Deutz Engine TCD 2015 Operation Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Operation Manual

TCD 2015

ProCarManuals.com

This engine is built exclusively for

purpose according to the scope

of delivery - defined by the equip-

ment manufacturer (use for the

intended purpose). Any use abo-

ve and beyond this is considered improper use.

The manufacturer will not be liable for damages

resulting from this. The user bears the sole risk.

Use for the intended purpose also includes ob-

servance of the operating, maintenance and re-

pair instructions specified by the manufacturer.

The engine may only be used, maintained and

repaired by persons who are familiar with it and

instructed in the dangers.

The pertinent rules for the prevention of acci-

dents and other generally recognised safety and

industrial medicine rules must be observed.

When the engine is running there is a danger of

injury caused by:

– rotating / hot parts

– in engines with external ignition (high electri-

cal voltage), avoid touching at all costs!

Unauthorised modifications to the engine exclu-

de manufacturer liability for resulting damages.

Equally, manipulations to the injection and cont-

rol system can affect the engine's performance

and the exhaust characteristics. Compliance

with legal environmental regulations will no lon-

ger be guaranteed in this case.

Do not modify, obstruct the cooling air flow area

to the fan, unhindered cooling air supply must be

guaranteed.

The manufacturer will accept no liability for da-

mages resulting from this.

Only DEUTZ original parts may be used when

carrying out maintenance/repair work on the en-

gine. These have been designed especially for

your engine and ensure a trouble-free operation.

Failure to observe this will void the warranty !

Maintenance/cleaning work on the engine may

only be carried out when the engine is not run-

ning and has cooled down.

When doing this, make sure that the electrical

systems are switched off (remove ilgnition key).

The specifications for accident prevention with

electrical systems (e.g. -VDE-0100/-0101/-0104/

-0105 Electrical measures against dangerous

touch voltages) must be observed.

Cover all electrical components tightly when

cleaning with liquids.

Do not work on the fuel system when the engine

is running - Danger to life.

Wait for the pressure to drop after the engine co-

mes to a standstill (in engines with DEUTZ Com-

mon Rail about 5 minutes, otherwise 1 minute)

because the system is under high pressure Dan-

ger to life.

During the first trial run do not stand in the dan-

ger area of the engine.

In case of leaks danger due to high pressure -

Danger to life.

– Go to the workshop ilmmediately in case of

leaks.

– Make sure the engine is not started acciden-

tally during repairs when working on the fuel

system - Danger to life.

Danger

This symbol is used for all safety in-

structions which, if not observed, pre-

sent a direct danger to life and limb for

the person involved. Observe these

carefully. Also pass on the safety in-

structions to your operating personnel.

Furthermore, the legislation for "gene-

ral regulations for safety and the pre-

vention of accidents" must be

observed.

Caution

This symbol indicates a danger to the

component / engine. The appropriate

instructions must be followed otherwi-

se the component / engine may be de-

stroyed.

ProCarManuals.com

Operation Manual TCD 2015

3

Foreword

Dear customer,

Congratulations on your purchase of this

DEUTZ engine. The DEUTZ air/liquid-cooled

engines are developed for a broad spectrum of

applications. A wide range of variants ensures

that the respective requirements are met.

The engine is equipped according to the instal-

lation case you have specified, i.e. not all the

parts described in this instruction manual are

installed in your engine.

We have done our best to highlight the diffe-

rences so that you can easily find the operating

and maintenance instructions relevant to your

engine.

Please make sure that this instruction manual

is available to everyone involved in the opera-

tion, maintenance and repair of the engine and

that they have understood the contents.

We will be glad to answer any inquiries you

may have.

Your

DEUTZ AG.

Engine number

Please enter the engine number here.( 6)

This will simplify the handling of customer ser-

vice, repair and spare parts queries.

Note

Illustrations and data in this instruction manual

are subject to technical changes in the course

of further development of the engine.

Reprinting and reproduction of any kind, even

in part, require our express permission.

Order number

0312 3412 en

ProCarManuals.com

Contents

4

Preface . . . . . . . . . . . . . . . . . . . . . . . . . . 3

1 General . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Engine description . . . . . . . . . . . . . . . . 6

2.1 Engine type. . . . . . . . . . . . . . . . . . . . . . 6

2.2 Engine diagram . . . . . . . . . . . . . . . . . . 7

2.3 Lubricating oil circuit . . . . . . . . . . . . . . 11

2.4 Fuel circuit . . . . . . . . . . . . . . . . . . . . . 12

2.5 Coolant circuit . . . . . . . . . . . . . . . . . . . 13

2.6 Electrics . . . . . . . . . . . . . . . . . . . . . . . 14

3 Operation . . . . . . . . . . . . . . . . . . . . . . . 15

3.1 Ambient conditions . . . . . . . . . . . . . . . 15

3.2 Initial commissioning . . . . . . . . . . . . . 16

3.3 Start process . . . . . . . . . . . . . . . . . . . 18

3.4 Operation monitoring . . . . . . . . . . . . . 19

3.5 Stop process. . . . . . . . . . . . . . . . . . . . 21

4 Consumables . . . . . . . . . . . . . . . . . . . . 22

4.1 Lubricating oil . . . . . . . . . . . . . . . . . . . 22

4.2 Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4.3 Coolant . . . . . . . . . . . . . . . . . . . . . . . . 25

