Mitsubishi 6M60 Diesel Engine Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Service Manual

99709-51100 For use with the FD80N-FD160N Service Manuals.

6M60-TL Diesel Engine

GROUP INDEX

00

11

12

13A

13E

14

15

17

54

61

GENERAL ........................................

ENGINE............................................

LUBRICATION .................................

FUEL AND ENGINE CONTROL......

ELECTRONICALLY CONTROLLED

FUEL SYSTEM ..................................

COOLING.........................................

INTAKE AND EXHAUST .................

EMISSION CONTROL .....................

ELECTRICAL...................................

SPECIAL EQUIPMENT ...................

FOREWORD

This Shop Manual is published for the information and

guidance of personnel responsible for maintenance of the

Mitsubishi 6M60-TL series diesel engine, and includes

procedures for adjustment and maintenance services.

We earnestly look forward to seeing that this manual is

made full use of in order to perform correct services with

no wastage.

For more details, please consult your nearest authorized

Mitsubishi forklift truck dealer.

Kindly note that the specifications and maintenance ser-

vice figures are subject to change without prior notice in

line with improvement which will be effected from time to

time in the future.

SEPTEMBER 2006

Applicable models

6M60-TL

(for industrial use)

00-1

13E

13A

GROUP 00 GENERAL

HOW TO READ THIS MANUAL ......................................................... 00-2

ENGINE NUMBER ............................................................................ 00-7

PRECAUTIONS FOR MAINTENANCE OPERATION ....................... 00-8

DIAGNOSTIC CODES

1. Using Multi-Use Tester .............................................................. 00-17

2. Use of Blinking Warning Lamp for Diagnostic Code .................... 00-19

3. Up-Time Service Tool Functions .................................................... 00-21

4. Troubleshooting ............................................................................... 00-29

TABLE OF STANDARD TIGHTENING TORQUES .......................... 00-31

00-2

This manual consists of the following parts:

• Specifications

• Structure and Operation

• Troubleshooting

• General Inspection and Adjustment

• Service procedures

General Inspection and Adjustment

• Procedures for inspection and adjustment of individual parts and assemblies as mounted on the machine are de-

scribed including specific items to check and adjust. Specified or otherwise, inspection should be performed for

looseness, play, backlash, crack, damage, etc.

Service procedure

• Procedures for servicing components and parts off the machine are described centering on key points in their re-

moval, installation, disassembly, reassembly, inspection, etc.

Inspection

• Check items subject to “acceptable/unacceptable” judgement on the basis of service standards are all given.

• Some routine visual checks and cleaning of some reused parts are not described but must always be included in

actual service work.

Caution

• This service manual contains important cautionary instructions and supplementary information under the follow-

ing four headings which identify the nature of the instructions and information:

Terms and Units

• Front and rear

The forward running direction of the machine is referred to as the front and the reverse running direction is re-

ferred to as the rear.

• Left and right

Left hand side and right hand side, when facing the forward running direction of the machine, are respectively left

and right.

Standard value

• Standard value dimensions in designs indicating: the design dimensions of individual parts, the standard clear-

ance between two parts when assembled, and the standard value for an assembly part, as the case may be.

Limit

• When the value of a part exceeds this, it is no longer serviceable in respect of performance and strength and must

be replaced or repaired.

DANGER

Precautions that should be taken in handling potentially dangerous substances

such as battery fluid and coolant additives.

WARNING

Precautionary instructions, which, if not observed, could result in serious injury or

death.

CAUTION

Precautionary instructions, which, if not observed, may result in damage to or de-

struction of equipment or parts.

NOTE

Suggestions or supplementary information for more efficient use of equipment or

better understandings.

HOW TO READ THIS MANUAL

00

00-3

Tightening torque

• Values are directly specified for out-of-standard tightening torques for bolts and nuts.

• Where there is no specified figure for tightening torque, follow the table covering standard tightening torques.

• When the item is to be tightened in a wet state, “wet” is indicated. Where there is no indication, read it as dry.

Units

• Tightening torques and other parameters are given in SI* units with metric units added in brackets { }. Values in

engine specifications, performance curves, and other items taken from official approval documents are given only

in metric units.

