Nissan ZD30 & TD27Ti Engines Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

ENGINE MECHANICAL

SECTION EM

CONTENTS

ZD

PRECAUTIONS ...............................................................3

Parts Requiring Angular Tightening .............................3

Liquid Gasket Application Procedure ..........................3

PREPARATION ................................................................4

Special Service Tools ..................................................4

Commercial Service Tools ...........................................6

NOISE, VIBRATION AND HARSHNESS (NVH)

TROUBLESHOOTING .....................................................8

NVH Troubleshooting Chart - Engine Noise ...............9

MEASUREMENT OF COMPRESSION PRESSURE ....10

INTERCOOLER ............................................................. 11

Removal and Installation ........................................... 11

INTAKE MANIFOLD ......................................................12

Removal and Installation ...........................................12

Inspection...................................................................13

CATALYST AND TURBOCHARGER ............................14

Removal and Installation ...........................................14

Inspection...................................................................15

EXHAUST MANIFOLD ..................................................18

Removal and Installation ...........................................18

Inspection...................................................................19

ROCKER COVER ..........................................................20

Removal and Installation ...........................................20

OIL PAN & OIL STRAINER...........................................22

Removal and Installation ...........................................22

VACUUM PUMP ............................................................24

Removal and Installation ...........................................24

TIMING CHAIN ..............................................................26

Removal and Installation ...........................................26

Removal .....................................................................26

Installation ..................................................................28

CAMSHAFT ...................................................................30

Removal and Installation ...........................................30

Removal .....................................................................30

Inspection...................................................................31

Installation ..................................................................33

VALVE CLEARANCE INSPECTIONS AND

ADJUSTMENTS.............................................................35

Inspection...................................................................35

Adjustments ...............................................................36

TIMING GEAR ...............................................................38

Removal and Installation ...........................................38

Removal .....................................................................39

Inspection...................................................................41

Installation ..................................................................46

OIL SEAL REPLACEMENT ..........................................50

CYLINDER HEAD..........................................................52

Removal and Installation ...........................................52

Removal .....................................................................52

Inspection...................................................................53

Installation ..................................................................54

Disassembly...............................................................57

Inspection...................................................................58

Assembly ...................................................................61

ENGINE REMOVAL .......................................................63

Precautions ................................................................63

Removal .....................................................................63

Installation ..................................................................65

Inspection...................................................................65

CYLINDER BLOCK .......................................................66

Selection Procedure for Selective Part

Combination ...............................................................67

Disassembly...............................................................67

Inspection...................................................................71

Assembly ...................................................................80

SERVICE DATA AND SPECIFICATIONS (SDS) ..........84

General Specifications ...............................................84

Compression Pressure ..............................................84

Cylinder Head ............................................................84

Valve ..........................................................................84

Valve Seat ..................................................................87

Camshaft and Camshaft Bearing ..............................89

Cylinder Block ............................................................90

Piston, Piston Ring and Piston Pin ...........................90

Connecting Rod .........................................................91

Crankshaft..................................................................92

Available Main Bearing ..............................................92

Available Connecting Rod Bearing............................93

Miscellaneous Components.......................................94

TD27Ti

PRECAUTIONS .............................................................95

Parts Requiring Angular Tightening ...........................95

Liquid Gasket Application Procedure ........................95

PREPARATION ..............................................................96

Special Service Tools ................................................96

Commercial Service Tools .........................................99

ENGINE COMPONENTS - Outer Parts .....................100

ENGINE COMPONENTS - Internal Parts ..................102

COMPRESSION PRESSURE......................................103

Measurement of Compression Pressure .................103

CYLINDER HEAD........................................................104

Removal ...................................................................105

Disassembly.............................................................106

Inspection.................................................................107

Assembly ................................................................. 113

Installation ................................................................ 114

OIL SEAL REPLACEMENT ........................................ 117

TURBOCHARGER....................................................... 119

Removal and Installation ......................................... 119

Inspection................................................................. 119

ENGINE REMOVAL .....................................................123

ENGINE OVERHAUL ..................................................125

Disassembly.............................................................125

Inspection.................................................................127

Assembly .................................................................138

SERVICE DATA AND SPECIFICATIONS (SDS) ........143

General Specifications .............................................143

Inspection and Adjustment ......................................144

CONTENTS (Cont’d)

EM-2

Parts Requiring Angular Tightening

I Use an angle wrench for the final tightening of the cylinder head

bolts.

I Do not use a torque value for final tightening.

I The torque value for these parts are for a preliminary step.

I Ensure thread and seat surfaces are clean and coated with

engine oil.

