Operation Manual

TCD 2012 L04/06 4V

TCD 2013 L04/06 4V

OBJ_DOKU-12638-001.fm Seite 1 Mittwoch, 22. August 2007 9:25 09

Downloaded from www.Manualslib.com manuals search engine

Notes

2 © 2007

Notes

This engine is defined exclusively for purpose

according to the scope of delivery and built by

the equipment manufacturer (use for the intend-

ed purpose). Any other use above and beyond

this will be considered as misuse. The manufac-

turer will not accept any liability for damages re-

sulting from this. The user bears the sole risk.

Use for the intended purpose also includes ob-

servance of the operating, maintenance and re-

pair conditions specified by the manufacturer.

The engine should only be operated, serviced

and repaired by personnel trained in its use and

the hazards involved.

The pertinent rules for the prevention of acci-

dents and other generally recognised safety and

industrial medicine rules must be observed.

When the engine is running there is a danger of

injury caused by:

– rotating and hot components

– on motors with external ignition (high electri-

cal voltage). Contact must be avoided!

Unauthorised engine modifications will invalidate

any liability claims against the manufacturer for

resultant damage.

Equally, manipulations to the injection and con-

trol system can affect the engine's performance

and the exhaust characteristics. Adherence to

legislation on pollution can no longer be guaran-

teed under such conditions.

Do not change the cooling air feed area to the

blower of fan. An unobstructed cooling air supply

must be guaranteed.

The manufacturer will accept no liability for dam-

age resulting from this.

When carrying out maintenance work on the en-

gine, the use of DEUTZ original parts is pre-

scribed. These are specially designed for your

engine and guarantee perfect operation.

Non-compliance results in the expiry of the war-

ranty!

Maintenance/cleaning work on the engine may

only be carried out when the engine is not run-

ning and has cooled down.

When doing this, make sure that the electrical

system is switched off (remove ignition key).

The specifications for accident prevention with

electrical systems (e.g. VDE-0100/-0101/-0104/-

0105 Electrical protective measures against dan-

gerous contact voltages) must be observed.

Cover all electrical components tightly when

cleaning with liquids.

Do not work on the fuel system while the engine

is running - Danger to life!

Wait for the pressure to drop after the engine has

come to a standstill (in engines with DEUTZ

Common Rail about 5 minutes, otherwise

1 minute) because the system is under high

pressure - Danger to life!

During the first trial run do not stand in the dan-

ger area of the engine.

Danger due to high pressure in case of leaks -

Danger to life!

– In case of leaks immediately contact work-

shop.

– When working on the fuel system, make sure

that the engine is not started inadvertently

during repairs - Danger to life!

OBJ_DOKU-12638-001.fm Seite 2 Mittwoch, 22. August 2007 9:25 09

Downloaded from www.Manualslib.com manuals search engine

Foreword

© 2007 3

Dear customer,

Congratulations on the purchase of your DEUTZ en-

gine.

DEUTZ air/liquid-cooled engines are developed for a

broad spectrum of applications. Consequently, a

wide range of variants is offered to meet the require-

ments of specific cases.

The engine is equipped accordingly for the particular

installation situation, i.e. not all the components de-

scribed in the operating manual are installed in your

engine.

We have endeavoured to highlight any differences

so that you will be able to locate the operating and

maintenance instructions applicable to your engine

more quickly and easily.

Please make sure that this operating manual is avail-

able to everyone involved in the operation, mainte-

nance and repair of the engine and that they have

understood the contents.

If you have any queries, please contact us, we'll be

happy to advise you.

Sincerely,

DEUTZ AG

Engine serial number

Please enter the engine serial number here. This will

simplify the handling of customer service, repair and

spare parts queries.

Notes

We reserve the right to make technical changes to

the descriptions and data in this operating manual in

the interest of further development of the engines.

This document may only be reprinted and repro-

duced, even in part, with our express permission.

