1972-1990 Chevrolet Small-Block Engine Overhaul Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Contents

Chapter 1 Introduction

How to use this repair manual 1-1

What is an overhaul? 1-1

Engine identification 1-2

Parts interchangeability 1-6

Buying parts 1-11

Chapter 2 Tools and equipment

A place to work 2-1

Tools and equipment 2-3

Fasteners 2-37

Component disassembly 2-41

Gasket sealing surfaces 2-41

Hose removal tips 2-42

Automotive chemicals and lubricants 2-42

Safety first! 2-43

Chapter 3 Diagnosing engine problems

General information 3-1

Reading symptoms 3-1

Measuring oil consumption 3-2

Diagnostic checks 3-2

Is the engine worth rebuilding? 3-11

Chapter 4 Preparing for an overhaul

Preparing to remove the engine 4-1

Removing the engine 4-2

Removing the external engine components 4-11

Chapter 5 Overhauling the cylinder heads

Removing the cylinder heads 5-1

Rebuilding the cylinder heads 5-3

Inspecting the valve springs 5-11

Assembling the heads 5-13

Installing the heads 5-14

Installing the valve train 5-16

Chapter 6 Overhauling the engine block

Disassembly 6-1

Cleaning and inspection 6-5

Machine shop procedures 6-17

Choosing piston rings and honing the cylinders 6-19

Reassembly 6-21

Chapter 7 Reassembling and installing the engine

Introduction 7-1

Replacing the front transmission seal 7-1

Assembling the engine 7-3

\r\staU\ngthe engine 7-14

Starting the engine 7-15

Breaking in the engine 7-16

Chapter 8 Related repairs

Carburetor overhaul 8-1

Distributor overhaul 8-3

Fuel pump overhaul 8-5

Starter overhaul 8-5

Generator overhaul 8-10

Alternator overhaul 8-10

Chapter 9 Improving performance and economy

Introduction 9-1

Camshaft selection 9-3

Exhaust modifications 9-8

Ignition systems 9-11

Intake manifolds 9-12

Carburetors 9-14

Making it all work together 9-18

Engine swaps 9-18

Glossary GL-1

Appendix

A Booster battery (jump) starting AP-1

B Conversion factors AP-2

C Electrical glossary AP-3

D Understanding wiring diagrams AP-12

Index iND-1

Introduction

How to use

this repair manual

The manual is divided into Chapters. Each Chapter is

sub-divided into Sections, some of which consist of con-

secutively numbered Paragraphs (usually referred to as

"Steps", since they're normally part of a procedure). If the

material is basically informative in nature, rather than a

step-by-step procedure, the Paragraphs aren't numbered.

The first three Chapters contain material on preparing

for an overhaul. The remaining Chapters cover the specifics

of the overhaul procedure.

Comprehensive Chapters covering tool selection and

usage, safety and general shop practices have been

included.

The term "see illustration" (in parentheses), is used in

the text to indicate that a photo or drawing has been

included to make the information easier to understand (the

old cliche "a picture is worth a thousand words" is espe-

cially true when it comes to how-to procedures). Also, every

attempt is made to position illustrations directly opposite

the corresponding text to minimize confusion. The two

types of illustrations used (photographs and line drawings)

are referenced by a number preceding the caption. Illustra-

tion numbers denote Chapter and numerical sequence

within the Chapter (i.e., 3.4 means Chapter 3, illustration

number four in order).

The terms "Note", "Caution", and "Warning" are used

throughout the text with a specific purpose in mind - to

attract the reader's attention. A "Note" simply provides

information required to properly complete a procedure or

information which will make the procedure easier to under-

stand. A "Caution" outlines a special procedure or special

steps which must be taken when completing the procedure

where the Caution is found. Failure to pay attention to a

Caution can result in damage to the component being

repaired or the tools being used. A "Warning" is included

where personal injury can result if the instructions aren't fol-

lowed exactly as described.

Even though extreme care has been taken during the

preparation of this manual, neither the publisher nor the

author can accept responsibility for any errors in, or omis-

sions from, the information given.

What is an overhaul?

An engine overhaul involves restoring the internal parts

to the specifications of a new engine. During an overhaul,

the piston rings are replaced and the cylinder walls are

reconditioned (rebored and/or honed). If a rebore is done,

new pistons are required. The main bearings, connecting

rod bearings and camshaft bearings are generally replaced

with new ones and, if necessary, the crankshaft may be

reground to restore the journals.