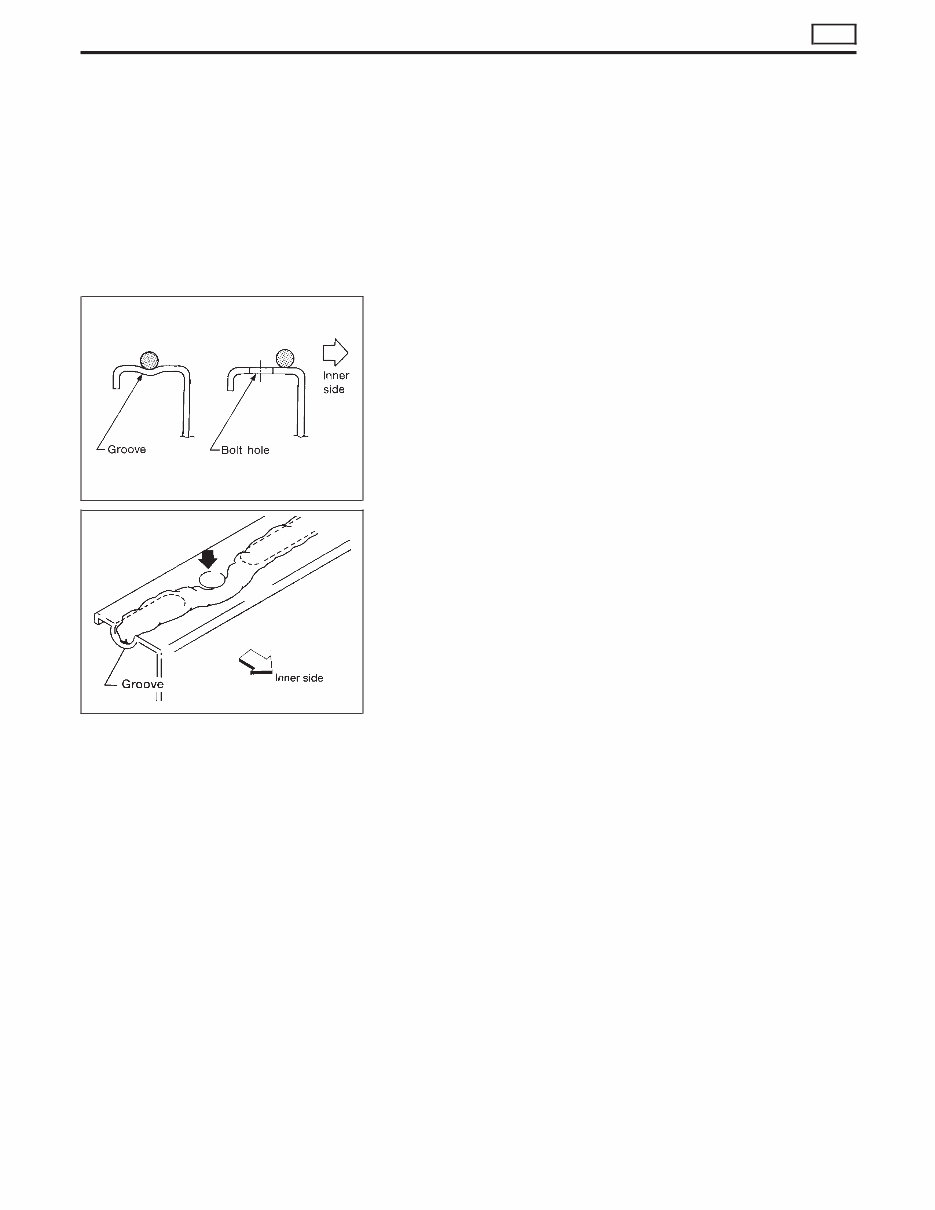

Liquid Gasket Application Procedure

1. Use a scraper to remove old liquid gasket from mating

surfaces and grooves. Also, completely clean any oil from

these areas.

2. Apply a continuous bead of liquid gasket to mating sur-

faces. (Use Genuine Liquid Gasket or equivalent.)

I Be sure liquid gasket diameter is as specified.

3. Apply liquid gasket around the inner side of bolt holes

(unless otherwise specified).

4. Assembly should be done within 5 minutes after coating.

5. Wait at least 30 minutes before refilling engine oil and

engine coolant.

