KOHLER COMMand CH25 CH730 CH26 Full Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

CH18-CH25, CH620-CH730, CH740, CH750

Service Manual

2 Safety

3 Maintenance

5 Specifications

15 Tools and Aids

18 Troubleshooting

22 Air Cleaner/Intake

23 Fuel System

29 Governor System

31 Lubrication System

33 Electrical System

49 Starter System

58 Clutch

60 Disassembly/Inspection and Service

75 Reassembly

IMPORTANT: Read all safety precautions and instructions carefully before operating equipment. Refer to operating

instruction of equipment that this engine powers.

Ensure engine is stopped and level before performing any maintenance or service.

1 24 690 06 Rev. J KohlerEngines.com

Safety

2 24 690 06 Rev. J KohlerEngines.com

SAFETY PRECAUTIONS

WARNING: A hazard that could result in death, serious injury, or substantial property damage.

CAUTION: A hazard that could result in minor personal injury or property damage.

NOTE: is used to notify people of important installation, operation, or maintenance information.

WARNING

Explosive Fuel can cause

fires and severe burns.

Do not fill fuel tank while

engine is hot or running.

Gasoline is extremely flammable

and its vapors can explode if

ignited. Store gasoline only in

approved containers, in well

ventilated, unoccupied buildings,

away from sparks or flames.

Spilled fuel could ignite if it comes

in contact with hot parts or sparks

from ignition. Never use gasoline

as a cleaning agent.

WARNING

Rotating Parts can cause

severe injury.

Stay away while engine

is in operation.

Keep hands, feet, hair, and

clothing away from all moving

parts to prevent injury. Never

operate engine with covers,

shrouds, or guards removed.

WARNING

Carbon Monoxide can

cause severe nausea,

fainting or death.

Avoid inhaling exhaust

fumes.

Engine exhaust gases contain

poisonous carbon monoxide.

Carbon monoxide is odorless,

colorless, and can cause death if

inhaled.

WARNING

Accidental Starts can

cause severe injury or

death.

Disconnect and ground

spark plug lead(s) before

servicing.

Before working on engine or

equipment, disable engine as

follows: 1) Disconnect spark plug

lead(s). 2) Disconnect negative (–)

battery cable from battery.

WARNING

Hot Parts can cause

severe burns.

Do not touch engine

while operating or just

after stopping.

Never operate engine with heat

shields or guards removed.

WARNING

Cleaning Solvents can

cause severe injury or

death.

Use only in well

ventilated areas away

from ignition sources.

Carburetor cleaners and solvents

are extremely flammable. Follow

cleaner manufacturer’s warnings

and instructions on its proper and

safe use. Never use gasoline as a

cleaning agent.

CAUTION

Electrical Shock can

cause injury.

Do not touch wires while

engine is running.

CAUTION

Damaging Crankshaft

and Flywheel can cause

personal injury.

Using improper procedures can

lead to broken fragments. Broken

fragments could be thrown from

engine. Always observe and use

precautions and procedures when

installing flywheel.

CAUTION

Failure to utilize or

reassemble debris

screen as designed could

result in debris screen

failure and serious

personal injury.

WARNING

Uncoiling Spring can

cause severe injury.

Wear safety goggles or

face protection when

servicing retractable

starter.

Retractable starters contain a

powerful, recoil spring that is

under tension. Always wear safety

goggles when servicing retractable

starters and carefully follow

instructions in Retractable Starter

for relieving spring tension.

Maintenance

3 24 690 06 Rev. J KohlerEngines.com

MAINTENANCE INSTRUCTIONS

WARNING

Before working on engine or equipment, disable engine as

follows: 1) Disconnect spark plug lead(s). 2) Disconnect

negative (–) battery cable from battery.

Accidental Starts can cause severe injury or

death.

Disconnect and ground spark plug lead(s)

before servicing.

Normal maintenance, replacement or repair of emission control devices and systems may be performed by any repair

establishment or individual; however, warranty repairs must be performed by a Kohler authorized dealer.

