ISUZU Diesel Engine 6BG1 Instruction Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

GENERAL INFORMATION 1-I

SECTION 1

GENERAL INFORMATION

TABLE OF CONTENTS

ITEM PAGE

General repair instructions ............................................................................... l- 2

Notes on the format of this manual ..................................................................... l- 2

Main data and specifications ............................................................................. l- 6

Tightening torque specifications

I

........................................................................ 1- 8

Angular nut and bolt tightening method ............................................................... l-10

Major parts fixing nuts and bolts . ........................................................................ l-12

Identifications .............................................................................................. l-23

13 GENERAL INFORMATION

1 .

2 .

3 .

4 .

5 .

6 .

7 .

8 .

9 .

10 .

11 .

12 .

GENERAL REPAIR INSTRUCTIONS

Before performing any service operation with the engine mounted, disconnect the grounding cable

from the battery.

This will reduce the chance of cable damage and burning due to short circuiting.

Always use the proper tool or tools for the job at hand.

.

mere specified, use the specially designed tool or tools.

L

Use genuine ISUZU parts referring ISUZU PARTS CATALOG for the engines surely.

Never reuse cotter pins, gaskets, O-rings, lock washers, and self locking nuts. Discard them as you

remove them. Replace them with new ones.

Always keep disassembled parts neatly in groups. This will ensure a smooth reassembly operation.

It is especially important to keep fastening parts separate. These parts vary in hardness and design,

depending on their installation position.

‘ ,

‘ .

r. I--

All parts should be carefully cleaned before inspection or reassembly.

Oil ports and other openings should be cleaned with compressed air to make sure that they are com-

pletely free of obstructions.

Rotating and sliding part surfaces should be lubricated with oil or grease before reassembly.

If necessary, use a sealer on gaskets to prevent leakage.

Nut and bolt torque specifications should be carefully followed.

Always release the air pressure from any machine-mounted air tank(s) before dismounting the engine

or disconnecting pipes and hoses. To not do so is extremely dangerous.

Always check and recheck you work. No sewice operation is complete until you have done this.

Information contained in the “Main Data and Specifications” of the Workshop Manual and the

Instruction Book may differ. In this case, the information contained in the Instruction Bo.ok should be

considered applicable. z

NOTES ON THE FORMAT OF THIS MANUAL

This Workshop Manual is applicable to the 4BG1, 4BGlT, 6BG1, and 6BGlT family of industrial diesel

engines. Unless otherwise specified, these engines have common parts and components as well as data

and qqecifications.

Illustrations used in this Workshop Manual are based on the 6BGl and 6BGlT engines.

The 4BGlTengine and the 6BGlT engine are turbocharged.

.

1 .

2 .

3 .

4 .

5 .

Find the applicable section by referring to the Table of Contents at the beginning of the Manual.

Cdmmon technical data such as general maintenance items, service specifications, and tightening

torques are included in the “General Information” section.

Each section is divided into sub-sections dealing with disassembly, inspection and repair, and

reassembly.

The section ENGINE ASSEMBLY is an exception. This part is divided into three sections to facilitates

quick indexing.

When the same servicing operation is applicable to<--everal different units, the manual will direct you

to the appropriate page.

For the sake of brevity, self-explanatory removal and installation procedures are omitted.

More complex procedures are covered in detail.

