SERIES 60 SERVICE MANUAL

ABSTRACT

This manual provides instruction for servicing on-highway applications of the Detroit Diesel

Series 60 Diesel and Natural Gas-Fueled Engines.

Speci fi cally a basic overview of each major component and system along with recommendations

for removal, cleaning, inspection, criteria for replacement, repair and installation and mechanical

troubleshooting are contained in this manual.

DDEC III/IV troubleshooting concerns are contained in the DDEC III/IV Single ECM

Troubleshooting Guide, 6SE497.

DDEC V troubleshooting concerns are contained in the DDEC V Troubleshooting Guide, 6SE570.

All information subject to change without notice. (Rev. 2005)

6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION i

SERIES 60 SERVICE MANUAL

ENGINE EXHAUST

Consider the following before servicing engines:

PERSONAL INJURY

Diesel engine exhaust and some of its constituents are

known to the State of California to cause cancer, birth

defects, and other reproductive harm.

□ Always start and operate an engine in a well ventilated

area.

□ If operating an engine in an enclosed area, vent the

exhaust to the outside.

□ Do not modify or tamper with the exhaust system or

emission control system.

(Rev. 2005) All information subject to change without notice.

ii 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION

SERIES 60 SERVICE MANUAL

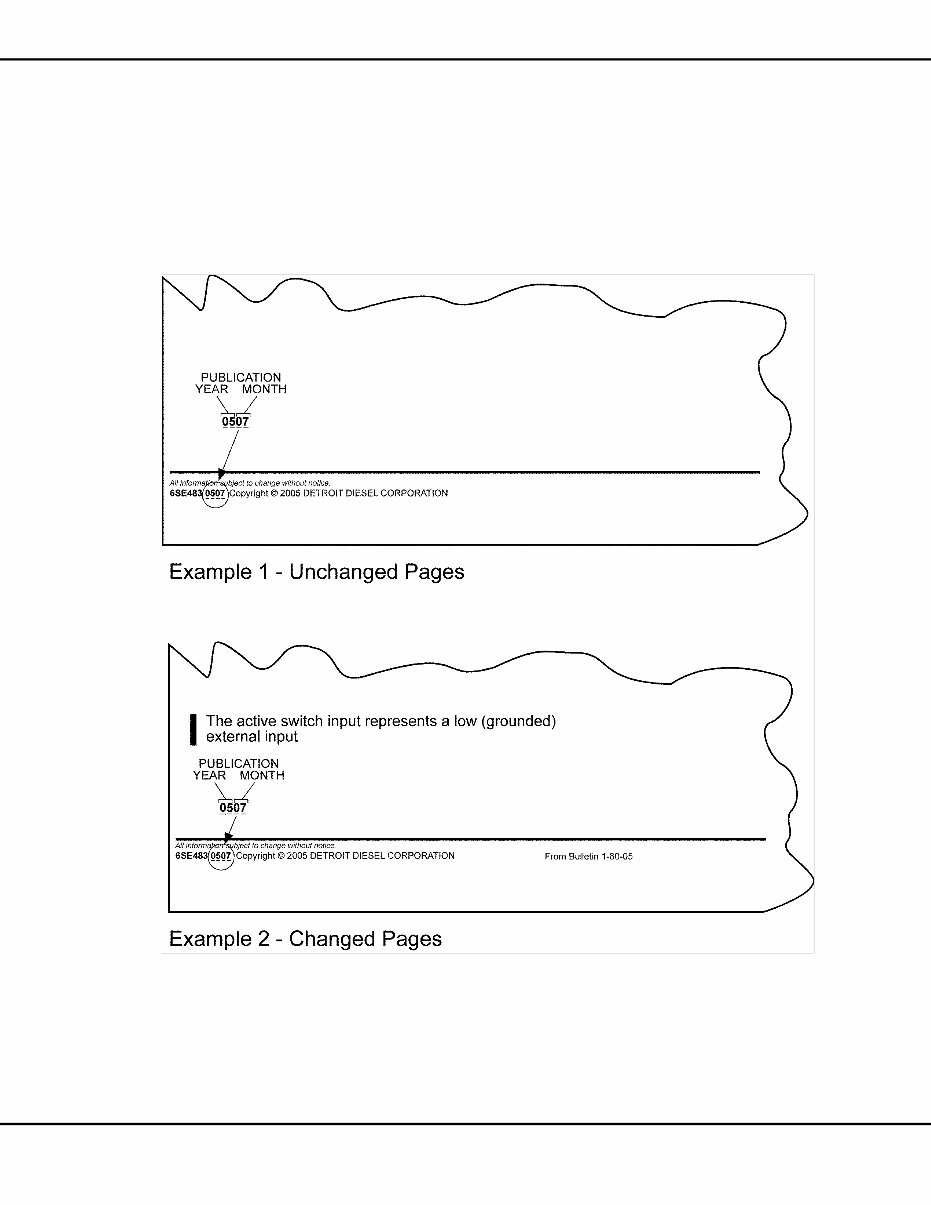

REVISION NOTIFICATION

Modi fi cations to this manual are announced in the form of Service Information

Bulletins. The bulletins include attachment pages and are posted on the World Wide Web

(www.detroitdiesel.com/svc/sibindex.htm).

Revisions to this manual will be sent marked with a revision bar (see Example 2). Sections

containing revisions will have a third line in the page footer (compare Examples 1 and 2).

All information subject to change without notice. (Rev. 2005)

6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION iii

SERIES 60 SERVICE MANUAL

(Rev. 2005) All information subject to change without notice.

iv 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION

SERIES 60 SERVICE MANUAL

TABLE OF CONTENTS

GENERAL INFORMATION ...................................................................... 1

SCOPE AND USE OF THIS MANUAL .................................................... 3

CLEARANCE OF NEW PARTS AND WEAR LIMITS .............................. 3

THE FOUR CYCLE PRINCIPLE FOR DIESEL ENGINES ...................... 4

FOUR CYCLE PRINCIPLE FOR NATURAL GAS ENGINES .................. 6

GENERAL DESCRIPTION ...................................................................... 8

GENERAL SPECIFICATIONS ................................................................. 14

GENERAL SPECIFICATIONS FOR THE SERIES 60G ENGINE ............ 15

ENGINE MODEL, SERIAL NUMBER AND OPTION LABEL ................... 16

ENGINE MODEL, SERIAL NUMBER AND OPTION LABEL (SERIES

