CUMMINS NTC-400 BC2 Diesel Engine Service Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

TM 9-2815-226-34-1

DIRECT SUPPORT AND GENERAL SUPPORT

MAINTENANCE SERVICE MANUAL

FOR

ENGINE, DIESEL, 6 CYLINDER

INLINE, TURBOCHARGED,

CUMMINS MODEL NTC-400 BC2

NSN 2815-01-156-6210

SEPTEMBER 1985

TM 9-2815-226-34-1

C1

Direct Support and General Support

Maintenance Service Manual

ENGINE, DIESEL, 6 CYLINDER

INLINE, TURBOCHARGED

CUMMINS MODEL NTC-400 BC 2

(2815-01-156-6210)

TM 9-2815-226-34, September 1985 is changed as follows:

1. Remove old pages and insert new pages as indicated below.

2. New or changed material is indicated by a vertical bar in the margin of the page.

3. Added or revised illustrations are indicated by a vertical bar adjacent to the illustration identification number.

4. The purpose of Change 1 to this manual is to identify configuration diffe rences between the 1980, 1982, and 1984

models. Model designators can be determined by viewing the data plate on your truck chassis.

Remove Pages Insert Pages Remove Pages Insert Pages

i i 3-139 and 3-140 3-139 and 3-140

ii ii 3-151 and 3-152 3-151 and 3-152

1-1 thru 1-4 1-1 thru 1-4 3-155 and 3-156 3-155 and 3-156

1-5/(1-6 blank) 1-5 and 1-6 3-177 thru 3-180 3-177 thru 3-180

3-29 thru 3-34 3-29 and 3-34 INDEX-1 and INDEX-2 INDEX-1 and INDEX-2

3-37 and 3-38 3-37 and 3-38

3-53 thru 3-56 3-53 thru 3-56

3-65 thru 3-68 3-65 thru 3-68.1/

(3-68.2 blank)

3-133 and 3-134 3-133 and 3-134

File this change sheet in front of the publication for reference purposes.

WARNING

EXHAUST FUMES

The following precautions must be observed to ensure the safety of personnel

when the engine of any vehicle is operated:

1. DO NOT operate personnel heater or engine of vehicle in a closed place unless the place has a lot of moving air.

2. DO NOT idle engine for long periods without ventilator blower operation. If tactical situation permits, open

hatches.

3. DO NOT drive any vehicle with inspection plates, cover plates, or engine compartment doors removed unless

necessary for maintenance purposes.

4. BE ALERT at all times during vehicle operation for exhaust odors and exposure symptoms. If either are present,

IMMEDIATELY VENTILATE personnel compartment. If symptoms persist, remove affected crew to fresh air;

keep warm; DO NOT PERMIT PHYSICAL EXERCISE; if necessary, give artificial respiration and get immediate

medical attention.

5. BE AWARE; neither the gas particulate filter un it nor the field protection mask for nuclear-biological-chemical

protection will protect you from carbon monoxide poisoning.

WARNING

COMPRESSED AIR

Compressed air used for cleaning purposes will not exceed 30 PSI (207 KPA). Use

only with effective chip guarding and personal protective equipment (goggles,

shield, gloves, etc.).

a

WARNING

FIRE AND EXPLOSION

Do not use gasoline for cleaning or as fuel.

Do not get battery electrolyte on your skin, clothing, or in your eyes. It is an acid

which can cause injury. Keep all sparks and flames away from batteries. The

battery gas is explosive.

When disconnecting battery terminals, always disconnect the ground terminal

first.

When reconnecting battery terminals, always connect the ground terminal last.

Methyl alcohol is highly flammable and poisonous, and can be absorbed through

the skin. Do not drink or breathe it. If you spill any on your skin, wash it off

immediately with water. Keep it away from sparks or flames.

Ether quick-start is explosive and poisonous. Do not permit canisters to be

subjected to excessive heat. Do not attempt to start vehicle if ether line to engine

is broken or disconnected.

When filling fuel tank with diesel fuel, be sure hose nozzle on container contacts

filler tube on fuel tank to carry off static electricity. Do not smoke, permit open

flame or uncovered battery compartments while you are servicing the diesel fuel

system.

Dry cleaning solvent P-D-680 is toxic and flammable. Wear protective goggles and

gloves and use only in well ventilated area. Avoid contact with skin, eyes, and

clothes, and do not breathe vapors. Do not use near open flame or excessive heat.