,

GENERAL INFORMATION 1-3

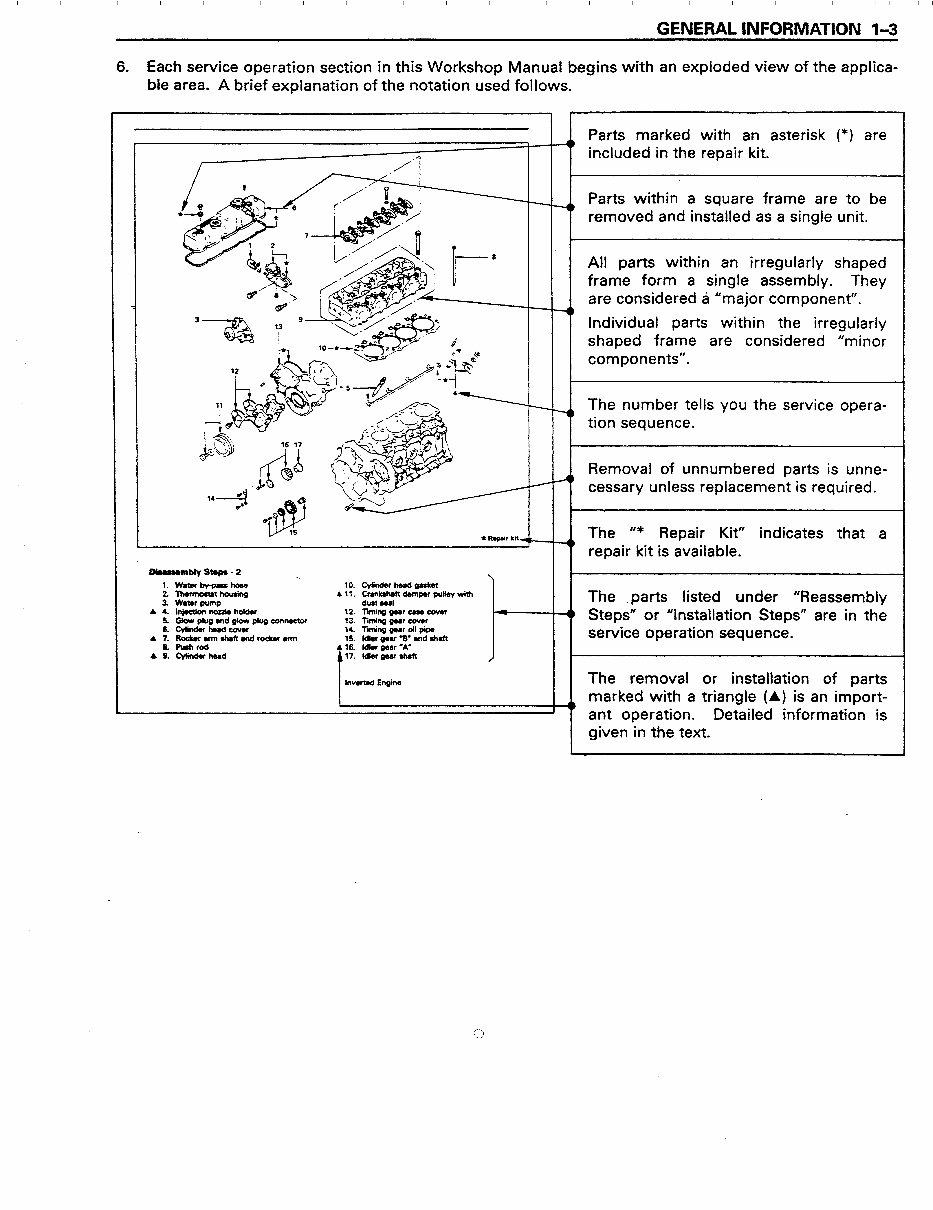

6. Each service operation section in this Workshop Manual begins with an exploded view of the applica-

ble area. A brief explanation of the notation used follows.

o&sumblystaps-2

-.

1. W8terby-passho8e

2. ThwmosUtfiou8ing

.3. WatDrpfJmp

A 4. l~rKuzleholder

5. Glow plug and gJow plug connector

6. cylllherdcowr

A 7. Rocbrarmshaftandrockerrrm

S. fbhrod

A 9. c-w

10. Cylinder he8d gultet

A 11. Crankshaftdamper pulley with

dust seal

12. liming gear cue cutter

13. liming gmr cover

14. Tf gear oil pipe

15. ldktr gear 3. rnd shaft

16. ldbr war -A’

l?. Mkr gear shaft

I

lnvwted Engine

I-

Parts marked with an asterisk (*) are

included in the repair kit.

Parts within a square frame are to be

removed and installed as a single unit.

All parts within an irregularly shaped

frame form a single assembly. They

are considered ti “major component”.

Individual parts within the irregularly

shaped frame are considered “minor

components”.

The number tells you the service opera-

tion sequence.

Removal of unnumbered parts is unne-

cessary unless replacement is required.

The ‘ I* Repair Kit” indicates that a

repair kit is available.

The .parts listed under “Reassembly

Steps” or “Installation Steps” are in the

service operation sequence.

The removal or installation of parts

marked with a triangle (A) is an import-

ant operation. Detailed information is

given in the text.

I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I II I I I I I I&!.- 1

,

1” GENERAL INFORMATION

7. Below is a sample of the text of the Workshop Manual.

This is the item shown in the illus-

4 tration. It is marked with a triangle

(A) on the Major Components page.

Special tools are identified by the

from the upper face of the cylinder head.