Generally, the valves are serviced as well, since they're

usually in less-than-perfect condition at this point. While the

engine is being overhauled, other components, such as the

distributor, starter and alternator, can be rebuilt as well. The

end result should be like a new engine that will give many

thousands of trouble-free miles. Note: Critical cooling sys-

tem components such as the hoses, drivebelts, thermostat

1-1

Haynes Chevrolet engine overhaul manual

1.1 Typical Chevrolet code number locations

and water pump MUST be replaced with new parts when an

engine is overhauled. The radiator should be checked care-

fully to ensure that it isn't clogged or leaking; if in doubt,

replace it with a new one. Also, always install a new oil

pump when overhauling the engine - we recommend

against rebuilt pumps.

It's not always easy to determine when, or if, an engine

should be completely overhauled, as a number of factors

must be considered.

High mileage is not necessarily an indication that an

overhaul is needed, while low mileage doesn't preclude the

need for an overhaul. Frequency of servicing is probably the

most important consideration. An engine that's had regular

and frequent oil and filter changes, as well as other required

maintenance, will most likely give many thousands of miles

of reliable service. Conversely, a neglected engine may

require an overhaul very early in its life.

Excessive oil consumption is an indication that piston

rings, valve seals and/or valve guides are in need of atten-

tion. Make sure that oil leaks aren't responsible before

deciding that the rings and/or guides are bad. Perform a

compression check (see Chapter 3) and have a leak-down

test performed by an experienced tune-up mechanic to

determine the extent of the work required.

If the engine is making obvious knocking or rumbling

noises, the connecting rod and/or main bearings may be at

fault. Check the oil pressure with a gauge installed in place

of the oil pressure sending unit or switch (see Chapter 3)

and compare it to the specifications for the particular

engine (see the Haynes Automotive Repair Manual for your

vehicle). If it's extremely low (generally, less than 10 psi at

idle), the bearings and/or oil pump are probably worn out.

Loss of power, rough running, excessive valvu train

noise and high fuel consumption rates may also point to the

need for an overhaul, especially if they're all present at the

same time. If a complete tune-up doesn't remedy the situa-

tion, major mechanical work is the only solution.

Before beginning the engine overhaul, read through

this entire manual to familiarize yourself with the scope and

requirements of the job. Overhauling an engine isn't partic-

1.2 Check for a casting number at the rear of the

block (arrow)

ularly difficult if you have the correct equipment; however, it

is time consuming. Plan on the vehicle being tied up for a

minimum of two weeks, especially if parts must be taken to

an automotive machine shop for repair or reconditioning.

Check on availability of parts and make sure that any nec-

essary special tools and equipment are obtained in

advance. Most work can be done with typical hand tools,

although a number of precision measuring tools are

required for inspecting parts to determine if they must be

replaced. Often an automotive machine shop will handle

the inspection of parts and offer advice concerning recon-

ditioning and replacement.

Engine identification

Identifying just which engine you have is critical

because Chevrolet engines which are very similar in

appearance can be quite different in important details.

Prior to 1972 on passenger cars and 1973 on light

trucks, the Vehicle Identification Number (VIM) only indicates

whether the vehicle originally came with a six-cylinder or a

V8. Some of these engines can be identified by the decals

on the air cleaner or the valve covers. If these markings are

missing or you suspect they are incorrect, check for num-

bers on the engine. Record the VIN number (see illustra-

tion) and also the casting number on the rear of the engine

block between the distributor and bellhousing (see illustra-

tion). Also note the shape of the casting marks on the ends

of the cylinder heads (later models don't have these). Using

this information, check with your local dealer parts depart-

ment or salvage yard for assistance in identification.

