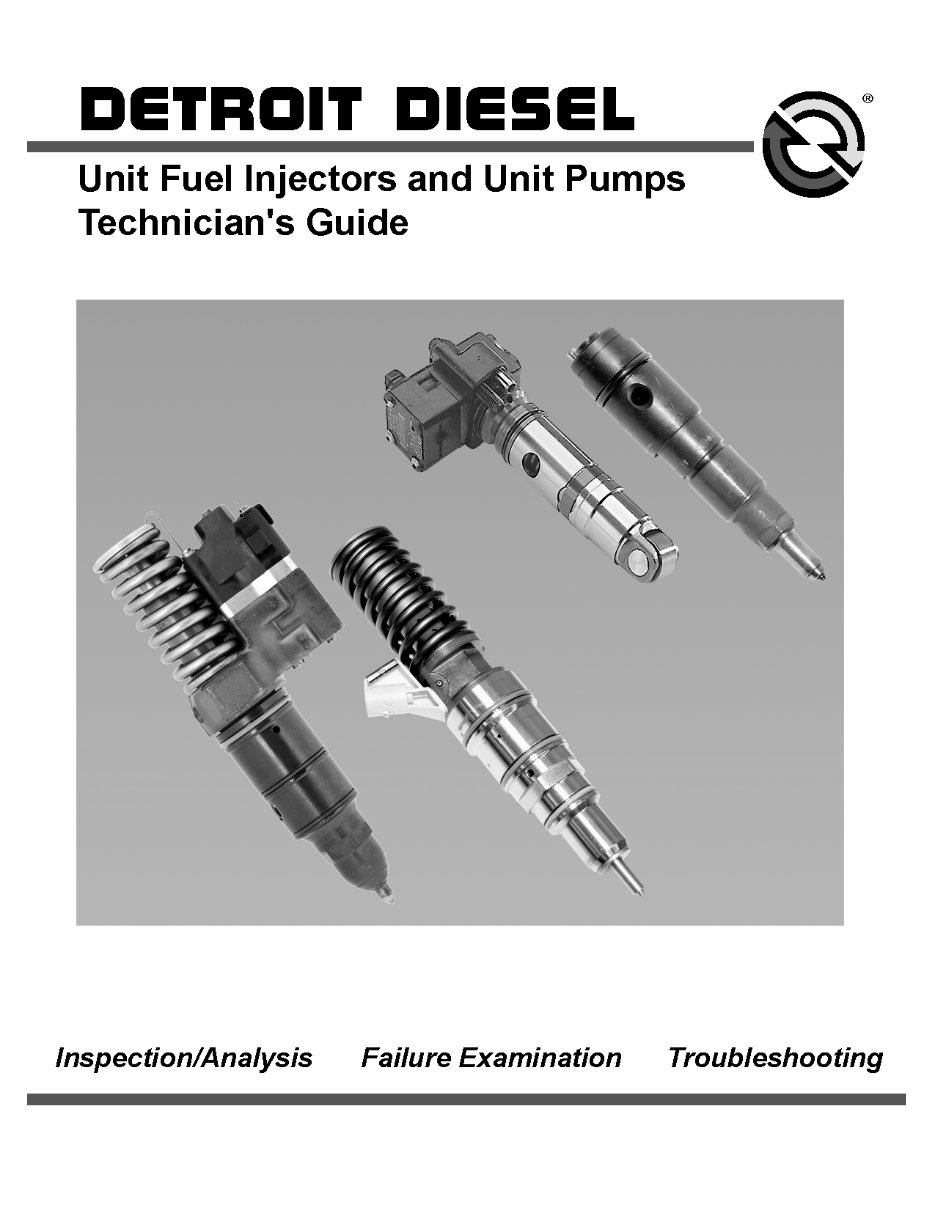

Detroit Diesel Unit Fuel Injectors and Unit Pumps Technician’s Guide

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

ATTENTION

This document is a guideline for qualified personnel. It explains the operation of the fuel

injections system for Detroit Diesel Corporation four-cycle engines and Mercedes Benz MBE

900 and MBE 4000 engines. Detroit Diesel Corporation makes no representations or warranties

regarding the information contained in this document. The information contained in this

document may not be complete and is subject to change without notice.

Trademark Information

Pro-Chek

®

, Power Guard

®

, Series 50

®

, Diagnostic Link

®

, Detroit Diesel

®

, DDC

®

, Series 60

®

,

DDEC

®

, and the spinning arrows design are registered trademarks of Detroit Diesel Corporation.

