Lombardini Marine Engines LGA 280-340 OHC Series Workshop Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

WORK SHOP

MANUAL

LGA 280-340 OHC Series engines,code 1-5302- 528

SERVICE

LGA 280 OHC

LGA 340 OHC

COMPILER TECO/ATI REG. CODE

1-5302-528

MODEL N°

50805

DATE OF ISSUE

31.07.2001

REVISION 00

ENDORSED DATE

31.07.2001

1st Edition

1

SERVICE

PREFACE

Every attempt has been made to present within this service manual, accurate and up to date technical information.

However, development on the Lombardini series is continuos. Therefore, the information within this manual is subject

to change without notice and without obligation.

The information contained within this service manual is the sole property of Lombardini. As such, no reproduction or

replication in whole or part is allowed without the express written permission of Lombardini.

Information presented within this manual assumes the following:

1- The person or persons performing service work on Lombardini series engines is properly trained and equipped to

safely and professionally perform the subject operation;

2- The person or persons performing service work on Lombardini series engines possesses adequate hand and

Lombardini special tools to safely and professionally perform the subject service operation;

3- The person or persons performing service work on Lombardini series engines has read the pertinent information

regarding the subject service operations and fully understands the operation at hand.

GENERAL SERVICE MANUAL NOTES:

1- Use only genuine Lombardini repair parts. Failure to use genuine Lombardini parts could result in sub-standard

performance and low longevity.

2- All data presented are in metric format. That is, dimensions are presented in millimeters (mm), torque is presented

in Newton-meters (Nm), weight is presented in kilograms (Kg), volume is presented in liters or cubic centimeters

(cc) and pressure is presented in barometric units (bar).

COMPILER TECO/ATL REG. CODE

1-5302-528

MODEL N°

50805

DATE OF ISSUE

31.07.2001

REVISION 00

ENDORSED DATE

31.07.2001

3

WARRANTY CERTIFICATE

WARRANTY CERTIFICATE

Engine manufactured by Lombardini S.r.l., are warranted to be free of defects in workmanship or materials for 12

months from the date of delivery to the first purchaser or non more than two (2) years from date of engine delivery to

the Original Equipment Manufacturer as defined by Lombardini invoicing, whichever occurs firsts, except as defined

below.

Stationary applications, working at constant speed and/or slightly variable speeds, are excluded from the above

terms. Stationary/fixed speed applications will be warranted to be free of material/workmanship defects for a

maximum operational period of 1000 hours or 12months from the date of first purchase, whichever occurs first. The

two (2) year limitation from date of Lombardini invoice will remain intact as described above.

Modification of Lombardini products by the Original Equipement Manufacturer or the end user with respect to cooling

systems, filtration systems, induction systems, exhaust systems, lubrication system, fuel system, fuel system

settings, etc., will require special written warranty agreements. A test certificate/approval by the R&D/Application

engineering department of Lombardini or associated Lombardini companies concerning modified Lombardini products

will entitle Warranty as defined above. Warranty will not be granted on any modified Lombardini product without

special written approval by Lombardini.

Within the above stated periods Lombardini will replace and/or repair, at the option of Lombardini, any part or

component that, upon examination by Lombardini or an authorized Lombardini agent, is found to be defective in

workmanship or materials. Any other responsibility/obligation for different expenses, damages and direct/indirect

losses deriving from the engine use or from both the total or partial impossibility of use, is excluded.

The repair or replacemnt of any component will not extend or renew the warranty period. Direct labor required to make

repairs or to replace components found to be defective in materials or workmanship will be completed at no cost to

the end user. Lombardini in not responsible however for indirect costs of removing/installing the engine assembly.

Further, Lombardini is not responsible for the costs of transportation of the machine or components requiring repair or

for service supplies such as lubricating oils and filters.

Lombardini Warranty obligations will be cancelled if:

- Lombardini engines are applied to a given machine causing working engine parameters outside Lombardini

application guidelines.

- Lombardini engines are not serviced and maintained according to the "USE and MAINTENANCE" booklet.

- Any seal affixed to the engine by Lombardini has been tampered with or removed.

- Engines have been disassembled, repaired or altered by any party other than an authorized Lombardini agent.

