Isuzu 6UZ1X Engine OEM Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

CNH

Copyright © 2006 CNH France S.A.

Printed in France

November 2006 Lep 87606798A

SERVICE MANUAL

6UZ1X

ISUZU ENGINE

NOT FOR PRINT

Lep 87606798A Issued 11/06

NOT FOR PRINT

General Information OA-1

General Information

General Information

Contents

General Information . . . . . . . . . . . . . . . . . . . . . . . 0A-2

Service Precautions . . . . . . . . . . . . . . . . . . . . . . 0A-2

Reading the Model . . . . . . . . . . . . . . . . . . . . . . . 0A-6

General Information . . . . . . . . . . . . . . . . . . . . . . 0A-6

NOT FOR PRINT

General Information OA-2

General Information

Service Precautions

In order to work safely

1. Use an engine stand when lowering the engine

from the machine.

Do not put the engine on the ground directly. And

put it so that the oil pan is not affected.

2. When performing by two persons or more, confirm

safety each other.

3. If performing repair on the electrical system, always

disconnect the negative cable from the battery

terminal beforehand. Before removing the battery

cover, keep fire away.

4. In badly ventilated indoor workshop, do not run the

engine for a long time or perform painting work.

5. Be sure to use special tools as instructed. Use of

other than the specified tool may cause damage of

parts or injury.

6. Maintain tools, measuring equipment and special

tools in good condition, and prepare them before

use. Do not use worn wrenches, hammers that has

the rounded striking surface of the head or chipped

chisels, etc.

7. When using devices such as a grinder, crane and

welder, follow the instructions and use a special

care.

Also, when performing other works, protect

yourself with clothes and other safety tools.

WSHK0190

WSHK0191

NOT FOR PRINT

General Information OA-3

8. After servicing the fuel system, always check for

fuel leakage. (This may cause a fire.)

9. When handling highly-volatile material, take

extreme care not to let it catch fire.

Be sure to wipe off spilled oil and grease on

rubbers, as this may cause the rubber to

deteriorate.

Replacement parts and part numbers

1. Always replace the packing, oil seal, O-ring,

caulking lock nut, folding type lock plate, split pin,

etc. with new ones every time they are

disassembled.

2. The part number information in this manual may

not represent availability of supply, or the numbers

may have been changed due to revision. Always

check the numbers with the part catalog before

use.

Liquid gasket

1. Remove old liquid gasket completely from liquid

gasket applied area on each part using a scraper

during disassembly. Wipe off oil, water, dust, etc.

with cloth and apply specified liquid gasket on each

area before assembly.

2. If the gasket remover (ThreeBond, Pando 391D) is

used to clean easily, it is recommended that you

wait for about 10 minutes after application, and

then remove it.

However, do not use it for resin or painted parts.

3. Be careful to apply appropriate amount, not

excessively or insufficiently.

Always, the start and end of the application should

be overlapped.

4. Take care not to misalign the applied part and

opposite one when assembling it after application.

If the parts are misaligned, apply the liquid gasket

again. Especially for the oil pan, use the same size

of studs as a guide since it has no positioning such

as a knock pin.

5. Apply liquid gasket and assemble it within 7

minutes.

If more than 7 minutes have elapsed, remove the

existing liquid gasket and apply again.

6. Start the engine more than 30 minutes after each

part is assembled.

Liquid gasket

WSHK0192

Sealed Location Product Name Manufacturer

Upper surface of the mating portion between cylinder block –

flywheel housing

1207B ThreeBond

Between front cover – cylinder block 1201 ThreeBond

Between cylinder block – flywheel housing – crank case 1201 ThreeBond

Between cylinder block – crank case FMD –127 Loctite

Lower surface of the mating portion between crankcase – flywheel

housing

1207B ThreeBond

NOT FOR PRINT

General Information OA-4

• Be sure to use liquid gasket of product name

described above or equivalent product.

• Use the appropriate amount of liquid gasket.

Follow the instructions of products.