SEM164F

AEM080

PRECAUTIONS

ZD

EM-3

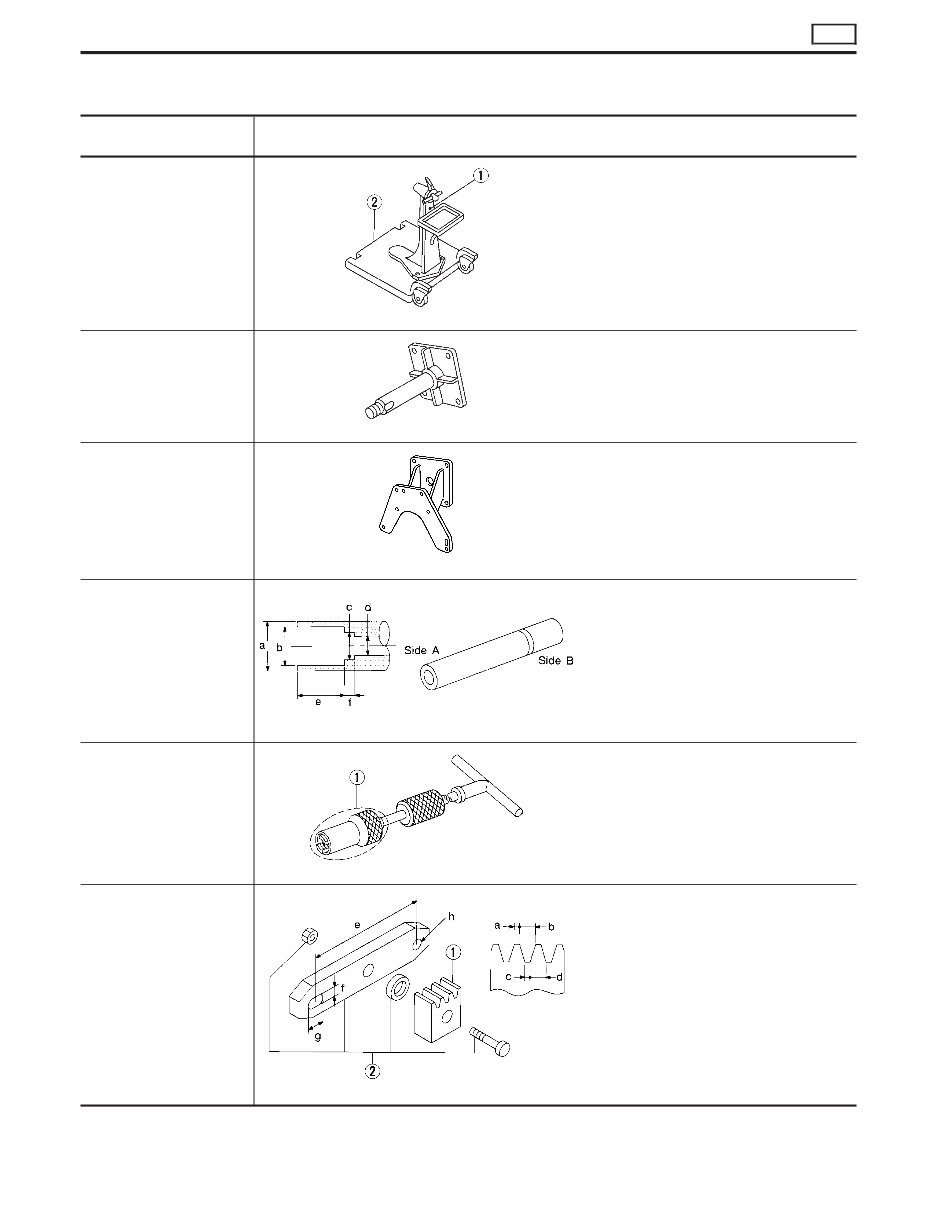

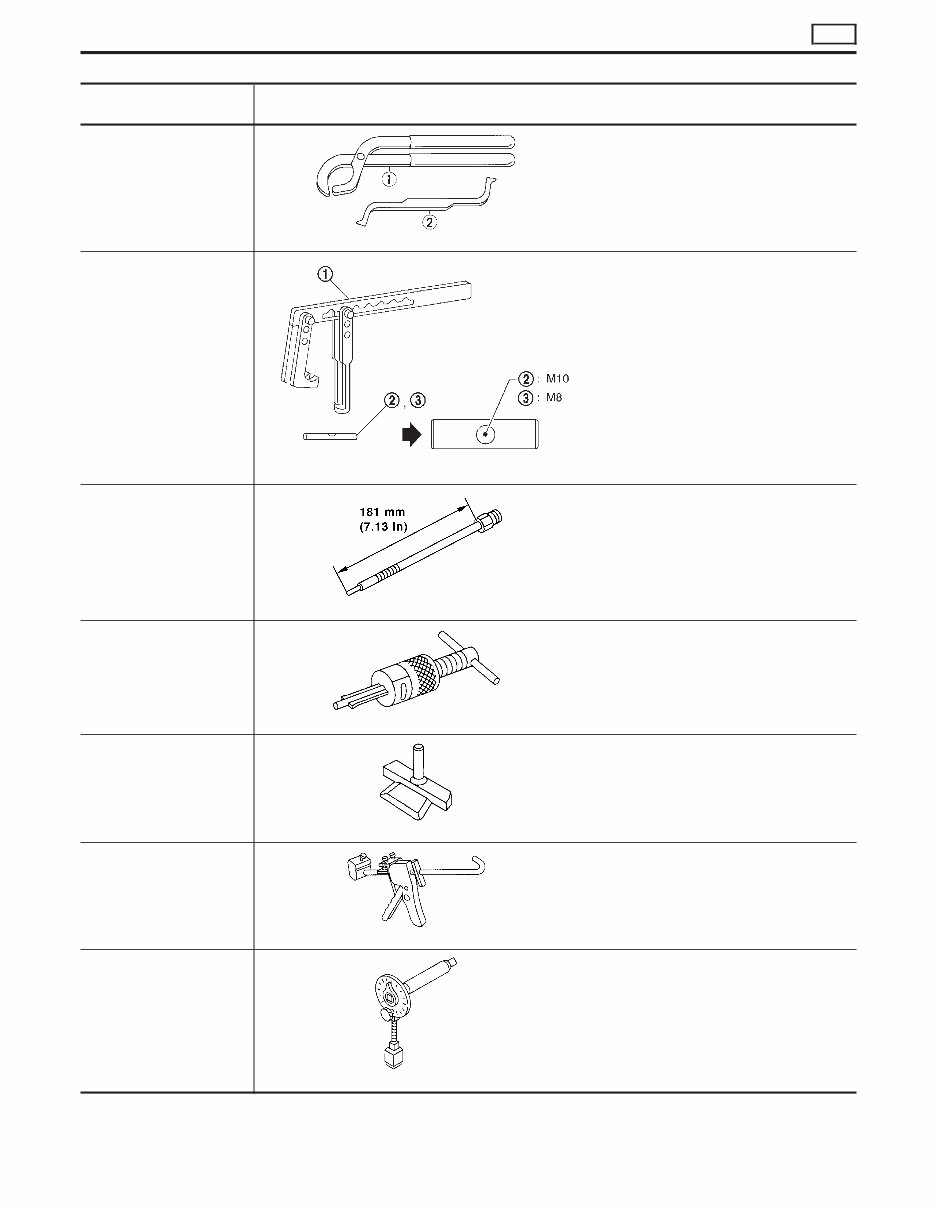

Special Service Tools

Tool number

Tool name

Description

ST0501S000

Engine stand assembly

q 1 ST05011000

Engine stand

q 2 ST05012000

Base

NT042

Disassembling and assembling

KV10106500

Engine stand shaft

NT028

KV11106101

Engine sub-attachment

NT819

KV10115600

Valve oil seal drift

NT603

Installing valve oil seal

Use side A.