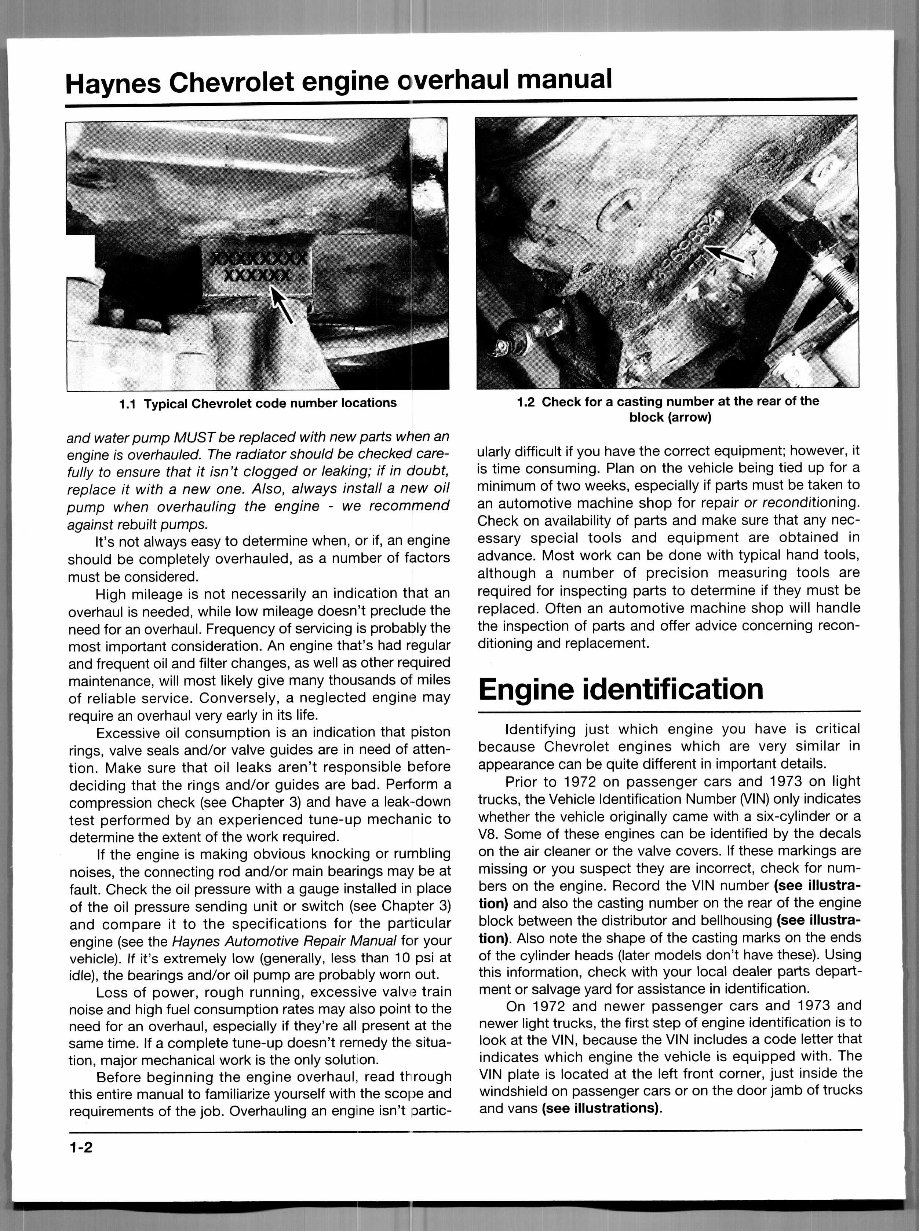

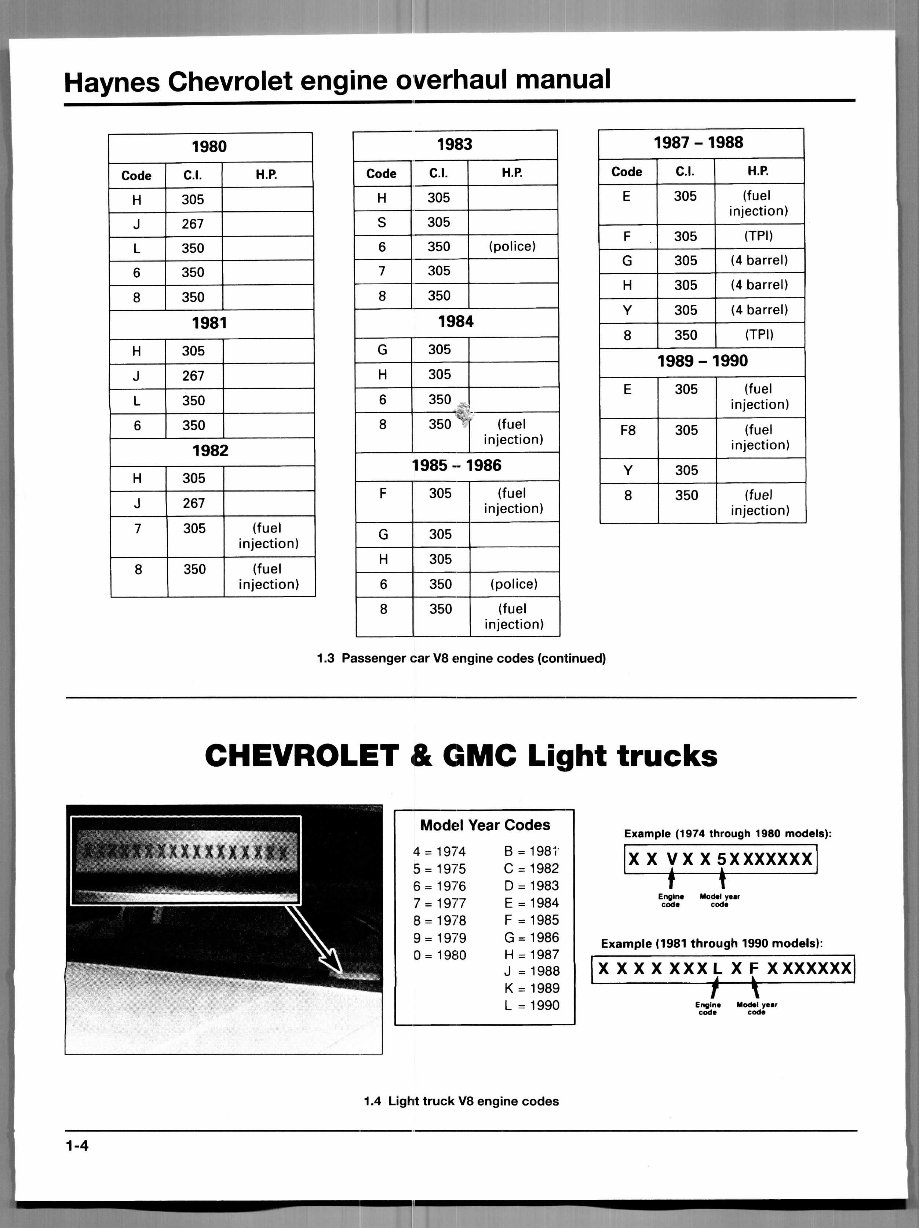

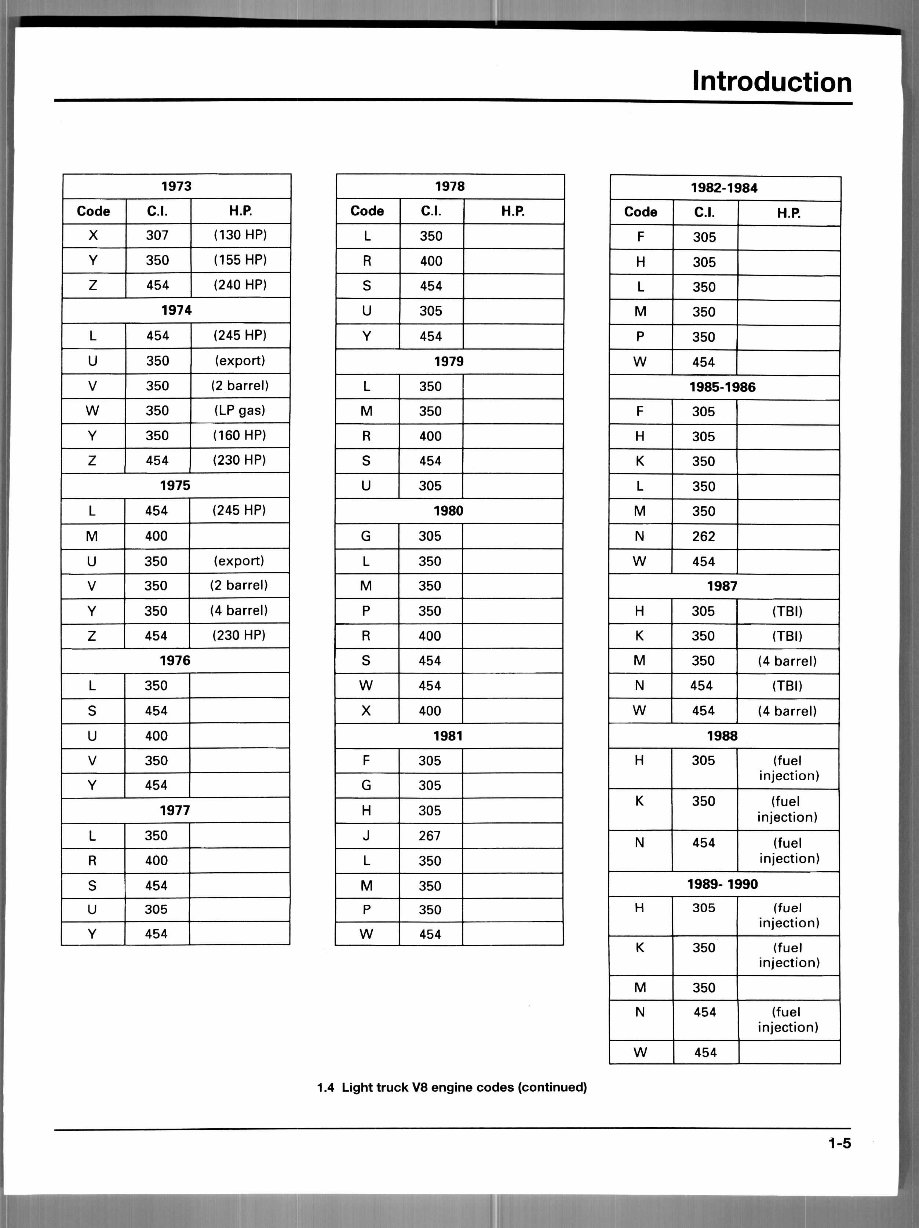

On 1972 and newer passenger cars and 1973 and

newer light trucks, the first step of engine identification is to

look at the VIN, because the VIN includes a code letter that

indicates which engine the vehicle is equipped with. The

VIN plate is located at the left front corner, just inside the

windshield on passenger cars or on the door jamb of trucks

and vans (see illustrations).

1-2

Introduction

CHEVROLET

Passenger Cars

Example (1972 through 1980 models)

Model Year Codes

2 = 1972

3 = 1973

4 = 1974

5 = 1975

6 = 1976

7 = 1977

8 = 1978

9 = 1979

0 = 1980

B =1981

C = 1982

D = 1983

E = 1984

F =1985

G = 1986

H = 1987

J =1988

K = 1989

L =1990

X X XX L S^X XXXXXX

Engine Model year

code code

Example (1981 through 1990 models):

X XXX XXX L X BX XXXXXX

Engine Model year

code code

1972

Code

F

H

J

K

L

R

S

U

V

\N

C.I.

