ISUZU Petrol Engine 6VD1 3.2 Workshop Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

6A–1 ENGINE MECHANICAL (6VD1 3.2L)

RODEO

ENGINE

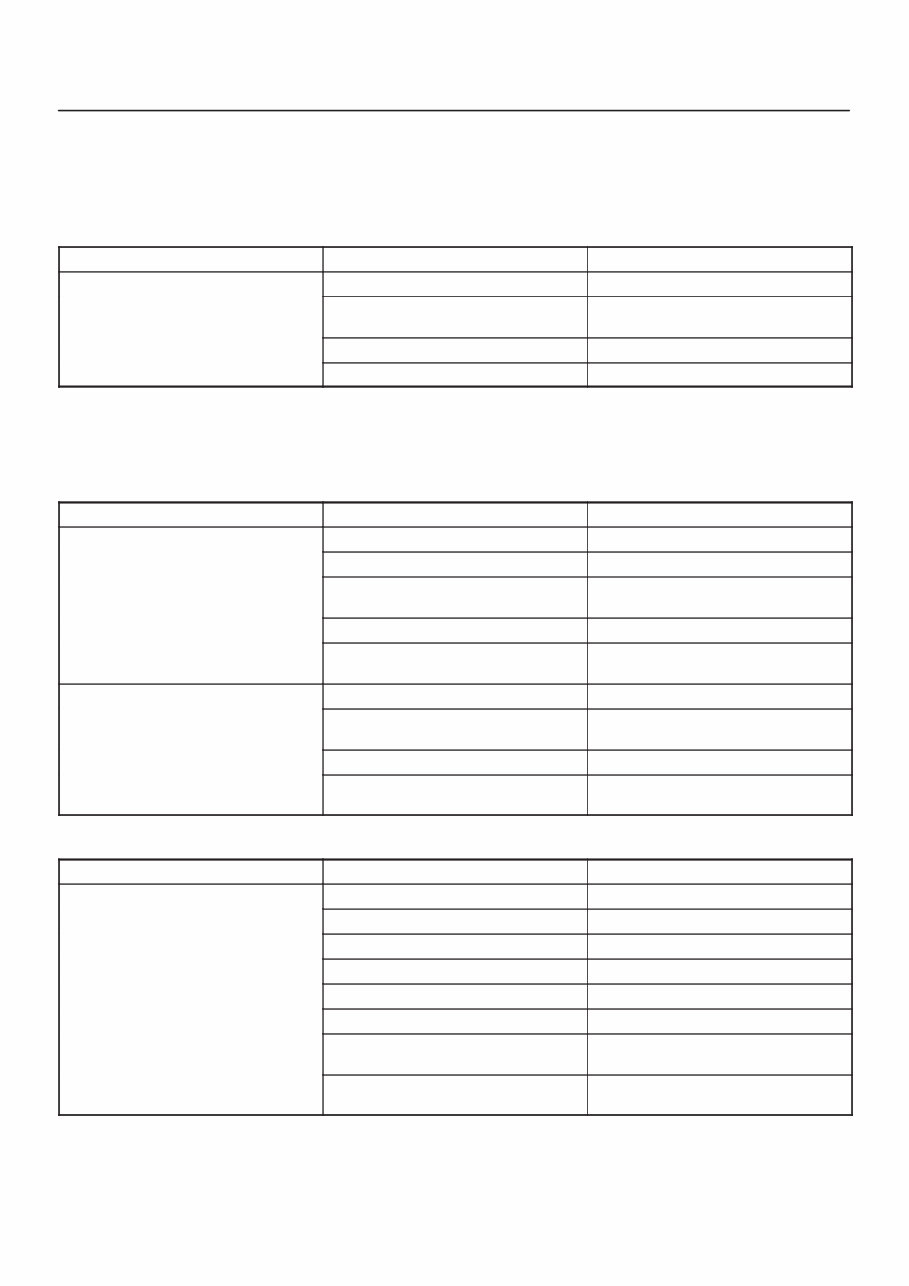

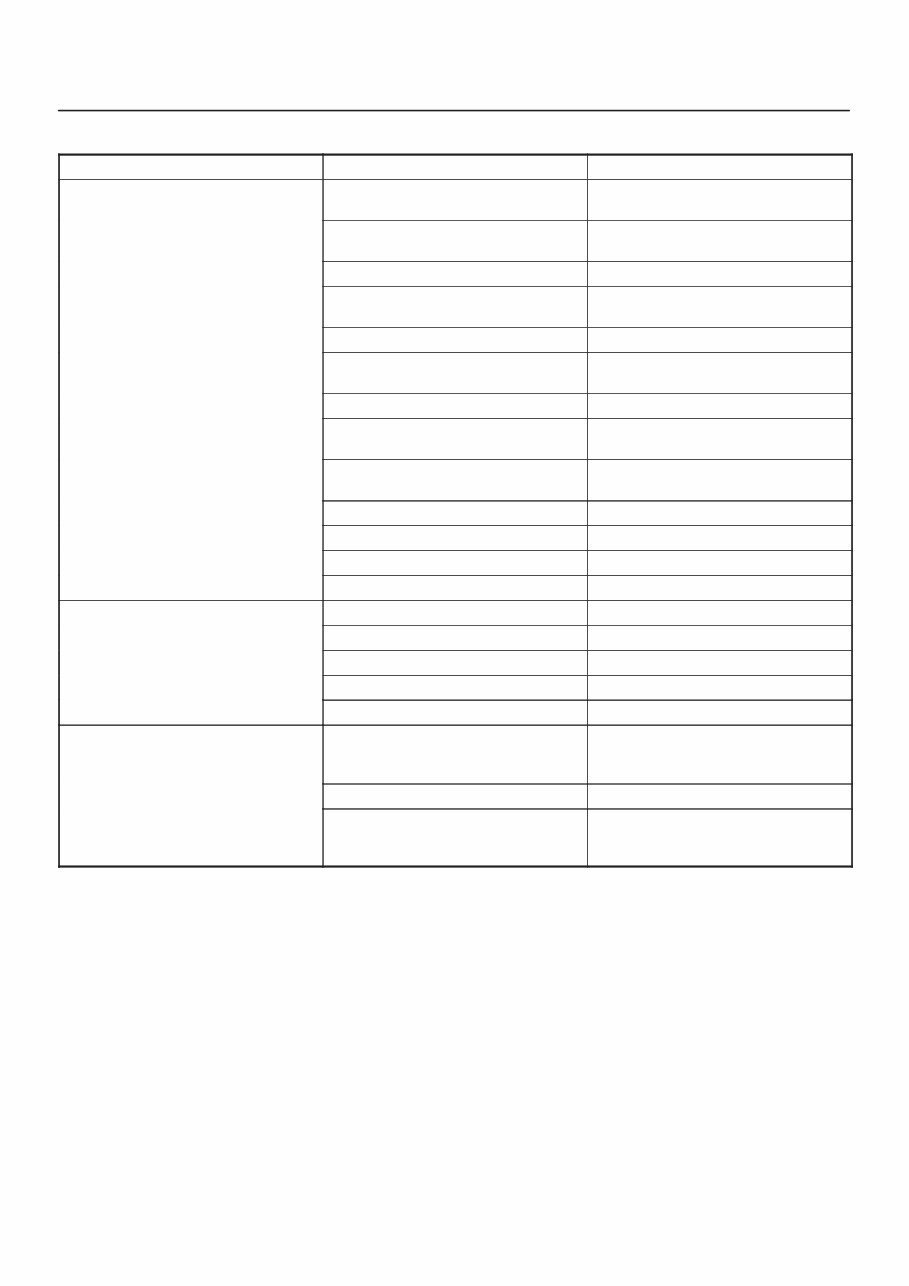

CONTENTS

Engine Mechanical 6A–1 . . . . . . . . . . . . . . . . . . . . . .

Engine Cooling 6B–1 . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Fuel 6C–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Electrical 6D1–1 . . . . . . . . . . . . . . . . . . . . . . . .

Ignition System 6D2–1 . . . . . . . . . . . . . . . . . . . . . . . . .

Starting and Charging System 6D3–1 . . . . . . . . . . . .

Driveability and Emissions 6E1–1 . . . . . . . . . . . . . . . .

Engine Exhaust 6F–1 . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Lubrication 6G–1 . . . . . . . . . . . . . . . . . . . . . .

Engine Speed Control System 6H–1 . . . . . . . . . . . .

Induction 6J–1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE MECHANICAL (6VD1 3.2L)

CONTENTS

Service Precaution 6A–2 . . . . . . . . . . . . . . . . . . . . . .

General Description 6A–3 . . . . . . . . . . . . . . . . . . . . .

Engine Diagnosis 6A–4 . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head Cover LH 6A–19 . . . . . . . . . . . . . . . . .

Removal 6A–19 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–20 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head Cover RH 6A–21 . . . . . . . . . . . . . . . . .

Removal 6A–21 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–21 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Common Chamber 6A–22 . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–22 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–22 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Manifold LH 6A–24 . . . . . . . . . . . . . . . . . . . . .

Removal 6A–24 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–24 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Manifold RH 6A–25 . . . . . . . . . . . . . . . . . . . .

Removal 6A–25 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–25 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft Pulley 6A–26 . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–26 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–26 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Timing Belt 6A–27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–27 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–28 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft 6A–32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–32 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–33 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head 6A–36 . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–36 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–36 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Stem Oil Controller , Valve Spring and

Valve Guide 6A–38 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–38 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–38 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piston, Piston Ring and Connecting Rod 6A–39 . . .

Removal 6A–39 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–40 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft and Main Bearings 6A–41 . . . . . . . . . . . .

Removal 6A–41 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–42 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rear Oil Seal 6A–46 . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–46 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–46 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Assembly 6A–47 . . . . . . . . . . . . . . . . . . . . . . . .

Removal 6A–47 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 6A–47 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head 6A–51 . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head and Associated Parts 6A–51 . . . . .

Disassembly 6A–51 . . . . . . . . . . . . . . . . . . . . . . . . . .

Clean 6A–52 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–52 . . . . . . . . . . . . . . . . . .

Reassembly 6A–53 . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Spring, Oil Controller, Valve,

Valve Guide 6A–55 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valve Spring, Oil Controller, Valve,

Valve Guide and Associated Parts 6A–55 . . . . . . .