Letters and numbers contained in a

circle refer to the illustration.

set.

guides.

Symbols indicate the type of service

or step to be per-

formed. A detailed explanation of

these symbols follows.

Y

Service data and specifications are

given in this table.

8. The following symbols appear throughout this Workshop Manual. They tell you the type of service

operation or step to perform.

q

CI)

. . .

0

*+ l **

III

+$+ . . .

cl

$+ l l l

ltrl

. . .

0

*

. . .

El

aB ...

.

.

l!!il

.

. . .

B!l

. . .

Removal

Installation

Disassembly

Reassembly

Alignment (Marks)

Directional Indication

Inspection

Measurement

Sealant Application

-

El

D

II)

. ..

l5l

.. .

V

?

0. . .

m

. . .

El

bl . . .

cl

0

. . .

0

qy5 l l l

cl

-b

...

Adjustment

Cleaning

Important Operation Requiring Extra Care

Specified Torque (Tighten)

Special Tool Use Required or Recommended

(lsuzu Tool or Tools)

Commercially Available Tool Use Required or

Recommended

Lubrication (Oil)

(2

Lubrication (Grease)

I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I II I I I I I I II

I‘

GENERAL INFORMAiiON l-5

9 .

10 .

II .

Measurement criteria are defined by the terms “standard” and “limit”.

A measurement falling within the “standard” range indicates that the applicable part or parts are ser-

vicea ble.

“Limit” should be thought of as an absolute value.

A measurement which is outside the “limit” indicates that the applicable part or parts must be either

repaired or replaced.

Components and parts are listed in the singular form throughout the Manual.