Method of application

1. Wipe off water, oil or grease from contact surface.

The contact surface should be dry.

2. Apply liquid gasket of specified bead width on the

one side of contact surfaces. At this time, there

should be no gap in bead.

Note:

If the method of application is described in service

manual, follow the description.

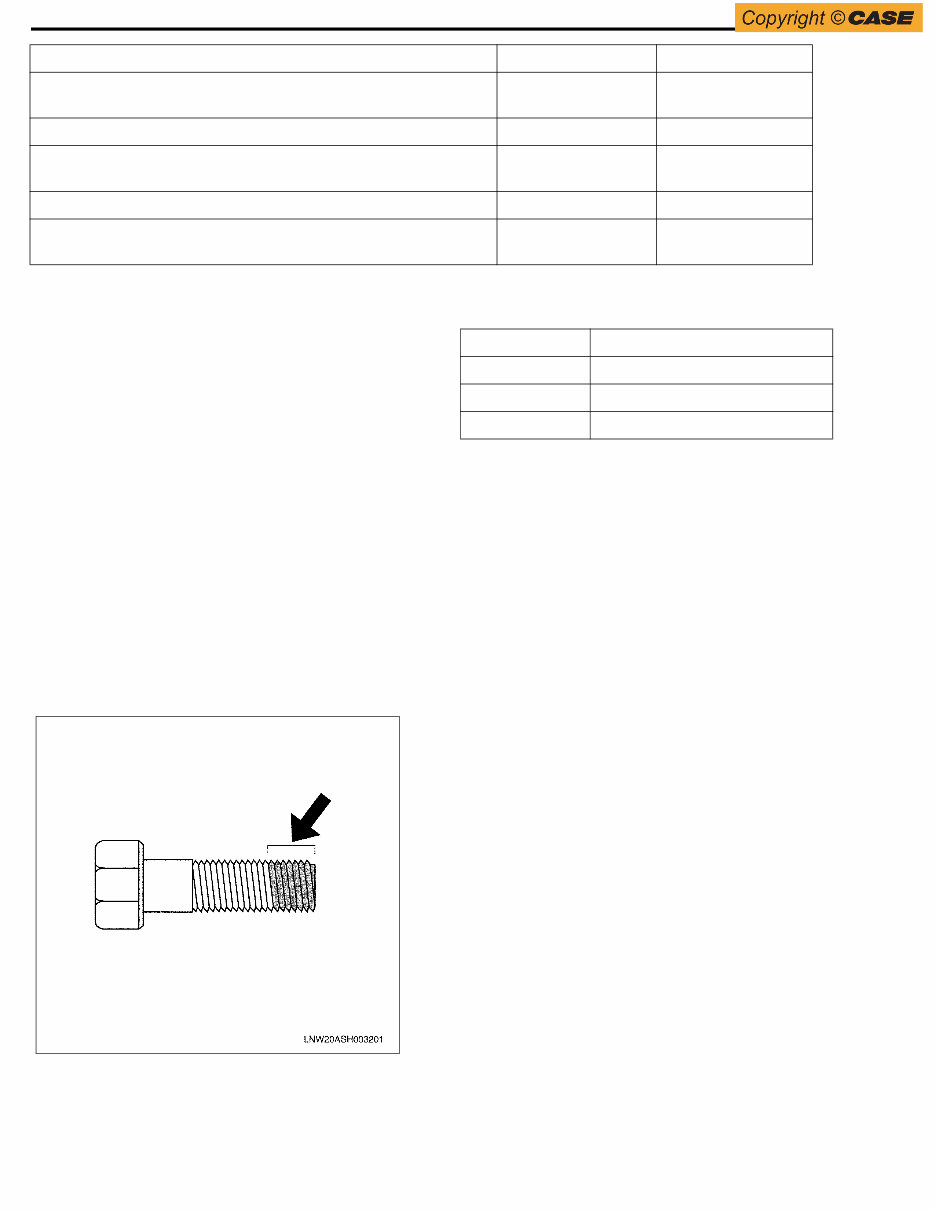

Work procedure

1. Wipe off oil, grease and water completely from the

contact surface of bolt, bolt hole and threads

portion of nut. The contact surface should be dry.