- Spare parts used are not original Lombardini.

- Fuel injection system/component failures caused by the use of unauthorized fuel types or poor quality fuels are

not covered under the Lombardini warranty policy.

- Electrical system failures due to the modification of Lombardini supplied harnesses, modification of Lombardini

supplied control panels, OEM/end user supplied/installed relays, controls, etc. are not covered under warranty.

Following expiration of the above stated warranty period(s) and limitations, Lombardini will have no further

responsibility for warranty and will consider our obligation for warranty complete.

The above warranty certificate will be in effect starting July 1, 1993 and cancels/replaces any and all explicit or implicit

warranty policies on the part of Lombardini. The above warranty conditions can from this date forward be modified only

in writing.

REG. CODE

1-5302-528

MODEL N°

50805

DATE OF ISSUE

31.07.2001

REVISION 00

DATE

31.07.2001

ENDORSED COMPILER TECO/ATL

4

INDEX

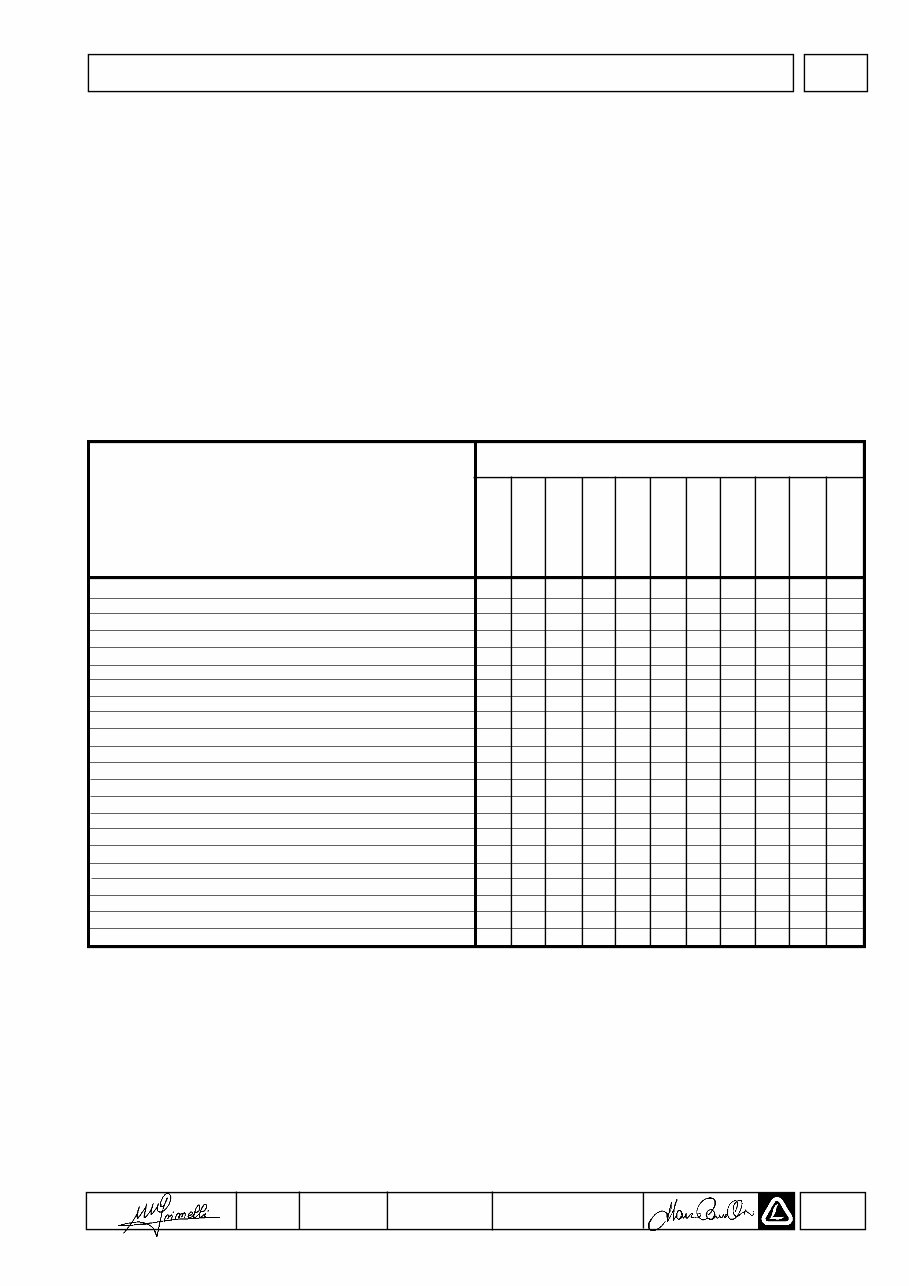

I TROUBLE SHOOTING

II WARNING SIGNS - SAFETY INSTRUCTIONS

III ENGINE IDENTIFICATION

IV TECHNICAL FEATURES

V CHARACTERISTICS

VI OVERALL DIMENSION

VII MAINTENANCE - RECOMMENDED OIL TYPE - REFILLING

VIII DISASSSEMBLY/REASSEMBLY

General information for correct repairs

Engine disassembly

Engine preparation

Flywheel extraction

Head disassembly

Disassembly of camshaft-tappets valves

Timing pulley removal

Timing cover removal

Crankshaft extraction

Cylinder head

Camshaft

Valves - guides - seats - valve spring - tappets

Valves and valve-guides dimensions after assembly in the head

Valves and valve-guides gap

Valve guide

Oil seal ring on valve guide

Valve seats

Valve springs

Tappets

Breather valve

Cylinder

Connecting rod

Piston and rings

Crankshaft

Main journals and crank pin diameter (mm)

Governor and balancing shaft gear command

Balancing shaft

Speed governor

Bearings

Crankcase and timing cover

Recoil starter

Rope and return spring replacement

Oil watch device (optional)

Crancshaft and oil seal rings

Piston and connecting rods

Speed governor

Timing cover

This manual gives the main instructions on how to repair LOMBARDINI LGA 280-340 OHC