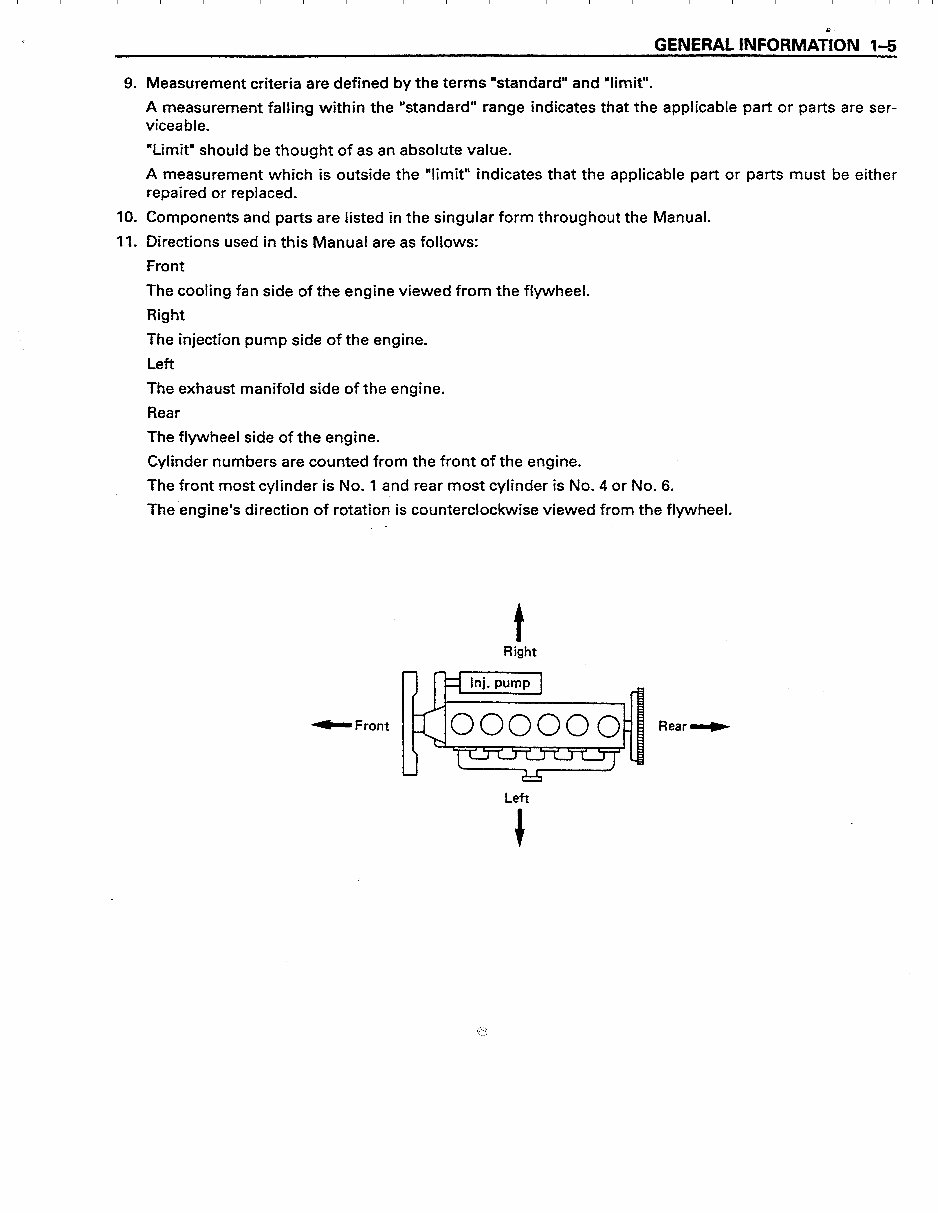

Directions used in this Manual are as follows:

Front

The cooling fan side of the engine viewed from the flywheel.

Right

The injection pump side of the engine.

Left

The exhaust manifold side of the engine.

Rear

The flywheel side of the engine.

Cylinder numbers are counted from the front of the engine.

The front most cylinder is No. 1 and rear most cylinder is No. 4 or No. 6.

The’engine’s direction of rotation is counterclockwise viewed from the flywheel.