Disassembly 6A–55 . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–56 . . . . . . . . . . . . . . . . . .

Reassembly 6A–59 . . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft 6A–62 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Camshaft and Associated Parts 6A–62 . . . . . . . . .

Disassembly 6A–62 . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–63 . . . . . . . . . . . . . . . . . .

Reassembly 6A–65 . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft 6A–68 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft and Associated Parts 6A–68 . . . . . . . .

Disassembly 6A–68 . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–69 . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–71 . . . . . . . . . . . . . . . . . .

Reassembly 6A–72 . . . . . . . . . . . . . . . . . . . . . . . . . .

6A–2 ENGINE MECHANICAL (6VD1 3.2L)

Piston and Connecting Rod 6A–76 . . . . . . . . . . . . . . .

Piston, Connecting Rod and Associate

Parts 6A–76 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Disassembly 6A–76 . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–77 . . . . . . . . . . . . . . . . . .

Reassembly 6A–81 . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Block 6A–83 . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Block and Associated Parts 6A–83 . . . . .

Disassembly 6A–83 . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection and Repair 6A–84 . . . . . . . . . . . . . . . . . .

Reassembly 6A–85 . . . . . . . . . . . . . . . . . . . . . . . . . .

Main Data and Specification 6A–88 . . . . . . . . . . . . . .

Special Tool 6A–94 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING, REFER TO

THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN POSSIBLE

AIR BAG DEPLOYMENT, PERSONAL INJURY, OR

OTHERWISE UNNEEDED SRS SYSTEM REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, or other

corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener. When

you install fasteners, use the correct tightening

sequence and specifications. Following these

instructions can help you avoid damage to parts and

systems.

6A–3 ENGINE MECHANICAL (6VD1 3.2L)

General Description

Engine Cleanliness And Care

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousandths of a

millimeter (ten thousandths of an inch). Accordingly,

when any internal engine parts are serviced, care and

cleanliness are important. Throughout this section, it

should be understood that proper cleaning and protection

of machined surfaces and friction areas is part of the

repair procedure. This is considered standard shop

practice even if not specifically stated.

D A liberal coating of engine oil should be applied to all

friction areas during assembly to protect and lubricate

the surfaces on initial operation.

D Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

D At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

D Battery cables should be disconnected before any

major work is performed on the engine. Failure to

disconnect cables may result in damage to wire

harness or other electrical parts.

D The six cylinders of this engine are identified by

numbers; Right side cylinders 1, 3 and 5, Left side

cylinders 2, 4 and 6, as counted from crankshaft

pulley side to flywheel side.

General Information on Engine Service

The following information on engine service should be

noted carefully, as it is important in preventing damage

and contributing to reliable engine performance.

D When raising or supporting the engine for any reason,

do not use a jack under the oil pan. Due to the small

clearance between the oil pan and the oil pump

strainer, jacking against the oil pan may cause

damage to the oil pick–up unit.

D The 12–volt electrical system is capable of damaging

circuits. When performing any work where electrical

terminals could possibly be grounded, the ground

cable of the battery should be disconnected at the

battery.

D Any time the intake air duct or air cleaner is removed,

the intake opening should be covered. This will

protect against accidental entrance of foreign

material into the cylinder which could cause extensive

damage when the engine is started.

Cylinder Block

The cylinder block is made of aluminum die–cast casting

for 75°V–type six cylinders. It has a rear plate integrated

structure and employs a deep skirt. The cylinder liner is

cast and the liner inner diameter and crankshaft journal

diameter are classified into grades. The crankshaft is

supported by four bearings of which width is different

between No.2, No.3 and No.1, No.4; the width of No.3

bearing on the body side is different in order to support the

thrust bearing. The bearing cap is made of nodular cast

iron and each bearing cap uses four bolts and two side

bolts.

Cylinder Head

The cylinder head, made of aluminum alloy casting

employs a pent–roof type combustion chamber with a

spark plug in the center. The intake and exhaust valves

are placed in V–type design. The ports are cross–flow

type.

Valve Train

Intake and exhaust camshaft on the both side of banks

are driven through an camshaft drive gear by timing belt.

The valves are operated by the camshaft and the valve

clearance is adjusted to select suitable thickness shim.

Intake Manifold

The intake manifold system is composed of the aluminum

cast common chamber and intake manifold attached with

six fuel injectors.

Exhaust Manifold

The exhaust manifold is made of nodular cast iron.

Pistons and Connecting Rods

Aluminum pistons are used after selecting the grade that

meets the cylinder bore diameter. Each piston has two

compression rings and one oil ring. The piston pin made

of chromium steel is offset 1mm toward the thrust side,

and the thrust pressure of piston to the cylinder wall varies

gradually as the piston travels. The connecting rods are

made of forged steel. The connecting rod bearings are

graded for correct size selection.

Crankshaft and Bearings

The crankshaft is made of Ductile cast–iron. Pins and

journals are graded for correct size selection for their

bearing.