WARNING

EXHAUST PIPE AND MUFFLER

During normal operation, the exhaust pipe and muffler can become very hot. Do

not touch these components with your bare hands.

b

WARNING

ENGINE COOLANT

Take extreme care when removing engine coolant tank fill cap if temperature gage

reads above 195°F (91ºC), to prevent burns or serious injury.

WARNING

JACKING UP TRUCK

Hydraulic jack is intended for lifting the truck, not for supporting the vehicle when

performing maintenance. To prevent serious injury, do not get under truck unless

it is properly supported with blocks or jack stands.

WARNING

COOLING FAN

When working in engine compartment with the engine running, stay clear of the

cooling fan. The fan may engage automatically at any time and can cause serious

injury.

WARNING

HOISTING TRUCK

Direct personnel to stand clear during hoisting operation. Failure to do this may

cause injury to personnel.

C

TM 9-2815-226-34-1

TECHNICAL MANUAL

No. 9-2815-226-34-1

DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE MANUAL

ENGINE, DIESEL, 6 CYLINDER INLINE, TURBOCHARGED,

CUMMINS MODEL NTC-400 BC2

REPORTING ERRORS AND RECOMMENDING IMPROVEMENTS

You can help improve this manual. If you find any mistakes or if you know of a way to improve the

procedures, please let us know. Mail your letter, DA Form 2028 (Recommended Changes to Publications

and Blank Forms), or DA Form 2028-2 located in the back of this manual directly to: Commander, US Army

Tank-Automotive command, ATTN: AMSTA-MBS, Warren, MI 48397-5000. A reply will be furnished to you.

VOLUME 1 OF 2

Page

CHAPTER 1 INTRODUCTION .......................................................................................................... 1-1

Section I General Information .................................................................................................. 1-1

Section II Equipment Description and Data ................................................................................. 1-3

CHAPTER 2 DIRECT SUPPORT AND GENERAL SUPPORT

MAINTENANCE INSTRUCTIONS .................................................................................. 2-1

Section I Repair Parts, Special Tools, TMDE, and......................................................................

Support Equipment .

Section II Troubleshooting......................................................................................................... 2-1

Section III General Maintenance ................................................................................................ 2-1

CHAPTER 3 REPAIR OF ENGINE ASSEMBLY ................................................................................. 3-1

Section I General ..................................................................................................................... 3-1

Section II Engine Disassembly................................................................................................... 3-28

Section III Cylinder Block Repair ................................................................................................. 3-57

Section IV Cylinder Liners Inspection........................................................................................... 3-115

Section V Crankshaft Assembly Repair....................................................................................... 3-117

Section VI Bearing Halves Inspection .......................................................................................... 3-126

Section VII Connecting Rod Repair .............................................................................................. 3-127

Section VIII Piston Assembly Repair ............................................................................................. 3-140

Section IX Camshaft Repair ........................................................................................................ 3-146

Change 1 i

TM 9-2815-226-34-1

Page

Section X Gear Case Cover Repair ............................................................................................ 3-150

Section XI Cylinder Head Assembly Repair .................................................................................. 3-156

Section XII Rocker Lever Housing Assembly Repair ...................................................................... 3-198

Section XIII Push Tubes Repair ................................................................................................... 3-210

Section XIV Cam Follower Housing Assembly Repair ..................................................................... 3-212

Section XV Vibration Damper Repair ........................................................................................... 3-224

Section XVI Flex Disk and Ring Gear Assembly Repair .................................................................. 3-226

VOLUME 2 OF 2

Section XVII Flywheel Housing Repair ............................................................................................ 3-229

Section XVIII Rear Cover Repair .................................................................................................... 3-230

Section XIX Rocker Lever Covers Repair ....................................................................................... 3-231

Section XX Oil Pump Assembly Repair ......................................................................................... 3-234

Section XXI Oil Pan Repair .......................................................................................................... 3-240

Section XXII Oil Cooler Assembly Repair ........................................................................................ 3-244

Section XXIII Aftercooler Repair...................................................................................................... 3-250

Section XXIV Exhaust Manifold Repair ............................................................................................. 3-253

Section XXV Accessory Drive Assembly ......................................................................................... 3-254

Section XXVI Engine Brake Assembly Repair................................................................................... 3-257