gasoline-fuelled engines, updated as of 31.07.2001.

Page 7

" 8-9

" 10

" 11

" 12

" 13

" 14

" 17

17

17

17

17

17

18

18

18

18

18

19

19

19

20

20

20

21

22

22

22

22

23

23-24

25

25

25

26

26

26

26

27

27

28

28

28

29

29

INDEX

COMPILER TECO/ATL REG. CODE

1-5302-528

MODEL N°

50805

DATE OF ISSUE

31.07.2001

REVISION 00

ENDORSED DATE

31.07.2001

5

INDEX

Timing pulley assembling

Cylinder head assembling

Camshaft assembling and valve clearance adjustment

Timing adjustement and assembling of the toothed belt

Flywheel assembly and coil gap adjustment

Carburetor

Lubrication

IX ELECTRONIC IGNITION

Electronic ignition

Spark plugs

X ELECTRIC STARTING

Electric starting

Electrical start system standard

System checks

Alternator

Rectifier

Starting motor

Battery

Starting panel

Lighting system with alternator

Characteristics with alternator 180 W (optional)

XI REGISTRAZIONI

Engine assembling

Governor lever adjustment

Engine test

Starting with the recoil starter

Electric starting

Carburetor and R.P.M. adjustment

XII STORAGE

Storage

Temporary inactivity

Preparation for starting

XIII INSTALLATION - INCLINATION AND OPERATING LIMITS

Axial load - radial load and maximum overhang

Installation

Inclination and operating limits

XIV TORQUE SETTING

Main torque specifications

Standard bolt torque specifications

XV SPECIAL TOOLS

Special tools

XVI PISTON-CYLINDER OVERSIZE TABLE - TOLERANCES OF CRANKSHAFT JOURNAL

GRINDINGS - TABLE OF CLEARANCES AND ADJUSTMENTS

Piston-cylinder oversize table

Tolerances of crankshaft journal grindings

Table of clearances and adjustments

29

29

30

31

31

32

32

Page 33

33

33

" 34

34

34

34

34

34

35

35

35

35

35

" 36

36

36

36

37

37

37

" 38

38

38

38

" 39

39

39

39

" 40

40

41

" 42

42

" 43

43

43

43

REG. CODE

1-5302-528

MODEL N°

50805

DATE OF ISSUE

31.07.2001

REVISION 00

DATE

31.07.2001

ENDORSED COMPILER TECO/ATL

6

NOTE

COMPILER TECO/ATL REG. CODE

1-5302-528

MODEL N°

50805

DATE OF ISSUE

31.07.2001

REVISION 00

ENDORSED DATE

31.07.2001

7

TROUBLE SHOOTING I

Listed below are some of the possible causes of engine operating defects.