Side A

a: 20 (0.79) dia.

b: 13 (0.51) dia.

c: 10.3 (0.406) dia.

d: 8 (0.31) dia.

e: 10.7 (0.421)

f: 5 (0.20)

Unit: mm (in)

KV10107902

Valve oil seal puller

q 1 KV10116100

Valve oil seal puller

adapter

NT605

Removing valve oil seal

KV101056S0

Ring gear stopper

q 1 KV10105630

Adapter

q 2 KV10105610

Plate

NT617

Preventing crankshaft from rotating

a: 3 (0.12)

b: 6.4 (0.252)

c: 2.8 (0.110)

d: 6.6 (0.260)

e: 107 (4.21)

f: 14 (0.55)

g: 20 (0.79)

h: 14 (0.55) dia.

Unit: mm (in)

PREPARATION

ZD

EM-4

Tool number

Tool name

Description

KV101151S0

Lifter stopper set

q 1 KV10115110

Camshaft pliers

q 2 KV10115120

Lifter stopper

NT041

Changing shims

KV101092S0

Valve spring compressor

q 1 KV10109210

Compressor

q 2 KV10109220

Adapter

NT718

Disassembling and assembling valve compo-

nents

ED19600620

Compression gauge adapter

NT820

Checking compression pressure

ST16610000

Pilot bushing puller

NT045

Removing crankshaft pilot bushing

KV10111100

Seal cutter

NT046

Removing steel oil pan and rear timing chain

case

WS39930000

Tube presser

NT052

Pressing the tube of liquid gasket

KV10112100

Angle wrench

NT014

Tightening bolts for bearing cap, cylinder head,

etc.

PREPARATION

ZD

Special Service Tools (Cont’d)

EM-5

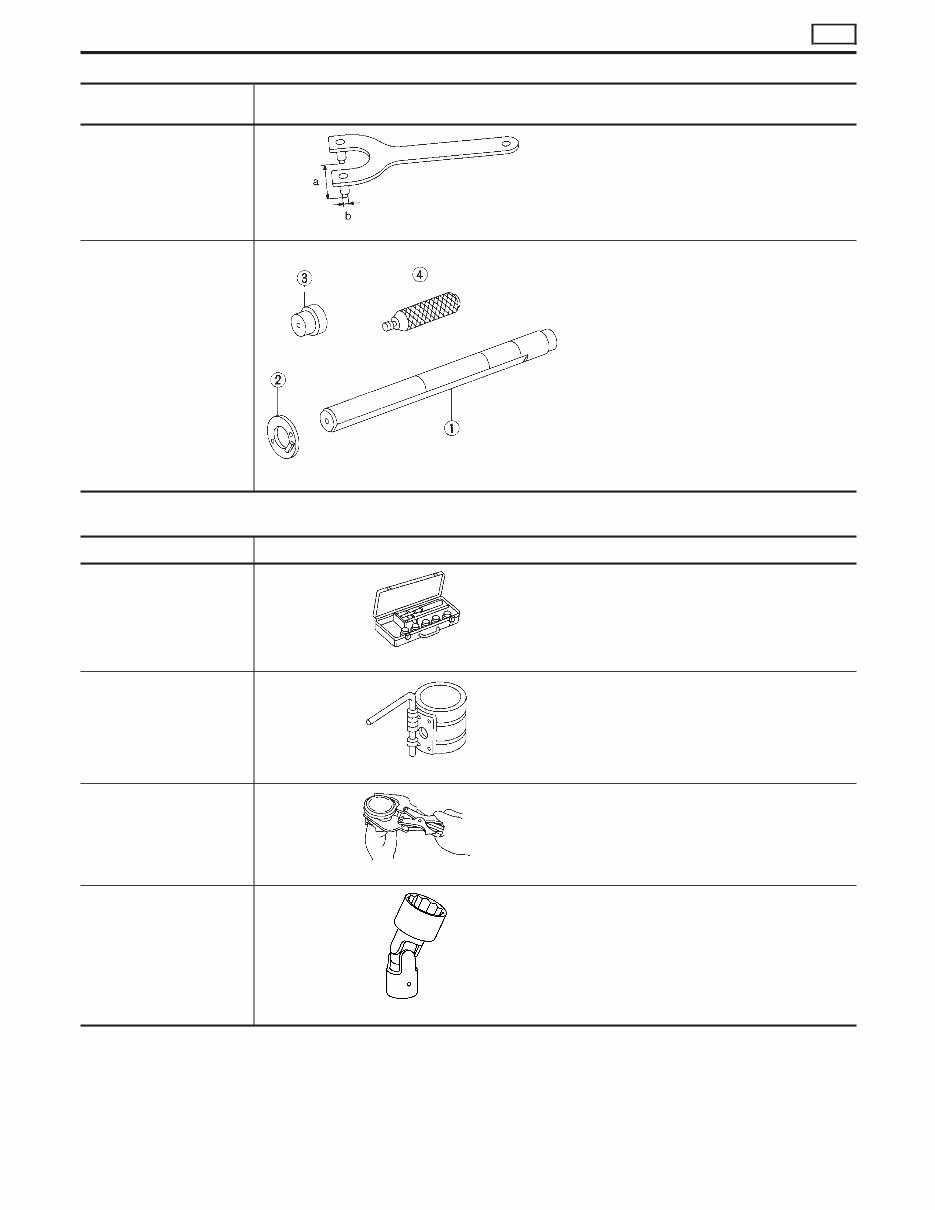

Tool number

Tool name

Description

KV10109300

Pulley holder

NT628

a: 68 mm (2.68 in)

b: 8 mm (0.31 in) dia.

