KOHLER COMMand PRO Model CV980 28HP Engine Full Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SERVICE MANUAL

HORIZONTAL CRANKSHAFT

COMMAND CH18-745

Kohler Engine Parts Call K&T 606-678-9623 or 606-561-4983

www.mymowerparts.com

1.1

1

Section 1

Safety and General Information

CH18-745

Safety Precautions

To ensure safe operation please read the following statements and understand their meaning. Also

refer to your equipment manufacturer's manual for other important safety information. This manual

contains safety precautions which are explained below. Please read carefully.

WARNING

Warning is used to indicate the presence of a hazard that can cause severe personal injury, death,

or substantial property damage if the warning is ignored.

CAUTION

Caution is used to indicate the presence of a hazard that will or can cause minor personal injury or

property damage if the caution is ignored.

NOTE

Note is used to notify people of installation, operation, or maintenance information that is important

but not hazard-related.

For Your Safety!

These precautions should be followed at all times. Failure to follow these precautions could result in

injury to yourself and others.

Rotating Parts can cause severe

injury.

Stay away while engine is in

operation.

WARNING

Rotating Parts!

Keep hands, feet, hair, and

clothing away from all moving

parts to prevent injury. Never

operate the engine with covers,

shrouds, or guards removed.

Hot Parts can cause severe burns.

Do not touch engine while operating

or just after stopping.

WARNING

Hot Parts!

Engine components can get

extremely hot from operation. To

prevent severe burns, do not

touch these areas while the

engine is running - or immediately

after it is turned off. Never operate

the engine with heat shields or

guards removed.

Accidental Starts can cause

severe injury or death.

Disconnect and ground spark plug

leads before servicing.

WARNING

Accidental Starts!

Disabling engine. Accidental

starting can cause severe injury

or death. Before working on the

engine or equipment, disable the

engine as follows: 1) Disconnect the

spark plug lead(s). 2) Disconnect

negative (-) battery cable from

battery.

Kohler Engine Parts Call K&T 606-678-9623 or 606-561-4983

www.mymowerparts.com

1.2

Section 1

Safety and General Information

Carbon Monoxide can cause

severe nausea, fainting or death.

Do not operate engine in closed or

confined area.

WARNING WARNING

Electrical Shock can cause injury.

Do not touch wires while engine is

running.

CAUTION

Uncoiling Spring can cause severe

injury.

Wear safety goggles or face

protection when servicing retractable

starter.

WARNING

Explosive Gas can cause fires and

severe acid burns.

Charge battery only in a well

ventilated area. Keep sources of

ignition away.

Lethal Exhaust Gases!

Engine exhaust gases contain

poisonous carbon monoxide.

Carbon monoxide is odorless,

colorless, and can cause death if

inhaled. Avoid inhaling exhaust

fumes, and never run the engine

in a closed building or confined

area.

Spring Under Tension!

Retractable starters contain a

powerful, recoil spring that is under

tension. Always wear safety

goggles when servicing retractable

starters and carefully follow

instructions in the "Retractable

Starter" Section 7 for relieving

spring tension.

Explosive Gas!

Batteries produce explosive

hydrogen gas while being

charged. To prevent a fire or

explosion, charge batteries only in

well ventilated areas. Keep

sparks, open flames, and other

sources of ignition away from the

battery at all times. Keep batteries

out of the reach of children.

Remove all jewelry when servicing

batteries.

Before disconnecting the negative

(-) ground cable, make sure all

switches are OFF. If ON, a spark

will occur at the ground cable

terminal which could cause an

explosion if hydrogen gas or

gasoline vapors are present.

Electrical Shock!

Never touch electrical wires or

components while the engine is

running. They can be sources of

electrical shock.

Explosive Fuel can cause fires and

severe burns.

Stop engine before filling fuel tank.

WARNING

Explosive Fuel!