Fuel Pro

®

is a registered trademark of Davco Manufacturing, L.L.C. Biobor

®

is a registered

trademark of United States Borax and Chemical Corporation. Pro-Link

®

is a registered trademark

of Micro Processor Systems, Inc. All other trademarks used are the property of their respective

owners.

UNIT FUEL INJECTORS AND UNIT PUMP TECHNICIAN GUIDE

TABLE OF CONTENTS

1 INTRODUCTION ................................................................................................................. 1-1

1.1 DIESEL FUEL SYSTEM OVERVIEW ............................................................................. 1-1

1.1.1 SERIES 50/60 ELECTRONIC UNIT INJECTOR ........................................................ 1-5

1.1.2 MBE 900 AND MBE 4000 UNIT PUMP AND NOZZLE .............................................. 1-10

2 SAFETY .............................................................................................................................. 2-1

2.1 GENERAL SAFETY PRECAUTIONS TO OBSERVE WHEN WORKING ON THE

ENGINE .......................................................................................................................... 2-2

2.1.1 EXHAUST (START/RUN ENGINE) ............................................................................. 2-2

2.1.2 ITEMS UNDER TENSION .......................................................................................... 2-3

2.1.3 WORK PLACE ............................................................................................................ 2-3

2.1.4 FLUIDS AND PRESSURE .......................................................................................... 2-4

2.1.5 GLASSES ................................................................................................................... 2-5

2.1.6 FIRE ............................................................................................................................ 2-5

2.1.7 BATTERIES ................................................................................................................ 2-6

2.1.8 CLOTHING ................................................................................................................. 2-7

2.1.9 AIR .............................................................................................................................. 2-7

3 INSPECTION AND REMOVAL OF SYSTEMS .................................................................. 3-1

3.1 SERIES 50/60 UNIT INJECTOR INSPECTION/REMOVAL ............................................ 3-1

3.2 MBE 900 UNIT PUMP INSPECTION/REMOVAL ........................................................... 3-2

3.3 MBE 4000 UNIT PUMP INSPECTION/REMOVAL ......................................................... 3-3

4 FUEL ................................................................................................................................... 4-1

4.1 FUEL ADDITIVES ........................................................................................................... 4-1

4.2 AIR IN FUEL ................................................................................................................... 4-1

4.3 FUEL CETANE NUMBER ............................................................................................... 4-1

4.4 FUEL FILTRATION .......................................................................................................... 4-2

4.5 FUEL STABILITY ............................................................................................................ 4-3

4.6 FUEL SULFUR CONTENT ............................................................................................. 4-3

4.7 FUEL TEMPERATURE ................................................................................................... 4-3

4.8 FUEL WATER CONTAMINATION ................................................................................... 4-3

5 ELECTRONIC CONTROL SYSTEMS ................................................................................ 5-1

5.1 DDEC ABBREVIATIONS AND TERMS .......................................................................... 5-1

5.2 DDEC AND PRO-LINK OPERATIONS ........................................................................... 5-3

5.2.1 RETRIEVING AND CLEARING CODES .................................................................... 5-3

5.2.2 UNIT INJECTOR CALIBRATION UPDATE ................................................................. 5-4

5.2.3 SNAPSHOT SEQUENCE ........................................................................................... 5-4

5.3 DDEC FOR MBE 900 AND MBE 4000 ENGINES .......................................................... 5-5

5.4 FUEL-RELATED ELECTRONIC FAULT CODES ........................................................... 5-5

5.4.1 FLASH CODE 37 - FUEL PRESSURE SENSOR/FUEL RESTRICTION SENSOR

VOLTAGE HIGH .......................................................................................................... 5-5

5.4.2 FLASH CODE 38 - FUEL PRESSURE SENSOR/FUEL RESTRICTION SENSOR

VOLTAGE LOW ........................................................................................................... 5-6

All information subject to change without notice. i

7SE500 0409 Copyright © 2004 DETROIT DIESEL CORPORATION

TABLE OF CONTENTS

5.4.3 FLASH CODE 47 - AIR/FUEL PRESSURE HIGH ...................................................... 5-6

5.4.4 FLASH CODE 48 - AIR/FUEL PRESSURE LOW ....................................................... 5-6

5.4.5 FLASH CODE 61 - INJECTOR RESPONSE TIME LONG ......................................... 5-7

5.4.6 FLASH CODE 71 - INJECTOR RESPONSE TIME SHORT ....................................... 5-7

5.4.7 FLASH CODE 77 - ISOLATED FUEL ......................................................................... 5-7

6 FAILURE MODES ............................................................................................................... 6-1