Order number

0312 3536 en

OBJ_DOKU-12638-001.fm Seite 3 Mittwoch, 22. August 2007 9:25 09

Downloaded from www.Manualslib.com manuals search engine

Contents

4 © 2007

Notes . . . . . . . . . . . . . . . . . . . . . . . 2

Foreword. . . . . . . . . . . . . . . . . . . . . 3

1 General. . . . . . . . . . . . . . . . . . . . 5

2 Engine description . . . . . . . . . . . . . 7

Type . . . . . . . . . . . . . . . . . . . . . 7

Engine illustration. . . . . . . . . . . . . . . 9

Lubricating oil schematic . . . . . . . . . . .19

Fuel schematic . . . . . . . . . . . . . . . .20

Coolant schematic . . . . . . . . . . . . . .21

Exhaust gas recirculation . . . . . . . . . . .23

Electrics/Electronics . . . . . . . . . . . . .24

3 Operation . . . . . . . . . . . . . . . . . .26

Ambient conditions . . . . . . . . . . . . . .26

Commissioning . . . . . . . . . . . . . . . .27

Start procedure . . . . . . . . . . . . . . . .29

Operation monitoring . . . . . . . . . . . . .31

Stop procedure . . . . . . . . . . . . . . . .33

4 Operating media. . . . . . . . . . . . . . .34

Lubricating oil . . . . . . . . . . . . . . . . .34

Fuels . . . . . . . . . . . . . . . . . . . . .36

Coolant . . . . . . . . . . . . . . . . . . . .37

5 Maintenance . . . . . . . . . . . . . . . . .38

Maintenance schedule . . . . . . . . . . . .38

6 Service and maintenance . . . . . . . . . .41

Lubricating oil system. . . . . . . . . . . . .41

Fuel system. . . . . . . . . . . . . . . . . .43

Cooling system . . . . . . . . . . . . . . . .47

Engine cleaning. . . . . . . . . . . . . . . .49

Suction system . . . . . . . . . . . . . . . .50

Belt drives . . . . . . . . . . . . . . . . . .53

Setting work . . . . . . . . . . . . . . . . .55

Electrical system . . . . . . . . . . . . . . .60

7 Faults. . . . . . . . . . . . . . . . . . . . .62

Fault table . . . . . . . . . . . . . . . . . .62

Engine management . . . . . . . . . . . . .65

8 Transport and storage . . . . . . . . . . .67

Transport . . . . . . . . . . . . . . . . . . .67

Protecting the engine against corrosion . . .68

9 Technical data . . . . . . . . . . . . . . . .70

Engine and setting data . . . . . . . . . . .70

OBJ_DOKU-12638-001.fm Seite 4 Mittwoch, 22. August 2007 9:25 09

Downloaded from www.Manualslib.com manuals search engine

General

© 2007 5

1

DEUTZ diesel engines

DEUTZ diesel engines are the product of years of re-

search and development. Profound know-how com-

bined with high quality requirements are the

guarantee for the production of engines with a long

life, high reliability levels and low fuel consumption.

Obviously the high requirements for the protection of

the environment are also met.

Safety precautions when the engine is

running

Maintenance work or repairs may only be performed

on the shut-down engine. Make sure that the engine

cannot be started inadvertently - Danger of acci-

dent!

When the work is complete, be sure to refit any pan-

els and guards that have been removed.

Observe industrial safety regulations when running

the engine in an enclosed space or underground.

When working on the running engine, work clothing

must be close fitting.

Never fill the fuel tank while the engine is running.

Service and Maintenance

Service and maintenance are also decisive for

whether the engine satisfactorily meets the set de-

mands. Recommended service intervals must there-

fore be observed and service and maintenance work

must be carried out conscientiously.

Special care should be taken under abnormally de-

manding operating conditions.

Original DEUTZ parts

Original DEUTZ parts are subject to the same strict

quality demands as the DEUTZ engines. Further de-

velopments for improving the engines are also intro-

duced in the original DEUTZ parts of course. Only

the use of original DEUTZ parts manufactured ac-

cording to the state-of-the-art can guarantee perfect

functioning and high reliability.

DEUTZ Xchange components

DEUTZ replacement parts are a low-cost alternative.

Of course, the quality standards here are just as high

as for new parts. DEUTZ replacement parts are

equal to the original DEUTZ parts in function and re-

liability.