Gasoline is extremely flammable

and its vapors can explode if

ignited. Store gasoline only in

approved containers, in well

ventilated, unoccupied buildings,

away from sparks or flames. Do not

fill the fuel tank while the engine is

hot or running, since spilled fuel

could ignite if it comes in contact

with hot parts or sparks from

ignition. Do not start the engine

near spilled fuel. Never use

gasoline as a cleaning agent.

Cleaning Solvents can cause

severe injury or death.

Use only in well ventilated areas

away from ignition sources.

WARNING

Flammable Solvents!

Carburetor cleaners and solvents

are extremely flammable. Keep

sparks, flames, and other sources

of ignition away from the area.

Follow the cleaner manufacturer’s

warnings and instructions on its

proper and safe use. Never use

gasoline as a cleaning agent.

Kohler Engine Parts Call K&T 606-678-9623 or 606-561-4983

www.mymowerparts.com

1.3

Section 1

Safety and General Information

1

A. Model No.

Version Code

S = Electric Start

C H 18 S

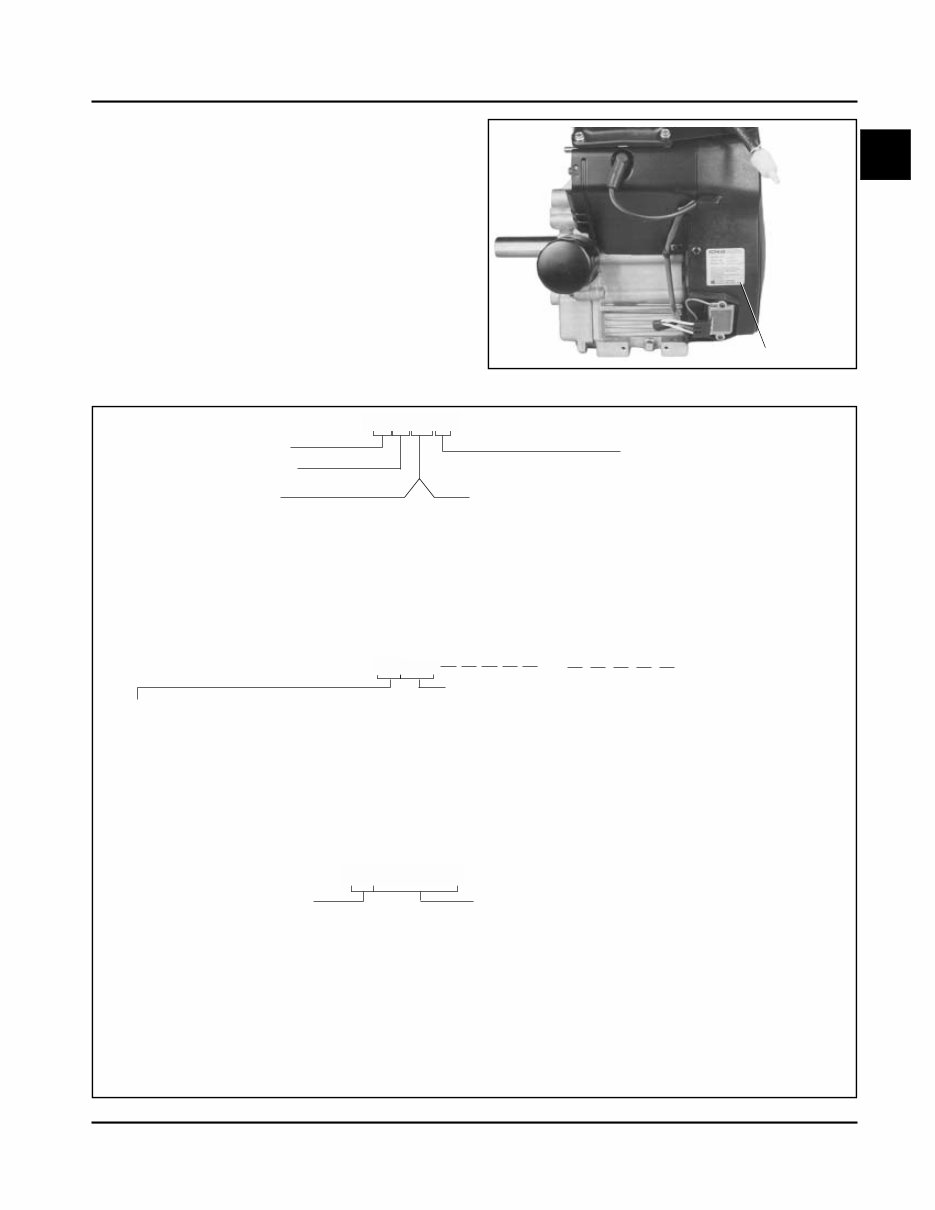

Engine Identification Numbers

When ordering parts, or in any communication

involving an engine, always give the Model,

Specification and Serial Numbers, including letter

suffixes if there are any.

The engine identification numbers appear on a decal,

or decals, affixed to the engine shrouding. See Figure

1-1. An explanation of these numbers is shown in

Figure 1-2.

Figure 1-1. Engine Identification Decal Location.

Variation of

Basic Engine

B. Spec. No.

62500

Command Engine

Horizontal Crankshaft

Horsepower

17 = 17 HP

18 = 18 HP

20 = 20 HP

22 = 22 HP

23 = 23 HP

25 = 25 HP

26 = 26 HP

Numerical Designation

730

740

745

or

Engine Model Code

Code Model

62 CH18

64 CH20

66 CH22 (624 cc)

68 CH25

76 CH22/23 (674 cc)

78 CH26

CH730-0001

CH740-0001

CH745-0001

Complete Spec Number

(Incorporating Model

No. with Variation No. of

Basic Spec.)

or

Figure 1-2. Explanation of Engine Identification Numbers.