MAINTENANCE SCHEDULE

Weekly

● Check heavy-duty air cleaner element. Air Cleaner/Intake

Every 25 Hours or Annually¹

● Service/replace low-profile precleaner. Air Cleaner/Intake

Every 100 Hours or Annually¹

● Replace low-profile air cleaner element. Air Cleaner/Intake

● Change oil. Lubrication System/Clutch

● Remove cooling shrouds and clean cooling areas. Air Cleaner/Intake

● Check oil cooler fins, clean as necessary (if equipped). Lubrication System

Every 200 Hours

● Change oil filter. Lubrication System

● Replace fuel filter.

Every 250 Hours¹

● Replace heavy-duty air cleaner element and check inner element. Air Cleaner/Intake

Every 500 Hours¹

● Replace heavy-duty inner air cleaner element. Air Cleaner/Intake

● Replace spark plugs and set gap. Electrical System

Every 500 Hours

2

● Have crankshaft spline lubricated.

1

Perform these procedures more frequently under severe, dusty, dirty conditions.

2

Have a Kohler authorized dealer perform this service.

REPAIRS/SERVICE PARTS

Kohler genuine service parts can be purchased from Kohler authorized dealers. To find a local Kohler authorized

dealer visit KohlerEngines.com or call 1-800-544-2444 (U.S. and Canada).