6A–4 ENGINE MECHANICAL (6VD1 3.2L)

Engine Diagnosis

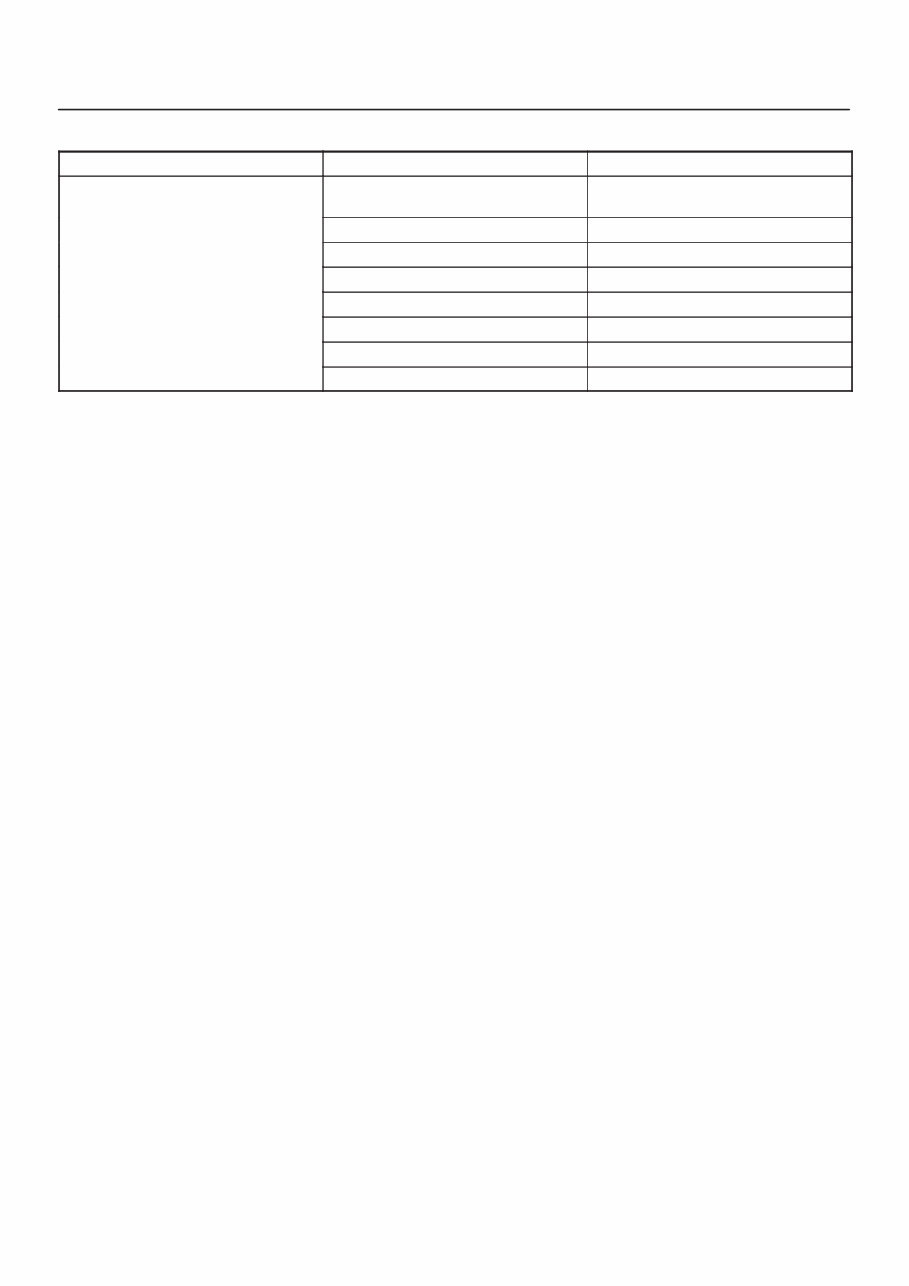

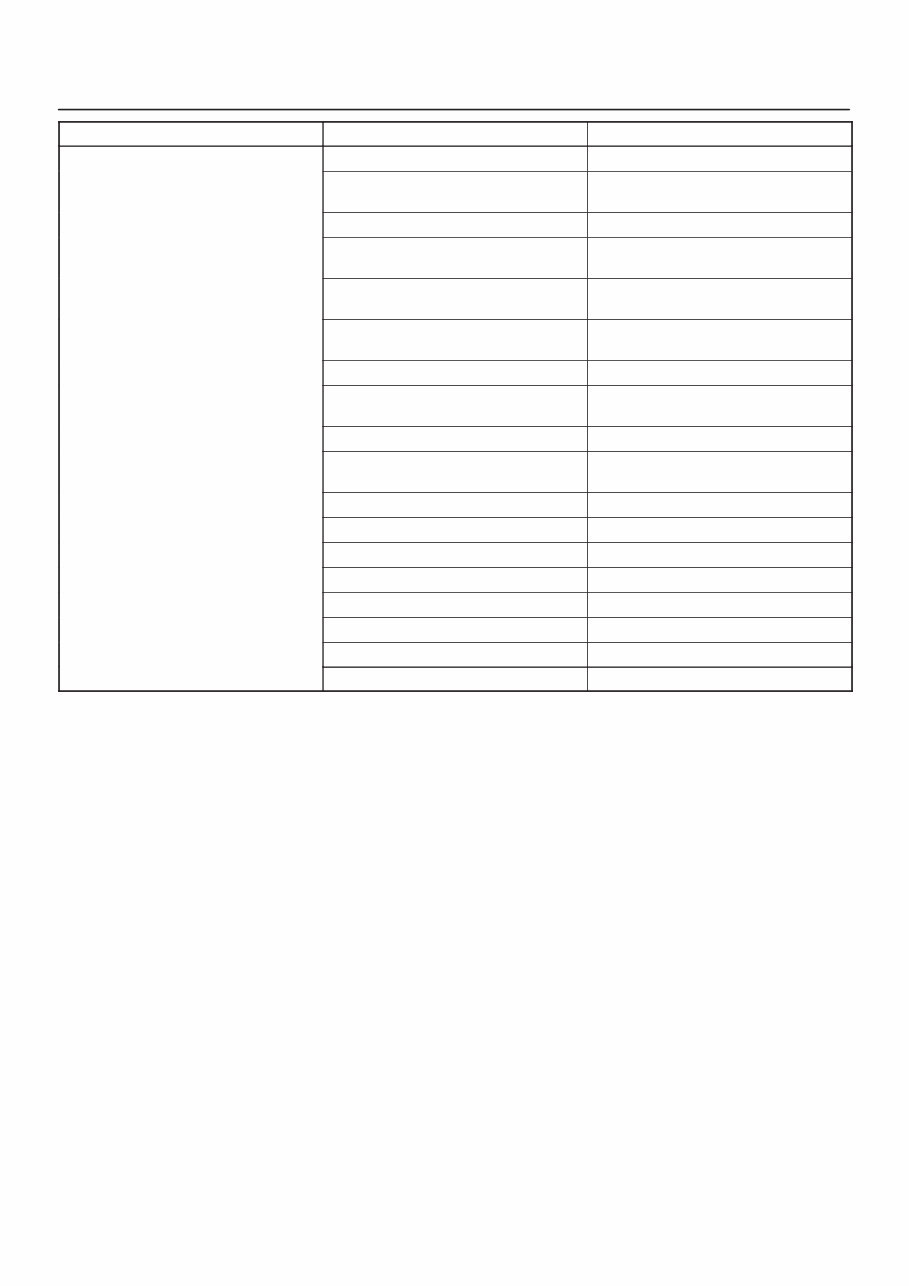

Hard Starting

1. Starting Motor Does Not Turn Over

Troubleshooting Procedure

Turn on headlights and starter switch.

Condition Possible cause Correction

Headlights go out or dim

considerably

Battery run down or under charged Recharge or replace battery

considerably

Terminals poorly connected Clean battery posts and terminals

and connect properly

Starting motor coil circuit shorted Overhaul or replace

Starting motor defective Overhaul or replace

2. Ignition Trouble — Starting Motor Turns Over But Engine Does Not Start

Spark Test

Disconnect an ignition coil from any spark plug. Connect

the spark plug tester J–26792 (ST–125), start the engine,

and check if a spark is generated in the spark plug tester.

Before starting the engine, make sure that the spark plug

tester is properly grounded. To avoid electrical shock, do

not touch the part where insulation of the ignition coil is

broken while the engine is running.

Condition Possible cause Correction

Spark jumps across gap Spark plug defective Clean, adjust spark gap or replace

Ignition timing incorrect Refer to Ignition System

Fuel not reaching fuel injector(s) or

engine

Refer to item 3 (Trouble in fuel

system)

Valve timing incorrect Adjust

Engine lacks compression Refer to item 4 (Engine lacks

compression)

No sparking takes place Ignition coil disconnected or broken Connect properly or replace

