MTU 4000 series engines Service Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Engine exhaust may be harmful to your health if inhaled.

To reduce the chance of personal injury and/or property

damage, the following instructions must be carefully

observed.

Proper service and repair are important to the safety of the

service technician and the safe, reliable operation of the

engine. If part replacement is necessary, the part must

be replaced with one of the same part number or with an

equivalent part number. Do not use a replacement part of

lesser quality.

The service procedures recommended and described in

this manual are effective methods of performing repair.

Some of these procedures require the use of specially

designed tools.

Accordingly, anyone who intends to use a replacement

part, procedure or tool which is not recommended,

must first determine that neither personal safety nor the

safe operation of the engine will be jeopardized by the

replacement part, procedure or tool selected.

It is important to note that this manual contains various

"Cautions" and "Notices" that must be carefully observed

in order to reduce the risk of personal injury during

repair or the possibility that improper repair may damage

the engine or render it unsafe. It is also important to

understand that these "Cautions" and "Notices" are not

exhaustive, because it is impossible to warn personnel of

the possible hazardous consequences that might result

from failure to follow these instructions.

Abstract

This manual provides instruction for construction and industrial and marine applications of

Detroit Diesel Series 4000 Engines.

Specifically, a basic overview of each major component and system along with recommendations

for removal, cleaning, inspection, criteria for replacement, repair and installation and mechanical

troubleshooting are contained in this manual.