Section XXVII Fuel Injector Repair .................................................................................................... 3-262

Section XXVIII Fuel Pump Repair ..................................................................................................... 3-287

Section XXIX Turbocharger Repair ................................................................................................. 3-374

Section XXX Water Pump and Idler Pulley Assembly Repair ............................................................ 3-390

Section XXXI Engine Reassembly ................................................................................................... 3-398

Section XXXII Engine Testing .......................................................................................................... 3-462

Section XXXIII Preparation for Storage or Shipment ........................................................................... 3-472

APPENDIX A REFERENCES ............................................................................................................. A-1

APPENDIX B EXPENDABLE SUPPLIES AND MATERIALS LIST ......................................................... B-1

APPENDIX C TORQUE LIMITS .......................................................................................................... C-1

INDEX ......................................................................................................................... INDEX-1

ii

TM 9-2815-226-34-1

CHAPTER 1

INTRODUCTION

Section I. GENERAL INFORMATION

1-1. SCOPE.

a. Type of Manual:Direct Support and General Support Maintenance.

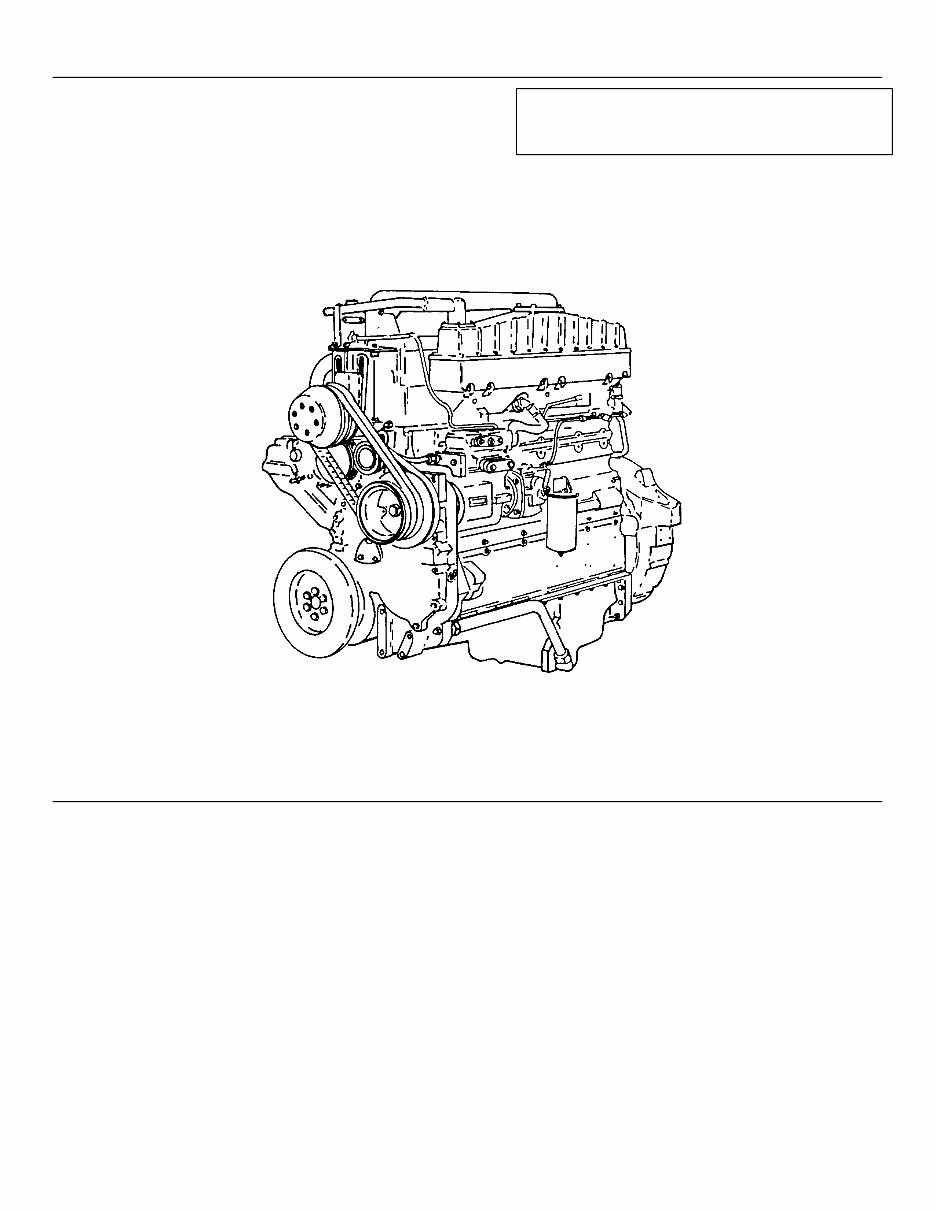

b. Model Number and Equipment Name: Cummins Model NTC-400 BC2, Six-Cylinder Inline, Turbocharged Diesel