60G ENGINE) .......................................................................................... 19

REPLACING AND REPAIRING ............................................................... 20

DISASSEMBLY ........................................................................................ 20

CLEANING ............................................................................................... 21

SAFETY PRECAUTIONS ....................................................................... 27

FLUOROELASTOMER (VITON) CAUTION ............................................. 40

ENGINE VIEWS ....................................................................................... 41

ENGLISH TO METRIC CONVERSION .................................................... 46

DECIMAL AND METRIC EQUIVALENTS ................................................ 47

SPECIFICATIONS ................................................................................... 48

1 ENGINE

1.1 CYLINDER BLOCK AND CYLINDER LINER .......................................... 1-3

1.2 CYLINDER HEAD .................................................................................... 1-30

1.3 VALVE AND INJECTOR OPERATING MECHANISM .............................. 1-60

1.4 VALVES, SPRINGS, GUIDES, INSERTS, SEALS AND ROTATORS ...... 1-79

1.5 ENGINE LIFTER BRACKETS .................................................................. 1-106

1.6 ROCKER COVER .................................................................................... 1-111

1.7 CRANKSHAFT ........................................................................................ 1-129

1.8 CRANKSHAFT OIL SEALS ..................................................................... 1-150

1.9 CRANKSHAFT MAIN BEARINGS ........................................................... 1-164

1.10 GEAR CASE COVER PRE-EXHAUST GAS RECIRCULATION (EGR) .. 1-175

1.11 GEAR CASE COVER EXHAUST GAS RECIRCULATION (EGR)

MODEL .................................................................................................... 1-190

1.12 GEAR CASE PRE-EXHAUST GAS RECIRCULATION (EGR) ................ 1-210

1.13 GEAR CASE EXHAUST GAS RECIRCULATION (EGR) MODEL ........... 1-231

1.14 CRANKSHAFT VIBRATION DAMPER .................................................... 1-242

1.15 CRANKSHAFT PULLEY .......................................................................... 1-252

1.16 FLYWHEEL ............................................................................................. 1-266

1.17 RING GEAR ............................................................................................. 1-275

1.18 FLYWHEEL HOUSING ............................................................................ 1-277

1.19 PISTON AND PISTON RING ................................................................... 1-285

All information subject to change without notice. (Rev. 2005)