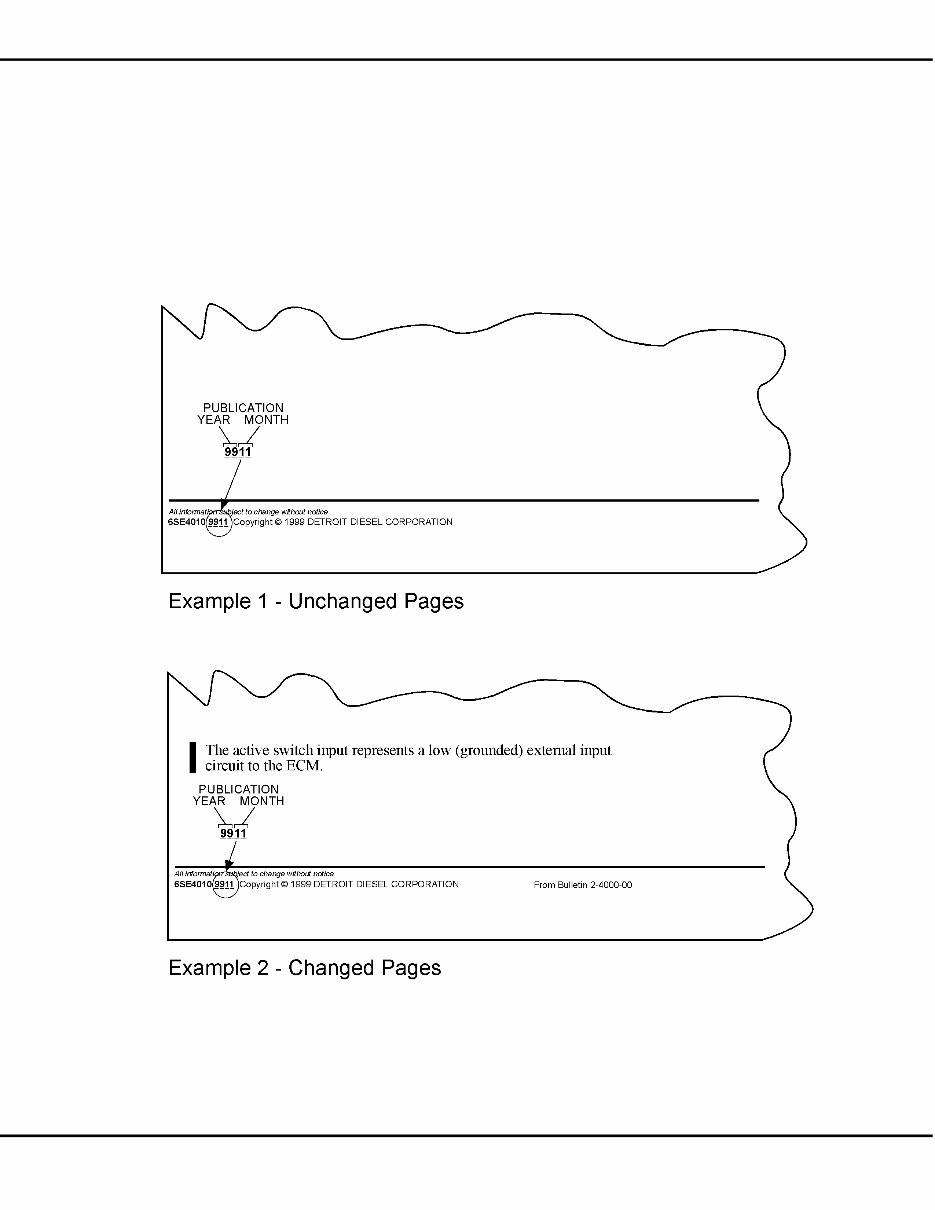

Revision Notification

Modification to this manual are announced in the form of Service Information Bulletins.

The bulletins include attachment pages and are posted on the World Wide Web

(www.detroitdiesel.com/svc/sibinex.htm).

Revisions to this manual will be sent marked with a revision bar (see Example 2). Sections

containing revisions will have a third line in the page footer (compare Examples 1 and 2).

Engine Exhaust

Consider the following before servicing engines:

To avoid injury while operating an engine, ensure the work

area is properly ventilated. Engine exhaust is toxic.

Please note this caution and remember:

Always start and operate the engine in a well-ventilated area.

If in an enclosed area, vent the exhaust to the outside.

Do not modify or tamper with the exhaust system.

For accurate dynamometer readings during an engine run-in, the chassis dynamometer

roommust be properly ventilated. See Figure 1.