2. Apply Loctite on 1/3 of the tip of threads.

3. Tighten the bolt to the specified torque.

Important:

After tightening, do not give excessive torque or

vibration for at least 1 hour until Loctite hardens.

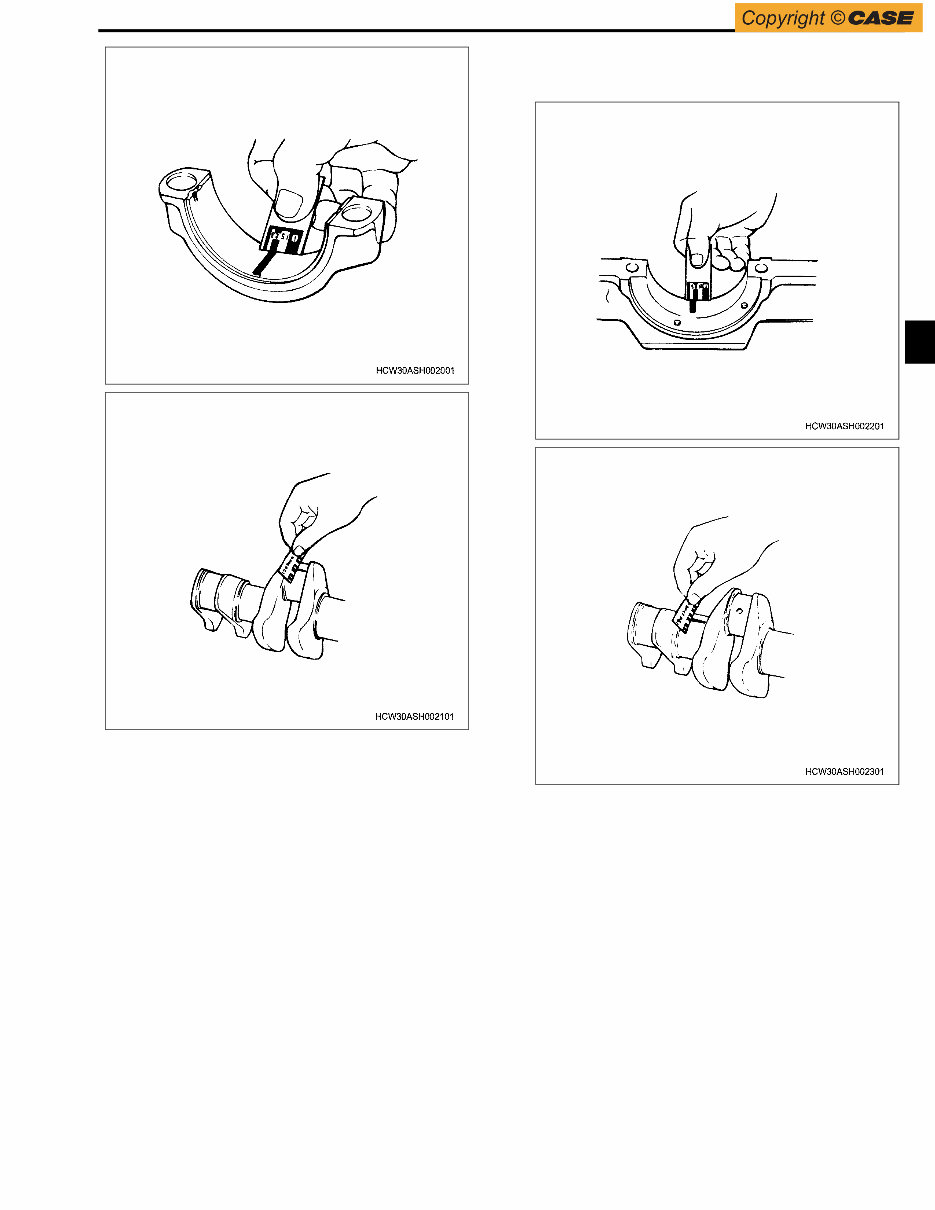

How to use Plastigauge

(Example) Measurement of clearance between

connecting rod bearing and crank pin

• Clean the connecting rod and the bearing, and

assemble the bearing to the connecting rod.