Asbestos

The gaskets used in this engine contain no asbestos.

Please use the appropriate spare parts for mainte-

nance and repair work.

Service

We want to preserve the high performance of our en-

gines, and with it the confidence and satisfaction of

our customers. We are therefore represented world-

wide by a network of service branches.

The DEUTZ name does not merely stand for engines

that are the products of extensive development

work, DEUTZ also stands for complete service pack-

ages that ensure optimum operation of our engines,

and for customer services operations that you can

count on.

Please contact your service partner in case of mal-

functions and sare parts inquiries. Our specially

trained personnel will ensure fast, professional re-

pairs using original DEUTZ spare parts in case of

damage.

The DEUTZ home page gives you a continuously up-

to-date overview of the service partners in your vicin-

ity with notes on product responsibilities and servic-

es. Or you can use another fast, convenient way via

the Internet under www.deutzshop.de. The DEUTZ

P@rts Online parts catalogue gives you a direct con-

tact to your nearest local service partner.

Masthead

DEUTZ AG

Ottostraße 1

51149 Cologne

Telephone:+49 (221) 822-0

Fax: +49 (221) 822-5850

www.deutz.com

E-mail: info@deutz.com

California

Proposition 65 Warning

Diesel engines and some of its constituents are

known to the State of California to cause cancer,

birth defects and other reproductive harm.

OBJ_DOKU-12638-001.fm Seite 5 Mittwoch, 22. August 2007 9:25 09

Downloaded from www.Manualslib.com manuals search engine

General

6 © 2007

1

Danger

Caution

Notes

This symbol is used for all safety instruc-

tions which, if not observed, present a di-

rect danger to life and limb for the person

involved. Observe these carefully. The at-

tention of operating personnel should be

drawn to these safety instructions. Further-

more, the legislation for "general regula-

tions for safety and the prevention of

accidents" must be observed.

This symbol indicates a danger to the part

and engine. The relevant instructions must

be observed, failure to do so can lead to de-

struction of the part and the engine.

This symbol accompanies notes of a gen-

eral kind.