KV111045S1

Balancer shaft bearing

replacer set

q 1 KV11104510

Replacer bar

q 2 KV11104521

Guide plate

q 3 KV11104530

Adapter

(Front bearing)

q 4 ST15243000

Drift

NT258

Removing and installing balancer shaft bearing

Commercial Service Tools

Tool name Description

Valve seat cutter set

NT048

Finishing valve seat dimensions

Piston ring compressor

NT044

Installing piston assembly into cylinder bore

Piston ring expander

NT030

Removing and installing piston ring

Standard Universal

NT808

Removing and installing transmission mount

PREPARATION

ZD

Special Service Tools (Cont’d)

EM-6

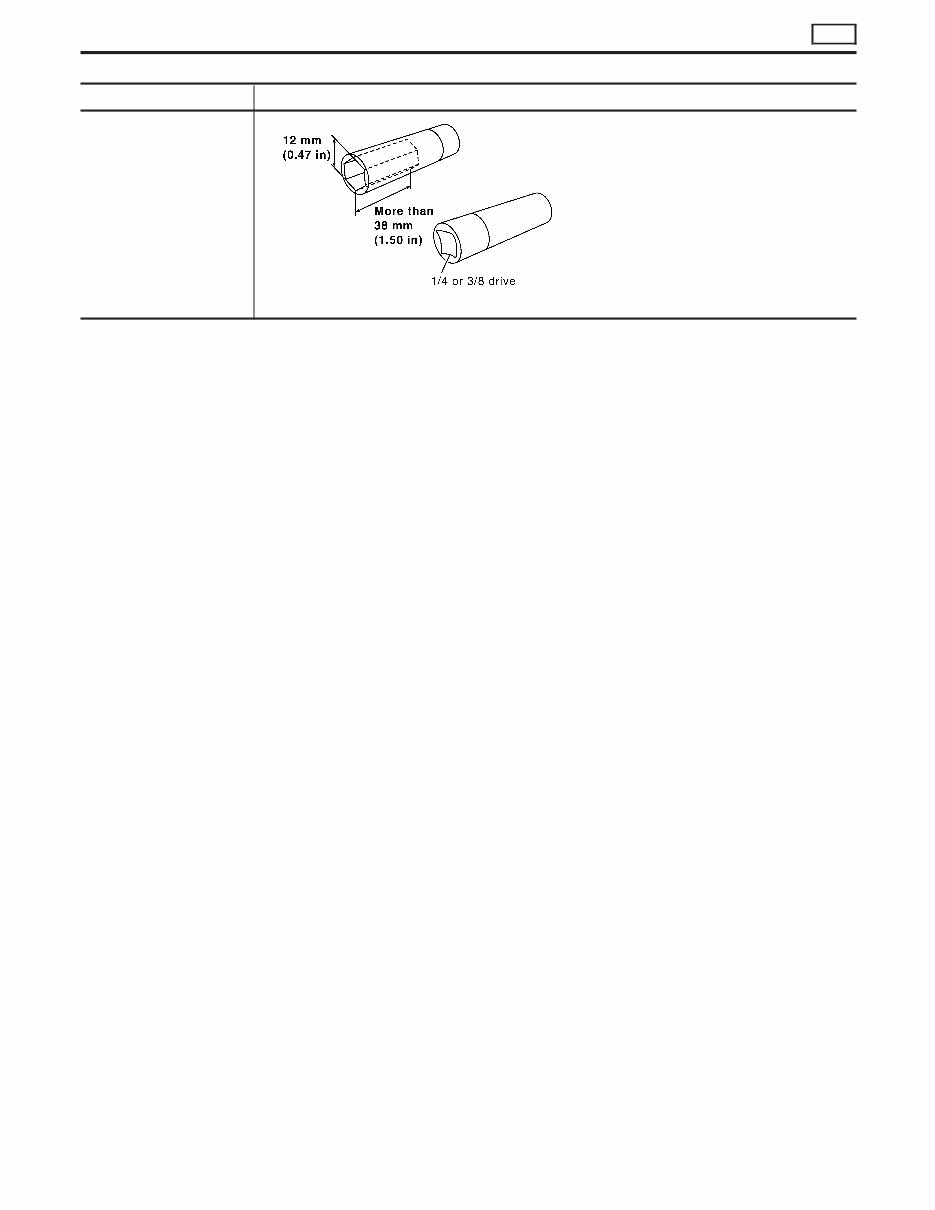

Tool name Description

Deep socket (12 mm)

NT821

Removing and installing glow plugs

PREPARATION

ZD

Commercial Service Tools (Cont’d)