. -

b Front

t

Right

Rear W

Left

+

I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I II I I I I I I II

f=. - 1

l-6 GENERAL INFORMATION

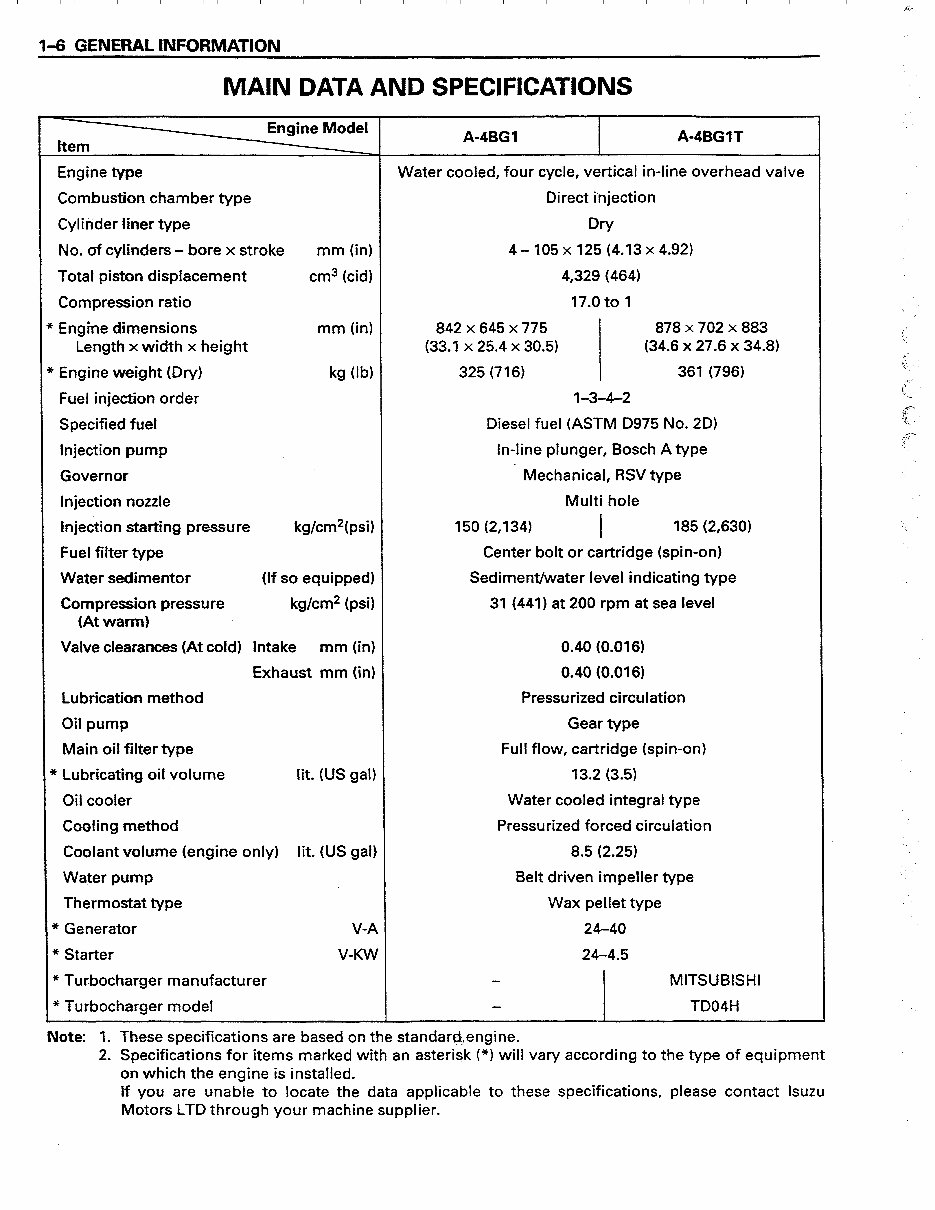

MAIN DATA AND SPECIFICATIONS

Engine Model

Item

A-4BGl A-4BGlT

-

Engine type Water cooled, four cycle, vertical in-line overhead valve

Combustion chamber type

Direct injection

Cylinder liner type Dry

No. of cylinders - bore x stroke mm (in) 4 - 105 x 125 (4.13 x 4.92)

Total piston displacement cm3 (cid) 4,329 (464)

Compression ratio

17.0 to I

f Engine dimensions mm (in) 842x645~775 878 x 702 x 883

Length x width x height (33.1 x 25.4 x 30.5) (34.6 x 27.6 x 34.8)

’ Engine weight (Dry) kg (lb)

325 (716) 361 (796)

Fuel injection order

I-3-4-2

Specified fuel

Diesel fuel (ASTM D975 No. 2D)

Injection pump

In-line plunger, Bosch A type

Governor

Mechanical, RSV type

Injection nozzle

Multi hole

injection starting pressure kg/cm2( psi) 150 (2,134)

I

185 (2,630)

Fuel filter type

Center bolt or cartridge (spin-on)

Water sedimentor (If so equipped) Sediment/water level indicating type

Compression pressure kg/cm2 (psi) 31 (441) at 200 rpm at sea level

(At warm)

Valve clearances (At cold) Intake mm (in) 0.40 (0.016)

Exhaust mm (in) 0.40 (0.016)

Lubrication method

Pressurized circulation

Oil pump

Gear type

Main oil filter type

Full flow, cartridge (spin-on)

)cLubricating oil volume lit. (US gal) 13.2 (3.5)

Oil cooler Water cooled integral type

Cooling method Pressurized forced circulation

Coolant volume (engine only) lit. (US gal) 8.5 (2.25)

Water pump

Belt driven impeller type

i

Thermostat type Wax pellet type

* Generator V-A 24-40

* Starter V-KW 24-4.5

* Turbocharger manufacturer

MITSUBISHI

* Turbocharger model

TDO4H

Note: 1. These specifications are based on the standareengine.

I

:’

!

c-

\.?,

‘L

.@-

jJ

I

*‘ I

c

.Tp’

t,. / .

r-pa.

‘ i‘

tJ

k

._

2. Specifications for items marked with an asterisk (*) will vary according to the type of equipment

on which the engine is installed.

If you are unable to locate the data applicable to these specifications, please contact lsuzu

Motors LTD through your machine supplier.

