Cummins NTC400 Diesel Engine Service & Repair Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

HEADQUARTERS, DEPARTMENT OF THE ARMY

JULY 2005

TM 9-2815-225-34&P

DIRECT SUPPORT AND GENERAL SUPPORT

MAINTENANCE MANUAL INCLUDING

REPAIR PARTS AND SPECIAL

TOOLS LIST (RPSTL)

FOR

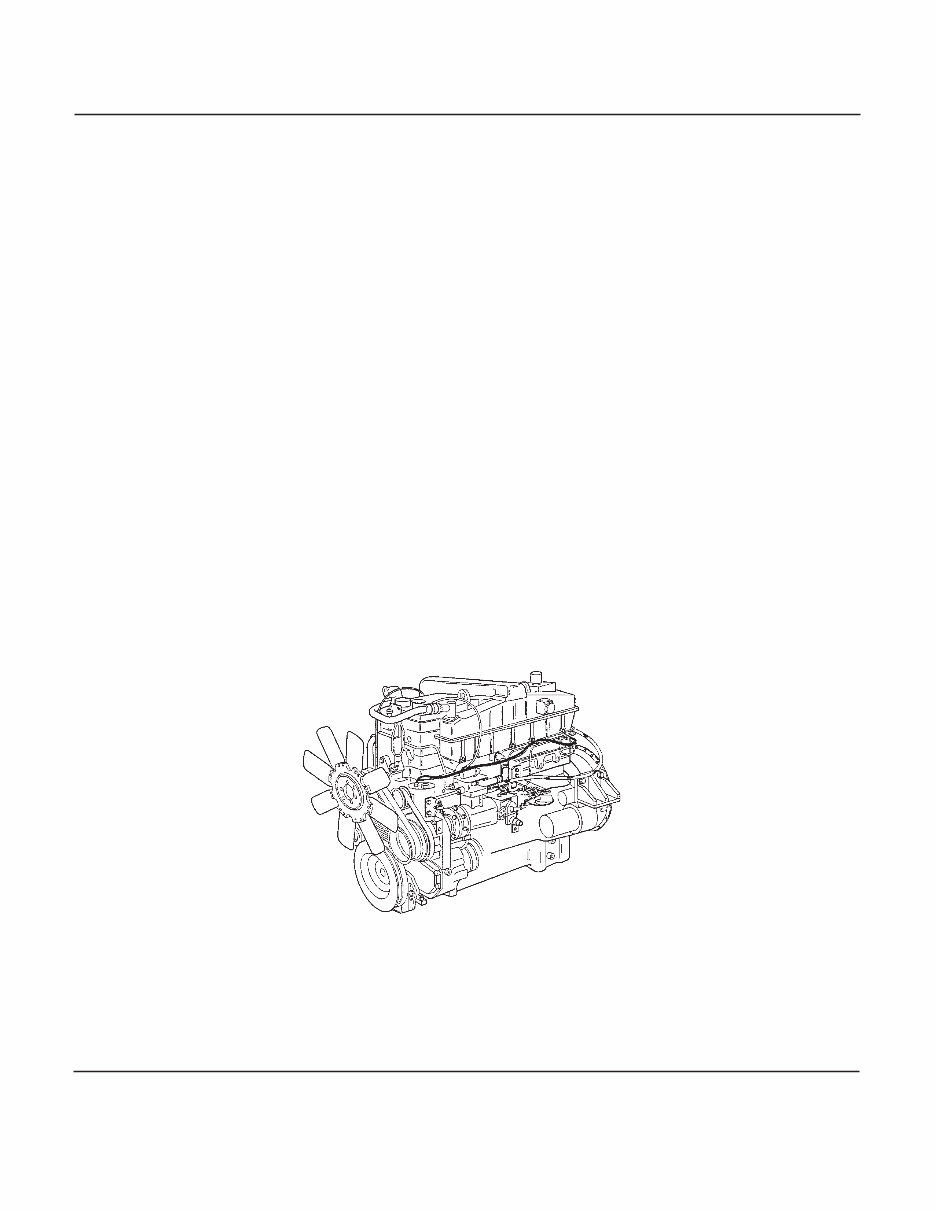

ENGINE, DIESEL: 6 CYLINDER IN-LINE

TURBOCHARGED, CUMMINS MODEL NTC-400

BIG CAM I

(NSN 2815-01-082-8125)

BIG CAM III

(NSN 2815-01-142-2745)

BIG CAM III SHOWN.