Electronic Ignition System with

module

Replace

Poor connections in engine harness Correct

Powertrain Control Module cable

disconnected or defective

Correct or replace

3. Trouble In Fuel System

Condition Possible cause Correction

Starting motor turns over and spark

occurs but engine does not start

Fuel tank empty Fill

occurs but engine does not start.

Water in fuel system Clean

Fuel filter clogged Replace filter

Fuel pipe clogged Clean or replace

Fuel pump defective Replace

Fuel pump circuit open Correct or replace

Evaporative Emission Control

System circuit clogged

Correct or replace

Multiport Fuel Injection System faulty Refer to “Electronic Fuel Injection”

section

6A–5 ENGINE MECHANICAL (6VD1 3.2L)

4. Engine Lacks Compression

Condition Possible cause Correction

Engine lacks compression Spark plug loosely fitted or spark

plug gasket defective

Tighten to specified torque or replace

gasket

Valve timing incorrect Adjust

Cylinder head gasket defective Replace gasket

Valve incorrectly seated Lap valve

Valve stem seized Replace valve and valve guide

Valve spring weakened or broken Replace

Cylinder or piston rings worn Overhaul engine

Piston ring seized Overhaul engine.

Engine Compression Test Procedure

1. Start and run the engine until the engine reaches

normal operating temperature.

2. Turn the engine off.

3. Remove all the spark plugs.

4. Remove ignition coil fuse (15A) and disable the

ignition system.

5. Remove the fuel pump relay from the relay and fuse

box.