SERIES 4000 12/16V SERVICE MANUAL

TABLE OF CONTENTS

A GENERAL INFORMATION ................................................ A -1

A 001 IMPORTANT INFORMATION ...................................... A -3

A 002 GENERAL ENGINE INFORMATION ............................... A -11

A 003 TORQUE SPECIFICATIONS ....................................... A -23

A 004 SAFETY PRECAUTIONS .......................................... A -33

A 005 GENERAL DESCRIPTION OF SERIES 4000 OPERATION .......... A -47

A 006 DATA SHEETS .................................................... A -51

A 007 CONVERSION TABLES ........................................... A -65

A 008 REPAIRING THREADED BORES .................................. A -71

B OPERATION SCHEDULES ................................................ B -1

B 001 CHECKING ENGINE CONDITION BEFORE A MAJOR OVERHAUL . B -3

B 002 W5 MAINTENANCE OPERATIONS ................................ B -7

B 003 W6 MAINTENANCE OPERATIONS ................................ B -13

B 004 ENGINE REMOVAL ............................................... B -17

B 005 ENGINE RUN-IN .................................................. B -21

B 006 ENGINE INSTALLATION AND OPERATION ........................ B -29

C MAINTENANCE .......................................................... C -1

C 010 CYLINDER BLOCK ............................................... C -3

C 011.05 CYLINDER BLOCK ....................................... C -5

C 011.05.01 General View .................................. C -7

C 011.05.02 Special Tools .................................. C -11

C 011.05.04 Before-Removal Operations .................... C -12

C 011.05.05 Removal of Cylinder Block and Main Bearings . . . C -13

C 011.05.06 Disassembly of Cylinder Block and Main

Bearings ...................................... C -20

C 011.05.08 Inspection and Repair ......................... C -34

C 011.05.10 Assembly of Crankshaft and Main Bearings ..... C -54

C 011.05.11 Installation of Cylinder Block and Main Bearings . C -76

C 011.05.12 After-Installation Operations .................... C -86

C 013.05 CYLINDER LINER ........................................ C -87

C 013.05.01 General View .................................. C -89

C 013.05.02 Special Tools .................................. C -92

C 013.05.04 Before-Removal Operations .................... C -93

C 013.05.05 Removal of Cylinder Liner ...................... C -94

C 013.05.08 Inspection and Repair ......................... C -96

C 013.05.11 Installation of Cylinder Liner .................... C -101

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION i

SERIES 4000 12/16V SERVICE MANUAL

C 013.05.12 After-Installation Operations .................... C -106

C 014.05 OIL PAN ................................................. C -107

C 014.05.01 General View .................................. C -109

C 014.05.02 Special Tools .................................. C -113

C 014.05.04 Before-Removal Operations .................... C -114

C 014.05.05 Removal of Oil Pan ............................. C -115

C 014.05.08 Inspection and Repair ......................... C -118

C 014.05.11 Installation of Oil Pan ........................... C -120

C 014.05.12 After-Installation Operations .................... C -130

C 015.05 LIFTING ATTACHMENTSFOR ENGINE AND RUNNING

GEAR ................................................... C -131

C 015.05.01 General View .................................. C -133

C 015.05.04 Before-Removal Operations .................... C -135

C 015.05.05 Removal of Engine Lifting Attachments .......... C -136

C 015.05.08 Inspection and Repair ......................... C -137

C 015.05.11 Installation of Engine Lifting Attachments ........ C -139

C 015.05.12 After-Installation Operations .................... C -140

C 016.05 FLYWHEEL HOUSING ................................... C -141

C 016.05.01 General View .................................. C -143

C 016.05.02 Special Tools .................................. C -145

C 016.05.04 Before-Removal Operations .................... C -146

C 016.05.05 Removal of Flywheel Housing .................. C -147

C 016.05.06 Disassembly of Flywheel Housing ............... C -150

C 016.05.08 Inspection and Repair ......................... C -152

C 016.05.10 Assembly of Flywheel Housing ................. C -154

C 016.05.11 Installation of Flywheel Housing ................ C -157

C 016.05.12 After-Installation Operations .................... C -160

C 018.11 M CYLINDER BLOCK VENTILATION ........................ C -161

C 018.05.01 M General View ................................. C -163

C 018.05.04 M Before-Removal Operations .................... C -166

C 018.05.05 M Removal of the Marine Cylinder Block Ventilation

System ........................................ C -167

C 018.05.06 M Disassembly of the Marine Cylinder Block

Ventilation System ............................. C -169

C 018.05.08 M Inspection and Repair .......................... C -176

C 018.05.10 M Assembly of the Marine Cylinder Block Ventilation

System ........................................ C -178

C 018.05.11 M Installation of the Marine Cylinder Block

Ventilation ..................................... C -185

C 018.05.12 M After-Installation Operations .................... C -187

All information subject to change without notice.