5 Maintenance . . . . . . . . . . . . . . . . . . . . . 27

5.1 Maintenance schedule . . . . . . . . . . . . 27

6 Care and maintenance work . . . . . . . . 29

6.1 Lubricating oil system . . . . . . . . . . . . 29

6.2 Fuel system . . . . . . . . . . . . . . . . . . . . 31

6.3 Cooling system . . . . . . . . . . . . . . . . . . 34

6.4 Engine cleaning . . . . . . . . . . . . . . . . . 36

6.5 Intake system . . . . . . . . . . . . . . . . . . . 37

6.6 Belt drives . . . . . . . . . . . . . . . . . . . . . . 39

6.7 Adjustments . . . . . . . . . . . . . . . . . . . . 40

6.8 Electrical system . . . . . . . . . . . . . . . . 42

7 Faults . . . . . . . . . . . . . . . . . . . . . . . . . . 44

7.1 Fault table . . . . . . . . . . . . . . . . . . . . . 44

7.2 Engine management . . . . . . . . . . . . . 46

8 Transport and storing . . . . . . . . . . . . 48

8.1 Engine transport . . . . . . . . . . . . . . . . 48

8.2 Preservation. . . . . . . . . . . . . . . . . . . . 49

9 Technical data . . . . . . . . . . . . . . . . . . . 51

9.1 Technical data . . . . . . . . . . . . . . . . . . 51

ProCarManuals.com

1

General

5

DEUTZ diesel engines

are the product of years of research and deve-

lopment. The profound expertise gained th-

rough this, in combination with high demands

on quality, attests to the fact that our engines

possess all the qualities of long life, high relia-

bility and low fuel consumption. Naturally the

high requirements for protection of the environ-

ment are also met.

Safety precautions when the engine is

running

Only carry out maintenance work or repairs

with the engine switched off. Ensure that the

engine cannot be started unintentionally - dan-

ger of accidents!

Re-install any removed protective equipment

upon completion of the work.

Observe industrial safety regulations when

operating the engine in enclosed spaces or un-

derground.

When working on the running engine, work clo-

thing must be close fitting.

Only re-fuel with the engine switched off.

Maintenance and care

are decisive for whether the engine satisfacto-

rily meets the set demands. Compliance with

the prescribed maintenance times and the ca-

reful execution of maintenance and care work

are therefore essential.

Difficult operating conditions deviating from

normal operation must be observed especially.

Original DEUTZ parts

are subject to the same strict quality require-

ments as the DEUTZ engines. Further deve-

lopments for the improvement of the engines

are also introduced for the original DEUTZ

parts of course. Only the use of original

DEUTZ parts manufactured according to the

latest state of knowledge will guarantee perfect

functioning and high reliability.

DEUTZ Xchange components

DEUTZ Xchange components are a low-cost

alternative. The same high quality standards

as for new parts apply here of course. DEUTZ

Xchange components are equivalent to the ori-

ginal DEUTZ parts in function and reliability.

Asbestos

Gaskets used in this engine are asbestos-free.

Please use the appropriate spare parts for

maintenance and repair work.

Service

We want to preserve the high performance of

our engines and with it the confidence and sa-

tisfaction of our customers. Therefore we are

represented by a network of service branches

world-wide.

The name DEUTZ stands not only for an engi-

ne which is the result of sophisticated develop-

ment work, DEUTZ Parts catalogue also

stands for a complete service package which

guarantees the optimum operation of our engi-

nes and for a customer service on which you

can rely.

Contact one of our responsible service repre-

sentatives in case of operation malfunctions

and spare parts inquiries. Our trained specia-

list personnel ensures fast, professional re-

pairs using original parts in the event of

damage.

The DEUTZ homepage with references to pro-

duct responsibilities and services always gives

you an up-to-date overview of the DEUTZ part-

ners in your area. Or use the fast, comfortable

route via the Internet under www.deutz-

shop.de. With the DEUTZ P@rts OnlineParts-

Catalogue you have direct contact to the

nearest local DEUTZ Service Station.