Maintenance

4 24 690 06 Rev. J KohlerEngines.com

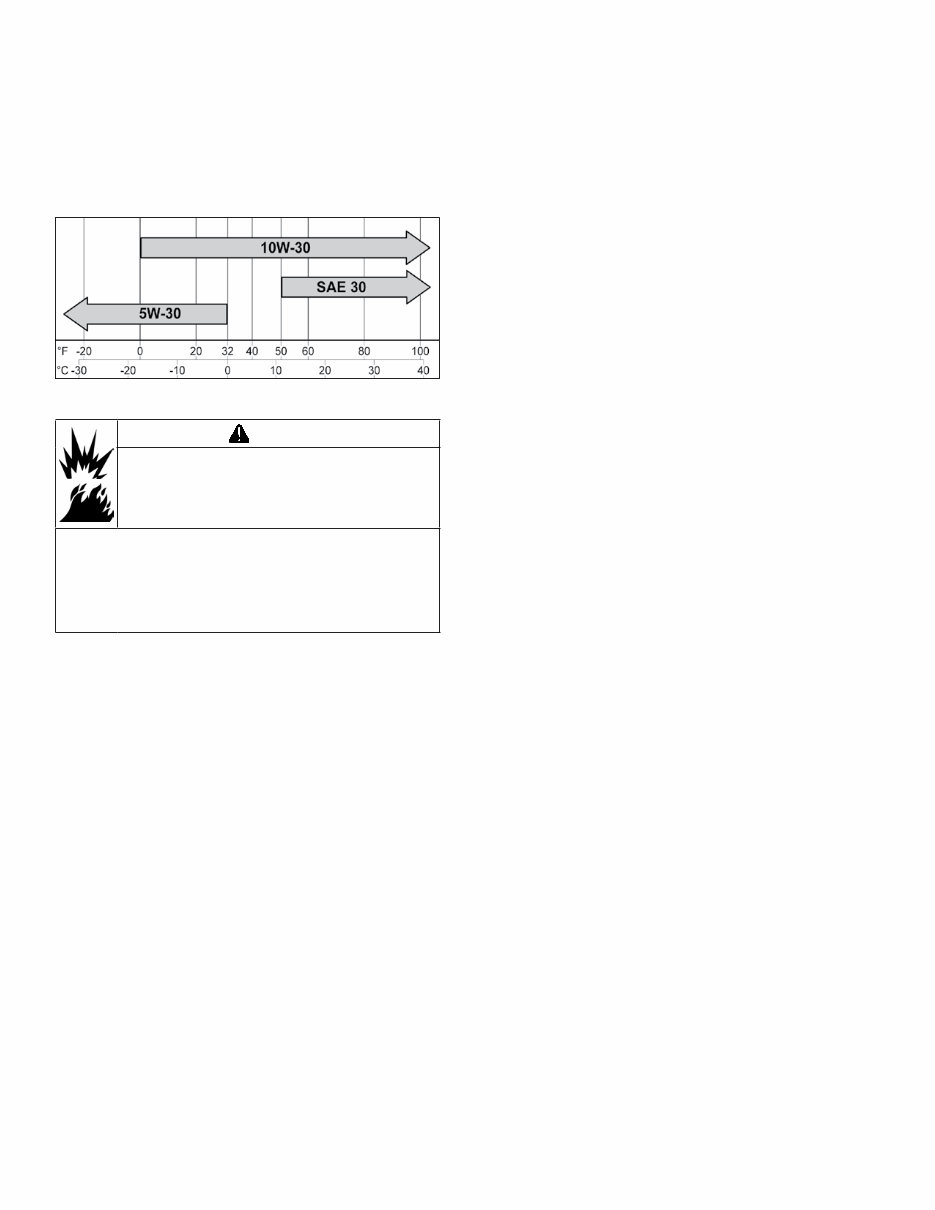

OIL RECOMMENDATIONS

We recommend use of Kohler oils for best performance.

Other high-quality detergent oils (including synthetic)

of API (American Petroleum Institute) service class SJ

or higher are acceptable. Select viscosity based on

air temperature at time of operation as shown in table

below.

FUEL RECOMMENDATIONS

WARNING

Explosive Fuel can cause fires and severe

burns.

Do not fill fuel tank while engine is hot or

running.

Gasoline is extremely flammable and its vapors can

explode if ignited. Store gasoline only in approved

containers, in well ventilated, unoccupied buildings,

away from sparks or flames. Spilled fuel could ignite

if it comes in contact with hot parts or sparks from

ignition. Never use gasoline as a cleaning agent.

NOTE: E15, E20 and E85 are NOT approved and

should NOT be used; effects of old, stale or

contaminated fuel are not warrantable.

Fuel must meet these requirements:

● Clean, fresh, unleaded gasoline.

● Octane rating of 87 (R+M)/2 or higher.

● Research Octane Number (RON) 90 octane minimum.

● Gasoline up to 10% ethyl alcohol, 90% unleaded is

acceptable.

● Methyl Tertiary Butyl Ether (MTBE) and unleaded

gasoline blend (max 15% MTBE by volume) are

approved.

● Do not add oil to gasoline.

● Do not overfill fuel tank.

● Do not use gasoline older than 30 days.

STORAGE

If engine will be out of service for 2 months or more

follow procedure below.

1. Add Kohler PRO Series fuel treatment or equivalent

to fuel tank. Run engine 2-3 minutes to get stabilized

fuel into fuel system (failures due to untreated fuel

are not warrantable).

2. Change oil while engine is still warm from operation.

Remove spark plug(s) and pour about 1 oz. of

engine oil into cylinder(s). Replace spark plug(s) and

crank engine slowly to distribute oil.