*SI: Le Système International d’Unités

Item SI unit {metric unit} Conversion factor

Force N {kgf} 9.80665 N {1 kgf}

Moment of force N·m {kgf·m} 9.80665 N·m {1 kgf·m}

Pressure

Positive pressure kPa {kgf/cm

2

} 98.0665 kPa {1 kgf/cm

2

}

Vacuum pressure

kPa {mmHg} 0.133322 kPa {1 mmHg}

Pa {mmH

2

O} 9.80665 Pa {1 mmH

2

O}

Volume dm

3

{L} 1 dm

3

{1 L}

Heat quantity J {kcal} 4186.05 J {1 kcal}

Heat flow W {kcal/h} 1.16279 W {1 kcal/h}

Power kW {PS} 0.7355 kW {1 PS}

Angle ˚ –

Temperature ˚C –

Electric current A –

Voltage V –

Resistance Ω –

Electric power W –

Unit SI unit Foot-pound unit Conversion rate

Force N (Newton) lbf 1 N = 0.2248 lbf

Moment of force N·m lbf.ft 1 N·m = 0.7375 lbf.ft

Pressure kPa (kilopascal) lbf/in.

2

1 kPa = 0.145 lbf/in.

2

1 kPa = 0.2953 in. Hg

Volume

L

cm

3

cm

3

gal.

oz

cu.in.

1 L = 0.2642 gal. (U.S.)

1 L = 0.220 gal. (Imp.)

1 cm

3

= 0.033814 oz (U.S.)

1 cm

3

= 0.035195 oz (Imp.)

1 cm

3

= 0.061023 cu.in.

Power kW (kilowatt) HP 1 kW = 1.34 HP

Temperature ˚C ˚F t˚C = (1.8t˚C + 32)˚F

Mass quantity of

matter

kg

g

lb

oz

1 kg = 2.2046 lb

1 g = 0.035274 oz

Dimension

m

mm

ft.

in.

1 m = 3.2808 ft.

1 mm = 0.03937 in.

Stress N/cm

2

lbf/in.

2

1 N/cm

2

= 1.45 lbf/in.