ALL TRUCKS M915-M920 AND M915A4 CAN BE EQUIPPED WITH EITHER BIG CAM I OR BIG CAM III ENGINES.

DISTRIBUTION STATEMENT A: Approved for public release; distribution is unlimited.

Supersedes copy dated August 2001

TM 9-2815-225-34&P

a

WARNING SUMMARY

Operating a deadlined vehicle without preliminary inspection will cause further damage to a

malfunctioning component and possible injury to personnel.

Use extreme care when handling heavy parts. Provide adequate support and use assistance during

procedure. Ensure that any lifting device used is in good operating condition and of suitable load

capacity. Keep clear of heavy components supported only by lifting device. Failure to comply may result

in death or injury to personnel.

Compressed air used for cleaning purposes must not exceed 30 psi. Use only with effective chip

guarding and personal protective equipment (goggles/shield, gloves, etc.). Failure to comply may result

in death or injury to personnel.

When removing hood tilt assist cables, hood must be supported. Failure to comply may result in

damage to equipment or injury to personnel.

Use pry bars to free engine hangups or snags. Do not use hands. Failure to comply may result in

damage to equipment or death or injury to personnel.

Use extreme care during engine accessory removal. Engine parts are heavy. Failure to comply may

result in death or injury to personnel.

Eye protection must be worn when using wire brush for cleaning. Failure to comply may result in

injury to personnel.

Wear rubber gloves when removing piston pin to prevent burns from hot water or hot piston. Failure to

comply may result in injury to personnel

Oil pump pressure regulator spring is under tension. Remove oil pump pressure regulator slowly and

wear proper eye protection. Failure to comply may result in injury to personnel.

Oil pump pressure regulator spring is under tension. Install oil pump pressure regulator screw slowly

and wear proper eye protection. Failure to comply may result in injury to personnel.

Oil pump pressure regulator spring is under tension. Remove oil pump bypass screw slowly and wear

proper eye protection. Failure to comply may result in injury to personnel.

Turbine wheel machined edges are very sharp. Wear protective gloves when handling turbine wheel.

Failure to comply may result in injury to personnel.

Control valve cover is under control valve outer spring pressure. Hold cover securely when removing

screws. Failure to comply may cause injury to personnel.

Slave piston spring is highly compressed. Be extremely careful during disassembly. Personal injury can

occur if spring force is not controlled.

Use gloves during piston pin installation if piston has been soaked in hot water. Failure to comply may

result in injury to personnel.

Do not perform fuel system procedures while smoking or within 50 ft (15.2 m) of sparks or open flame.

Diesel fuel is flammable and may explode. Failure to comply may result in injury or death to personnel.

TM 9-2815-225-34&P

b

WARNING SUMMARY (Contd)

Allow adequate ventilation for engine exhaust gases. Do not perform fuel system procedures while

smoking or within 50 ft (15.2 m) of sparks or open flame. Diesel fuel is flammable and may explode.

Failure to comply may result in serious injury or death to personnel.

Use extreme caution during disassembly or assembly; engine components are heavy. Failure to comply

may result in damage to equipment or injury to personnel.

All personnel must stand clear during lifting operations. A snapped chain or swinging or shifting load

may result in injury to personnel.

When installing hood tilt assist cables, hood must be supported. Failure to comply may result in

damage to equipment or injury to personnel.

Compressed air source must not exceed 30 psi (207 kPa). Wear eyeshields when cleaning with

compressed air. Failure to comply may result in injury to personnel.

TM 9-2815-225-34&P

A/B blank

LIST OF EFFECTIVE PAGES/WORK PACKAGES

The date of issue for original pages/work pages for this TM is:

Original 21 July 2005

TOTAL NUMBER OF PAGES IN THIS PUBLICATION IS 651.

TOTAL NUMBER OF WORK PACKAGES IS 62.