3. Disconnect negative (-) battery cable.

4. Store engine in a clean, dry place.

Specifications

5 24 690 06 Rev. J KohlerEngines.com

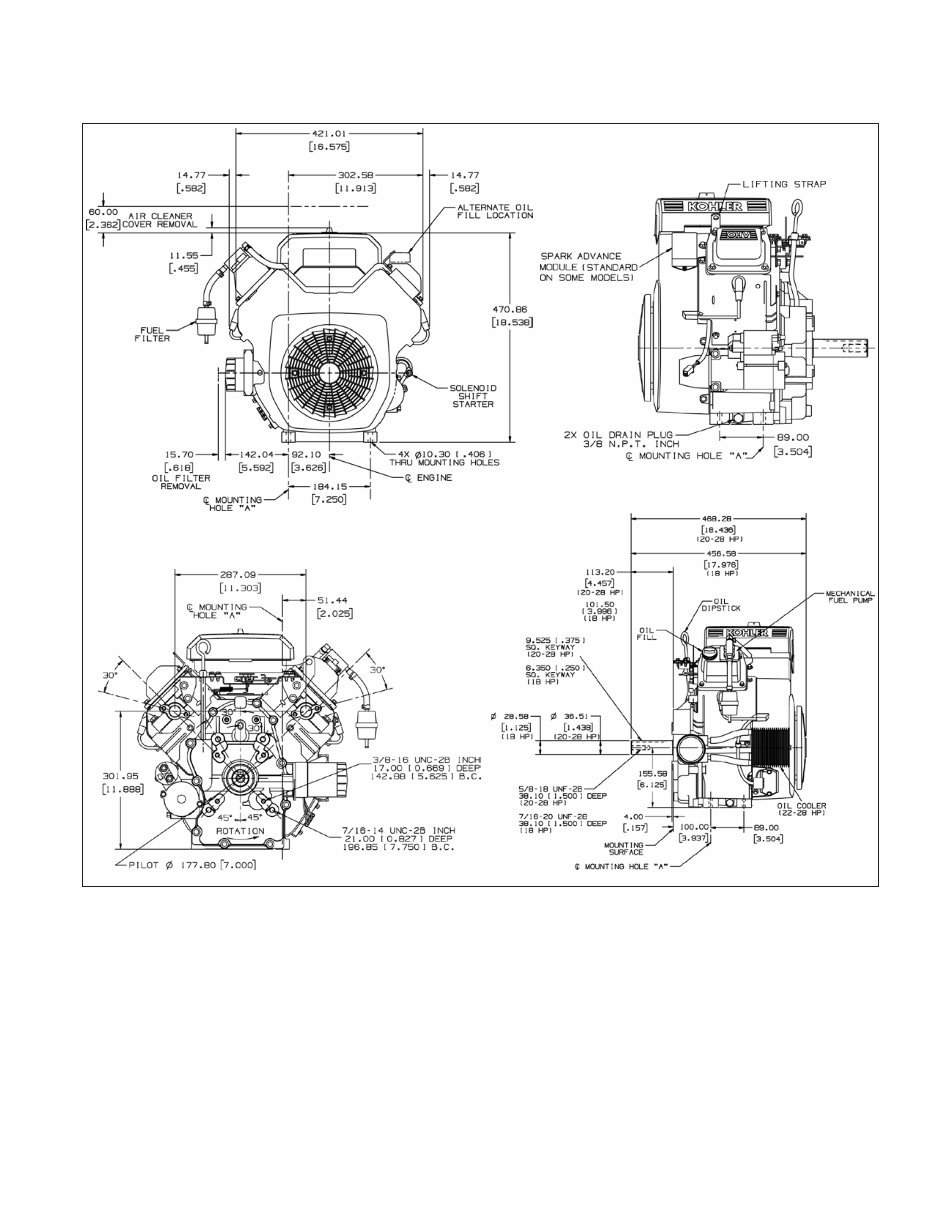

Engine Dimensions with Low-Profile Air Cleaner

Dimensions in millimeters.

Inch equivalents shown in [ ].

Specifications

6 24 690 06 Rev. J KohlerEngines.com

SOLENOID

SHIFT STARTER

15.58

[.613]

SPARK PLUG

526.49

[20.728]

PRIMARY AIR FILTER

ELEMENT REMOVAL

414.17

[16.306]

SAFETY AIR FILTER

ELEMENT REMOVAL

130.00

[5.118]

AIR FILTER COVER

ASSEMBLY REMOVAL

272.17

[10.715]

304.48

[11.987]

424.61

[16.717]

135.00

[5.315]

AIR FILTER RAIN

CAP REMOVAL

93.33

[3.674]

OIL FILL

LOCATION

PULSE

FUEL PUMP

CRANKSHAFT

15.70

[.618]

OIL FILTER

REMOVAL

124.34

[4.895]

184.20

[7.252]

92.10

[3.626]

CRANKSHAFT

MOUNTING

HOLE “A”

ENGINE

3/8-16 UNC 2B

19.05 [.750]

1/4 IN. SQ KEYWAY 54.00

[2.126]

115.74

[4.557]

42.26

[1.664]

OIL DIPSTICK

626.92

[24.682]

1/4 IN. SQ KEYWAY

Ø 25.56

[1.125]

7/16-20 UNF 2B (INCH)

38.10 (1.500)

70.52

[2.776]

155.58

[6.125]

100.00

[3.937]

89.00

[3.504]

ENGINE

MOUNTING

SURFACE

514.05

[20.238]

ENGINE MOUNTING SURFACE

7/16-14 UNC 2B (INCH)

21.0 [.827]

Ø 196.85 [7.75]B.C.