6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION v

SERIES 60 SERVICE MANUAL

1.20 ONE-PIECE PISTON ASSEMBLY AND PISTON RING .......................... 1-306

1.21 PISTON AND CONNECTING ROD ASSEMBLY ..................................... 1-318

1.22 CONNECTING ROD ................................................................................ 1-345

1.23 CYLINDER LINER ................................................................................... 1-360

1.24 GEAR TRAIN AND ENGINE TIMING ...................................................... 1-373

1.25 COMPACT GEAR TRAIN AND ENGINE TIMING ................................... 1-399

1.26 CAMSHAFT GEAR ASSEMBLY SERIES 60 EXHAUST GAS

RECIRCULATION (EGR) MODEL ........................................................... 1-418

1.27 THRUST PLATE PERIMETER SEAL ...................................................... 1-445

1.28 CAMSHAFT AND CAMSHAFT BEARING ............................................... 1-458

1.29 CAMSHAFT DRIVE GEAR ...................................................................... 1-490

1.30 ADJUSTABLE IDLER GEAR ASSEMBLY ............................................... 1-503

1.31 ADJUSTABLE IDLER GEAR COMPACT GEAR TRAIN .......................... 1-512

1.32 BULL GEAR AND CAMSHAFT IDLER GEAR FOR THE COMPACT

GEAR TRAIN ........................................................................................... 1-518

1.33 BULL GEAR AND CAMSHAFT IDLER GEAR ASSEMBLY ..................... 1-525

1.34 CRANKSHAFT TIMING GEAR AND TIMING WHEEL ............................ 1-538

1.35 ACCESSORY DRIVE ............................................................................... 1-557

1.36 JAKE BRAKE ........................................................................................... 1-585

1.A ADDITIONAL INFORMATION .................................................................. 1-639

2 FUEL SYSTEM

2.1 DIESEL FUEL SYSTEM OVERVIEW ...................................................... 2-5

2.2 VEHICLE SAFETY FOR THE NATURAL GAS ENGINE ......................... 2-7

2.3 N2 ELECTRONIC UNIT INJECTOR ....................................................... 2-11

2.4 N2 FUEL INJECTOR TUBE AND O-RING .............................................. 2-28

2.5 N3 ELECTRONIC UNIT INJECTOR ....................................................... 2-42

2.6 N3 FUEL INJECTOR TUBE .................................................................... 2-55

2.7 FUEL PUMP WITH SEPARATE DRIVE SHAFT AND HUB ..................... 2-58

2.8 FUEL PUMP WITH ONE-PIECE DRIVE SHAFT AND HUB ASSEMBLY 2-79

2.9 FUEL PUMP DRIVE ................................................................................. 2-99

2.10 DIESEL FUEL FILTERS (SPIN-ON) ........................................................ 2-104

2.11 FUEL PRO 380/380E FUEL FILTER SYSTEM ........................................ 2-112

2.12 FUEL FILTER TYPE FOR THE SERIES 60G ENGINE ........................... 2-118

2.13 ASSEMBLY FUEL FILTER AND WATER SEPARATOR .......................... 2-126

2.14 ELECTRONIC ENGINE CONTROL ......................................................... 2-133

2.15 DDEC V ELECTRONIC CONTROL UNIT ............................................... 2-135

2.16 DDEC III/IV ELECTRONIC CONTROL MODULE ................................... 2-141

2.17 DDEC II ELECTRONIC CONTROL MODULE ......................................... 2-149

2.18 DDEC I ..................................................................................................... 2-159

2.19 PROGRAMMABLE READ-ONLY MEMORY (PROM) DDEC I ............... 2-165

2.20 ELECTRONIC DISTRIBUTOR UNIT DDEC I ......................................... 2-169

2.21 ELECTRONIC FOOT PEDAL ASSEMBLY ............................................. 2-172

2.22 TURBO SPEED SENSOR (TSS) ............................................................. 2-173

2.23 TURBO BOOST PRESSURE SENSOR .................................................. 2-177

2.24 AIR INTAKE PRESSURE SENSOR ......................................................... 2-179

2.25 OIL PRESSURE SENSOR ..................................................................... 2-181

(Rev. 2005) All information subject to change without notice.