THE PAGES/WORK PACKAGES CONSIST OF THE FOLLOWING:

Page No. . . . . . . . . . . . . . Change No. *

Warning a–Warning b . . . . . . . . . . . . . . 0

A . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0

B blank . . . . . . . . . . . . . . . . . . . . . . . . . . . 0

i . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0

ii blank . . . . . . . . . . . . . . . . . . . . . . . . . . . 0

iii–vii . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0

viii blank . . . . . . . . . . . . . . . . . . . . . . . . . 0

WP 0001 00–WP 0062 00 . . . . . . . . . . . 0

Index 1–Index 3 . . . . . . . . . . . . . . . . . . . 0

Index 4 blank . . . . . . . . . . . . . . . . . . . . . 0 0

*Zero in this column indicates original page.

i/ii blank

TM 9-2815-225-34&P

DIRECT SUPPORT AND GENERAL SUPPORT

MAINTENANCE MANUAL INCLUDING

REPAIR PARTS AND SPECIAL

TOOLS LIST (RPSTL)

FOR

ENGINE, DIESEL: 6 CYLINDER IN-LINE

TURBOCHARGED, CUMMINS MODEL NTC-400

BIG CAM I

(NSN 2815-01-082-8125)

BIG CAM III

(NSN 2815-01-142-2745)

ALL TRUCKS M915-M920 AND M915A4 CAN BE EQUIPPED WITH EITHER BIG CAM I OR

BIG CAM III ENGINES.

DISTRIBUTION STATEMENT A: Approved for public release; distribution is unlimited.

HEADQUARTERS,

DEPARTMENT OF THE ARMY

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

You can help improve this publication. If you find any mistakes or if you know of a way to

improve the procedures, please let us know. Submit your DA Form 2028 (Recommended

Changes to Publications and Blank Forms), through the Internet, on the Army Electronic

Product Support (AEPS) website. The Internet address is http://aeps.ria.army.mil . If you

need a password, scroll down and click on “ACCESS REQUEST FORM.” The DA Form 2028

is located in the ONLINE FORMS PROCESSING section of the AEPS. Fill out the form and

click on SUBMIT. Using this form on the AEPS will enable us to respond quicker to your

comments and better manage the DA Form 2028 program. You may also mail, fax or E-mail

your letter or DA Form 2028 direct to: AMSTA-LC-CI Tech Pubs, TACOM-RI, 1 Rock Island

Arsenal, Rock Island, IL 61299-7630. The E-mail address is TACOM-TECH-

PUBS @ria.army.mil . The fax number is DSN 793-0726 or Commercial (309) 782-0726.

*Supersedes copy dated 28 August 2001

iii

TM 9-2815-225-34&P

TABLE OF CONTENTS

W ork Package/Page No.

How to Use This Technical Manual (TM) . . . . . . . . . . . . . . . . . . v

CHAPTER 1 GENERAL INFORMATION, EQUIPMENT

DESCRIPTION, AND THEORY OF OPERATION

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0001 00-1

Equipment Characteristics, Capabilities, and Features . . . . . . . WP 0002 00-1

Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0003 00-1

CHAPTER 2 TROUBLESHOOTING PROCEDURES

Engine Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0004 00-1

CHAPTER 3 MAINTENANCE INSTRUCTIONS

Preventive Maintenance Checks and

Services (PMCS) Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0005 00-1

Preventive Maintenance Checks and

Services (PMCS) Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0006 00-1

Big Cam I Engine Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0007 00-1

Big Cam III Engine Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0008 00-1

Mounting Engine on Maintenance Stand . . . . . . . . . . . . . . . . . . . WP 0009 00-1

Engine Accessories Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0010 00-1

Cylinder Head and Cylinder Head Components Removal . . . . . WP 0011 00-1

Cylinder Block Components Removal . . . . . . . . . . . . . . . . . . . . . . WP 0012 00-1

Cylinder Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0013 00-1

Cylinder Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0014 00-1

Vibration Damper and Crankshaft Pulley

Cleaning and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0015 00-1

Crankshaft Cleaning and Inspection . . . . . . . . . . . . . . . . . . . . . . WP 0016 00-1

Flexplate, Flywheel, Flywheel Housing, and Rear Cover

Cleaning and Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0017 00-1

Pistons, Connecting Rods, and Bearings . . . . . . . . . . . . . . . . . . . WP 0018 00-1