• Cut the Plastigauge in the width of the crank pin,

and place it parallel, away from the oil hole of the

pin.

• Align the stamp mark of connecting rod with that of

cap, and assemble them to the crank pin. Apply

molybdenum disulphide to the threads and the

seating surface of the tightening bolts, and tighten

the bolts on the cap alternately to the specified

torque.

Important:

Never move the connecting rod while using the

Plastigauge.

• Carefully remove the cap and the connecting rod,

and measure the width (clearance) of flattened

Plastigauge using the scale printed on the bag.

Lower surface of the mating portion between crankcase – front

cover

1207B Three Bond

Contact part of cylinder head that nozzle sleeve is pushed to TL290 Loctite

Sealing cup push part between cylinder block – head 962T

123T

Loctite

Hermetic seal

Plug nipple of oil cooler #575 Loctite

O-ring omission prevention agent 1208

CH Dyne #290

Three Bond

Cement dyne

Sealed Location Product Name Manufacturer

Type Measurable Range (mm)

PG-1 (Green) 0.025 — 0.076

PR-1 (Red) 0.051 — 0.152

PB-1 (Blue) 0.102 — 0.229

NOT FOR PRINT

General Information OA-5

(Example) Measurement of clearance between

crankshaft bearing and crankshaft journal.

• Clean the bearing installation surfaces on the

crankcase and on the cylinder block, and the

bearings. Then assemble each bearing to the

cylinder block and the crankcase.

• Put the crankshaft on the cylinder block carefully,

and rotate the crankshaft for approx. 30 degrees to

fit in.

• Cut the Plastigauge in the width of the crankshaft

journal, and place it parallel, away from the oil hole

of the journal.

• Put the crankcase on the cylinder block carefully,

and apply molybdenum disulphide to the threads

and the seating surface of the tightening bolts.

Then tighten them to the specified torque in the

specified order.

Important:

Never rotate the crankshaft while using the Plastigauge.

• Carefully remove the crankcase, and measure the

width (clearance) of the flattened Plastigauge using

the scale printed on the bag.