vi 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION

SERIES 60 SERVICE MANUAL

2.26 OIL TEMPERATURE SENSOR .............................................................. 2-183

2.27 AIR TEMPERATURE SENSOR ............................................................... 2-185

2.28 AIR TEMPERATURE SENSOR FOR HIGH PRESSURE FUEL

SYSTEM .................................................................................................. 2-188

2.29 COOLANT TEMPERATURE SENSOR .................................................... 2-190

2.30 SYNCHRONOUS REFERENCE SENSOR GEAR CASE MOUNTED .... 2-192

2.31 SYNCHRONOUS REFERENCE SENSOR \ CAMSHAFT POSITION

SENSOR CAMSHAFT GEAR COVER MOUNTED ................................. 2-194

2.32 TIMING REFERENCE SENSOR ............................................................ 2-197

2.33 COOLANT LEVEL SENSOR .................................................................. 2-199

2.34 FUEL PRESSURE SENSOR .................................................................. 2-203

2.35 FUEL TEMPERATURE SENSOR ........................................................... 2-205

2.36 EXHAUST GAS OXYGEN SENSOR FOR SERIES 60G ENGINES ....... 2-208

2.37 EXHAUST TEMPERATURE SENSOR FOR THE SERIES 60G

ENGINES ................................................................................................. 2-211

2.38 KNOCK SENSOR AND SIGNAL NOISE ENHANCEMENT FILTER

MODULE .................................................................................................. 2-212

2.39 BAROMETRIC PRESSURE SENSOR FOR THE SERIES 60G ENGINE

WITH HIGH PRESSURE FUEL SYSTEM .............................................. 2-215

2.40 OVERVIEW OF HIGH PRESSURE FUEL SYSTEM FOR SERIES 60G

ENGINES ................................................................................................. 2-217

2.41 FUEL PRESSURE GAGES FOR THE SERIES 60G ENGINE WITH A

HIGH PRESSURE FUEL SYSTEM ......................................................... 2-223

2.42 VENTING AND LEAK CHECKING PROCEDURES FOR A NATURAL

GAS ENGINE (HIGH PRESSURE SYSTEM) ......................................... 2-225

2.43 HIGH PRESSURE FUEL REGULATOR FOR THE SERIES 60G

ENGINE ................................................................................................... 2-229

2.44 PULSE WIDTH MODULATED STEPPER MOTOR VALVE (PSV) FOR

SERIES 60G AUTOMOTIVE ENGINES .................................................. 2-231

2.45 FUEL MIXER FOR THE SERIES 60G HIGH PRESSURE FUEL SYSTEM

.................................................................................................................. 2-234

2.46 FUEL SHUTOFF VALVE FOR SERIES 60G ENGINE WITH HIGH

PRESSURE FUEL SYSTEM ................................................................... 2-237

2.47 IMPCO LOW PRESSURE FUEL REGULATOR FOR THE SERIES 60G

ENGINE HIGH PRESSURE FUEL SYSTEM .......................................... 2-239

2.48 OVERVIEW OF THE LOW PRESSURE NATURAL GAS FUEL

SYSTEM .................................................................................................. 2-243

2.49 LOW PRESSURE FUEL REGULATOR FOR THE SERIES 60G

ENGINE ................................................................................................... 2-248

2.50 FUEL MIXER FOR THE SERIES 60G LOW PRESSURE SYSTEM ....... 2-252

2.51 VENTING AND LEAK CHECKING PROCEDURES FOR NATURAL GAS

ENGINE (LOW PRESSURE SYSTEM) .................................................. 2-255

2.A ADDITIONAL INFORMATION .................................................................. 2-257

3 LUBRICATION SYSTEM

3.1 OVERVIEW OF LUBRICATING SYSTEM ............................................... 3-3

3.2 OIL PUMP ................................................................................................ 3-8

All information subject to change without notice. (Rev. 2005)