3/8-16 UNC 2B (INCH)

17.0 [.669]

Ø 165.1 [6.50]B.C.

LIFT STRAP

285.90

[11.256]

50.85

[2.002]

30˚

30˚

301.36

[11.864]

2X OIL DRAIN PLUG

3/8 NPT (INCH)

MOUNTING HOLE “A”

440.88

[17.357]

LIFT STRAP

89.00

[3.504]

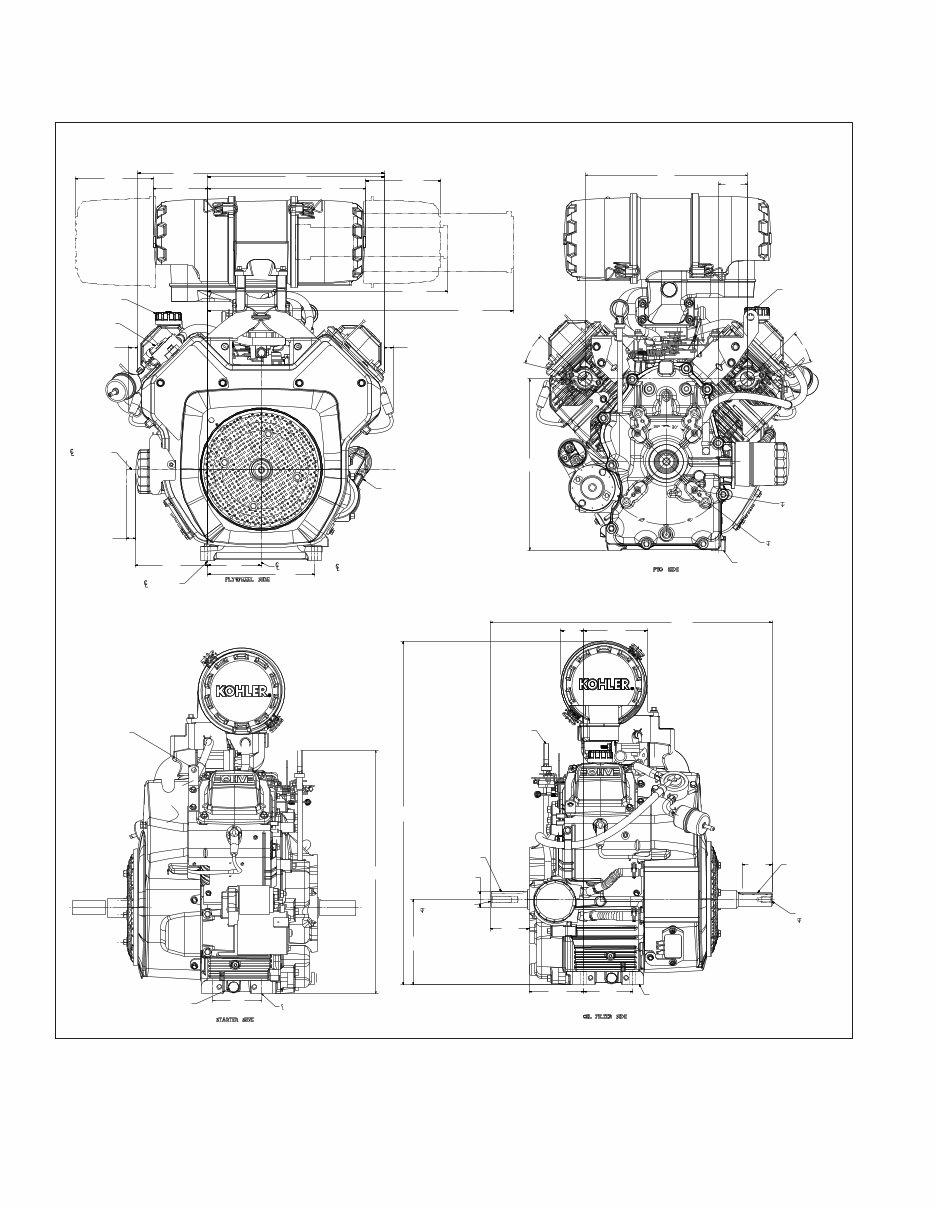

Engine Dimensions with Heavy-Duty Air Cleaner

Dimensions in millimeters.