2

Example: 390 N·m {40 kgf·m}

Metric unit

SI unit

00-4

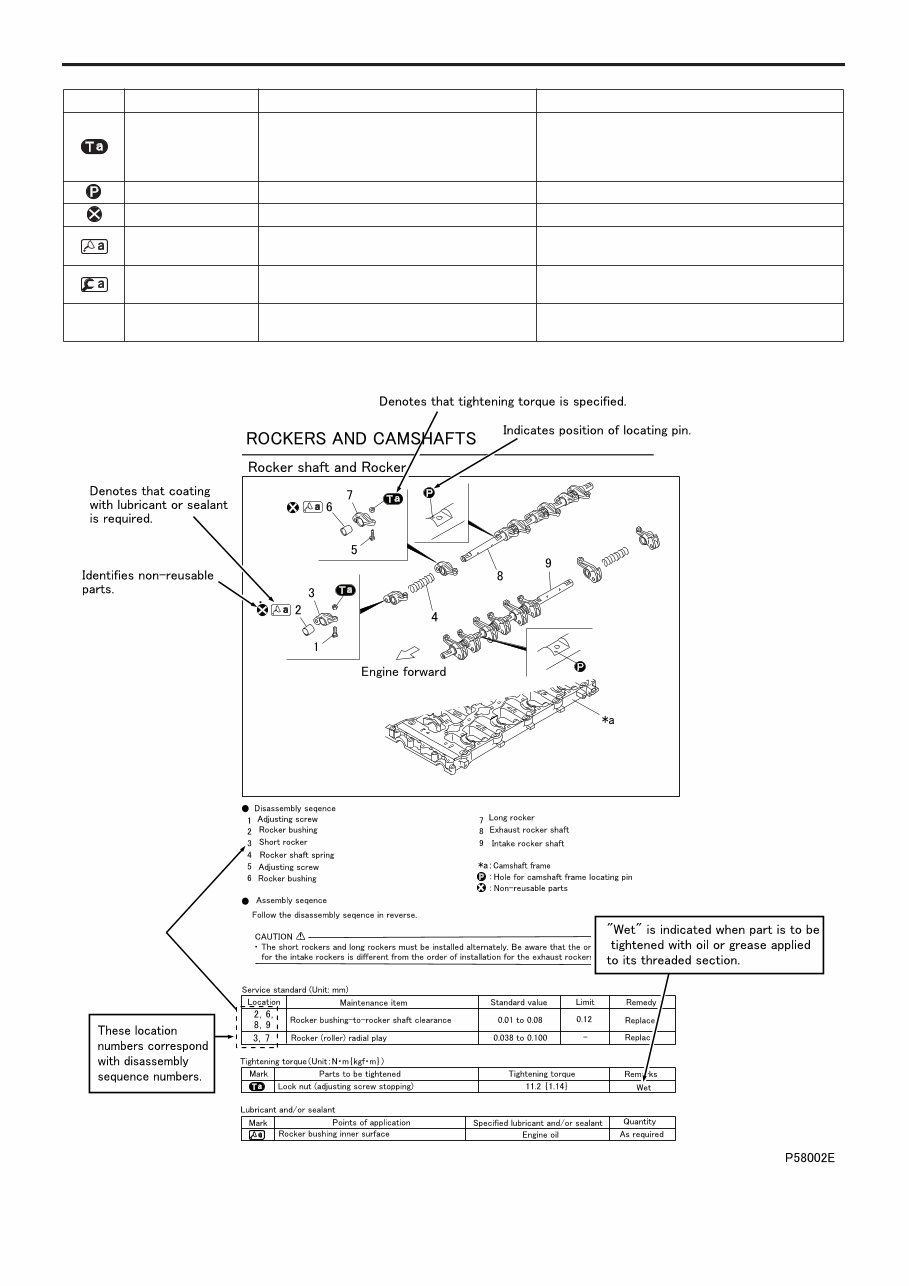

Symbol Denotation Application Remarks

Tightening torque

Parts not tightened to standard torques

(standard torques specified where neces-

sary for servicing)

Specified values shown in table

See Table of Standard Tightening Torques for

parts for which no tightening torques are speci-

fied.

Locating pin Parts to be positioned for installation

Non-reusable parts Parts not to be reused

Lubricant and/or

sealant

Parts to be coated with lubricant or sealant

for assembly or installation

Necessary lubricant and/or sealant, quantity re-

quired, etc. are specified in table.

