MITSUBISHI Engine SL S3L S3L2 S4L S4L2 Workshop Shop Manual

FULL COMPLETE MANUAL - CHECK FILE SIZE.

Mitsubishi Diesel Engine Workshop Service / Repair Manual.

- S3L

- S3L2

- S3L-T

- S3L2-T

- S4L

- S4L2

- S4L-T

- S4L2-T

This service manual has instructions and procedures for the Mitsubishi SL-series diesel engines turbo and non-turbo.

Correct servicing, test, and repair procedures will give the engine a long service life. Before starting a test, repair, or rebuild job, the serviceman must read the respective sections of this manual to know all the components he will work on.

Covers all you need to know in the service and repair of your engine - on CD format, all fully bookmarked.

GENERAL INFORMATION

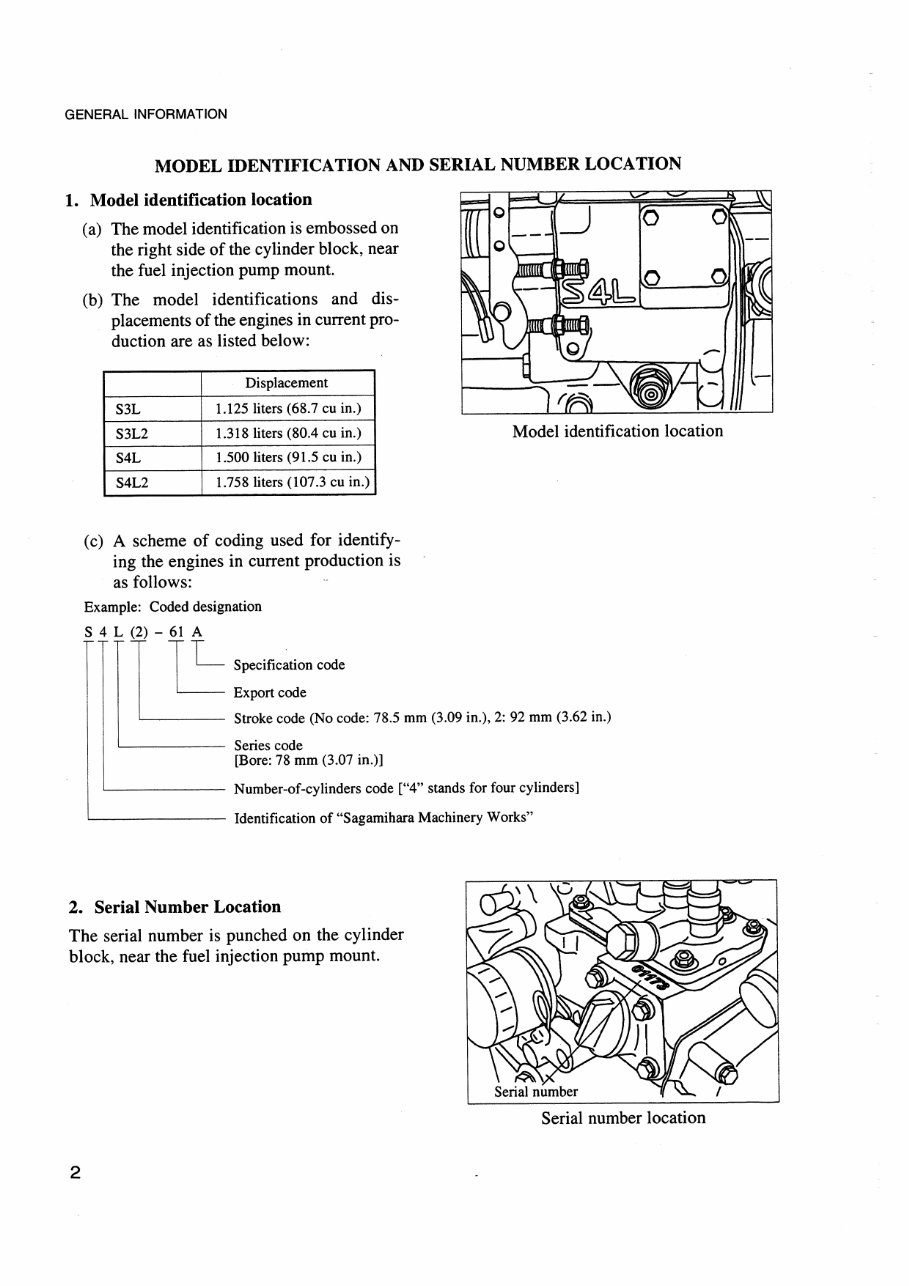

- MODEL IDENTIFICATION AND SERIAL NUMBER LOCATION

- Model identification location

- Serial Number Location

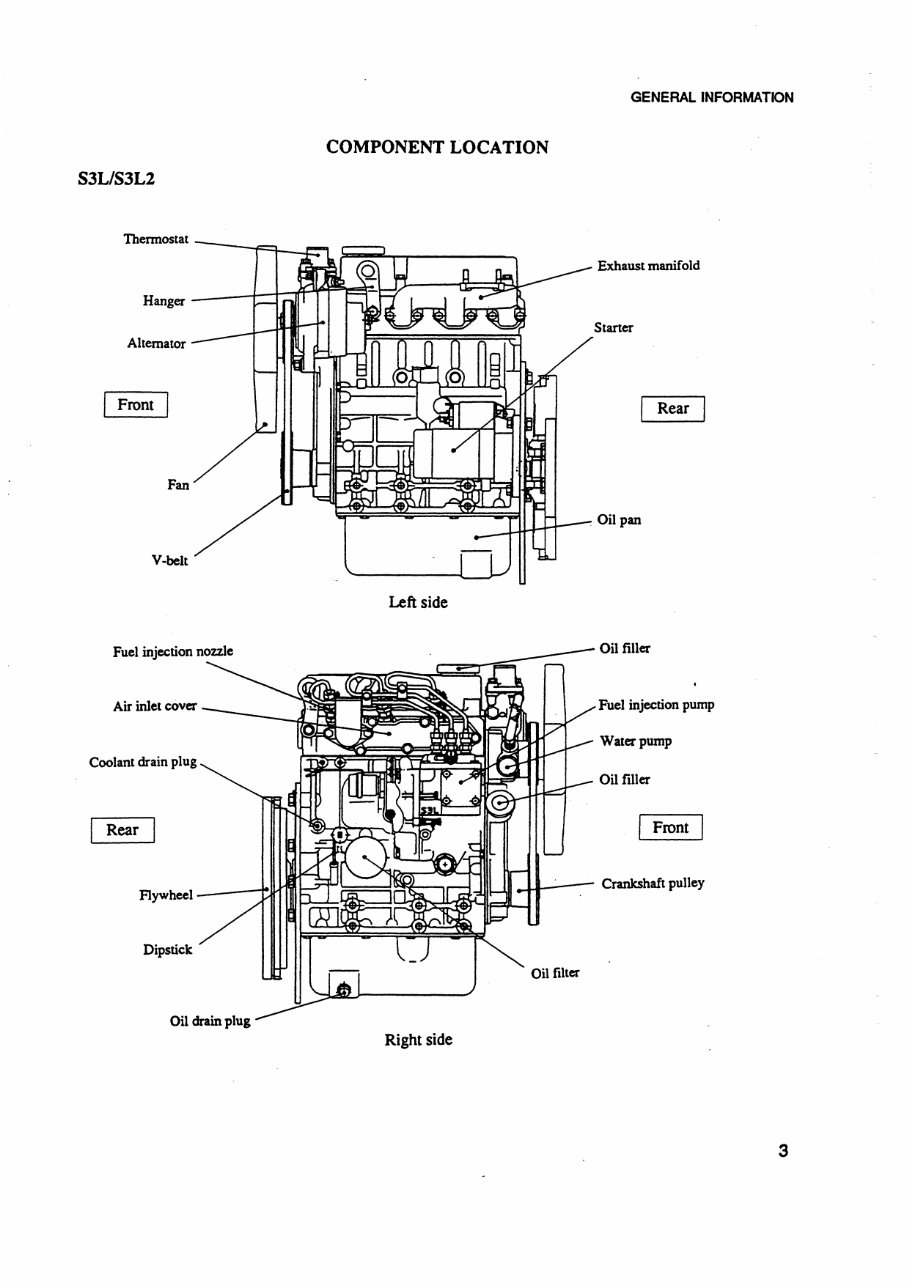

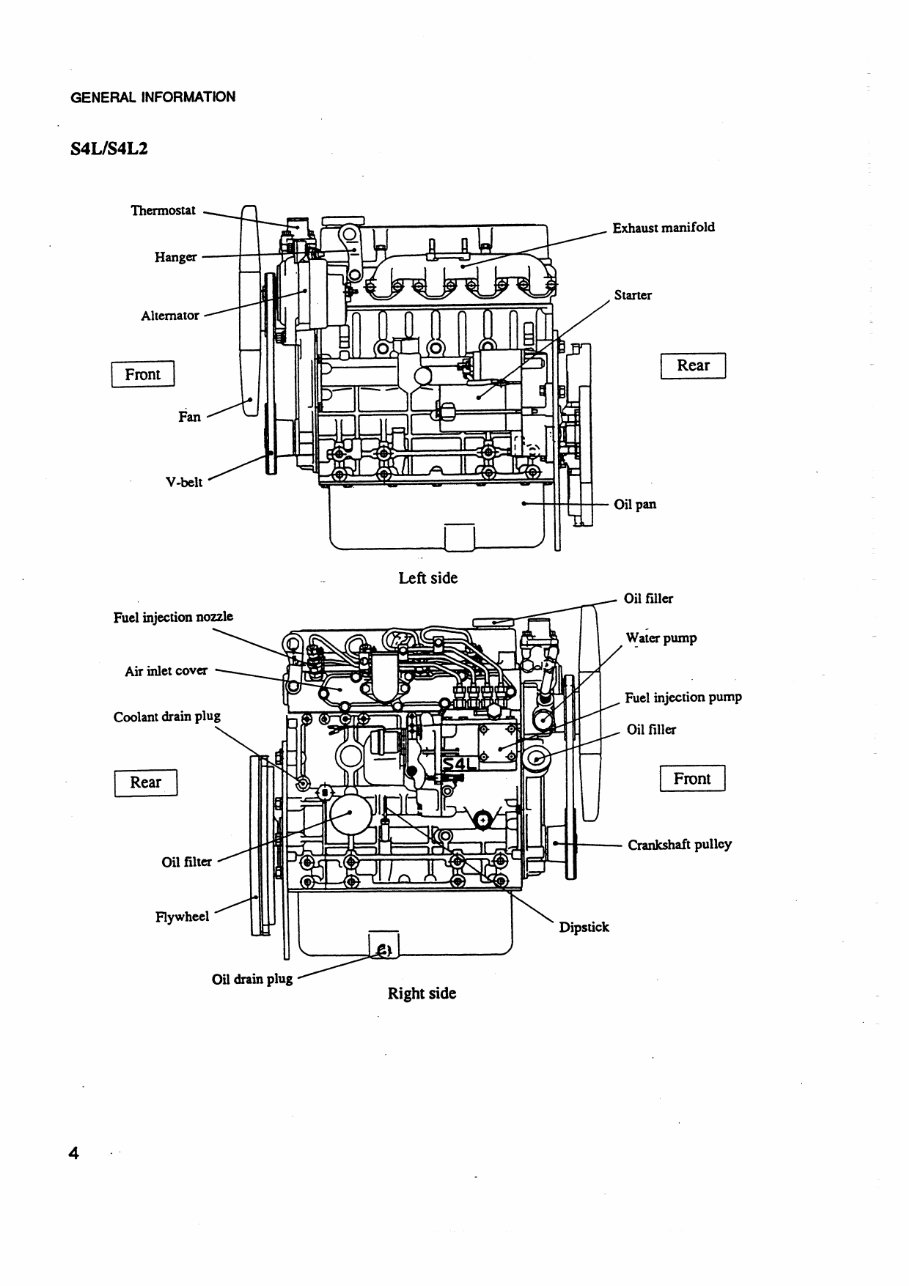

- COMPONENT LOCATION

- S3L/S3L2

- Engine S3L-T/S3L2-T

- S4L/S4L2

- Engine S4L-T/S4L2-T

- SPECIFICATIONS

OVERHAUL INSTRUCTIONS

- DETERMINING WHEN TO OVERHAUL THE ENGINE

- COMPRESSION PRESSURE MEASUREMENT

- Inspection

- Measurement

- TROUBLESHOOTING

- General

- Engine troubleshooting

- Starting system troubleshooting