6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION vii

SERIES 60 SERVICE MANUAL

3.3 OIL PRESSURE REGULATOR VALVE ................................................... 3-21

3.4 OIL PRESSURE RELIEF VALVE ............................................................. 3-28

3.5 OIL FILTER .............................................................................................. 3-34

3.6 OIL FILTER ADAPTOR ............................................................................ 3-36

3.7 THERMATIC OIL CONTROL VALVE ....................................................... 3-41

3.8 OIL COOLER (1991 AND LATER ENGINES) .......................................... 3-49

3.9 OIL COOLER (PRE-1991 ENGINES) ...................................................... 3-59

3.10 OIL LEVEL DIPSTICK ASSEMBLY ......................................................... 3-69

3.11 OIL PAN ................................................................................................... 3-74

3.12 VENTILATING SYSTEM .......................................................................... 3-82

3.A ADDITIONAL INFORMATION .................................................................. 3-91

4 COOLING SYSTEM

4.1 COOLING SYSTEM OVERVIEW ............................................................. 4-3

4.2 WATER PUMP (GEAR-CASE MOUNTED - 1991 AND LATER) (GCM) .. 4-7

4.3 WATER PUMP (FRONT MOUNTED) (FM) .............................................. 4-33

4.4 THERMOSTAT ........................................................................................ 4-58

4.5 COOLANT PRESSURE CONTROL CAP ................................................ 4-69

4.6 ENGINE COOLING FAN .......................................................................... 4-72

4.7 COOLANT FILTER AND CONDITIONER ................................................ 4-82

4.8 RADIATOR ............................................................................................... 4-84

4.A ADDITIONAL INFORMATION .................................................................. 4-85

5 FUEL, LUBRICATING OIL, AND COOLANT

5.1 FUEL ........................................................................................................ 5-3

5.2 LUBRICATING OIL (DIESEL) .................................................................. 5-10

5.3 LUBRICATING OIL FOR THE SERIES 60G ENGINE ............................. 5-15

5.4 COOLANT ................................................................................................ 5-17

6 AIR INTAKE SYSTEM

6.1 AIR INTAKE SYSTEM OVERVIEW ......................................................... 6-3

6.2 AIR CLEANER ......................................................................................... 6-7

6.3 INTAKE MANIFOLD ................................................................................. 6-9

6.4 CLOSED CRANKCASE BREATHER FOR SERIES 60G AUTOMOTIVE

ENGINES ................................................................................................. 6-18

6.5 TURBOCHARGER (DIESEL) .................................................................. 6-20

6.6 TURBOCHARGER SERIES 60 NATURAL GAS (AUTOMOTIVE)

ENGINE ................................................................................................... 6-43

6.7 RECIRCULATION VALVE FOR SERIES 60G AUTOMOTIVE ENGINE .. 6-61

6.8 CHARGE AIR COOLER ........................................................................... 6-63

6.9 THROTTLE ACTUATOR FOR THE SERIES 60G ENGINE .................... 6-72

6.10 AIR DRYER .............................................................................................. 6-76

6.A ADDITIONAL INFORMATION .................................................................. 6-77

7 EXHAUST SYSTEM

7.1 OVERVIEW OF EXHAUST MANIFOLD COMPONENTS ........................ 7-3

7.2 THREE-PIECE EXHAUST MANIFOLD WITH FEY RINGS ..................... 7-7

7.3 THREE-PIECE EXHAUST MANIFOLD WITHOUT FEY RINGS ............. 7-16

7.4 THREE-PIECE EXHAUST MANIFOLD WITH HEAT SHIELD ................. 7-23

(Rev. 2005) All information subject to change without notice.

viii 6SE483 0507 Copyright © 2005 DETROIT DIESEL CORPORATION

You're Reading a Preview

What's Included?

Lifetime Access

Access PDF Contents & Bookmarks

Print one or all pages of your manual