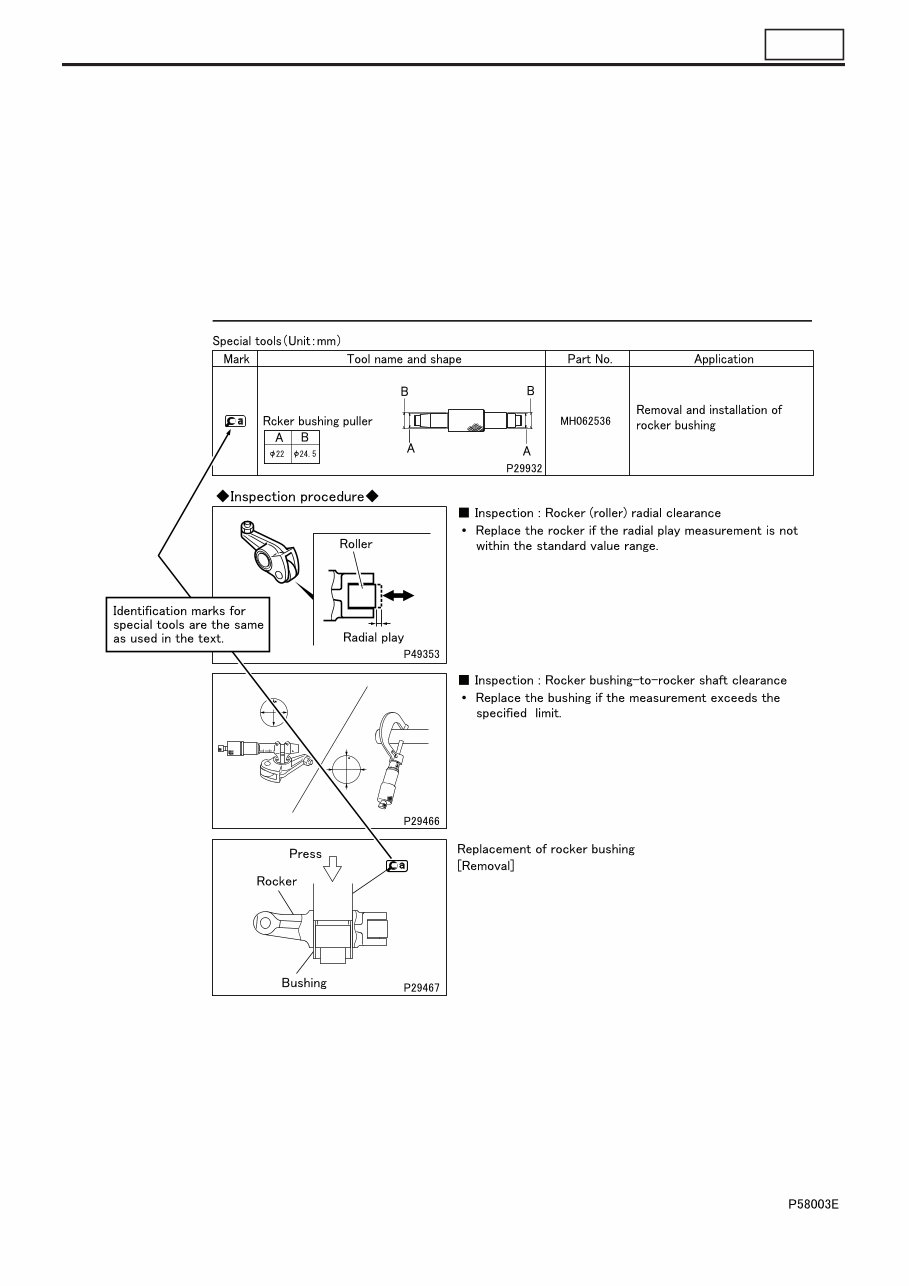

Special tool

Parts for which special tools are required for

service operation

Tool name/shape and part number are shown in

table.

*a Associated part

Parts associated with those removed/disas-

sembled for servicing

HOW TO READ THIS MANUAL

00

00-5

00-6

How to Use Diagnostic Codes <Electronically Controlled Fuel System (Gr13E)>

P125A: Common Rail Pressure M/V1 (high) (warning lamp flashes: 63)

Code generation criteria MPROP1 (rail pressure control valve) voltage is above standard valve.

Resetability

System recovers (power is re-supplied to electronic control unit) if signal

becomes normal when starter switch is turned OFF → ON.

Electronic control unit control

• Engine is stopped.

• Exhaust gas recirculation control is stopped.

In-

spec-

tion

item

Service data 0C: Difference Common Rail Pressure

Actuator test B9: Fuel Leak Check

Electronic control unit

connector

: Resistance of MPROP (rail pressure control valve)

Electrical part #574: MPROP1 (rail pressure control valve)

08

This section suggests areas to

inspect for each diagnostic

code.

TROUBLESHOOTING

1. Diagnostic Procedure

2. Diagnostic Precautions

3. Inspections Based On Diagnostic Codes

4. Multi-use Tester Service Data

5. Actuator Tests Performed Using Multi-use Tester

6. Inspections Performed At Electronic Control

Unit Connectors

There are the diagnostic code and message displayed on Multi-Use Tester.

Numerical values in parenthesis are added only when a diagnostic code indicated in

the Multi-Use Tester display differs from the code indicated by the number of warning

lamp flashes.

Refer to “Inspection of Electrical

Equipment.”

The contents of this manual include functions and parts that are not used in your truck depending on

the truck specifications. Please refer to the chassis service manual for the details.