Engine.

c. Purpose of Equipment: Engine for Truck Chassis, Direct Support Section, Topographic Support System (TSS).

1-2. MAINTENANCE FORMS, RECORDS, AND REPORTS. Department of the Army forms and procedures used for

equipment maintenance will be those prescribed by DA Pam 738-750, The Army Maintenance Management System

(TAMMS).

1-3. DESTRUCTION OF ARMY MATERIAL TO PREVENT ENEMY USE. Procedures outlined in TM 750-244-6

(Procedures for Destruction of Tank-Automotive Equipment to Prevent Enemy Use) are applicable to this equipment.

1-4. PREPARATION FOR STORAGE OR SHIPMENT. Instructions concerning storage or shipment of engine are found

in Chapter 3, Section XXXIII of this manual.

1-5. REPORTING EQUIPMENT IMPROVEMENT RECOMMENDATIONS (EIR). EIR can and must be submitted by

anyone who is aware of an unsatisfactory condition with the equipment design or use. It is not necessary to show a new

design or list a better way to perform a procedure. Just simply tell why the design is unfavorable or why a procedure is

difficult. EIR may be submitted on SF 368 (Quality Deficiency Report). Mail directly to: Commander, U.S. Army Tank -

Automotive Command, ATTN: AMSTA-QR, Warren, Michigan 48397-5000. A reply will be furnished to you.

Change 1 1-1

TM 9-2815-226-34-1

Section II. EQUIPMENT DESCRIPTION AND DATA

1-6. EQUIPMENT CHARACTERISTICS, CAPABILITIES, AND FEATURES. The following information describes engine

characteristics and features:

Camshaft: 2-1/2 inch diameter gear driven camshaft which controls all valve and injector movement. Made

of induction hardened alloy steel. Camshaft followers are roller type.

Connecting Rods: Drop forged, rifle drilled for pressure lubrication.

Crankshaft: High tensile strength steel forging. Bearing journals and fillets induction hardened. Fully

counterweighted.

Cylinder Block: Alloy cast iron with removable, wet liners.

Cylinder Head: Each head serves two cylinders. Drilled fuel supply and return lines. High temperature inserts on

exhaust valve seats.

Fuel System: Integral flyweight type governor.

Injectors: Camshaft actuated top stop type.

Intake Manifold: Single pass water aftercooler.

Lubricating Oil Cooler: Demand flow.