OBJ_DOKU-12638-001.fm Seite 6 Mittwoch, 22. August 2007 9:25 09

Downloaded from www.Manualslib.com manuals search engine

Type Engine description

© 2007 7

2

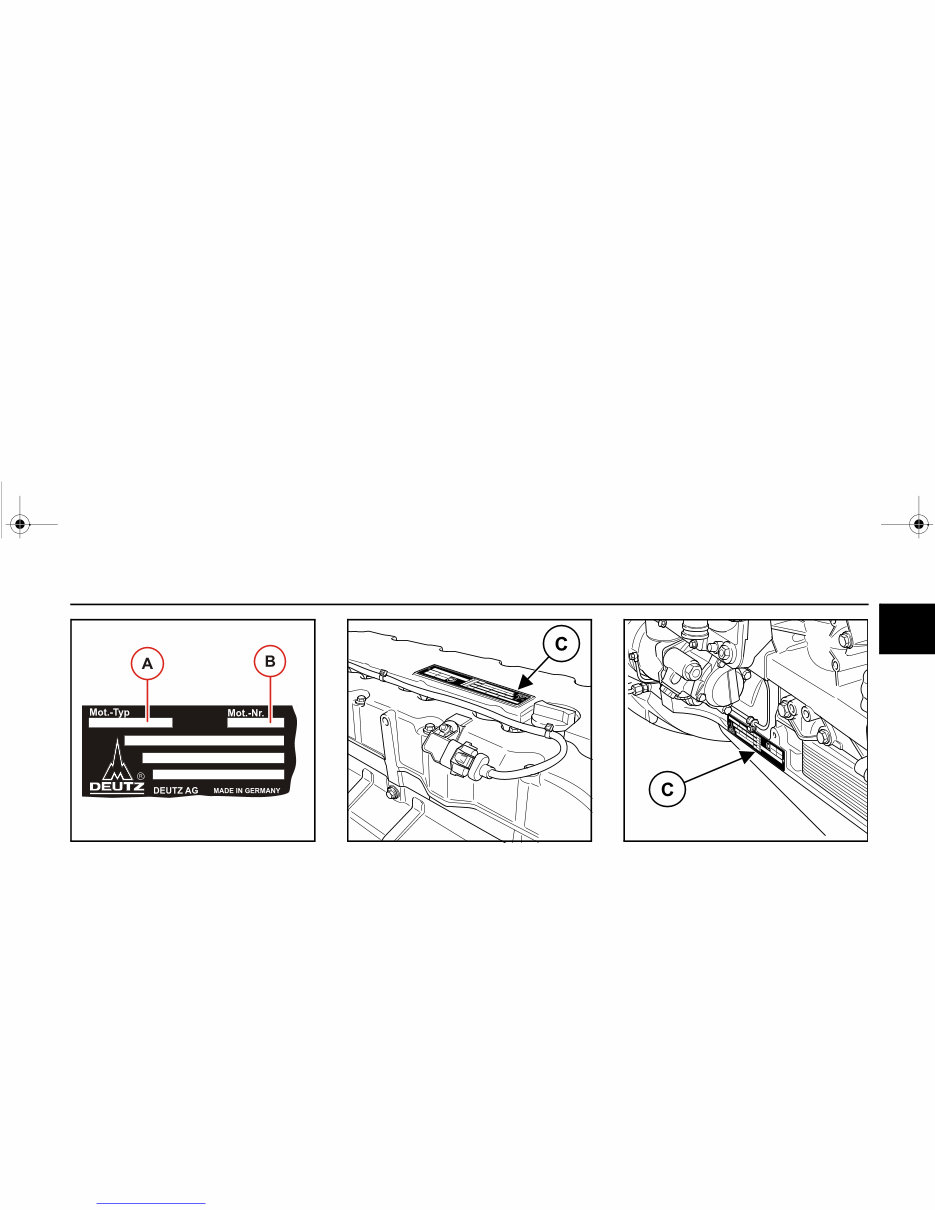

Rating plate

The engine type A , engine number B and the power

data are stamped on the rating plate.

The engine type and number must be stated when

purchasing spare parts.

Location of the rating plate

The rating plate C is mounted on the cylinder head

cover or crankcase.

OBJ_DOKU-12638-001.fm Seite 7 Mittwoch, 22. August 2007 9:25 09

Downloaded from www.Manualslib.com manuals search engine

Engine description Type

8 © 2007

2

Rating plate

Or the C rating plate is fixed sideways on the fly-

wheel side

Engine serial number

The engine number is stamped onto the crankcase

(arrow) and onto the rating plate.

Cylinder numbering

Cylinder arrangement

The cylinders are counted consecutively starting

from flywheel (1).

Direction of rotation

Looking at the power transmission side.

rotating to the left: counter-clockwise.

Engine sides

Looking at the power transmission side.