Inch equivalents shown in [ ].

Specifications

7 24 690 06 Rev. J KohlerEngines.com

ENGINE IDENTIFICATION NUMBERS

Kohler engine identification numbers (model, specification and serial) should be referenced for efficient repair,

ordering correct parts, and engine replacement.

Model ..................... CH620

Command Engine

Horizontal Shaft

Numerical Designation

Specification ............... CH620-0001

Serial ..................... 4323500328

Year Manufactured Code Factory Code

Code Year

43 2013

44 2014

45 2015

GENERAL SPECIFICATIONS

3,6

CH18/CH20/

CH22/

CH620/CH621/

CH640/CH641

CH22/CH23/

CH620

7

/

CH640

7

/

CH670/CH680

CH25/

CH730/

CH740

CH750

Bore 77 mm

(3.03 in.)

80 mm

(3.15 in.)

83 mm (3.27 in.)

Stroke 67 mm (2.64 in.) 69 mm

(2.7 in.)

Displacement 624 cc

(38 cu. in.)

674 cc

(41 cu. in.)

725 cc

(44 cu. in.)

747 cc

(46 cu. in.)

Oil Capacity (refill) 1.6-1.8 L (1.7-1.9 U.S. qt.)

Maximum Angle of Operation (@ full oil level)

4

25°

TORQUE SPECIFICATIONS

3,5

CH18/CH20/

CH22/

CH620/CH621/

CH640/CH641

CH22/CH23/

CH620/

CH640/

CH670/CH680

CH25/

CH730/

CH740

CH750

Blower Housing and Sheet Metal

M5 Fasteners 6.2 N·m (55 in. lb.) into new holes

4.0 N·m (35 in. lb.) into used holes

M6 Fasteners 10.7 N·m (95 in. lb.) into new holes

7.3 N·m (65 in. lb.) into used holes

Carburetor and Intake Manifold

Intake Manifold Mounting Fastener (torque in 2

increments)

first to 7.4 N·m (66 in. lb.)

finally to 9.9 N·m (88 in. lb.)

M6 Mounting Screw 6.2-7.3 N·m (55-65 in. lb.)

Adapter (for Heavy-Duty Air Cleaner) Mounting

Fastener

7.3 N·m (65 in. lb.)

Closure Plate

Fastener 24.4 N·m (216 in. lb.)

3

Values are in Metric units. Values in parentheses are English equivalents.

4

Exceeding maximum angle of operation may cause engine damage from insufficient lubrication.

5

Lubricate threads with engine oil prior to assembly.

6

Any and all horsepower (hp) references by Kohler are Certified Power Ratings and per SAE J1940 & J1995 hp

standards. Details on Certified Power Ratings can be found at KohlerEngines.com.

7

CH620/CH640 engines changed from 624cc to 674cc; displacement can be confirmed on engine nameplate.

Specifications

8 24 690 06 Rev. J KohlerEngines.com

TORQUE SPECIFICATIONS

3,5

CH18/CH20/

CH22/

CH620/CH621/

CH640/CH641

CH22/CH23/

CH620/

CH640/

CH670/CH680

CH25/

CH730/

CH740

CH750

Connecting Rod

Cap Fastener (torque in increments)

8 mm straight shank

8 mm step-down

6 mm straight shank

22.7 N·m (200 in. lb.)

14.7 N·m (130 in. lb.)

11.3 N·m (100 in. lb.)

Crankcase

Breather Cover Fastener 7.3 N·m (65 in. lb.)

Oil Drain Plug 13.6 N·m (10 ft. lb.)

Cylinder Head

Fastener (torque in 2 increments)

Nut first to 16.9 N·m (150 in. lb.)

finally to 35.5 N·m (315 in. lb.)

Bolt (torque in 2 increments) first to 22.6 N·m (200 in. lb.)

finally to 41.8 N·m (370 in. lb.)