6. Engage the starter and check that the cranking speed

is approximately 300 rpm.

7. Install cylinder compression gauge into spark plug

hole.

8. With the throttle valve opened fully, keep the starter

engaged until the compression gage needle reaches

the maximum level. Note the reading.

9. Repeat the test with each cylinder.

If the compression pressure obtained falls below the

limit, engine overhaul is necessary.

Limit; 1000 kPa (145 psi)

6A–6 ENGINE MECHANICAL (6VD1 3.2L)

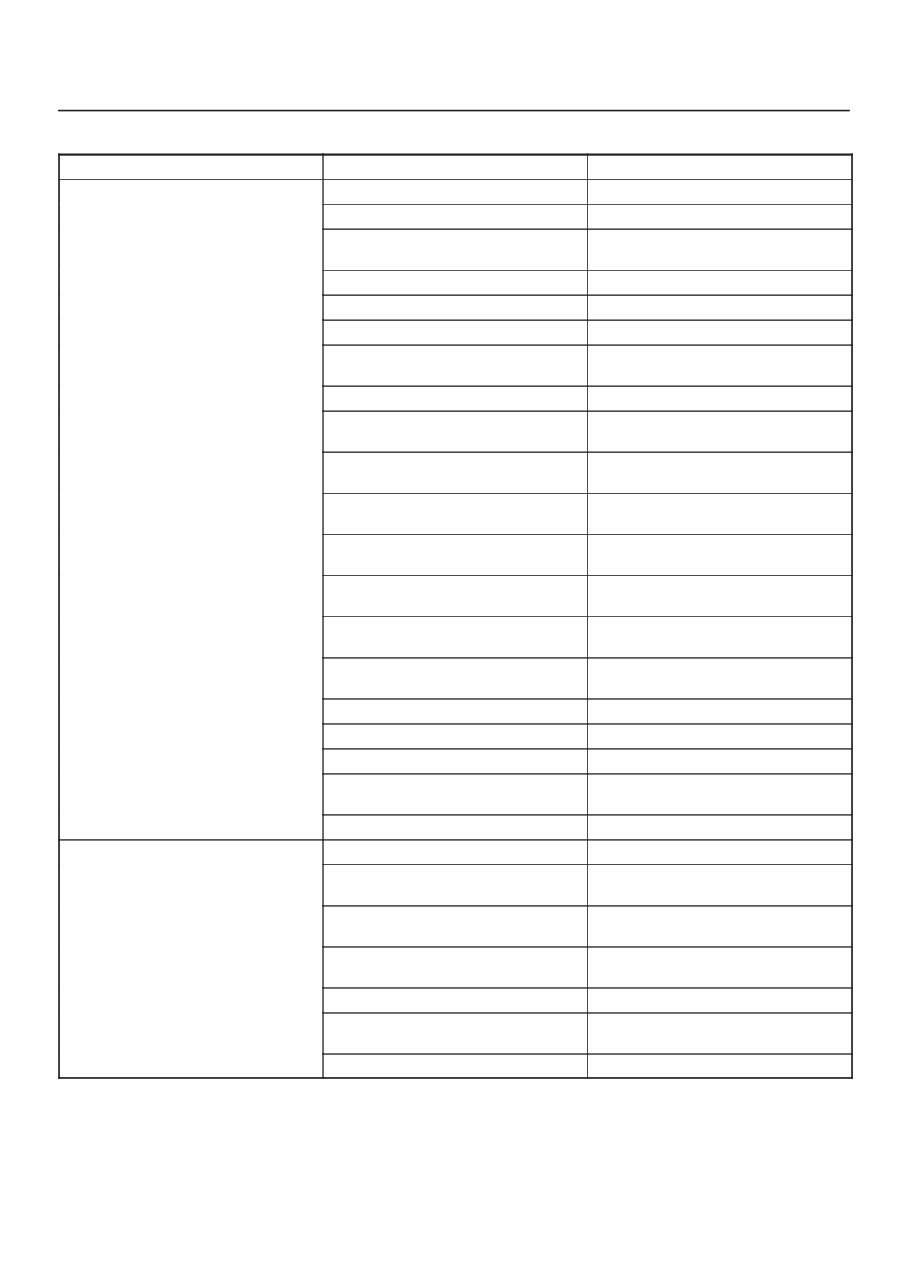

Rough Engine Idling or Engine Stalling

Condition Possible cause Correction

Trouble in fuel injection system Idle air control valve defective Replace

Throttle shutting off incomplete Correct or replace

Throttle position sensor circuit open

or shorted

Correct or replace

Fuel injector circuits open or shorted Correct or replace

Fuel injectors damaged Replace

Fuel pump relay defective Replace

Mass Airflow Sensor circuit open or

poor connections

Correct or replace

Mass Airflow Sensor defective Replace

Manifold Absolute Pressure Sensor

circuit open or poor connections

Correct or replace

Manifold Absolute Pressure Sensor

defective

Replace

Engine Coolant Temperature Sensor

circuit open or poor connections

Correct or replace

Engine Coolant Temperature Sensor

defective

Replace

Intake Air Temperature sensor circuit

open or poor connections

Correct or replace

Intake Air Temperature sensor

defective

Replace

Knock Sensor (KS) cable broken or

poor connections

Correct or replace

KS defective Replace

KS Module circuits open or ground Correct or replace

KS Module defective Replace

Vehicle Speed Sensor circuit open or

shorted

Correct or replace

Vehicle Speed Sensor defective Replace

Trouble in emission control system Powertrain Control Module defective Replace

Exhaust Gas Recirculation Valve

circuit open or poor connections

Correct or replace

Exhaust Gas Recirculation Valve

faulty

Replace

Canister purge valve circuit open or

poor connections

Correct or replace

Canister purge valve defective Replace

Evaporative Emission Canister

Purge control valve defective

Replace

Trouble in ignition system Refer to “Hard Start”