- BASIC PRECAUTIONS FOR DISASSEMBLY AND ASSEMBLY

- Disassembly

- Assembly

DISASSEMBLY

- PREPARATION FOR DISASSEMBLY

- Engine oil draining

- Coolant draining 1

- ELECTRICAL SYSTEM

- Starter

- Alternator

- Cooling System

- Cooling fan removal

- Thermostat case removal

- Water pump assembly removal

- Fuel System

- Fuel injection pipe removal

- Fuel injection nozzle removal

- Governor assembly removal

- Governor weight removal

- Fuel injection pump removal

- Lubrication System

- Oil filter removal

- Pressure relief valve removal

- Oil pressure switch removal

- AIR INLET SYSTEM AND EXHAUST SYSTEM

- Exhaust manifold removal

- Air inlet cover removal

- CYLINDER HEAD AND VALVE MECHANISM

- Rocker shaft assembly removal

- Rocker shaft disassembly

- Cylinder head bolt removal

- Cylinder head assembly removal

- Valve and valve spring removal

- Valve stem seal removal

- Timing Gears and Flywheel

- Flywheel removal

- Rear plate removal

- Oil seal case removal

- Tappet removal

- Speedometer driven gear removal

- Crankshaft pulley removal

- Timing gear case removal

- Timing gear backlash measurement

- Idler gear removal

- Camshaft removal

- Fuel injection pump camshaft removal

- Gear removal (when required)