Rocker Arm Screw 18.1 N·m (160 in. lb.)

Flywheel

Fan Fastener 9.9 N·m (88 in. lb.)

Flywheel Retaining Screw 66.4 N·m (49 ft. lb.)

Fuel Pump-Pulse

Fastener 2.3 N·m (20 in. lb.)

Governor

Lever Nut 6.8 N·m (60 in. lb.)

Ignition

Spark Plug 27 N·m (20 ft. lb.)

Module Fastener 4.0-6.2 N·m (35-55 in. lb.)

Rectifier-Regulator Fastener 1.4 N·m (12.6 in. lb.)

Muffler

Retaining Nut 24.4 N·m (216 in. lb.)

Oil Cooler

Adapter Nipple 27 N·m (20 ft. lb.)

Oil Sentry

™

Pressure Switch 4.5 N·m (40 in. lb.)

Solenoid (Starter)

Mounting Hardware

Nippondenso Starter

Delco-Remy Starter

6.0-9.0 N·m (53-79 in. lb.)

4.0-6.0 N·m (35-53 in. lb.)

Nut, Positive (+) Brush Lead

Nippondenso Starter

Delco-Remy Starter

8.0-12.0 N·m (71-106 in. lb.)

8.0-11.0 N·m (71-97 in. lb.)

3

Values are in Metric units. Values in parentheses are English equivalents.

5

Lubricate threads with engine oil prior to assembly.

Specifications

9 24 690 06 Rev. J KohlerEngines.com

TORQUE SPECIFICATIONS

3,5

CH18/CH20/

CH22/

CH620/CH621/

CH640/CH641

CH22/CH23/

CH620/

CH640/

CH670/CH680

CH25/

CH730/

CH740

CH750

Speed Control Bracket

Fastener 10.7 N·m (95 in. lb.) into new holes

7.3 N·m (65 in. lb.) into used holes

Starter Assembly

Thru Bolt

Inertia Drive

Nippondenso Solenoid Shift

Delco-Remy Solenoid Shift

4.5-5.7 N·m (40-50 in. lb.)

4.5-7.5 N·m (40-84 in. lb.)

5.6-9.0 N·m (49-79 in. lb.)

Mounting Screw 15.3 N·m (135 in. lb.)

Brush Holder Mounting Screw 2.5-3.3 N·m (22-29 in. lb.)

Stator

Mounting Screw 6.2 N·m (55 in. lb.)

Valve Cover

Gasket Style Cover Fastener 3.4 N·m (30 in. lb.)

Black O-Ring Style Cover Fastener

w/Shoulder Screws

w/Flange Screws and Spacers

5.6 N·m (50 in. lb.)

9.9 N·m (88 in. lb.)

Yellow or Brown O-Ring Style Cover Fastener

w/Integral Metal Spacers 6.2 N·m (55 in. lb.)

CLEARANCE SPECIFICATIONS

3

CH18/CH20/

CH22/

CH620/CH621/

CH640/CH641

CH22/CH23/

CH620/

CH640/

CH670/CH680

CH25/

CH730/

CH740

CH750

Camshaft

End Play (w/shim) 0.076/0.127 mm (0.0030/0.0050 in.)

Running Clearance 0.025/0.063 mm (0.0010/0.0025 in.)

Bore I.D.

New

Max. Wear Limit

20.000/20.025 mm (0.7874/0.7884 in.)

20.038 mm (0.7889 in.)

Bearing Surface O.D.

New

Max. Wear Limit

19.962/19.975 mm (0.7859/0.7864 in.)

19.959 mm (0.7858 in.)

Connecting Rod

Connecting Rod-to-Crankpin Running Clearance

New

Max. Wear Limit

0.030/0.055 mm (0.0012/0.0022 in.)

0.070 mm (0.0028 in.)

Connecting Rod-to-Crankpin Side Clearance 0.26/0.63 mm (0.0102/0.0248 in.)

Connecting Rod-to-Piston Pin Running Clearance 0.015/0.028 mm (0.0006/0.0011 in.)

Piston Pin End I.D.

New

Max. Wear Limit

17.015/17.023 mm (0.6699/0.6702 in.)