Carry out simple tests before proceeding with disassembly operations or making substitutions.

TROUBLE SHOOTING

Tank plug breather clogged

Tap clogged

Fuel filter clogged

Dirty carburetor

Carburetor needle valve blocked

Speed governor rod blocked

Grounded spark plug

Broken spark plug lead

Defective coil

Clogged air filter

Low oil level (oil watch alerted)

Air filter chocked

Blocked valves

Worn piston rings

Excessive valve play

Defective oil seals

Worn valve guides

Worn governor spring

Piston seizure

Loose head locking-nuts

Low idling rate

Driving belt broken

POSSIBLE CAUSES

TROUBLE

Noisy

No power

Starts and stops

Does not start

Light or

white smoke

Dark or

black smoke

Hunts

Consumes oil

Overheats

Does not accel.

Spark plug fails

to spark

•

•

•

• •

• • •

• • •

• •

• •

• •

• • •

• • •

•

• •

• • • •

• • • •

• • •

•

• • • •

• •

• • • •

• • •

•

•

REG. CODE

1-5302-528

MODEL N°

50805

DATE OF ISSUE

31.07.2001

REVISION 00

DATE

31.07.2001

ENDORSED COMPILER TECO/ATL

8

II

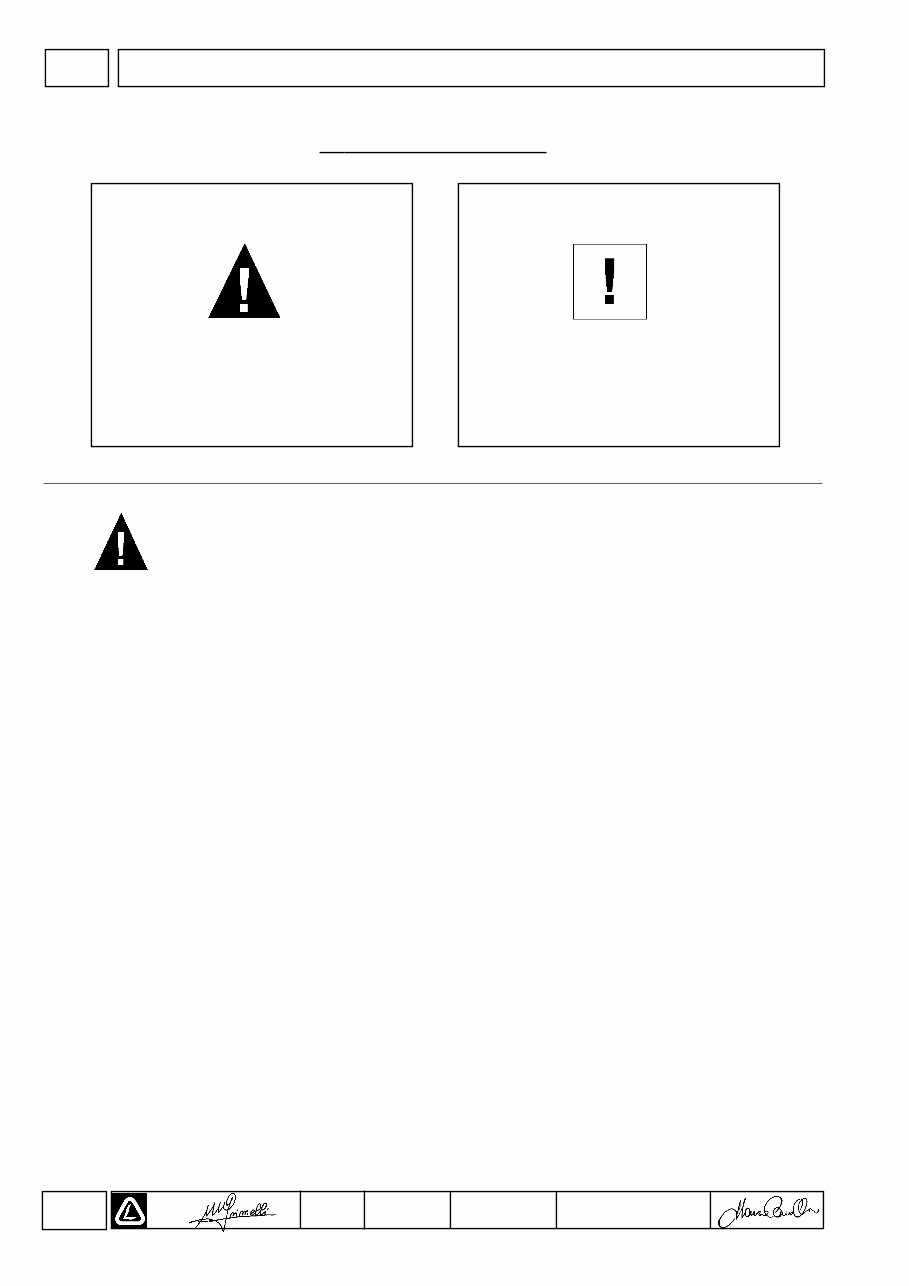

WARNING SIGNS - SAFETY INSTRUCTIONS

Failure to comply with these

instructions may result in

damages to persons and

property.

Failure to comply with these

instructions can lead to

technical damage to the

machine and/or installation.

DANGER

W ARNING SIGNS

CAUTION

• Lombardini engines are built to provide safe and longlasting performances, but in order to obtain these results it is

essential that the maintenance requirements described in the manual are observed along with the following safety

recommendations.

• The engine has been built to the specifications of a machine manufacturer, and it is his responsibility to ensure that

all necessary action is taken to meet the essential and legally prescribed health and safety requirements. Any use

of the machine other than that described cannot be considered as complying with its intended purpose as specified

by Lombardini, which therefore declines all responsibility for accidents caused by such operations.

• The following instructions are intended for the user of the machine in order to reduce or eliminate risks, especially

those concerning the operation and standard maintenance of the engine.