C. Serial No.

Year Manufactured Code

Code Y ear

21 1991

22 1992

23 1993

24 1994

25 1995

26 1996

27 1997

28 1998

29 1999

Factory Code

3305810334

Code Y ear

30 2000

31 2001

32 2002

33 2003

34 2004

35 2005

Identification Decal

Kohler Engine Parts Call K&T 606-678-9623 or 606-561-4983

www.mymowerparts.com

1.4

Section 1

Safety and General Information

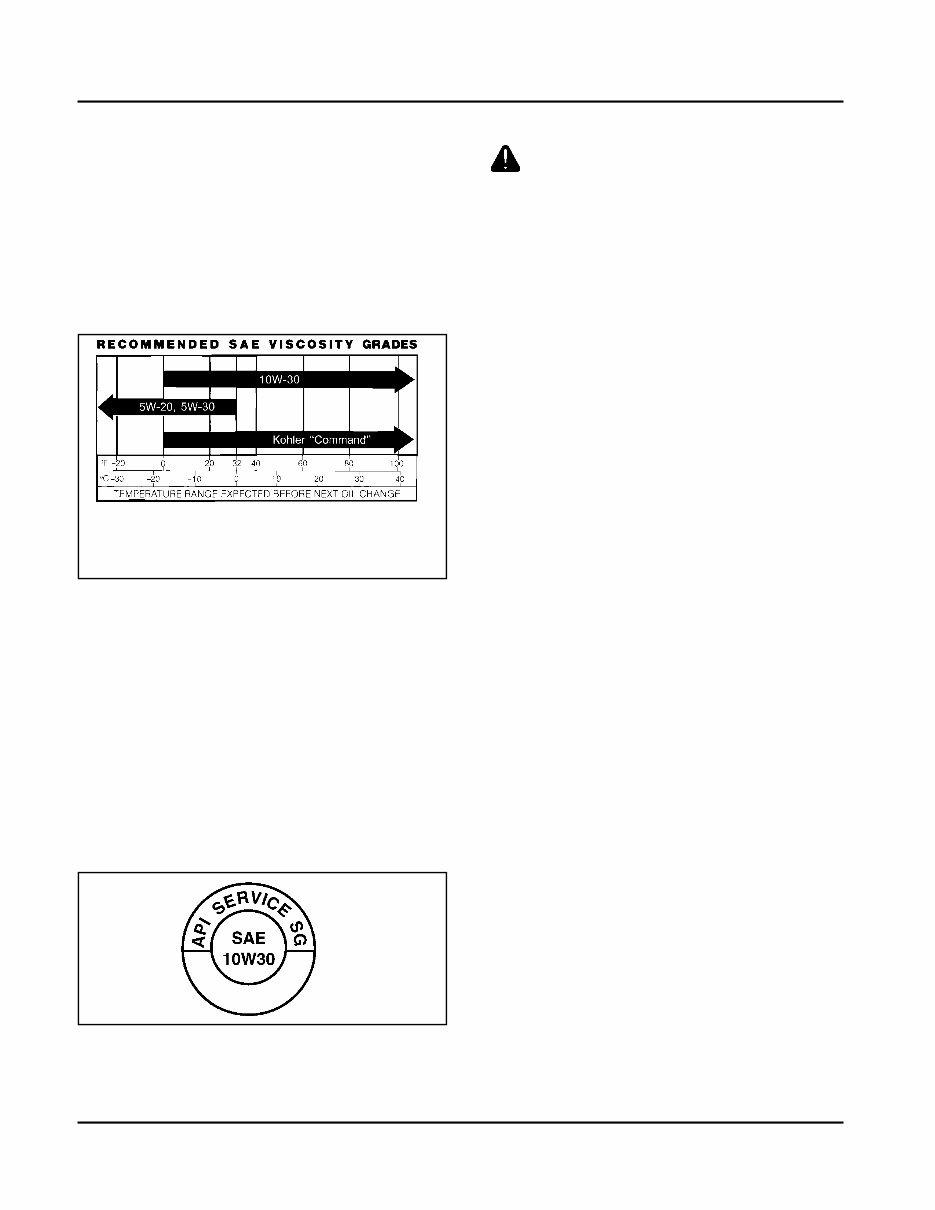

Oil Recommendations

Using the proper type and weight of oil in the crankcase

is extremely important. So is checking oil daily and

changing oil regularly. Failure to use the correct oil, or

using dirty oil, causes premature engine wear and failure.

Oil Type

Use high-quality detergent oil of API (American

Petroleum Institute) Service Class SG, SH, SJ or

higher. Select the viscosity based on the air temperature

at the time of operation as shown in the following table.

Fuel Recommendations

WARNING: Explosive Fuel!

Gasoline is extremely flammable and its vapors can

explode if ignited. Before servicing the fuel system,

make sure there are no sparks, open flames or other

sources of ignition nearby as these can ignite gasoline

vapors. Disconnect and ground the spark plug leads to

prevent the possibility of sparks from the ignition

system.

General Recommendations

Purchase gasoline in small quantities and store in

clean, approved containers. A container with a capacity

of 2 gallons or less with a pouring spout is

recommended. Such a container is easier to handle

and helps eliminate spillage during refueling.

Do not use gasoline left over from the previous

season, to minimize gum deposits in your fuel system

and to ensure easy starting.

Do not add oil to the gasoline.

Do not overfill the fuel tank. Leave room for the fuel to

expand.

Fuel Type

For best results, use only clean, fresh, unleaded

gasoline with a pump sticker octane rating of 87 or

higher. In countries using the Research method, it

should be 90 octane minimum.

Unleaded gasoline is recommended as it leaves less

combustion chamber deposits and reduces harmful

exhaust emissions. Leaded gasoline is not

recommended and must not be used on EFI engines,

or on other models where exhaust emissions are

regulated.

Gasoline/Alcohol blends

Gasohol (up to 10% ethyl alcohol, 90% unleaded

gasoline by volume) is approved as a fuel for Kohler

engines. Other gasoline/alcohol blends are not

approved.