GENERAL INFORMAnON 1-7

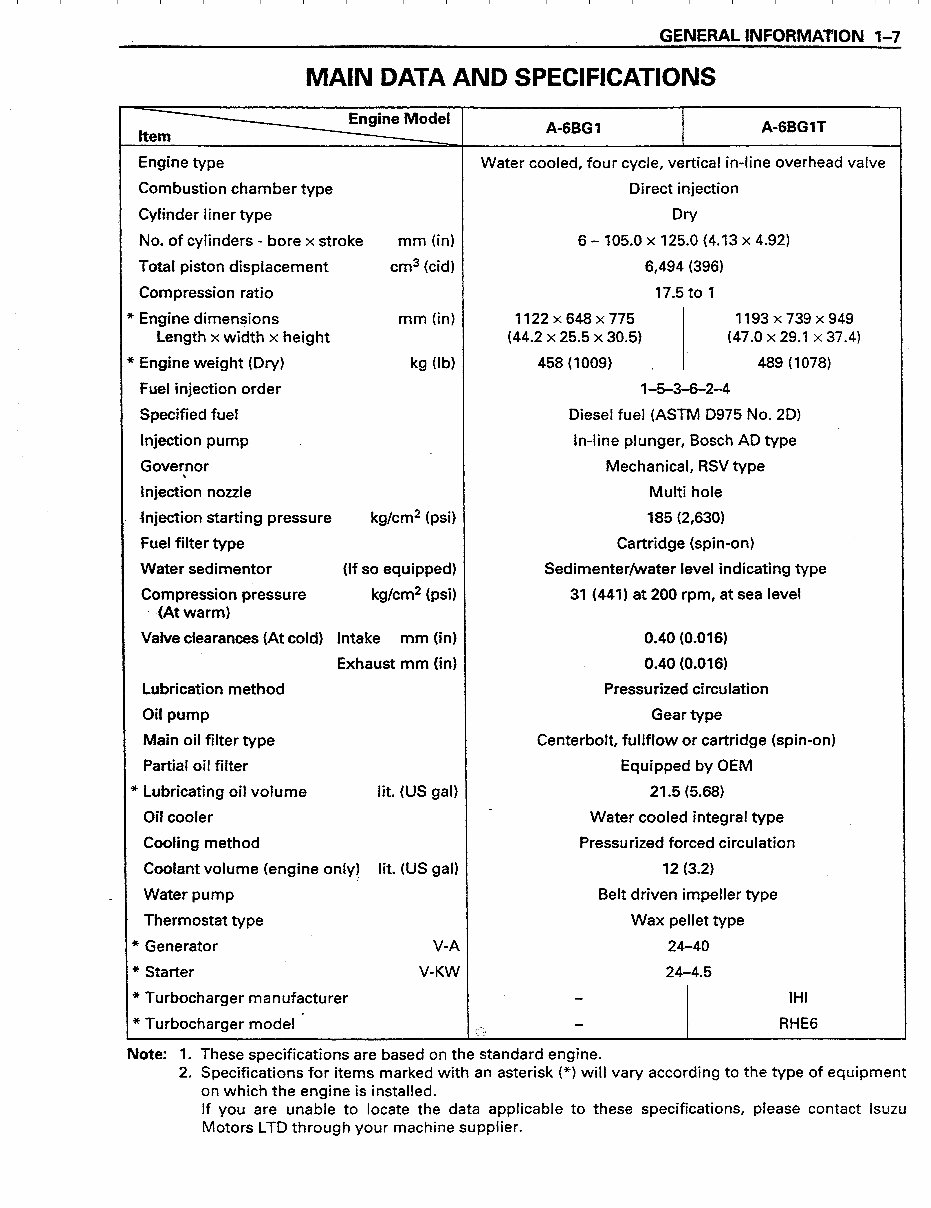

MAIN DATA AND SPECIFICATIONS

Engine Model

Item

A-6BGl A-6BG1T

Engine type Water cooled, four cycle, vertical in-line overhead valve

Combustion chamber type Direct injection

Cylinder liner type

Dry

No. of cylinders - bore x stroke mm (in) 6 - 105.0 x 125.0 (4.13 x 4.92)

Total piston displacement cm3 (cid) 6,494 (396)

Compression ratio 17.5 to 1

Engine dimensions mm (in) 1122x648~775 1193X739X949

Length x width x height (44.2 x 25.5 x 30.5) (47.0 x 29.1 x 37.4)

Engine weight (Dv) kg (lb) 458 (1009) \ 489 (1078)

Fuel injection order l-5-3-6-2-4

Specified fuel Diesel fuel (ASTM 0975 No. 20)

injection pump . In-line plunger, Bosch AD type

Governor

Inject& nozzle

Mechanical, RSV type

Multi hole

injection starting pressure kg/cm2 (psi) 185 (2,630)

Fuel filter type Cartridge (spin-on)

Water sedimentor (if so equipped) Sedimenter/water level indicating type

Compression pressure kg/cm* (psi) 31 (441) at 200 rpm, at sea level

. .(At warm)

Valve clearances (At cold) Intake mm (in) 0.40 (0.016)

Exhaust mm (in) 0.40 (0.016)

Lubrication method Pressurized circulation

Oil pump Gear type

Main oil filter type Centerbolt, fullflow or cartridge (spin-on)

Partial oil filter Equipped by OEM

’Lubricating oil volume lit. (US gal) 21.5 (5.68)

a

Oil cooler Water cooled integral type

Cooling method Pressurized forced circulation

Coolant volume (engine only) lit. (US gal) 12 (3.2)

Water pump Belt driven impeller type

Thermostat type Wax pellet type

t Generator V-A 24-40

e Starter V-KW 24-4.5

e Turbocharger manufacturer IHI

t Turbocharger model ’

-

(yJ

RHE6

Note: 1 . These specifications are based on the standard engine.