EM-7

SEM290G

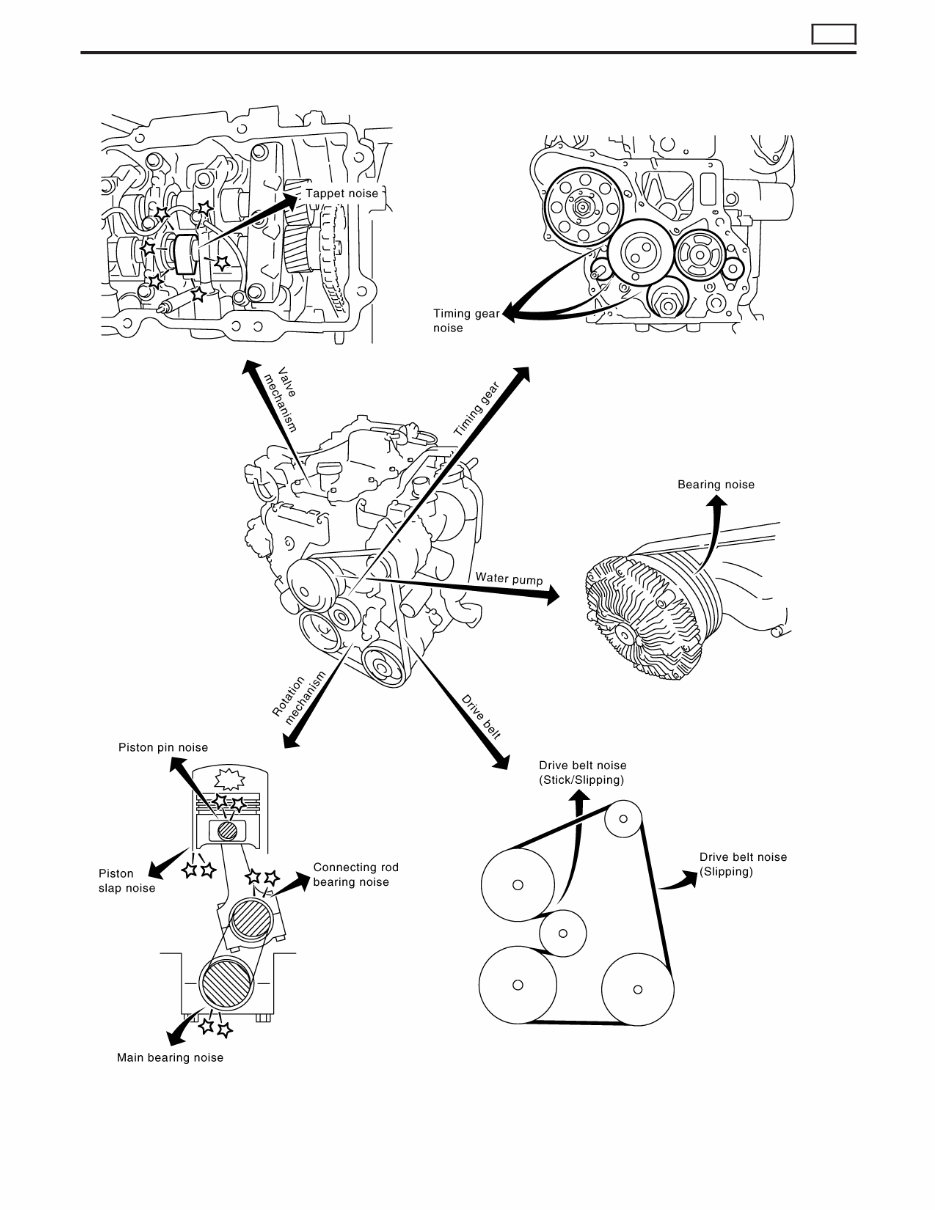

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

ZD

EM-8

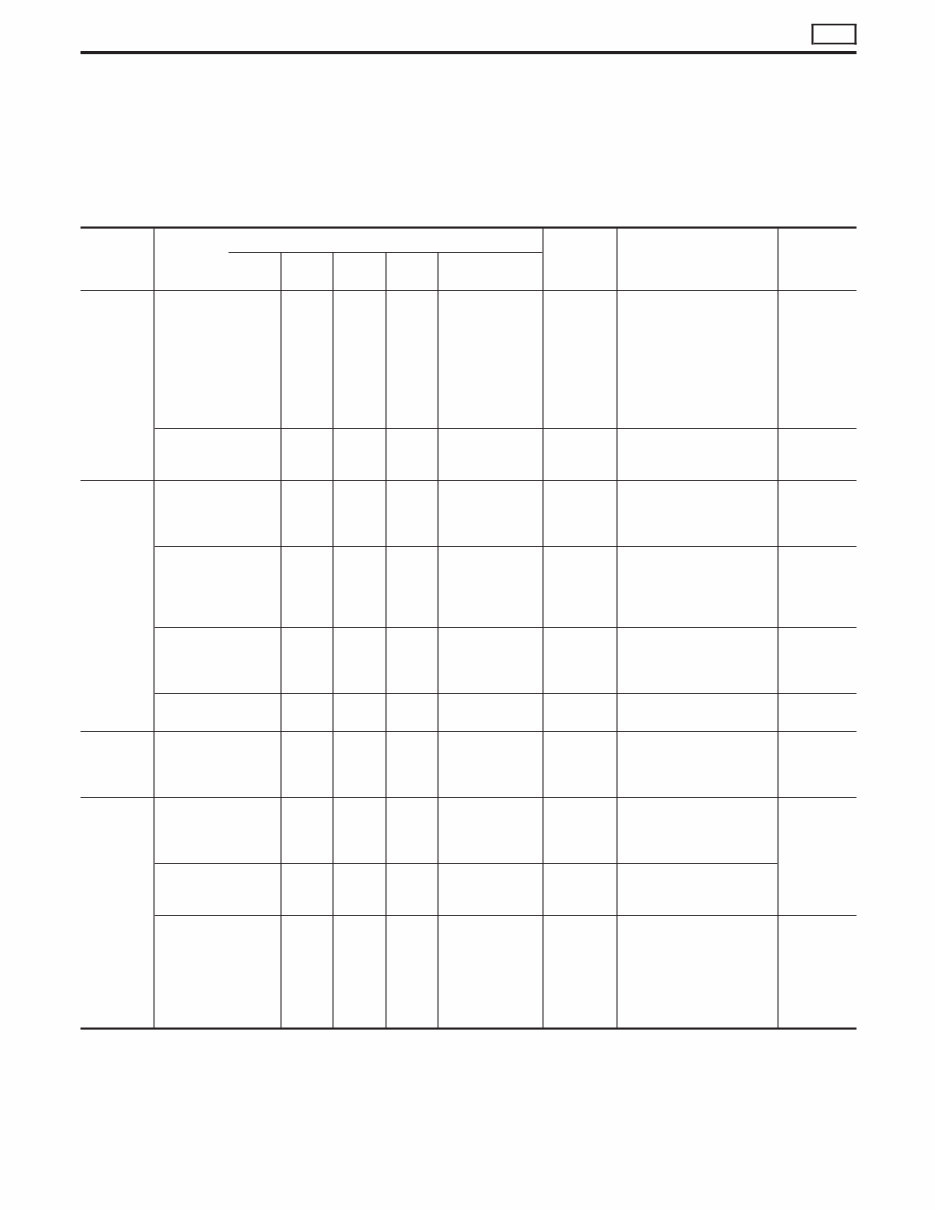

NVH Troubleshooting Chart — Engine Noise

Use the chart below to help you find the cause of the symptom.

1. Locate the area where noise occurs.

2. Confirm the type of noise.

3. Specify the operating condition of engine.

4. Check specified noise source.

If necessary, repair or replace these parts.

Location of

noise

Type of

noise

Operating condition of engine

Source of

noise

Check item

Reference

page

Before

warm-up

After

warm-up

When

starting

When

idling

When

racing

While

driving

Top of

engine

Rocker

cover

Cylinder

head

Ticking or

clicking

C A — A B —

Tappet

noise

Valve clearance

MA section

(“Adjusting

Intake &

Exhaust

Valve

Clearance”,

“ENGINE

MAINTE-

NANCE”)

Rattle C A — A B C

Camshaft

bearing

noise

Camshaft bushing clearance

Camshaft runout

EM-31, 31

Crankshaft

pulley

Cylinder

block (Side

of engine)

Oil pan

Slap or

knock

— A — B B —

Piston pin