Gasoline/Ether blends

Methyl Tertiary Butyl Ether (MTBE) and unleaded

gasoline blends (up to a maximum of 15% MTBE by

volume) are approved as a fuel for Kohler engines. Other

gasoline/ether blends are not approved.

NOTE: Using other than service class SG, SH, SJ or

higher oil or extending oil change intervals

longer than recommended can cause engine

damage.

NOTE: Synthetic oils meeting the listed classifications

may be used with oil changes performed at the

recommended intervals. However, to allow

piston rings to properly seat, a new or rebuilt

engine should be operated for at least 50 hours

using standard petroleum based oil before

switching to synthetic oil.

A logo or symbol on oil containers identifies the API

service class and SAE viscosity grade. See Figure 1-3.

Figure 1-3. Oil Container Logo.

Refer to Section 6 - “Lubrication System” for detailed

procedures on checking the oil, changing the oil and

changing the oil filter.

*

*Use of synthetic oil having 5W-20 or 5W-30 rating is

acceptable, up to 40°F.

**Synthetic oils will provide better starting in extreme

cold (below -10°F).

**

Kohler Engine Parts Call K&T 606-678-9623 or 606-561-4983

www.mymowerparts.com

1.5

Section 1

Safety and General Information

1

Periodic Maintenance Instructions

WARNING: Accidental Starts!

Disabling engine. Accidental starting can cause severe injury or death. Before working on the engine or

equipment, disable the engine as follows: 1) Disconnect the spark plug lead(s). 2) Disconnect negative (-) battery

cable from battery.

Maintenance Schedule

These required maintenance procedures should be performed at the frequency stated in the table. They should also

be included as part of any seasonal tune-up.

1

Perform these maintenance procedures more frequently under extremely dusty, dirty conditions.

2

Have a Kohler Engine Service Dealer perform this service.

3

Cleanout Kits 25 755 20-S (black) or 25 755 21-S (gold) allow cooling areas to be cleaned without removing

shrouds.

Storage

If the engine will be out of service for two months or

more, use the following storage procedure.

1. Clean the exterior surfaces of the engine. On

Electronic Fuel Injected (EFI) engines, avoid

spraying water at the wiring harness or any of the

electrical components.

2. Change the oil and oil filter while the engine is still

warm from operation. See “Change Oil and Oil

Filter” in Section 6.

3. The fuel system must be completely emptied, or

the gasoline must be treated with a stabilizer to

prevent deterioration. If you choose to use a

stabilizer, follow the manufacturer’s

recommendations, and add the correct amount

for the capacity of the fuel system.

Fill the fuel tank with clean, fresh gasoline. Run

the engine for 2 to 3 minutes to get stabilized fuel

into the rest of the system. Close the fuel shut-off

valve when the unit is being stored or transported.

To empty the system, run the engine until the tank

and the system are empty.

4. Remove the spark plugs and add one tablespoon

of engine oil into each spark plug hole. Install the

spark plugs, but do not connect the plug leads.

Crank the engine two or three revolutions.

5. On equipment with an EFI engine, disconnect the

battery or use a battery minder to keep the battery

charged during storage.