6.1 NORMAL INJECTOR ...................................................................................................... 6-2

6.2 SEIZED INJECTOR ........................................................................................................ 6-3

6.3 BROKEN INJECTOR FOLLOWER SPRING AND DAMAGED STATOR WITH BROKEN

STATOR SCREWS .......................................................................................................... 6-4

6.4 LOOSE STOP PLATE SCREW ....................................................................................... 6-5

6.5 MISSING STOP PLATE SCREW .................................................................................... 6-6

6.6 CRACKED INJECTOR BODY FAILURE ......................................................................... 6-7

6.7 BROKEN SOLENOID TERMINAL SCREW FAILURE .................................................... 6-8

6.8 FAILED OR BLOWN SPRAY TIP FAILURE .................................................................... 6-9

6.9 LOW PRESSURE PLUG LEAK ...................................................................................... 6-10

6.10 HIGH PRESSURE PLUG LEAK ..................................................................................... 6-11

6.11 BLACK OR GRAY SMOKE PROBLEM ........................................................................... 6-12

6.12 WHITE SMOKE PROBLEM ............................................................................................ 6-12

7 INJECTOR O-RINGS .......................................................................................................... 7-1

8 FUEL SYSTEM TESTS ....................................................................................................... 8-1

8.1 SERIES 50/60 DDEC CYLINDER CUTOUT TEST ......................................................... 8-1

8.2 SERIES 50/60 FAULTY FUEL INJECTOR TEST ............................................................ 8-4

8.3 SERIES 50/60 DDEC IMPROPER INJECTOR CALIBRATION TEST ............................ 8-4

8.4 SERIES 50/60 DDEC HIGH PRESSURE FUEL TEST ................................................... 8-6

8.5 SERIES 50/60 DDEC INSUFFICIENT FUEL FLOW TEST ............................................ 8-7

8.6 MBE CYLINDER CUTOUT TEST ................................................................................... 8-8

8.7 MBE 900 DOWNSTREAM (AFTER SECONDARY FILTER) PRESSURE TEST ........... 8-8

8.8 MBE 900 FLOW TEST AT NOZZLE HOLDER ................................................................ 8-9

8.9 MBE 900 FLOW TEST AT FUEL FILTER ........................................................................ 8-9

8.10 MBE 900 UPSTREAM PRESSURE TEST .................................................................... 8-11

8.11 MBE 900 INJECTOR LEAK TEST .................................................................................. 8-12

GLOSSARY ..................................................................................................................................... G-1

ii All information subject to change without notice.

7SE500 0409 Copyright © 2004 DETROIT DIESEL CORPORATION

UNIT FUEL INJECTORS AND UNIT PUMP TECHNICIAN GUIDE

LIST OF FIGURES

Figure 1-1 Schematic Diagram of Series 50/60 Fuel System ............................................. 1-3

Figure 1-2 Schematic Diagram of MBE 900 and MBE 4000 Fuel System ......................... 1-4

Figure 1-3 Injector Cup Insert ............................................................................................. 1-5

Figure 1-4 Series 50/60 Injector Components ................................................................... 1-6

Figure 1-5 Injector Cycle Graph ......................................................................................... 1-7

Figure 1-6 Former Injector N2 ............................................................................................ 1-8

Figure 1-7 Current Injector N3 ............................................................................................ 1-8

Figure 1-8 N3 Injector Advantages Over N2 Injector .......................................................... 1-9

Figure 1-9 MBE Unit Pump ................................................................................................. 1-10

Figure 1-10 General MBE Fuel System ................................................................................ 1-11

Figure 1-11 MBE 900 and MBE 4000 Unit Pump and Nozzle System ................................. 1-12

Figure 6-1 Normal Injector – No Failure ............................................................................. 6-2

Figure 6-2 Seized Injector Failure ....................................................................................... 6-3

Figure 6-3 Broken Injector Follower Spring And Damaged Stator With Broken Stator

Screws Failure .................................................................................................. 6-4

Figure 6-4 Loose Stop Plate Screw Failure ........................................................................ 6-5

Figure 6-5 Missing Stop Plate Screw Failure ...................................................................... 6-6

Figure 6-6 Cracked Injector Body Failure ........................................................................... 6-7

Figure 6-7 Broken Solenoid Terminal Screw Failure .......................................................... 6-8

Figure 6-8 Failed or Blown Spray Tip Failure ...................................................................... 6-9

Figure 6-9 Low Pressure Plug Leak ................................................................................... 6-10

Figure 6-10 High Pressure Plug Leak .................................................................................. 6-11

Figure 7-1 O-rings – N2 Injector ......................................................................................... 7-1

Figure 7-2 O-rings – N3 Injector ......................................................................................... 7-2

Figure 8-1 Cylinder Cutout Start-Up Display ...................................................................... 8-2

Figure 8-2 Results of a Cylinder Cutout Test ...................................................................... 8-3

All information subject to change without notice. iii

7SE500 0409 Copyright © 2004 DETROIT DIESEL CORPORATION

TABLE OF CONTENTS

iv All information subject to change without notice.