• The user should read these instructions carefully and get to know the operations described. By not doing so he

may place at risk his own health and safety and that of anyone else in the vicinity of the machine.

• The engine may be used or mounted on a machine only by personnel suitably trained in its operation and aware of

the dangers involved. This is particularly true for standard and, above all, special maintenance work. For special

maintenance contact personnel trained specifically by Lombardini. This work should be carried out in accordance

with existing literature.

• Lombardini declines all responsibility for accidents or for failure to comply with the requirements of law if changes

are made to the engine’s functional parameters or to the fuel flow rate adjustments and speed of rotation, if seals

are removed, or if parts not described in the operating and maintenance manual are removed and reassembled by

unauthorized personnel.

• In addition to all other machine specifications, ensure that the engine is in a near horizontal position when starting.

lf starting manually, ensure that the necessary operations can be performed without any risk of striking against

walls or dangerous objects. Rope starting (except for recoil rope starting) is not permitted even in emergencies.

• Check that the machine is stable so that there is no risk of it overturning.

• Get to know the engine speed adjustment and machine stop operations.

• Do not start the machine in closed or poorly ventilated environments. The internal combustion process generates

carbon monoxide, an odourless and highly toxic gas, so spending too long a time in an environment where the

engine discharges its exhaust products freely can lead to loss of consciousness and even death.

• The engine may not be used in environments containing flammable materials, explosive atmospheres or easily

combustible powders, unless adequate and specific precautions have been taken and are clearly stated and

certified for the machine.

• To prevent the risk of fire, keep the machine at a distance of at least one metre from buildings or other machines.

• Children and animals must be kept at a sufficient distance from the machine to prevent any danger resulting from

its operation.