6A–7 ENGINE MECHANICAL (6VD1 3.2L)

Condition Correction Possible cause

Others Engine lacks compression Refer to “Hard Start”

Valve incorrectly seated Lap valve

Air Cleaner Filter clogged Replace filter element

Valve timing incorrect Readjust

Idle air control valve broken Replace

Fast idle solenoid defective Replace

Positive Crankcase Ventilation valve

defective or clogged

Replace

Rough Engine Running

Condition Possible cause Correction

Engine misfires periodically Ignition coil layer shorted Replace

Spark plugs fouling Clean or install hotter type plug

Spark plug(s) insulator nose leaking Replace

Fuel injector(s) defective Replace

Powertrain control module faulty Replace

Engine knocks periodically Spark plugs running too hot Install colder type spark plugs

Powertrain control module faulty Replace

Engine lacks power Spark plugs fouled Clean

Fuel injectors defective Replace

Mass Airflow Sensor or Intake

Airflow Sensor circuit defective

Correct or replace

Manifold Absolute Pressure (MAP)

Sensor or Manifold Absolute

Pressure Sensor circuit defective

Correct or replace

Engine Coolant Temperature Sensor

or Engine Coolant Temperature

Sensor circuit defective

Correct or replace

Powertrain Control Module faulty Replace

Intake Air Temperature Sensor or

Intake Air Temperature Sensor

circuit defective

Correct or replace

Throttle Position Sensor or Throttle

Position Sensor circuit defective

Correct or replace

Knock Sensor or Knock Sensor

circuits defective

Correct or replace

Knock Sensor Module or Knock

Sensor Module circuits defective

Correct or replace

6A–8 ENGINE MECHANICAL (6VD1 3.2L)