ii Copyright © DETROIT DIESEL CORPORATION

SERIES 4000 12/16V SERVICE MANUAL

C 020 GEAR CASE ..................................................... C -189

C 024.05 GEAR CASE ............................................ C -191

C 024.05.01 General View .................................. C -193

C 024.05.02 Special Tools .................................. C -195

C 024.05.04 Before-Removal Operations .................... C -196

C 024.05.05 Removal Operations for Gear Case ............. C -197

C 024.05.08 Inspection and Repair ......................... C -200

C 024.05.11 Installation of Gear Case ....................... C -203

C 024.05.12 After-Installation Operations .................... C -210

C 025.05 GEAR TRAIN, GEAR CASE END ......................... C -211

C 025.05.01 General View .................................. C -213

C 025.05.04 Before-Removal Operations .................... C -214

C 025.05.05 Removal of Gear Train (Gear Case End) ........ C -215

C 025.05.08 Inspection and Repair ......................... C -218

C 025.05.10 Assembly of Gear Train (Gear Case End) ........ C -222

C 025.05.11 Installation of Gear Train (Gear Case End) ...... C -224

C 025.05.12 After-Installation Operations .................... C -228

C 030 RUNNING GEAR ................................................. C -229

C 031.05 CRANKSHAFT ........................................... C -231

C 031.05.01 General View .................................. C -233

C 031.05.02 Special Tool ................................... C -235

C 031.05.04 Before-Removal Operations .................... C -236

C 031.05.05 Removal of Crankshaft ......................... C -237

C 031.05.06 Disassembly of Crankshaft ..................... C -249

C 031.05.08 Inspection and Repair ......................... C -253

C 031.05.10 Assembly of Crankshaft ........................ C -307

C 031.05.11 Installation of Crankshaft ....................... C -312

C 031.05.12 After-Installation Operations .................... C -319

C 032.05 FLYWHEEL .............................................. C -321

C 032.05.01 General View .................................. C -323

C 032.05.02 Special Tools .................................. C -324

C 032.05.04 Before-Removal Operations .................... C -325

C 032.05.05 Removal of the Flywheel ....................... C -326

C 032.05.06 Disassembly of Flywheel ....................... C -331

C 032.05.08 Inspection and Repair ......................... C -332

C 032.05.10 Assembly of the Flywheel ...................... C -334

C 032.05.11 Installation of the Flywheel ..................... C -337

C 032.05.12 After-Installation Operations .................... C -343

C 035.05 CRANKSHAFT VIBRATION DAMPER ..................... C -345

C 035.05.01 General View .................................. C -347

C 035.05.02 Special Tools .................................. C -349

All information subject to change without notice.

Copyright © DETROIT DIESEL CORPORATION iii

SERIES 4000 12/16V SERVICE MANUAL

C 035.05.04 Before-Removal Operations .................... C -350

C 035.05.05 Removal of the Vibration Damper ............... C -351

C 035.05.06 Disassembly of the Vibration Damper ........... C -358

C 035.05.08 Inspection and Repair ......................... C -359

C 035.05.10 Assembly of Vibration Damper .................. C -360

C 035.05.11 Installation of the Vibration Damper ............. C -364

C 035.05.12 After-Installation Operations .................... C -370

C 037.05 PISTONS AND CONNECTING RODS ..................... C -371

C 037.05.01 General View .................................. C -373

C 037.05.02 Special Tools .................................. C -375

C 037.05.04 Before-Removal Operations .................... C -376

C 037.05.05 Removal of Piston with Connecting Rod ......... C -377

C 037.05.06 Disassembly of Piston with Connecting Rod ..... C -384

C 037.05.08 Inspection and Repair ......................... C -388

C 037.05.10 Assembly of Piston with Connecting Rod ........ C -422

C 037.05.11 Installation of Piston with Connecting Rod ....... C -431

C 037.05.12 After-Installation Operations .................... C -453

C 040 CYLINDER HEAD WITH FIXTURES ............................... C -455

C 041.05 CYLINDER HEAD ........................................ C -457

C 041.05.01 General View .................................. C -459

C 041.05.02 Special Tools .................................. C -462

C 041.05.04 Before-Removal Operations .................... C -463

C 041.05.05 Removal of Cylinder Head ...................... C -464

C 041.05.06 Disassembly of Cylinder Head .................. C -468

C 041.05.08 Inspection and Repair ......................... C -478

C 041.05.10 Assembly of Cylinder Head ..................... C -490

C 041.05.11 Installation of Cylinder Head .................... C -506

C 041.05.12 After-Installation Operations .................... C -513

C 050 VALVE OPERATING MECHANISM ................................. C -515

C 051.05 CAMSHAFT .............................................. C -517

C 051.05.01 General View ................................. C -519

C 051.05.02 Special Tools .................................. C -520

C 051.05.04 Before-Removal Operations .................... C -521

C 051.05.05 Removal of Camshaft .......................... C -522

C 051.05.08 Inspection and Repair .......................... C -530

C 051.05.11 Installation of Camshaft ........................ C -533

C 051.05.12 After-Installation Operations .................... C -550

C 052.05 CAMSHAFT DRIVE ...................................... C -551

C 052.05.01 General View ................................. C -553

C 052.05.02 Special Tools .................................. C -554

C 052.05.04 Before-Removal Operations .................... C -555

All information subject to change without notice.

iv Copyright © DETROIT DIESEL CORPORATION

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$26.99

Viewed 85 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$26.99

- The MTU 4000 series engines are known for their durability, reliability, and long service life.

- This comprehensive Service Manual Bundle covers all aspects of repair and maintenance for the MTU 4000 models: MTU 8V4000, MTU 12V4000, MTU 16V4000, and MTU 20V4000.

- It includes all necessary diagrams, illustrations, schematics, and specific instructions for basic maintenance and extensive repairs of each component.

- Professionals and DIY enthusiasts will find this manual an essential resource for servicing their engines, as it contains easy-to-understand instructions and troubleshooting information.

- Ensure your MTU 4000 series engines remain in top condition with this invaluable Service Manual Bundle, available for instant download.

Purchase the manual today to have all the information needed for service, maintenance, and repair at your fingertips.