SAFETY INSTRUCTIONS

COMPILER TECO/ATL REG. CODE

1-5302-528

MODEL N°

50805

DATE OF ISSUE

31.07.2001

REVISION 00

ENDORSED DATE

31.07.2001

9

WARNING SIGNS - SAFETY INSTRUCTIONS II

• Fuel is flammable, so the tank must be filled only when the engine is turned off. Dry carefully any fuel that may

have spilled, remove the fuel container and any cloths soaked in fuel or oil, check that any sound-absorbing panels

made of porous material are not soaked with fuel or oil, and make sure that the ground on which the machine is

located has not absorbed fuel or oil.

• To start the engine follow the specific instructions provided in the engine and/or machine operating manual. Do not

use auxiliary starting devices not originally installed on the machine (e.g. Startpilot systems which utilise ether etc.)

• Before starting, remove any tools that have been used for carrying out maintenance work to the engine and/or the

machine and check that any guards removed have been replaced. In cold climates it is possible to mix kerosene

with the diesel fuel to make the engine easier to start. The liquids must be mixed in the tank by pouring in first the

kerosene and then the diesel fuel. Consult Lombardini technical office for mixture proportions. Petrol may not be

used because of the risk of it forming flammable vapours.

• During operation the surface of the engine reaches temperatures that may be dangerous. Avoid in particular all

contact with the exhaust system.

• Before carrying out any work on the engine, turn it off and allow it to cool down. Do not perform any operation while

the engine is running.

• The liquid cooling circuit is under pressure. Do not carry out any checks before the engine has cooled down, and

even then open the radiator cap or the expansion tank cautiously. Wear protective clothing and glasses. lf there is

an electric fan, do not approach the engine while it is still hot as the fan may come on even when the engine is not

running. Clean the cooling system with the engine turned off.

• While cleaning the oil bath air filter, check that the oil is disposed of in such a way as not to harm the environment.

Any filtering sponges in the oil bath air filter should not be soaked with oil. The cyclone pre-filter cup must not be

filled with oil.

• Since the oil must be emptied out while the engine is still hot (approx. 80°C), particular care should be taken in

order to avoid burns. In any case make sure that oil does not come into contact with your skin because of the

health hazards involved.

• Check that the discharged oil, the oil filter and the oil contained in the oil filter are disposed of in such a way as not

to harm the environment.

• Close the fuel tank filler cap carefully after each fílling operation. Do not fill the tank right up to the top, but leave

sufficient space to allow for any expansion of the fuel.

• Fuel vapours are highly toxic, so fill up only in the open air or in well ventilated environments.

• Do not smoke or use naked flames while filling.

• Take care when removing the oil filter as it may be hot.

• The operations of checking, filling up and replacing the cooling liquid must be carried out with the engine turned off

and cold. Take particular care if liquids containing nitrites are mixed with others not containing these compounds

as this may give rise to the formation of nitrosamines which are a health hazard. The cooling liquid is polluting, so

dispose of in a manner that does not damage the environment.

• During operations which involve access to moving parts of the engine and/or removal of the rotary guards, disconnect

and insulate the positive cable of the battery so as to prevent accidental short circuits and activation of the starter

motor.

• Check the belt tension only when the engine is turned off.

• In order to move the engine use exclusively the eyebolts fitted for this purpose by Lombardini. These lifting points

are however not suitable for the entire machine, so in this case use the eyebolts fitted by the manufacturer.