- Oil pump removal

- Front plate removal

- Cylinder Block, Crankshaft, Pistons and Oil Pan

- Oil pan removal

- Oil screen removal

- Thrust clearance measurement for connecting rod big end

- Connecting rod cap removal

- Piston removal

- End play measurement for crankshaft

- Main bearing cap removal

- Crankshaft removal

- Piston separation from connecting rod

INSPECTION

- CYLINDER HEAD AND VALVE MECHANISM

- Cylinder head

- Rocker arms and rocker shaft

- Valve springs

- Valve push rods

- Valves, valve guides and valve seats

- Combustion jet replacement

- TIMING GEARS AND FLYWHEEL

- Camshaft

- Fuel injection pump camshaft

- Tappets

- Idler gear

- Flywheel and ring gear

- CYLINDER BLOCK, CRANKSHAFT, PISTONS AND OIL PAN

- Pistons, Piston Rings and Piston Pins

- Connecting rods

- Crankshaft

- Cylinder block

ASSEMBLY

- Cylinder Block, Crankshaft, Pistons and Oil pan

- Main bearing installation

- Crankshaft installation

- Main bearing cap installation

- Side seal installation

- Piston assembling to connecting rod

- Piston ring installation

- Piston and connecting rod installation

- Connecting rod cap installation

- Oil screen installation

- Oil pan installation

- Timing Gears and Flywheel

- Front plate installation

- Oil pump installation

- Engine turning

- Camshaft installation

- Idler gear installation

- Timing gear case installation

- Crankshaft pulley nut tightening

- P.T.O. gear installation

- Speedometer driven gear installation

- Tappet installation

- Oil seal case installation

- Rear plate installation

- Flywheel installation

- CYLINDER HEAD AND VALVE MECHANISM

- Cylinder head bottom face cleaning

- Valve stem seal installation

- Valve spring installation

- Installing valve block

- Cylinder head gasket installation

- Cylinder head installation

- Cylinder head bolt tightening

- Valve push rod installation

- Rocker shaft assembling

- Rocker shaft assembly installation

- Valve clearance adjustment

- Rocker cover installation

- AIR INLET SYSTEM AND EXHAUST SYSTEM

- Air inlet cover installation

- Exhaust manifold installation

- Fuel System

- Fuel injection nozzle installation

- Fuel injection pump installation

- Flyweight assembly installation

- Sliding sleeve installation

- Governor assembly installation

- Fuel injection line installation

- Lubrication system

- Pressure relief valve installation

- Oil filter installation

- Oil pressure switch installation

- Cooling system

- Water pump installation

- Thermostat installation

- Cooling fan installation

- Thermoswitch and thermounit combination installation

- Electrical System

- Glow plug installation

- Alternator installation

ELECTRICAL SYSTEM

- GENERAL

- Specifications (standard)

- Wiring diagrams

- STARTER

- Disassembly

- Inspection

- Assembly

- Inspection and Testing after Assembly

- ALTERNATOR

- Disassembly

- Inspection

- Assembly

- KEY SHUTOFF SYSTEM (ETS solenoid type)

- General

- Cord color (standard)

- Shutoff solenoid installation

- Inspection after assembly

- KEY SHUTOFF SYSTEM (ETR solenoid type)

- General

- Cord color (standard)

- Shutoff solenoid installation

- AUTOMATIC GLOW SYSTEM

- General

- Glow timer specification (standard)

- Glow plug relay specifications (standard)

- Glow plug inspection

COOLING SYSTEM

- GENERAL

- Schematic

- Specifications (standard)

- INSPECTION

- Water pump

- Thermostat (standard)

- Thermoswitch (standard)

- Thermounit (standard)

LUBRICATION SYSTEM

- GENERAL

- Schematic

- Specifications

- INSPECTION

- Oil pump

- Oil pressure switch

- Pressure relief valve

FUEL SYSTEM

- GENERAL

- Schematic

- Specifications (standard)

- FUEL INJECTION NOZZLE

- Inspection

- Disassembly and assembly

- FUEL INJECTION PUMP

- Test on engine

- Disassembly

- Inspection

- Assembly

- GOVERNOR

- Disassembly and inspection

- Assembly

- Torque spring set installation

- FUEL PUMP

- Inspection

- FUEL FILTER

AIR INLET SYSTEM AND EXHAUST SYSTEM

- GENERAL

- Schematic

- INSPECTION

- Inspection procedure

MAINTENANCE

- LUBRICATION AND MAINTENANCE CHART

- ENGINE OIL AND OIL FILTER

- Engine oil specifications

- Oil level check

- Oil and oil filter change

- Oil filter change

- VALVE CLEARANCE

- FUEL INJECTION TIMING

- FUEL FILTER

- FUEL SYSTEM PRIMING

- IDLE RPM SETTING

- FUEL INJECTION NOZZLES

- FAN BELT

SERVICE DATA

- SPECIFICATIONS

- Basic engine components

- Lubrication system

- Fuel system

- Air inlet system and exhaust system

- Cooling system (standard)

- Electrical system

- TIGHTENING TORQUES

- Major bolts and nuts

- Torques for bolts and nuts with standard threads

- Torques for plugs with taperlock threads

- SEALANTS

- SPECIAL TOOLS

Covers all you need to know in the service and repair of your engine