noise

Piston and piston pin clear-

ance

Connecting rod bushing

clearance

EM-71, 73

Slap or rap A — — B B A

Piston slap

noise

Piston-to-bore clearance

Piston ring side clearance

Piston ring end gap

Connecting rod bend and

torsion

EM-75, 72,

72, 73

Knock A B C B B B

Connecting

rod bearing

noise

Connecting rod bushing

clearance (Small end)

Connecting rod bearing

clearance (Big end)

EM-73, 77

Knock A B — A B C

Main bear-

ing noise

Main bearing oil clearance

Crankshaft runout

EM-78, 76

Front of

engine

Timing gear

cover

Tapping or

ticking

A A — B B B

Timing gear

noise

Timing gear backlash EM-41

Front of

engine

Squeaking

or fizzing

A B — B — C

Other drive

belts (Stick-

ing or slip-

ping)

Drive belts deflection

MA section

(“Checking

Drive Belts”,

“ENGINE

MAINTE-

NANCE”)

Creaking A B A B A B

Other drive

belts (Slip-

ping)

Idler pulley bearing operation

Squall

Creak

A B — B A B

Water pump

bearing

noise

Water pump bearing opera-

tion

LC section

(“Water

Pump

Inspection”,

“ENGINE

COOLING

SYSTEM”)