REG. CODE

1-5302-528

MODEL N°

50805

DATE OF ISSUE

31.07.2001

REVISION 00

DATE

31.07.2001

ENDORSED COMPILER TECO/ATL

10

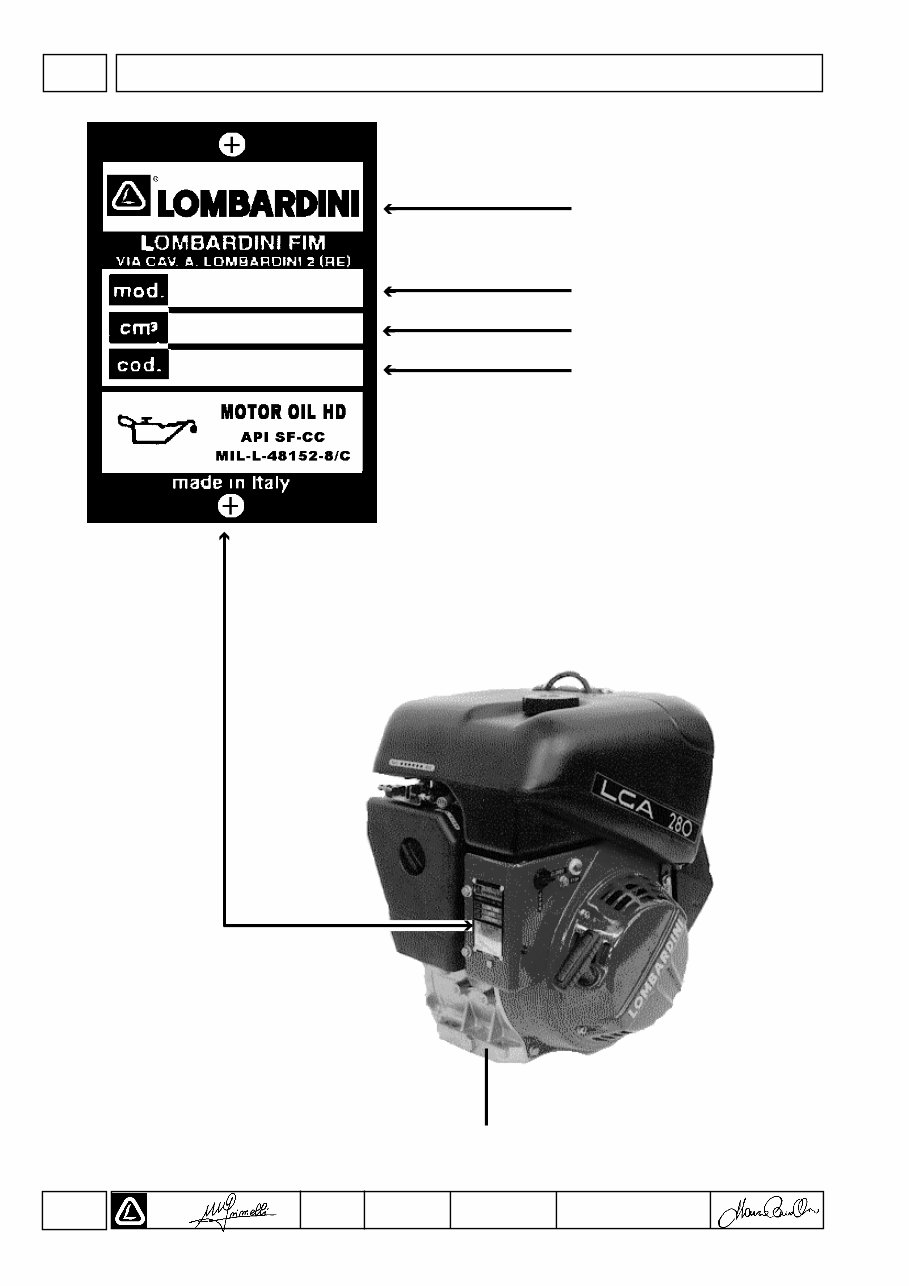

III

ENGINE IDENTIFICATION

LOMBARDINI

ENGINE TYPE

SWEPT VOLUME

CUSTOMER CODE

ENGINE IDENTIFICATION NUMBER

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$26.99

Viewed 80 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$26.99

- The Lombardini Marine Engines LGA 280-340 OHC Series Workshop Manual is a comprehensive guide for maintaining and repairing your Lombardini Marine Engine. This workshop manual covers all models within the LGA 280-340 OHC Series, ensuring that you have all the information you need to keep your engine in top condition.

- Whether you are a professional mechanic or a boat owner who likes to take care of their own engine, this workshop manual is an invaluable resource. With detailed instructions, illustrations, and specifications, you can confidently tackle any maintenance or repair task.

- Simply purchase online and receive instant access to the download link. Keep your Lombardini Marine Engine running smoothly with the LGA 280-340 OHC Series Workshop Manual.