NOT FOR PRINT

General Information OA-6

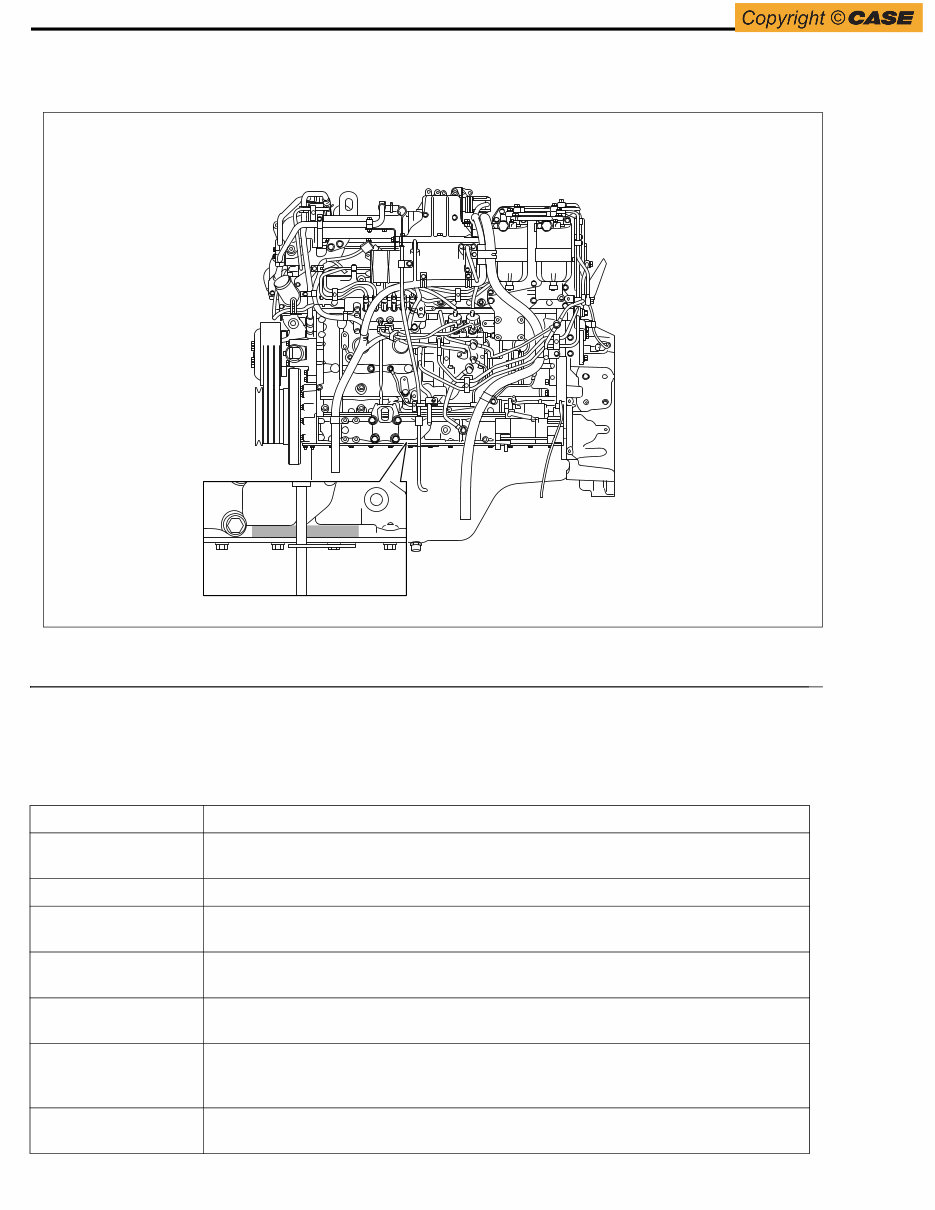

Reading the Model

Stamping position of engine number

Name

1. Engine Number Stamp (6UZ)1-······)

General Information

Description of terms and abbreviations

Definition of terms

WSUZ0142

Term Description

Specifications General term for the specified values that are necessary for service work, such as

nominal dimension, assembly specifications and service limit.

Nominal dimension It indicates the value without tolerance at the time of manufacture.

Assembly

specifications

It indicates the specified value after assembly, repair or adjustment.

Service limit It indicates the limit value that the part must be repaired or replaced when it reaches this

value (dimension).

Front/Rear, Right/Left,

Top/Bottom

These indicate directions same as those of the vehicle when mounted on.

Units In addition to SI unit, conventional unit is also shown (toque, pressure, force, in

particular).

[Example] Length: mm, Torque: N⋅m {kgf⋅m}

Warning It means the items that danger of personal life or serious injury may occur if you do not

follow.

NOT FOR PRINT

General Information OA-7

Abbreviation

SI (International System of Unit)

About changeover to SI (International System of

Unit)

This was introduced with the aim to internationally unify

the metric system and the units (Shakkanho (Japanese

measuring system), Foot-pound system, etc.) which are

used conventionally in various countries, and to control

the confusion among each unit (conversion by

calculation etc.)

Caution It means the items that injury or accident may occur if you do not follow.

Important It means the items that related parts and system may lose the normal performance, or a

fault may occur in vehicle.

Note It means the items which is noted in procedures.