307

350

350

350

350

400

402

402

454

454

H.P.

(130 HP)

(165 HP)

(175 HP)

(200 HP)

(255 HP)

(170 HP)

(210 HP)

(240 HP)

(230 HP)

(270 HP)

1973

F

H

J

K

R

T

X

Y

Z

307

350

350

350

400

350

454

454

454

(115HP)

(145 HP)

(190 HP)

(175 HP)

(150 HP)

(245 HP)

(215 HP)

(245 HP)

(275 HP)

1974

Code

H

J

K

L

R

T

U

Y

Z

C.I.

350

350

350

350

400

350

400

454

454

H.P.

(145 HP)

(195 HP)

(185 HP)

(160 HP)

(150 HP)

(245 HP)

(180 HP)

(235 HP)

(270 HP)

1975

G

H

J

L

T

U

Y

262

350

350

350

350

400

454

(145 HP)

(165 HP)

(155 HP)

(205 HP)

1976

Code

G

L

Q

C.I.

262

350

305

H.P.

(165 HP)

1976 (con't)

Code

S

U

V

X

C.I.

454

400

350

350

H.P.

(145 HP)

(210 HP)

1977

L

U

X

350

305

350

(170 HP)

(210 HP)

1978

H

L

350

350

(220 HP)

(170 HP)

1979

G

H

J

L

4

8

305

305

267

350

350

350

(2 barrel)

(4 barrel)

1.3 Passenger car V8 engine codes

1-3

Haynes Chevrolet engine overhaul manual