A: Closely related B: Related C: Sometimes related —: Not related

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTING

ZD

EM-9

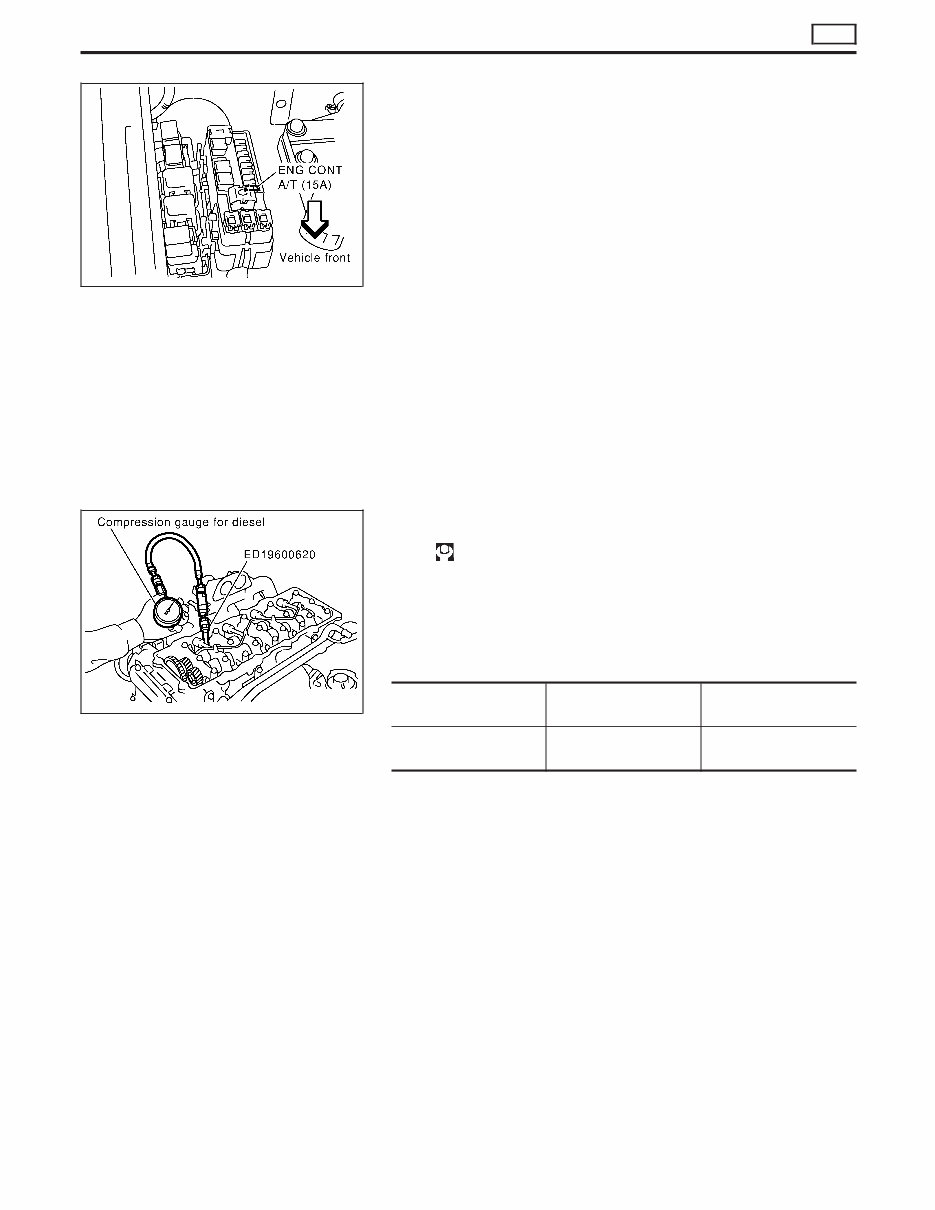

1. Warm up engine.

2. Turn ignition switch OFF.

3. Using CONSULT-II, make sure no error codes are indicated for

self-diagnosis items. Refer to EC section, “Fuel Pressure

Release”.

I Do not disconnect CONSULT-II until the end of this operation;

it will be used to check engine rpm and for error detection at

the end of this operation.

4. Disconnect the negative battery terminal.

5. Remove the following parts.

I Intercooler

I Throttle body

I Rocker cover

6. To prevent fuel from being injected during inspection, remove

fuel injection pump fuse [ENG CONT A/T (15A)] from fuse box

on the right side of engine compartment.

7. Remove glow plugs from all the cylinders.

I Before removal, clean the surrounding area to prevent

entry of any foreign materials into the engine.

I Carefully remove glow plugs to prevent any damage or

breakage.

I Handle with care to avoid applying any shock to glow

plugs.

8. Install adapter (SST) to installation holes of glow plugs and

connect compression gauge for diesel engine.

: 15 - 19 N⋅m (1.5 - 2.0 kg-m, 11 - 14 ft-lb)

9. Connect battery negative terminal.

10. Set the ignition switch to “START” and crank. When gauge

pointer stabilizes, read compression pressure and engine rpm.

Repeat the above steps for each cylinder.

I Always use a fully-charged battery to obtain specified

engine speed.

Unit: kPa (bar, kg/cm

2

, psi)/rpm

Standard Minimum

Difference limit between

cylinders

2,942 (29.42, 30.0, 427)/

200

2,452 (24.52, 25.0, 356)/

200

294 (2.94, 3.0, 43)/200

I When engine rpm is out of the specified range, check the spe-

cific gravity of battery liquid. Measure again under corrected

conditions.

I If engine rpm exceeds the limit, check valve clearance and

combustion chamber components (valves, valve seats, cylinder

head gaskets, piston rings, pistons, cylinder bores, cylinder

block upper and lower surfaces) and measure again.

11. Complete this operation as follows:

a. Turn the ignition switch to “OFF”.

b. Disconnect battery negative terminal.

c. Replace glow plug oil seals and install glow plugs.

d. Install fuel injection pump fuse [ENG CONT A/T (15A)].

e. Connect battery negative terminal.

f. Using CONSULT-II make sure no error code is indicated for

items of self-diagnosis. Refer to EC section, “Trouble Diagno-

sis — Index”.

YEM039

SEM334G

MEASUREMENT OF COMPRESSION PRESSURE

ZD

EM-10

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$28.99

Viewed 14 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$28.99

- The Nissan ZD30 & TD27Ti Engines Service & Repair Manual is a comprehensive guide designed for maintaining, troubleshooting, and replacing engine components.

- This professional technical manual offers step-by-step instructions, clear images, and exploded-view illustrations to assist both professional mechanics and DIY enthusiasts.

- It provides manufacturer-sourced procedures that are easy to understand, covering every troubleshooting and replacement procedure recommended by the manufacturer, including torque specs and detailed exploded-view illustrations.

- Compatible with various electronic devices such as PCs, Mac computers, Android and Apple smartphones, and tablets, this manual also offers the option to print a physical copy if desired.

- Available in English and compatible with Adobe Reader, this manual is a valuable resource for anyone seeking to service or repair their Nissan ZD30 & TD27Ti engines.

Upgrade your engine maintenance experience with this comprehensive and user-friendly manual.