Term Description

Abbreviation Description

AC Alternating Current

ACC Accessory

ACG Alternating Current Generator

API American Petrol Institute

ASM (Assy) Assembly

ATDC After Top Dead Center

BAT, BATT Battery

BRG, Brg Bearing

BKT, BRKT Bracket

BTDC Before Top Dead Center

CO Carbon Oxide

CONN Connector

CPU Central Processing Unit

C/U Control Unit

DC Direct Current

DI Direct Injection

ECU Engine Control Unit/Electronic

Control Unit

ECM Engine Control Module

EGR Exhaust Gas Recirculation

Exh, EXH Exhaust

Ft, FRT Front

FWD Forward

F/C Fuel Cut

GND Ground

IC Integrated Circuit

ID plate Identification Plate

IN Intake, Inlet

ISO International Organization for

Standardization

I/PUMP Injection Pump

JIS Japanese Industrial Standards

L/H, LH Left Hand

M/V Magnetic Valve

NOx Nitrogen Oxide

N-TDC Number - Top Dead Center

OPT Option

P Pole(S)

PCV Pump Control Valve/Positive

Crankcase Ventilation

PM Particulate Matter

PS Pre-Stroke

PTO Power Take Off

QOS Quick On System

Rr, RR Rear

R/H, RH Right Hand

R/L Relay

STD Standard

SW Switch

TICS Timing & Injection rate Control

System

A type of injection system

VGS Turbo Variable Geometry turbocharger

System

Variable turbo, VGS turbo

W/L Warning Lamp

Abbreviation Description

NOT FOR PRINT

General Information OA-8

In Japan, the new calculation method that fully adopts

SI unit was issued in 1992 and standardized in JIS-Z-

8203.

In this manual, SI units which are international unit

system are described, and conventional units are

also described in { }.

SI

Abbreviation of French word “Le S ysteme I nternational

d’Unites”