6. Store the engine in a clean, dry place.

• Replace fuel filter

1

(EFI engines). Section 5B

Daily or Before

Starting Engine

Maintenance Required Refer to: Frequency

• Fill fuel tank. Section 5

• Check oil level. Section 6

• Check air cleaner for dirty

1

, loose, or damaged parts. Section 4

• Check air intake and cooling areas, clean as necessary

1

. Section 4

• Service precleaner element

1

. Section 4 Every 25 Hours

• Replace air cleaner element

1

. Section 4

• Change oil. (More frequently under severe conditions.) Section 6

• Remove cooling shrouds and clean cooling areas

1,3

. Section 4

• Check oil cooler fins, clean as necessary (if equipped). Section 6

• Check spark plug condition and gap. Section 8

• Change oil filter. Section 6

Annually or

Every 500 Hours

• Have bendix starter drive serviced

2

. Section 8

• Have solenoid shift starter disassembled and cleaned

2

. Section 8

Every 100 Hours

Every 200 Hours

Every 1500 Hours

• Have crankshaft spline lubricated

2

. Section 2 Every 500 Hours

Every 250 Hours • Replace heavy-duty air cleaner element and check inner element

1

. Section 4

Kohler Engine Parts Call K&T 606-678-9623 or 606-561-4983

www.mymowerparts.com

1.6

Section 1

Safety and General Information

Figure 1-4. Typical Engine Dimensions CH Series with Standard Flat Air Cleaner.

Dimensions in millimeters.

Inch equivalents shown in ().