OBJ_DOKU-12638-001.fm Seite 8 Mittwoch, 22. August 2007 9:25 09

Downloaded from www.Manualslib.com manuals search engine

Engine illustration Engine description

© 2007 9

2

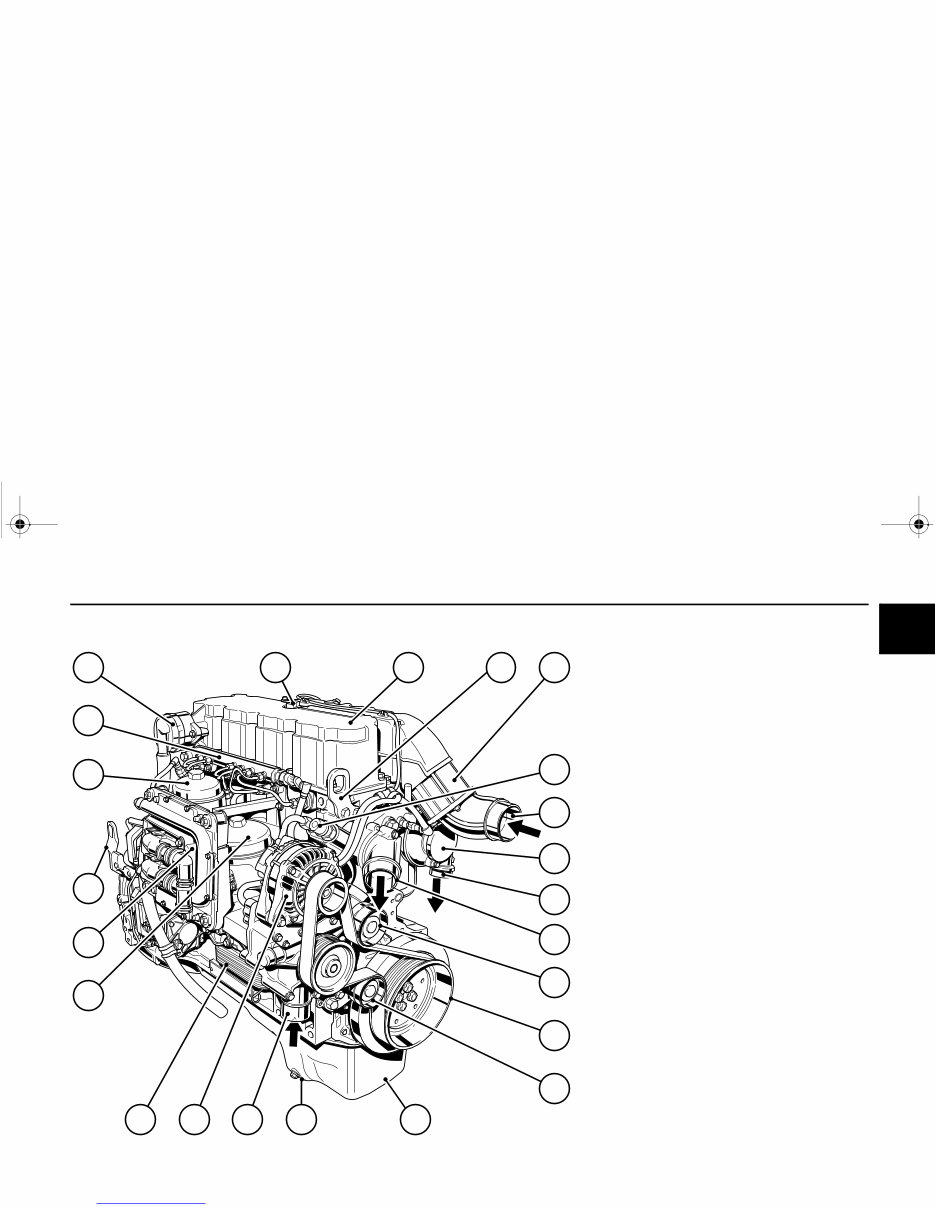

1 2 3

4

5

6

7

8

9

10

11

12 13 15 16 14

18

19

20

21 22

2

17

TCD 2013 L04 4V engine, view from right

(example)