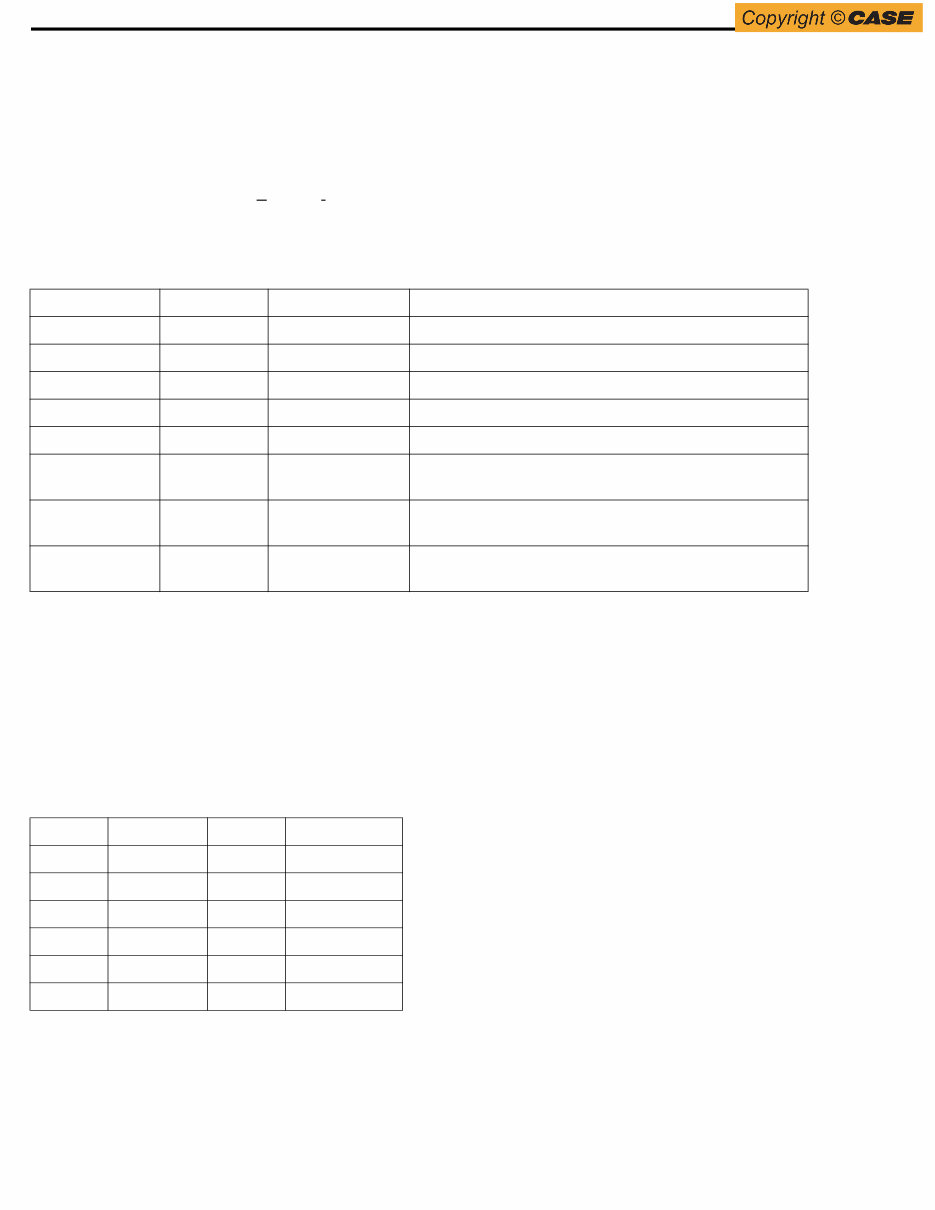

Relationship between SI and conventional units

*1 Some service data which have been issued already

use “kg” instead of “kgf” to represent force and weight

(mass) for convenience sake.

*2 The results of the conversion may be rounded to one

or two decimal places.

Conversion of numeric representation

Prefixes such as “k (kiro)” or “m (milli)” are used

for numeric conversion.

• 200 kgf/cm

2

= 19,620 kPa = 19.6 MPa

• 40 mmHg = 5,332 Pa = 5.3 kPa

Table of Isuzu standard tightening torque

The tightening torque values in the following table are

applied to the places where tightening torque is not

specified.

SI Conventional Unit Item, Unit Conversion

Length m m Same as conventional one

Weight (mass) kg kg Same as conventional one

Force N * kg, kgf 1 kgf = 9.80665 N

Torque N⋅m * kg⋅m, kgf⋅m 1 kgf⋅m = 9.80665 N⋅m

Pressure Pa * kg/cm

2

, mmHg 1 kgf/cm

2

= 9.80665 kPa, 1 mmHg = 133.3 Pa

Power output,

horsepower

W PS 1 PS = 0.74 kW

Cubic volume,

displacement

m

3

Liter, L, cc 1 Liter = 1 dm

3

, 1 cc = 1 mLiter = 1 cm

3

Fuel

consumption

g/(kW⋅h) g/(PS⋅h) 1 g/(PS⋅h) = 1.360 g/(kW⋅h)

M Mega 10

6

1,000,000

k Kiro 10

3

1,000

h Hecto 10

2

100

d Deci 10

-1

0.1

c Centi 10

-2

0.01

m Milli 10

-3

0.001

μ Micro 10

-6

0.000001

NOT FOR PRINT

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$71.99

Viewed 97 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$71.99

- This professional technical manual provides service, maintenance, troubleshooting, and replacement procedures for the Isuzu 6UZ1X engine.

- The manual includes step-by-step instructions, clear images, and exploded-view illustrations, making it useful for both professional mechanics and DIY enthusiasts.

- It is not a generic repair manual but the manufacturer-sourced OEM repair manual used by professional technicians.

- It contains every troubleshooting and replacement procedure provided by the manufacturer, eliminating the need to flip through numerous pages to find specific information.

- The manual is easily accessible and can be carried around, searched, bookmarked, and printed for convenience.

- Printable: Yes

- Language: English

- Compatibility: Compatible with various electronic devices, including PC & Mac computers, Android and Apple smartphones & tablets, etc.

- Requirements: Adobe Reader (free)