Kohler Engine Parts Call K&T 606-678-9623 or 606-561-4983

www.mymowerparts.com

1.7

Section 1

Safety and General Information

1

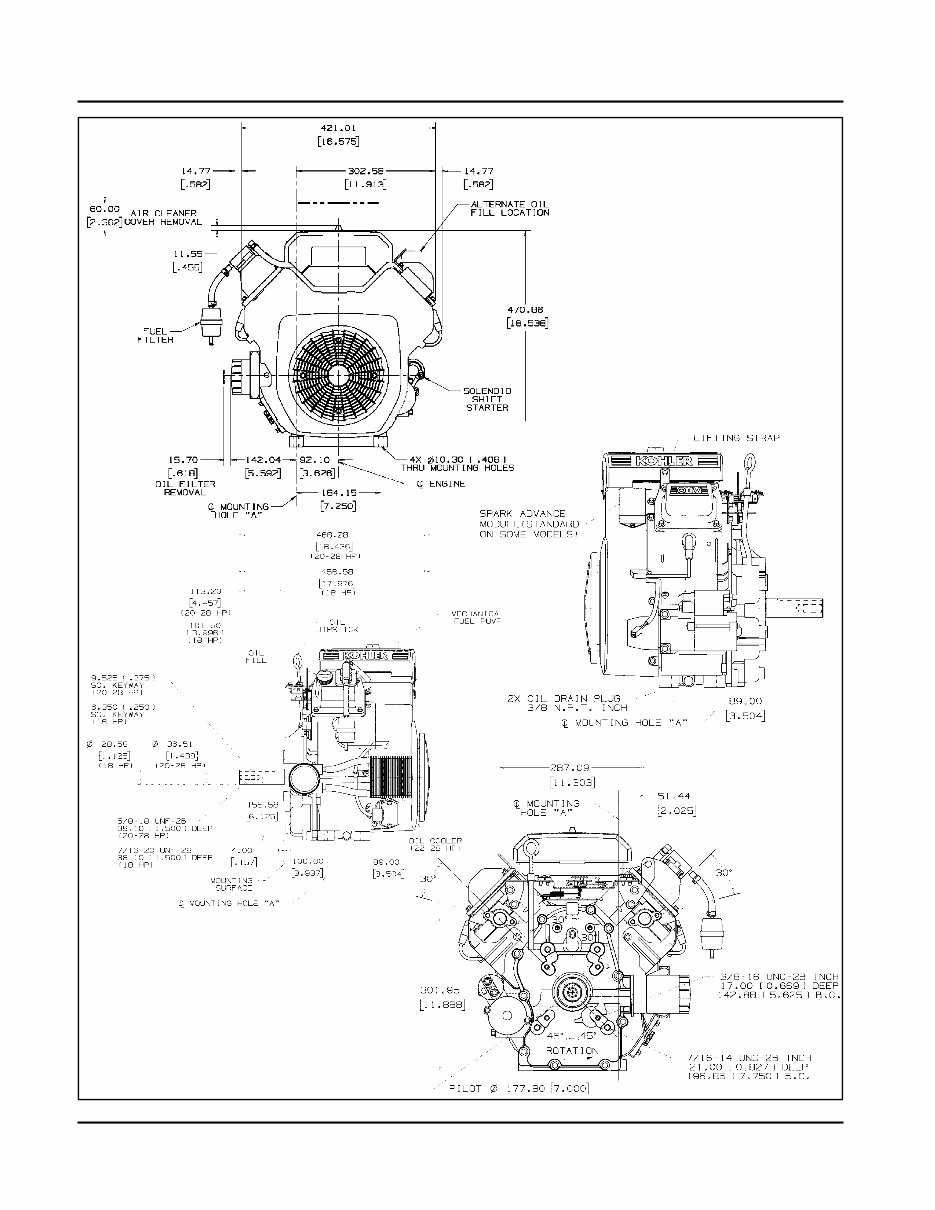

Figure 1-5. Typical Engine Dimensions CH EFI Series with Heavy-Duty Air Cleaner.

Dimensions in millimeters.

Inch equivalents shown in ().

Kohler Engine Parts Call K&T 606-678-9623 or 606-561-4983

www.mymowerparts.com

1.8

Section 1

Safety and General Information

General Specifications¹

Power (@ 3600 RPM, corrected to SAE J1995)

CH18 ............................................................................................................................ 13.4 kW (18 HP)

CH20 ............................................................................................................................ 14.9 kW (20 HP)

CH22/23 ....................................................................................................................... 16.4 kW (22 HP)

CH25, CH730 ............................................................................................................... 18.4 kW (25 HP)

CH26 ............................................................................................................................ 19.4 kW (26 HP)

CH740 .......................................................................................................................... 20.1 kW (27 HP)

CH745 .......................................................................................................................... 20.9 kW (28 HP)

Peak Torque

CH18 - @ 2200 RPM ................................................................................................... 44.4 N·m (32.8 ft. lb.)

CH20 - @ 2600 RPM ................................................................................................... 44.2 N·m (32.6 ft. lb.)

CH22/23 - @ 2200 RPM .............................................................................................. 51.7 N·m (38.2 ft. lb.)

CH25, CH730 - @ 2800 RPM ...................................................................................... 54.1 N·m (39.9 ft. lb.)

CH26 - @ 2800 RPM ................................................................................................... 54.2 N·m (40.0 ft. lb.)