2. Specifications for items marked with an asterisk (*) will vary according to the type of equipment

on which the engine is installed.

If you are unable to locate the data applicable to these specifications, please contact lsutu

Motors LTD through your machine supplier.

I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I II I I I I I 1pr -4 1 I

:.

1-8 GENERAL INFORMATION

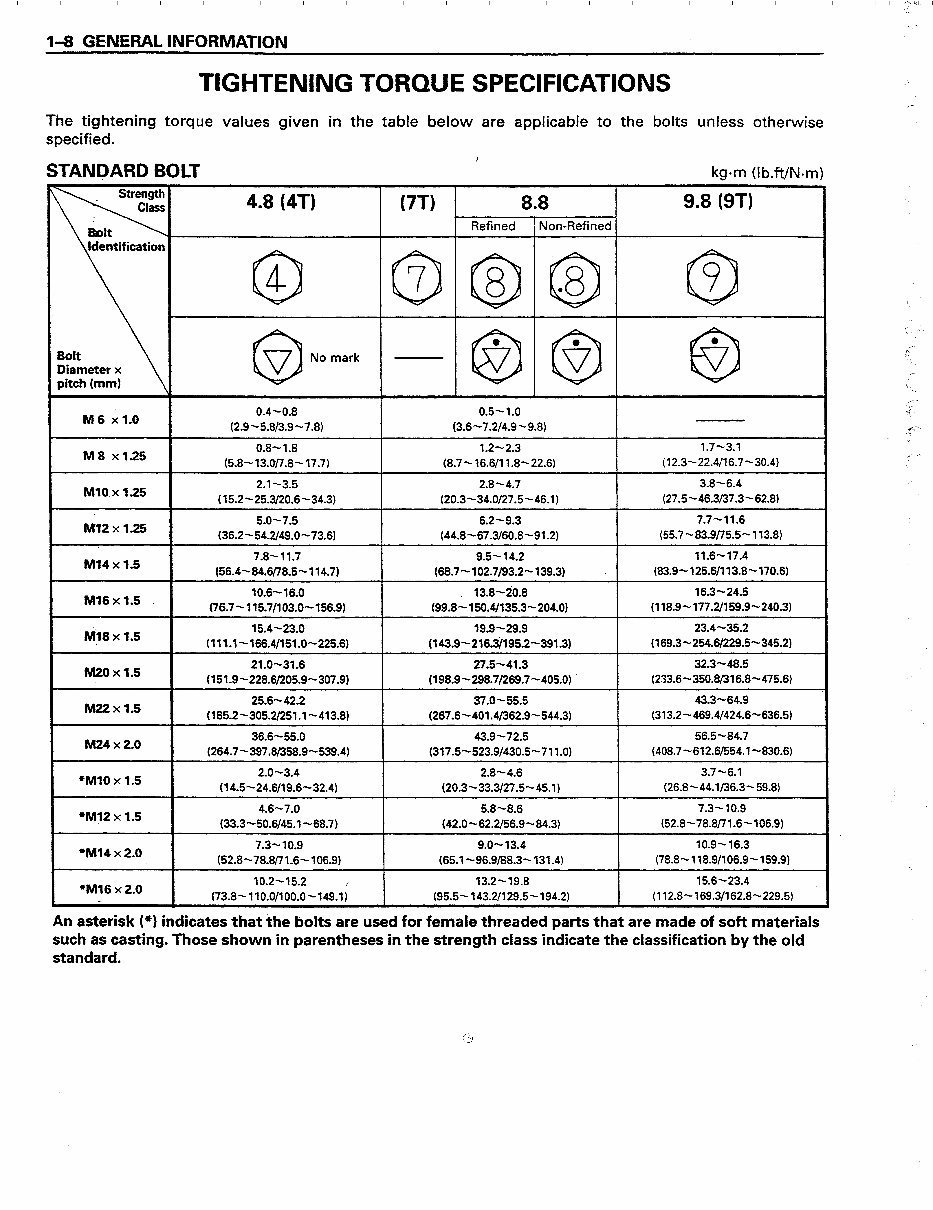

TIGHTENING TORQUE SPECIFICATIONS

The tightening torque values given in the table below are applicable to the bolts unless otherwise

specified.

