid loss, and

this helps to keep contaminants from entering the

system.

2. Disconnect the tube assembly (1) from the fuel

injection pump. Disconnect the tube assembly

(2) from the fuel injection pump.

3. Disconnect the wiring harness assembly from

the cold start advance unit (3). Disconnect the

wiring harness assembly from the engine shutoff

solenoid (4).

g00996410

Illustration 15

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$37.99

Viewed 81 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$37.99

This collection includes the following 4 manuals:

- Perkins 1103 and 1104,2490/1500 specification manual

- Perkins 1103 and 1104E disassembly and assembly manual. This is the factory manual 136 pages.

- DC11-Up (Machine)

- DD11-Up (Machine)

- DJ11-Up (Machine)

- DK11-Up (Machine)

- RE11-Up (Machine)

- RG11-Up (Machine)

- RJ11-Up (Machine)

- RR11-Up (Machine)

- RS11-Up (Machine)

- DF11-Up (Engine)

- DG11-Up (Engine)

- Perkins 1103,1104E operation and maintenance manual.

- DC (Engine)

- DD (Engine)

- DJ (Engine)

- DK (Engine)

- RE (Engine)

- RG (Engine)

- RJ (Engine)

- RR (Engine)

- RS (Engine)

- RT (Engine)

- DF (Engine)

- DG (Engine)

- Perkins 1103A-33T parts book, s/n up to U3200321W