Camshaft, Camshaft Followers, and Push Rods . . . . . . . . . . . . . WP 0019 00-1

Rocker Levers and Rocker Lever Housing . . . . . . . . . . . . . . . . . . WP 0020 00-1

Oil Cooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0021 00-1

Oil Pan, Dipstick, Oil Suction Tubes, and Breather Tube . . . . . WP 0022 00-1

Oil Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0023 00-1

Air Aftercooler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0024 00-1

Exhaust Manifold . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0025 00-1

Turbocharger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0026 00-1

Turbocharger HT-3B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0027 00-1

Front Gear Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0028 00-1

Accessory Drive and Accessory Drive Pulley . . . . . . . . . . . . . . . . WP 0029 00-1

Engine Retarder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0030 00-1

iv

TM 9-2815-225-34&P

TABLE OF CONTENTS (Contd)

W ork Package/Page No.

CHAPTER 3 MAINTENANCE INSTRUCTIONS (Contd)

Air Compressor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0031 00-1

Fuel Injector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0032 00-1

Fuel Pump Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0033 00-1

Solenoid Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0034 00-1

Fuel Damper and Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0035 00-1

Fuel Gear Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0036 00-1

Fuel Pump Governor Spring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0037 00-1

Fuel Pump Front Cover and Governor . . . . . . . . . . . . . . . . . . . . . WP 0038 00-1

Fuel Pump Main Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0039 00-1

Fuel Pump Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0040 00-1

Water Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0041 00-1

Cylinder Block Components Installation . . . . . . . . . . . . . . . . . . . WP 0042 00-1

Cylinder Head and Cylinder Head Components Installation . . . WP 0043 00-1

Fuel Pump Testing and Calibration . . . . . . . . . . . . . . . . . . . . . . . WP 0044 00-1

Engine Accessories Installation . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0045 00-1

Removing Engine from Maintenance Stand . . . . . . . . . . . . . . . . WP 0046 00-1

Engine Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0047 00-1

Big Cam III Engine Installation . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0048 00-1

Big Cam I Engine Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0049 00-1

Big Cam III Modification Kit Installation Instructions . . . . . . . WP 0050 00-1

General Maintenance Instructions . . . . . . . . . . . . . . . . . . . . . . . . WP 0051 00-1

Illustrated List of Manufactured Items . . . . . . . . . . . . . . . . . . . . WP 0052 00-1

Torque Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0053 00-1

Wear Limits . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0054 00-1

CHAPTER 4 SUPPORTING INFORMATION

References . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0055 00-1

Repair Parts Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0056 00-1

Repair Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0057 00-1

Repair Parts and Special Tools List (RPSTL) . . . . . . . . . . . . . . . WP 0058 00-1

National Stock Number (NSN) Index . . . . . . . . . . . . . . . . . . . . . . WP 0059 00-1

Expendable and Durable Items . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0060 00-1

Tools and Special Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0061 00-1

Mandatory Replacement Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . WP 0062 00-1

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Index-1

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Viewed 38 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Thank you for considering our comprehensive Cummins NTC400 Diesel Engine Service & Repair Manual.

DESCRIPTION:

- This manual provides detailed, step-by-step repair procedures with high-resolution images specifically tailored for the Cummins NTC400 Diesel Engine, ensuring accurate diagnostics and cost-effective repairs.

- Once downloaded, the manual is yours to keep forever. You can print individual pages, chapters, or the entire manual. It is fully compatible with tablets and smartphones for easy reference on the go.

MODELS COVERED:

- Cummins NTC400 Diesel Engine along with its integrated transmission and electronic systems.

CONTENTS:

- This high-quality manual covers all repair and service procedures from A-Z, including troubleshooting, maintenance, and technical specifications explicitly for the Cummins NTC400 Diesel Engine.

COMPUTER REQUIREMENTS:

- The manual is compatible with all PC & MAC Computers, tablets, and mobile phones. Adobe Reader is required, which is usually pre-installed or available as a free download.

INSTANT DELIVERY:

- Upon payment by Visa, MasterCard, or PayPal, the manual will be instantly emailed to the address provided during checkout.

Customer Satisfaction Guaranteed.