HOW TO READ THIS MANUAL

00

00-7

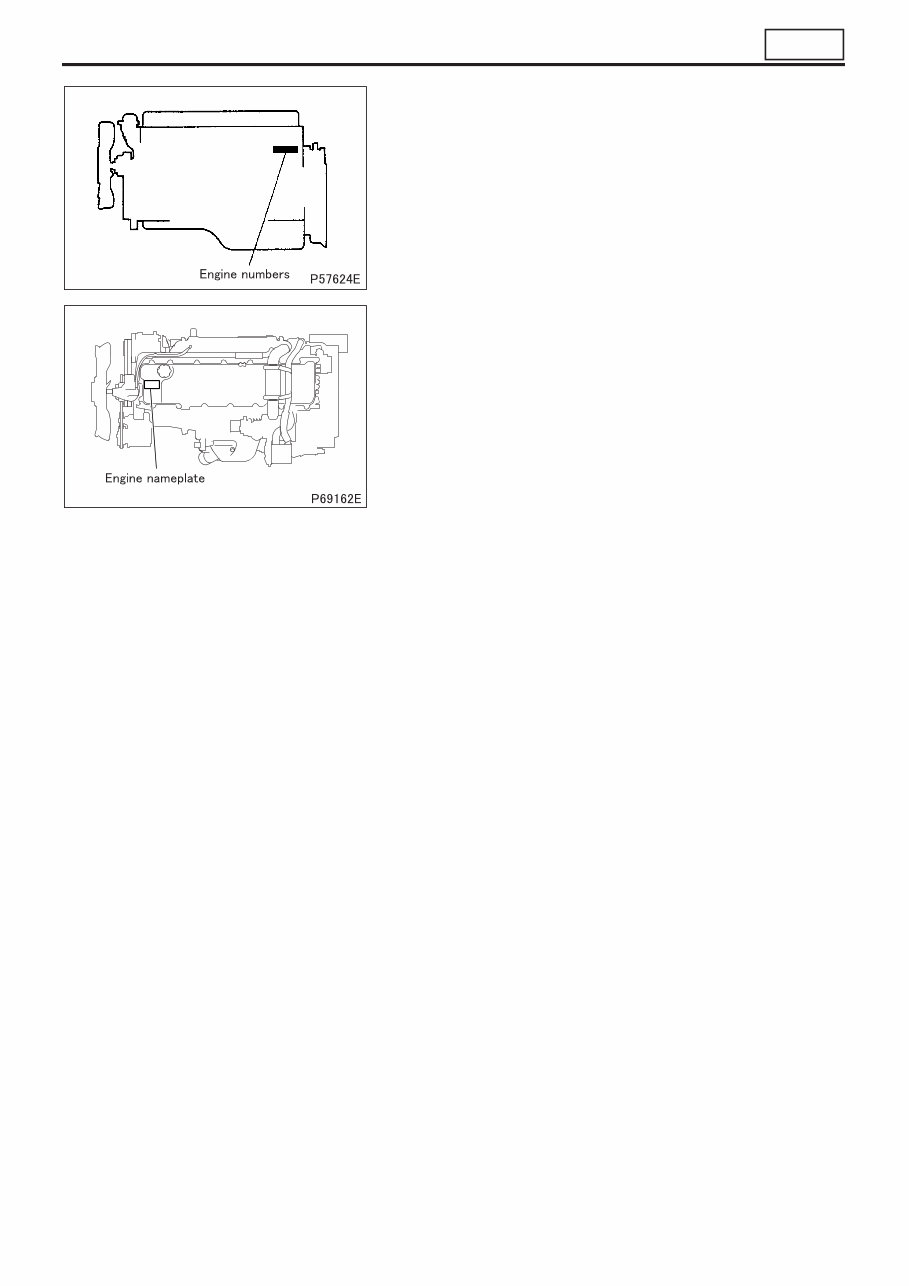

• Serial engine numbers are assigned to the engines in manufac-

turing sequence. Every engine has its own number. These num-

bers are required for registration and related inspection of the

vehicle.

• An engine nameplate indicates the following item.

• Engine model

ENGINE NUMBER

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

Viewed 63 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

This service repair manual is designed for the Mitsubishi 6M60-TL Diesel Engine, specifically for use with the FD80N-FD160N Mitsubishi Forklift Trucks. It includes the following chapters:

- FOREWORD

- GENERAL

- ENGINE

- LUBRICATION

- FUEL AND ENGINE CONTROL

- ELECTRONICALLY CONTROLLED FUEL SYSTEM

- COOLING

- INTAKE AND EXHAUST

- EMISSION CONTROL

- ELECTRICAL

- SPECIAL EQUIPMENT

The manual is available in a printable format and is presented in English.