CH740 - @ 3000 RPM ................................................................................................. 57.9 N·m (42.7 ft. lb.)

CH745 - @ 2200 RPM ................................................................................................. 60.7 N·m (44.8 ft. lb.)

Bore

CH18, CH20, CH22 (624 cc) ........................................................................................ 77 mm (3.03 in.)

CH22/23 (674 cc) ......................................................................................................... 80 mm (3.15 in.)

CH25, CH26, CH730-745 ............................................................................................. 83 mm (3.27 in.)

Stroke ................................................................................................................................. 67 mm (2.64 in.)

Displacement

CH18, CH20, CH22 (624 cc) ........................................................................................ 624 cc (38 cu. in.)

CH22/23 (674 cc) ......................................................................................................... 674 cc (41 cu. in.)

CH25, CH26, CH730-745 ............................................................................................. 725 cc (44 cu. in.)

Compression Ratio

CH18, CH20, CH22/23 ................................................................................................. 8.5:1

CH25, CH26, CH730-745 ............................................................................................. 9.0:1

Dry Weight

CH18, CH20, CH22/23 ................................................................................................. 41 kg (90 lb.)

CH25, CH26, CH730-745 ............................................................................................. 43 kg (94 lb.)

Oil Capacity (with filter)

CH18, CH20, CH22/23, CH25, CH26, CH730-745 ...................................................... 1.9 L (2.0 U.S. qt.)

Angle of Operation - Maximum (At Full Oil Level) All Directions ......................................... 25°

Blower Housing and Sheet Metal

M5 Fasteners Torque .......................................................................................................... 4.0 N·m (35 in. lb.)