DEUTZ AG

Deutz-Mülheimer Str. 147-149

D-51057 Köln

Phone: 0049-221-822-0

Fax: 0049-221-822-5304

Telex:8812-0 khd d

http://www.deutz.com

ProCarManuals.com

Engine description 2.1 Engine type

6

2

Company plate

The type A, the engine number B and the per-

formance data are stamped on the company

plate. The engine type and number must be

stated when purchasing spare parts.

Position of the company plate and

engine number

The company plate C and engine number D

are fixed or stamped on the crankcase.

General definitions

Cylinder arrangement, engine sides

and direction of rotation

Cylinder arrangement

The cylinders are counted consecutively, star-

ting from the flywheel1.

Direction of rotation

Looking onto drive side

left-hand rotation: counter-clockwise (see

example)

Engine sides

Looking at the power transmission side.

left,

right.

ProCarManuals.com

2

2.2 Engine diagram Engine description

7

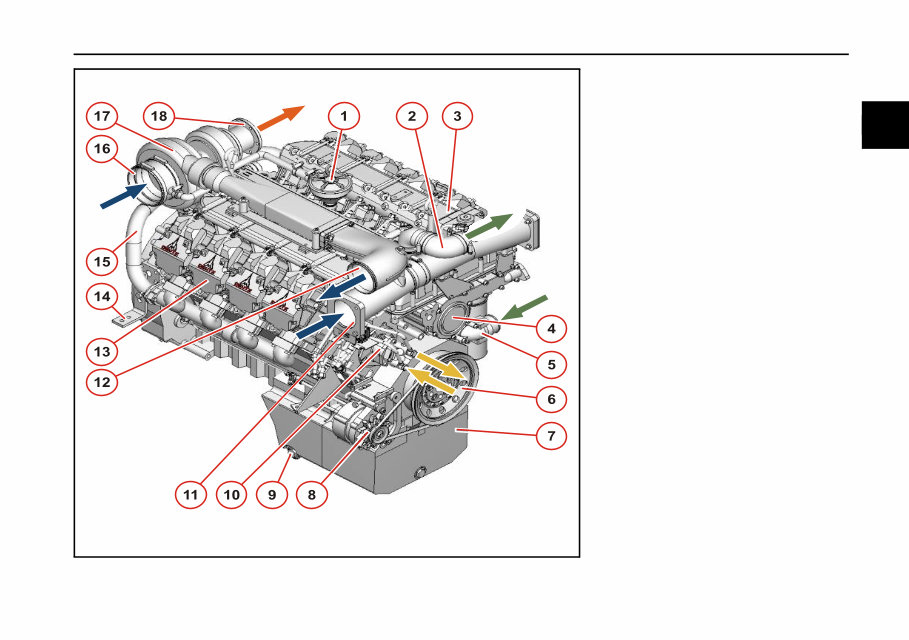

Example: TCD2015 V08 standard, industrial and vehicle engine, right side

1. Crankcase venting

2. Connection to coolant heat exchanger

3. Charge air duct

4. Coolant pump

5. Connection from coolant heat exchanger

6. Vibration damper / V-belt pulley

7. Lubricating oil tray

8. Generator

9. Oil drain plug

10.Fuel supply pump

11.Connection from charge air cooler left

(optional: right)