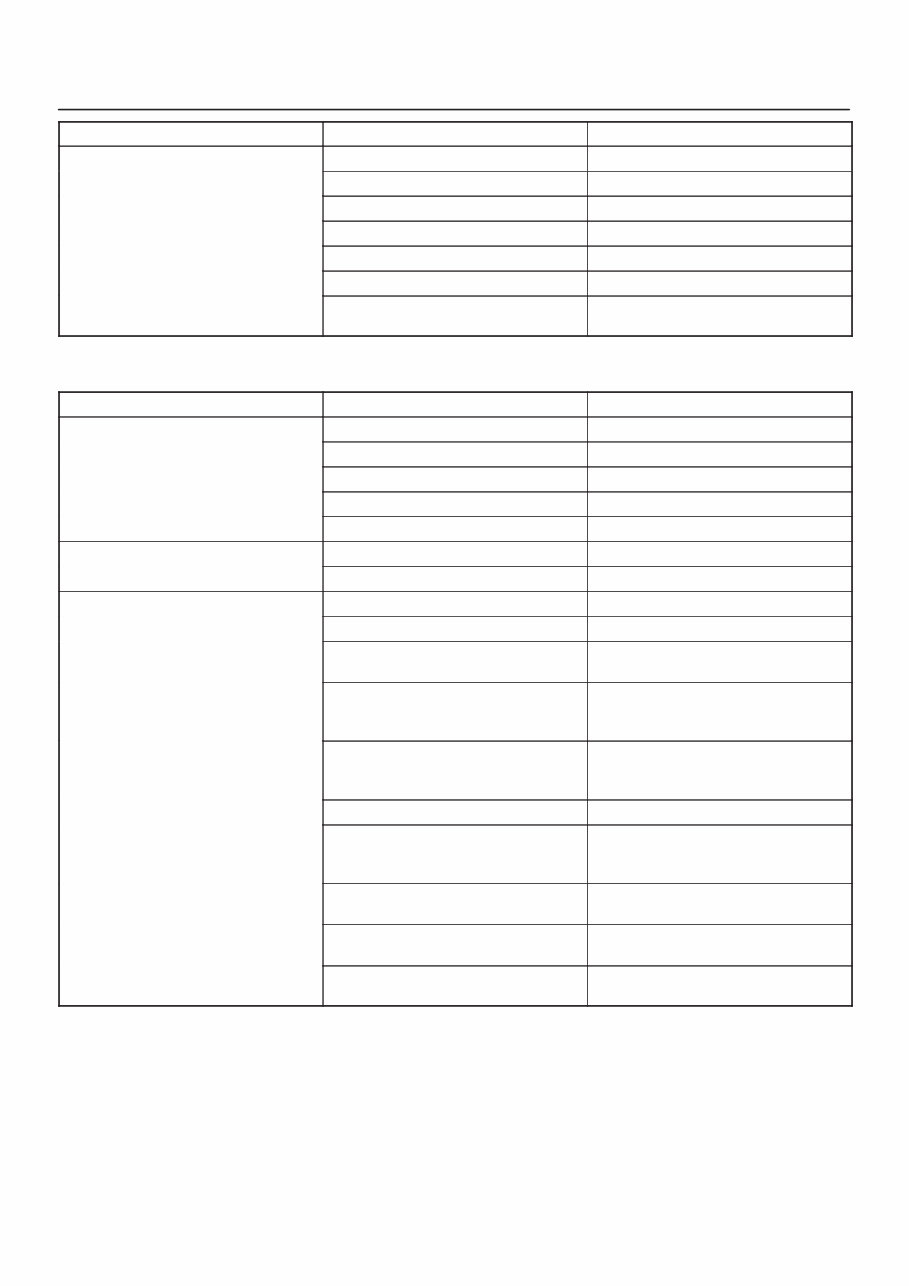

Hesitation

Condition Possible cause Correction

Hesitation on acceleration Throttle Position Sensor adjustment

incorrect

Replace throttle valve assembly

Throttle Position Sensor circuit open

or shorted

Correct or replace

Excessive play in accelerator linkage Adjust or replace

Mass Airflow Sensor circuit open or

poor connections

Correct or replace

Mass Airflow Sensor defective Replace

Manifold Absolute Pressure (MAP)

Sensor circuit open or shorted

Correct or replace

MAP Sensor defective Replace

Intake Air Temperature (IAT) Sensor

circuit open or poor connections

Correct or replace

Knock Sensor (KS) circuit open or

poor connections

Correct or replace

KS defective Replace

KS Module circuits open or shorted Correct or replace

KS Module defective Replace

IAT Sensor defective Replace

Hesitation at high speeds Fuel tank strainer clogged Clean or replace

(Fuel pressure too low)

Fuel pipe clogged Clean or replace

Fuel filter clogged Replace

Defective fuel pump system Check and replace

Fuel Pressure Control Valve leaking Replace

Hesitation at high speeds

(Fuel injector not working normally)

Power supply or ground circuit for

Multiport Fuel Injection System

shorted or open

Check and correct or replace

Fuel Injector defective Replace

Cable of Multiport Fuel Injection

System circuit open or poor

connections

Correct or replace

6A–9 ENGINE MECHANICAL (6VD1 3.2L)

Condition Correction Possible cause

Hesitation at high speeds Powertrain Control Module defective Replace

Throttle Position Sensor cable

broken or poor connections

Correct or replace

Throttle Position Sensor defective Replace

Engine Coolant Temperature Sensor

circuit open or shorted

Correct or replace

Engine Coolant Temperature Sensor

defective

Replace

Mass Airflow Sensor circuit open or

poor connections

Correct or replace

Mass Airflow Sensor defective Replace

MAP Sensor cable broken or poor

connections

Correct or replace

MAP Sensor defective Replace

IAT Sensor circuit open or poor

connections

Correct or replace

IAT Sensor defective Replace

KS circuit open or poor connections Correct or replace

KS defective Replace

KS Module circuit open or shorted Correct or replace

KS Module defective Replace

Throttle valve not fully opened Check and correct or replace

Air Cleaner Filter clogged Replace filter element

Power supply voltage too low Check and correct or replace

6A–10 ENGINE MECHANICAL (6VD1 3.2L)

Engine Lacks Power

Condition Possible cause Correction

Trouble in fuel system Fuel Pressure Control Valve not

working normally

Replace

Fuel injector clogged Clean or replace

Fuel pipe clogged Clean

Fuel filter clogged or fouled Replace

Fuel pump drive circuit not working

normally

Correct or replace

Fuel tank not sufficiently breathing

due to clogged Evaporative

Emission Control System circuit

Clean or replace

Water in fuel system Clean

Inferior quality fuel in fuel system Use fuel of specified octane rating

Powertrain Control Module supplied

poor voltage

Correct circuit

Throttle Position Sensor cable

broken or poor connections

Correct or replace

Throttle Position Sensor defective Replace

Mass Airflow Sensor not working

normally

Replace

Manifold Absolute Pressure Sensor

not working normally

Replace

Intake Air Temperature Sensor not

working normally

Replace

Engine Coolant Temperature Sensor

circuit open or shorted

Correct or replace

Engine Coolant Temperature Sensor

defective

Replace

Powertrain Control Module defective Replace

Trouble in intake or exhaust system Air Cleaner Filter clogged Replace filter element

Air duct kinked or flattened Correct or replace

Ignition failure ———— Refer to Hard Start Troubleshooting

Guide

Heat range of spark plug inadequate Install spark plugs of adequate heat

range

Ignition coil defective Replace

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 15 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

The Isuzu Petrol Engine 6VD1 3.2 Workshop Repair Manual is a comprehensive resource covering all the necessary information for servicing and repairing your Isuzu engine. With a substantial 440 pages, this manual provides detailed and accurate guidance, ensuring a proper factory manual experience without being scanned. It is a valuable tool for both professional mechanics and DIY enthusiasts.