1-2

TM 9-2815-226-34-1

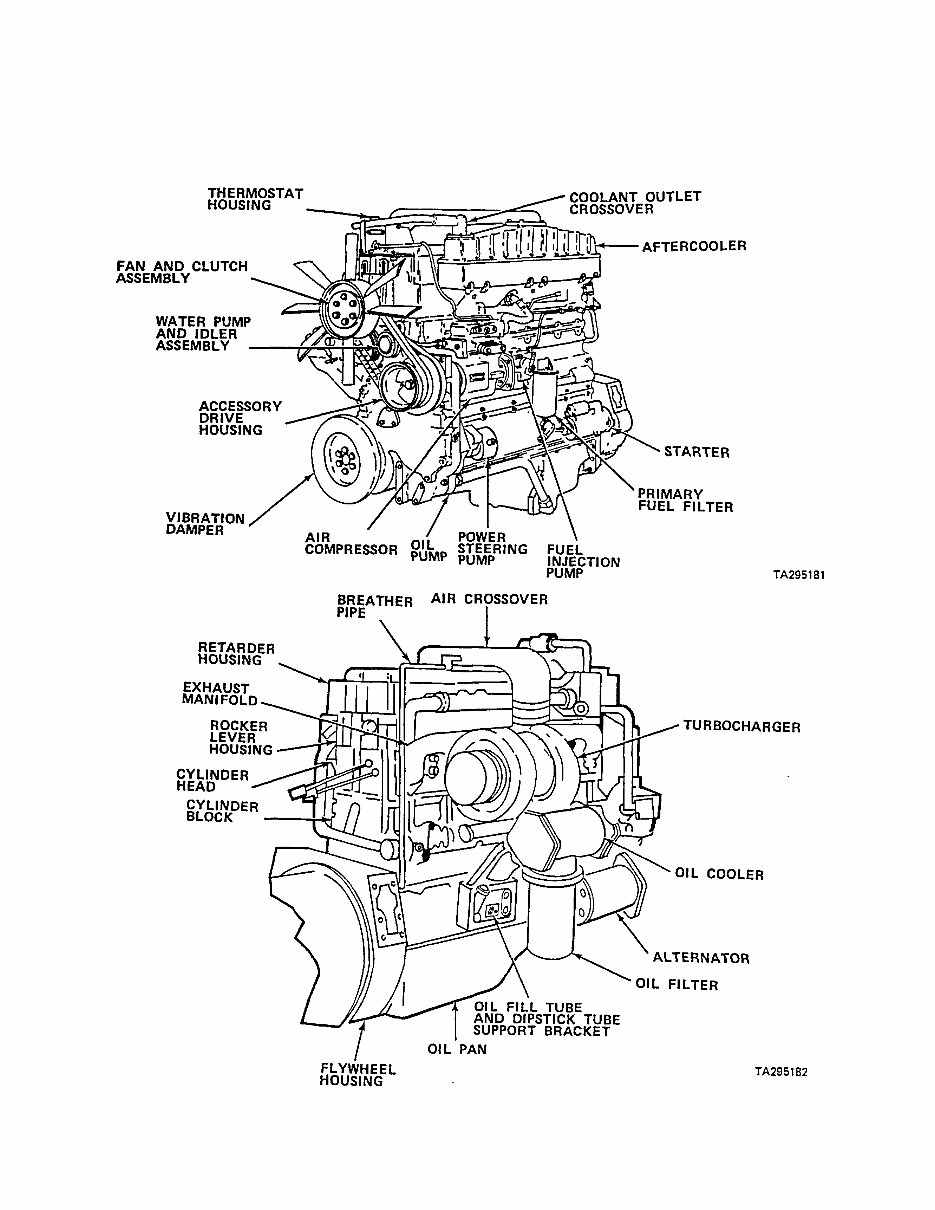

1-7. LOCATION AND DESCRIPTION OF MAJOR COMPONENTS. The illustrations below show the location of the

major engine components.

1-3

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 12 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

The CUMMINS NTC-400 BC2 Diesel Engine Manual is a comprehensive resource published by the Department of the Army on 10 April 1987. It is available in two volumes, totaling 560 pages on CD-ROM. This manual is a valuable tool for both professional mechanics and DIY enthusiasts.

- Volume 1 of 2 includes:

- Introduction

- General Information

- Equipment Description and Data

- DIRECT SUPPORT AND GENERAL SUPPORT MAINTENANCE INSTRUCTIONS

- Repair Parts, Special Tools, TMDE, and Support Equipment

- Troubleshooting

- General Maintenance

- REPAIR OF ENGINE ASSEMBLY

- General

- Engine Disassembly

- Cylinder Block Repair

- Cylinder Liners Inspection

- Crankshaft Assembly Repair

- Bearing Halves Inspection

- Connecting Rod Repair

- Piston Assembly Repair

- Camshaft Repair

- Gear Case Cover Repair

- Cylinder Head Assembly Repair

- Rocker Lever Housing Assembly Repair

- Push Tubes Repair

- Cam Follower Housing Assembly Repair

- Vibration Damper Repair

- Flex Disk and Ring Gear Assembly Repair

- Volume 2 of 2 includes:

- Flywheel Housing Repair

- Rear Cover Repair

- Rocker Lever Covers Repair

- Oil Pump Assembly Repair

- Oil Pan Repair

- Oil Cooler Assembly Repair

- Aftercooler Repair

- Exhaust Manifold Repair

- Accessory Drive Assembly

- Engine Brake Assembly Repair

- Fuel Injector Repair

- Fuel Pump Repair

- Turbocharger Repair

- Water Pump and Idler Pulley Assembly Repair

- Engine Reassembly

- Engine Testing

- Preparation for Storage or Shipment