7SE500 0409 Copyright © 2004 DETROIT DIESEL CORPORATION

UNIT FUEL INJECTORS AND UNIT PUMP TECHNICIAN GUIDE

1 INTRODUCTION

This technicians guide explains the fuel injection system operation in current on-highway,

four-cycle Detroit Diesel

®

Corporation engines. Series 50

®

, Series 60

®

, MBE 900, and MBE 4000

engines are the models covered in this guide. The main emphasis of this guide is on the unit

injector and the unit pump.

The heart of the diesel engine is the fuel injection system. It has the vital function of

communicating with the Electronic Control Module (ECM) and pumping a measured quantity

of fuel into each cylinder at precisely the right moment. This is achieved by Detroit Diesel

Corporation’s electronic control technology: Detroit Diesel Electronic Controls (DDEC

®

). The

unit injector does all this with simple design and few parts. The benefits are low unit cost and

minimal maintenance cost. The advantage of the 30,000 psi fuel injection pressure capability is

high velocity injection which translates into excellent penetration and atomization. As a result

of the ability to control injection spray, exhaust emissions and fuel consumption parameters are

optimized. These features help make the most efficient use of each ounce of fuel, minimizing

smoke, NOx, and HC emissions.

1.1 DIESEL FUEL SYSTEM OVERVIEW

The function of the fuel system is to store and supply fuel to the combustion chamber. The major

parts of the diesel fuel system are the fuel tank, fuel filters, fuel pump, electronic control module,

injection nozzles or injectors, and fuel lines.

There are differences between the Series 50/60 and the MBE fuel injection system. In the Series

50/60 engines, the unit injectors pressurize the fuel prior to injection. See Figure 1-1. The MBE

engines have a unit pump for each cylinder that produces the pressure and a high-pressure fuel

line that carries fuel to the injector nozzles. See Figure 1-2.

All information subject to change without notice. 1-1

7SE500 0409 Copyright © 2004 DETROIT DIESEL CORPORATION

INTRODUCTION

In the Series 50/60 engines, the fuel pump draws the fuel from the tank through low-pressure

fuel lines leading to the water separator (not all diesel engines have a water separator). In most

diesel engines, the fuel passes through a primary fuel filter before reaching the pump. The pump

circulates an excess supply of fuel through the injectors, which purges air from the fuel system

and also cools and lubricates the injectors. The unused portion of fuel returns to the fuel tank by

means of the fuel return line. The primary filter captures large contaminants from the fuel and

acts as a water separator. Water is heavier than diesel fuel and falls to the bottom of the primary

filter, where in most applications it can be drained. After passing through the pump, the fuel goes

through a secondary filter before reaching the fuel injectors to keep them clean and prevent them

free from damage. The fuel flows to the fuel injectors where it is injected into the cylinders.

The primary job of the entire fuel system is to inject a controlled amount of atomized fuel into

each engine cylinder at the precise time. Excess fuel exits at the rear of the cylinder head just

above the inlet, through a restrictive return fitting that maintains fuel pressure in the system. It

then returns back to the tank. See Figure 1-1.

The electronic unit injectors injects fuel directly into the combustion chamber. The injector

performs these three functions:

Creates the high fuel pressure required for efficient injection

Meters and injects the exact amount of fuel required to handle the power requirement

Atomizes the fuel for mixing with the air in the combustion chamber

1-2 All information subject to change without notice.

7SE500 0409 Copyright © 2004 DETROIT DIESEL CORPORATION

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Viewed 33 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Detroit Diesel

UNIT INJECTORS & UNIT PUMP TECHNICIAN MANUAL

This manual provides detailed information on inspection, analysis, failure examination, and troubleshooting of the fuel injection system for Detroit Diesel Corporation four-cycle engines and Mercedes Benz MBE 900 and MBE 4000 engines. It is a valuable resource for both professional mechanics and DIY enthusiasts.