1 Cylinder head cover

2 Transport device

3 Heating flange

4 Cab heater connection

5 Combustion air inlet

6 Connection from air filter

7 Cumbustion air outlet to the charge air cooler

8 Coolant outlet

9 Deflection pulley

10 Belt pulley on crankshaft

11 Tension pulley

12 Lubricating oil sump

13 Lubricating oil drain plug

14 Coolant inlet

15 Generator

16 Lube oil cooler

17 Lubricating oil filter

18 Engine control unit

19 Fuel filter

20 Rail with pressure reducing valve and pressure

sensor

21 Crankcase ventilation (open system)

22 Lubricating oil filling

OBJ_DOKU-12638-001.fm Seite 9 Mittwoch, 22. August 2007 9:25 09

Downloaded from www.Manualslib.com manuals search engine

Engine description Engine illustration

10 © 2007

2

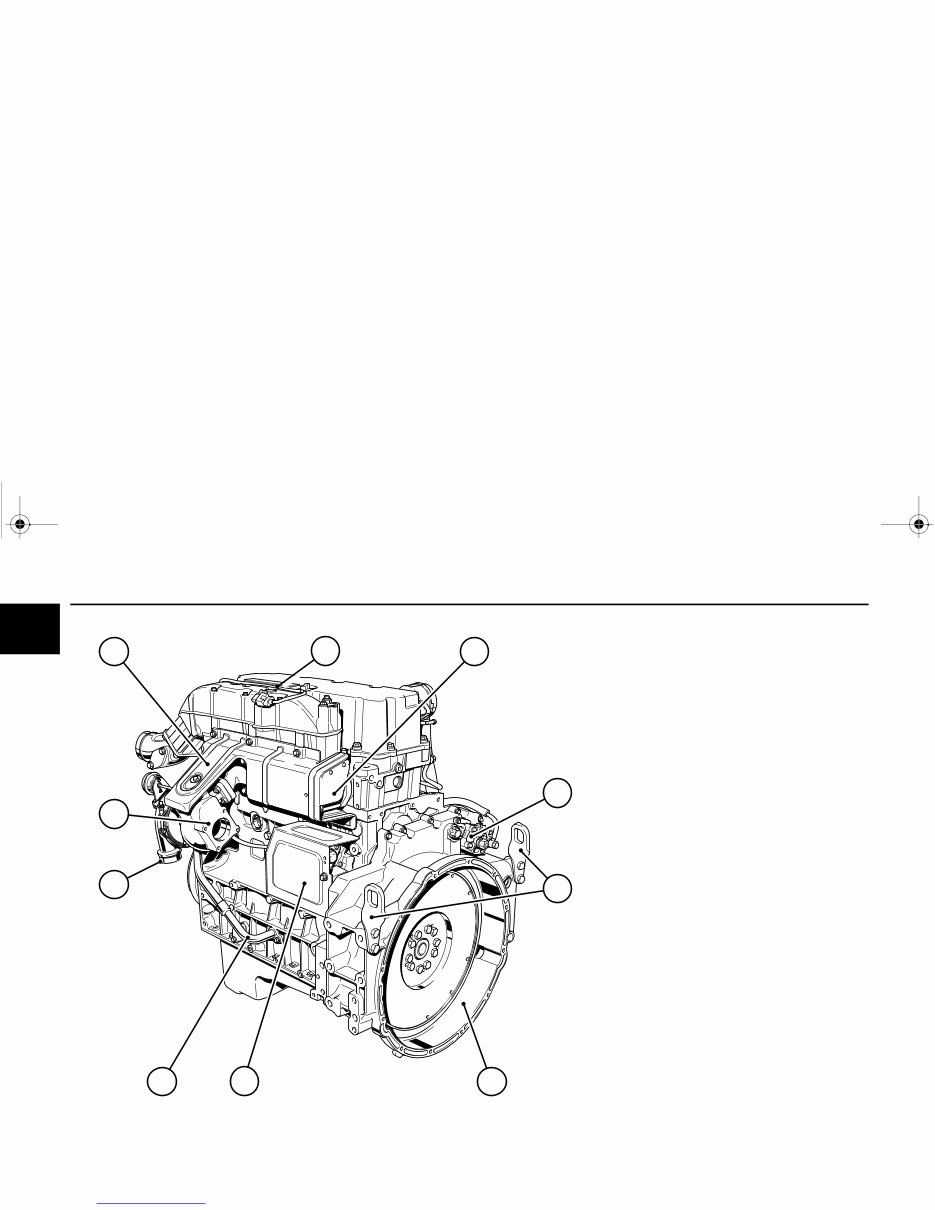

1 2

3

5 6 7

8

9

10

4

TCD 2013 L04 4V engine, view from left

(example)

1 Charge air temperature/pressure transmitter

2 Exhaust manifold line

3 Fuel supply pump

4 Transport device

5 Gear connection (SAE housing)

6 Starter cover

7 Lubricating oil return line from the exhaust turbo-

charger

8 Cumbustion air outlet to the charge air cooler

9 Exhaust gas outlet of the turbocharger

10 Shield (thermal protection)

OBJ_DOKU-12638-001.fm Seite 10 Mittwoch, 22. August 2007 9:25 09

Downloaded from www.Manualslib.com manuals search engine

You're Reading a Preview

What's Included?

Lifetime Access

Access PDF Contents & Bookmarks

Print one or all pages of your manual