M6 Fasteners Torque .......................................................................................................... 6.8 N·m (60 in. lb.)

Rectifier-Regulator Fastener Torque ................................................................................... 4.0 N·m (35 in. lb.)

¹Values are in Metric units. Values in parentheses are English equivalents. Lubricate threads with engine oil prior

to assembly.

Kohler Engine Parts Call K&T 606-678-9623 or 606-561-4983

www.mymowerparts.com

1.9

Section 1

Safety and General Information

1

Camshaft

End Play (With Shim) .................................................................................. 0.076/0.127 mm (0.0030/0.0050 in.)

Running Clearance ...................................................................................... 0.025/0.063 mm (0.0010/0.0025 in.)

Bore I.D.

New ....................................................................................................... 20.000/20.025 mm (0.7874/0.7884 in.)

Max. Wear Limit .................................................................................... 20.038 mm (0.7889 in.)

Camshaft Bearing Surface O.D.

New ....................................................................................................... 19.962/19.975 mm (0.7859/0.7864 in.)

Max. Wear Limit .................................................................................... 19.959 mm (0.7858 in.)

Carburetor and Intake Manifold

Intake Manifold Mounting Fastener Torque

Torque in Two Stages ............................................................................ initially to 7.4 N·m (66 in. lb.)

finally to 9.9 N·m (88 in. lb.)

Carburetor Mounting Screw Torque M6 ....................................................... 6.2-7.3 N·m (55-65 in. lb.)

Adapter (for Heavy Duty Air Cleaner) Mounting Fastener Torque ................ 7.3 N·m (65 in. lb.)

Connecting Rod

Cap Fastener Torque (torque in increments)

8 mm straight shank .............................................................................. 22.7 N·m (200 in. lb.)

8 mm step-down ................................................................................... 14.7 N·m (130 in. lb.)

6 mm straight shank .............................................................................. 11.3 N·m (100 in. lb.)

Connecting Rod-to-Crankpin Running Clearance

New ....................................................................................................... 0.030/0.055 mm (0.0012/0.0022 in.)

Max. Wear Limit .................................................................................... 0.070 mm (0.0028 in.)

Connecting Rod-to-Crankpin Side Clearance .............................................. 0.26/0.63 mm (0.0102/0.0248 in.)

Connecting Rod-to-Piston Pin Running Clearance ...................................... 0.015/0.028 mm (0.0006/0.0011 in.)

Piston Pin End I.D.

New ....................................................................................................... 17.015/17.023 mm (0.6699/0.6702 in.)

Max. Wear Limit .................................................................................... 17.036 mm (0.6707 in.)

Crankcase

Governor Cross Shaft Bore I.D.

6 mm Shaft

New ................................................................................................... 6.025/6.050 mm (0.2372/0.2382 in.)

Max. Wear Limit ................................................................................. 6.063 mm (0.2387 in.)

8 mm Shaft

New ................................................................................................... 8.025/8.075 mm (0.3159/0.3179 in.)

Max. Wear Limit ................................................................................. 8.088 mm (0.3184 in.)

Breather Cover Fastener Torque ................................................................. 7.3 N·m (65 in. lb.)

Oil Drain Plug Torque ................................................................................... 13.6 N·m (10 ft. lb.)

Kohler Engine Parts Call K&T 606-678-9623 or 606-561-4983

www.mymowerparts.com

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 41 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get instant access to the Complete Factory Service Repair Workshop Manual without any extra fees or expiry dates. This Professional Manual is suitable for both professional Mechanics and DIY enthusiasts, covering all repairs, servicing, and troubleshooting procedures with step-by-step instructions, detailed photos, diagrams, and highly detailed exploded diagrams & pictures.

Print out a single page or the entire manual as per your choice. The Manual can be used on multiple computers without any limitations or trial periods and can be used for life without the need to renew or pay any extra. It is fully compatible with all Windows & MAC Computers.

Click the button to get your hands on this comprehensive manual.