12.Connection to charge air cooler

13.Cylinder head cover

14.Transport bracket

15.Exhaust manifold

16.Connection from air filter

17.Turbocharger

18.Connection to exhaust silencer

ProCarManuals.com

Engine description 2.2 Engine diagram

8

2

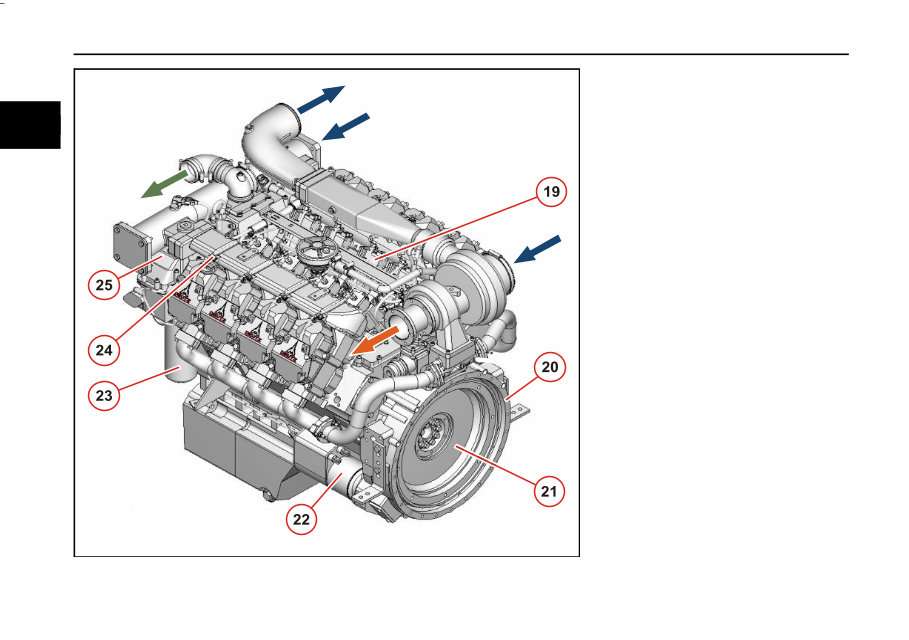

Example: TCD2015 V08 standard, industrial and vehicle engine, left side

19.Injection pump (plug-in pump)

20.Gear connection (SAE)

21.Flywheel

22.Starter

23.Lubrricating oil filter cartridge

24.High pressure pipe

25.Lubricating oil cooler

ProCarManuals.com

2

2.2 Engine diagram Engine description

9

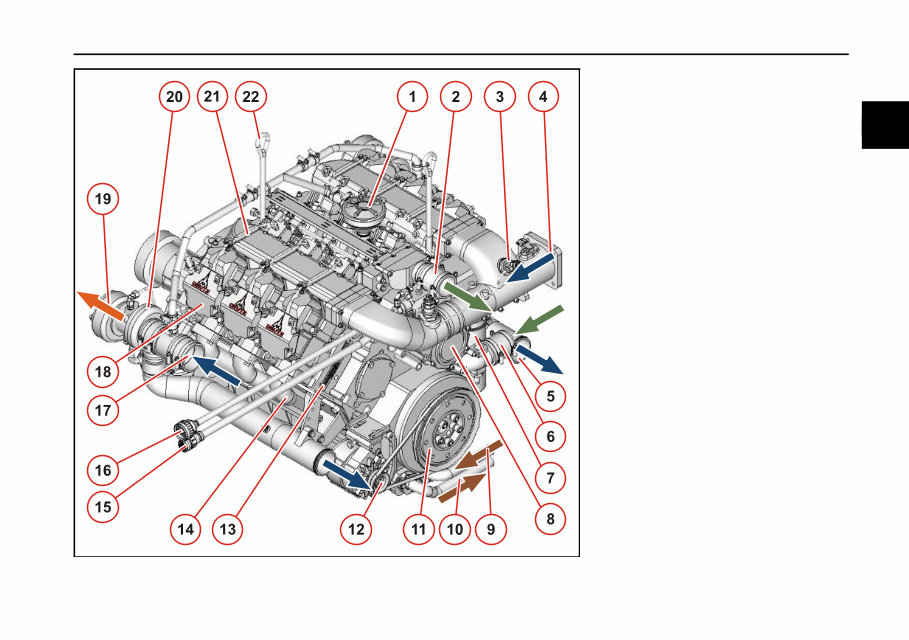

Example: TCD2015 V06 railway engine, right side

1. Crankcase venting

2. Connection to coolant heat exchanger

3. Spark plug

4. Connection from the charge air cooler

5. Connection to charge air cooler

6. Connection from coolant heat exchanger

7. Lubrricating oil filter cartridge

8. Coolant pump

9. Connection of separate lubricating oil tank

10.Connection to separate lubricating oil tank

11.Vibration damper / V-belt pulley

12.Generator

13.Engine rating plate (company plate)

14.Exhaust manifold

15.Connection to the EMR3 system

16.Connection to the MVS system

17.Connection from air filter

18.Cylinder head cover

19.Connection to exhaust silencer

20.Turbocharger

21.Charge air suction pipe

22.Transport device

ProCarManuals.com

Engine description 2.2 Engine diagram

10

2

Example: TCD2015 V06 railway engine, left side

23.Auxiliary drive

24.Engine mounting

25.Gear connection (SAE)

26.Flywheel

27.Free auxiliary drive

28.Crankcase vent pipe

29.Lubricating oil cooler

30.Injection pump (plug-in pump)

31.High pressure pipe

ProCarManuals.com

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

Viewed 62 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$52.99

- General

- Engine description

- Engine type

- Engine diagram

- Lubricating oil circuit

- Fuel circuit

- Coolant circuit

- Electrics

- Operation

- Ambient conditions

- Initial commissioning

- Start process

- Operation monitoring

- Stop process

- Consumables

- Lubricating oil

- Fuel

- Coolant

- Maintenance

- Maintenance schedule

- Care and maintenance work

- Lubricating oil system

- Fuel system

- Cooling system

- Engine cleaning

- Intake system

- Belt drives

- Adjustments

- Electrical system

- Faults

- Fault table

- Engine management

- Transport and storing

- Engine transport

- Preservation

- Technical data

- Technical data