STANDARD BOLT kg.m (I b.ft/N.m)

4.8 (4T) (7-n 88 0 9.8 (9T)

Refined Non-Refined

@I @@@I @

0 77 No mark -@@$I @

.

M6 x1.0 0.4-0.8 0.5-1.0

(2.9-5.813.9-7.8) (3.6-7.2/4.9-9.8)

M8 xl.25 0.8-1.8 1.2-2.3 x7-3.1

(5.8~~13.OjT.8-17.7) (8.7~16.6/11.8-22.6) (12.3-22.4/16.7-30.4)

Ml0 x 1.25 2.1-3.5 2.8-4.7 3.8-6.4

(15.2-25.3/20.6-34.3) (20.3434.0/27.5-46.1) (27.5~46.3/37.3-62.8)

M72 x 1.25 5.0-7.5 6.2-9.3 7.7-11.6

(36.2-54.2/49.0-73.6) (44.8~67.3/60.8-91.2) (55.7~83.9/75.5-113.8)

M34 x 1.5 7.8-11.7 9.5-14.2 11.6-17.4

(56.4-84.6178.5-114.7) (68.7-102.7/93.2-139.3) . (83.9~125.6/113.8-170.6)

Ml6 x 1.5 10.6-16.0 . 13.8-20.8 16.3-24.5

(76.7~115.7/103.0--156.9) (99.8-150.4/135.3-204.0) (118.9-177.2/159.9-240.3)

Nil8 x 1.5 15.4-23.0 19.9-29.9 23.4-35.2

.

(lll.l-166.4/151.0-225.6) (143.9-216.3/195.2-391.3) (169.34254.6/229.5-345.2)

nmxl.5 21.0-31.6 27.5-41.3 32.3-48.5

, (151.9-228.6/205.9-307.9) (198.9-298.7/269.7-405.0) (233.6~350.8/316.8-475.6)

M22xl.5 25.6-42.2 37.0-55.5 43.3-64.9

(185.2-305.2/251.1-413.8) (267.6-401.4/362.9-544.3) (313.2-469.4/424.6-636.5)

M24 x 2.0 36.6-55.0 43.9-72.5 56.5-84.7

(264.7-397.8/358.9-539.4) (317.5~523.9/430.5-711.0) (408.7-612.6/554.1-830.6)

*Ml0 x 1.5 2.0-3.4 2.8-4.6 3.7-6.1

(14.5-24.6/19.6-32.4) (20.3-33.3127.5-45.1) (26.8-44.1/36.3-59.8)

I

*Ml2 x 1.5 4.6-7.0 5.8-8.6 7.3-10.9

(33.3-50.6/45.1-68.7) (42.0~62.2/56.9-84.3) (52.8-78.8/7X6-106.9)

*Ml4 x 2.0 7.3-10.9 9.0-13.4 10.9-16.3

(52.8-78.8/77.6-106.9) (65.1~96.9/88.3-131.4) (78.8~118.9/106.9-159.9)

10.2-15.2 *Ml6 x 2.0

173.8~110.0/100.0-149.1;

13.2-19.8 15.6-23.4

I (95.5~143.2/129.5-194.2) (112.8-169.3/162.8-229.5)

r

J

,I

‘\

i -

&~

,a-

,<.

‘C

A

_--

r,.-

‘3

,Tc-\

: 3

\

An asterisk (*) indicates that *he bolts are used for female threaded parts that are made of soft materials

such as casting. Those shown in parentheses in the strength class indicate the classification by the old

standard.

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

Viewed 55 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

This Workshop Service/Repair Manual for the ISUZU DIESEL ENGINE 6BG1 is a comprehensive guide suitable for all PC-based Windows operating systems and Mac. It contains technical repair information essential for rebuilding or maintaining the ISUZU DIESEL ENGINE 6BG1, making it valuable for both professional mechanics and DIY enthusiasts.

- Lubrication & Maintenance

- Suspension

- Brakes

- Cooling System

- Electrical System

- Engine

- Fuel System

- Exhaust System

- Transmission

- Heating and Air Conditioning

- Emission Control Systems

- Body

- Wiring Diagrams

- And much more

This manual covers every part of the car and allows for easy printing of all or selected pages. It includes numerous pictures and diagrams for reference. With email delivery, there's no need to wait for shipping, providing quick access to the manual.