17.036 mm (0.6707 in.)

3

Values are in Metric units. Values in parentheses are English equivalents.

5

Lubricate threads with engine oil prior to assembly.

Specifications

10 24 690 06 Rev. J KohlerEngines.com

CLEARANCE SPECIFICATIONS

3

CH18/CH20/

CH22/

CH620/CH621/

CH640/CH641

CH22/CH23/

CH620/

CH640/

CH670/CH680

CH25/

CH730/

CH740

CH750

Crankcase

Governor Cross Shaft Bore I.D.

6 mm Shaft

New

Max. Wear Limit

8 mm Shaft

New

Max. Wear Limit

6.025/6.050 mm (0.2372/0.2382 in.)

6.063 mm (0.2387 in.)

8.025/8.075 mm (0.3159/0.3179 in.)

8.088 mm (0.3184 in.)

Crankshaft

End Play (free) 0.070/0.590 mm (0.0028/0.0230 in.)

End Play (w/thrust bearing components) 0.070/1.190 mm (0.0028/0.0468 in.)

Except CH25 Engines Below Serial No. 2403500008 0.050/0.750 mm (0.0020/0.0295 in.)

Bore (in crankcase)

New

Max. Wear Limit

40.965/41.003 mm (1.6128/1.6143 in.)

41.016 mm (1.6148 in.)

Crankshaft to Sleeve Bearing (crankcase)

Running Clearance-New 0.03/0.09 mm (0.0012/0.0035 in.)

Bore (in closure plate)

New 40.987/40.974 mm (1.6136/1.6131 in.)

Crankshaft Bore (in closure plate)-to-Crankshaft

Running Clearance-New 0.039/0.074 mm (0.0015/0.0029 in.)

Flywheel End Main Bearing Journal

O.D. - New

O.D. - Max. Wear Limit

Max. Taper

Max. Out-of-Round

40.913/40.935 mm (1.6107/1.6116 in.)

40.84 mm (1.608 in.)

0.022 mm (0.0009 in.)

0.025 mm (0.0010 in.)

Closure Plate End Main Bearing Journal

O.D. - New

O.D. - Max. Wear Limit

Max. Taper

Max. Out-of-Round

40.913/40.935 mm (1.6107/1.6116 in.)

40.84 mm (1.608 in.)

0.022 mm (0.0009 in.)

0.025 mm (0.0010 in.)

Connecting Rod Journal

O.D. - New

O.D. - Max. Wear Limit

Max. Taper

Max. Out-of-Round

35.955/35.973 mm (1.4156/1.4163 in.)

35.94 mm (1.415 in.)

0.018 mm (0.0007 in.)

0.025 mm (0.0010 in.)

T.I.R.

PTO End, Crank in Engine

Entire Crank, in V-Blocks

0.279 mm (0.0110 in.)

0.10 mm (0.0039 in.)

Cylinder Bore

Bore I.D.

New 77.000/

77.025 mm

(3.0315/

3.0325 in.)

80.000/

80.025 mm

(3.1496/

3.1506 in.)

82.988/83.013 mm

(3.2672/3.2682 in.)

Max. Wear Limit 77.063 mm

(3.0340 in.)

80.065 mm

(3.1522 in.)

83.051 mm

(3.2697 in.)

Max. Out-of-Round 0.12 mm (0.0047 in.)

Max. Taper 0.05 mm (0.0020 in.)

Cylinder Head

Max. Out-of-Flatness 0.076 mm (0.003 in.) 0.1 mm (0.004 in.)

3

Values are in Metric units. Values in parentheses are English equivalents.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 30 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get instant access to the Complete Factory Service Repair Workshop Manual without any extra fees or expiry dates. This Professional Manual is suitable for both professional Mechanics and DIY enthusiasts, covering all repairs, servicing, and troubleshooting procedures with step-by-step instructions, detailed photos, diagrams, and highly detailed exploded diagrams & pictures.

Print out a single page or the entire manual as per your choice. The Manual can be used on multiple computers without any limitations or trial periods and can be used for life without the need to renew or pay any extra. It is fully compatible with all Windows & MAC Computers.

Click the button to get your hands on this comprehensive manual.