1980

Code

H

J

L

6

8

C.I.

305

267

350

350

350

H.P.

1981

H

J

L

6

305

267

350

350

1982

H

J

7

8

305

267

305

350

(fuel

injection)

(fuel

injection)

Code

H

S

6

7

8

G

H

6

8

F

G

H

6

8

198:

C.I.

305

305

350

305

350

198'

305

305

350 _

350**

1985 - '

305

305

305

350

350

}

H.P.

(police)

1

[

(fuel

injection)

1986

(fuel

injection)

(police)

(fuel

injection)

1987 - 1988

Code

E

F

G

H

Y

8

C.I.

305

305

305

305

305

350

H.P.

(fuel

injection)

(TPI)

(4 barrel)

(4 barrel)

(4 barrel)

(TPI)

1989 - 1990

E

F8

Y

8

305

305

305

350

(fuel

injection)

(fuel

injection)

(fuel

injection)

1.3 Passenger car V8 engine codes (continued)

CHEVROLET & CMC Light trucks

Model Year Codes

4 = 1974

5 = 1975

6 = 1976

7 = 1977

8=1978

9=1979

0=1980

B = 1981

C = 1982

D = 1983

E = 1984

F = 1985

G = 1986

H = 1987

J =1988

K = 1989

L = 1990

Example (1974 through 1980models):

XX VXX5XXXXXXX

1—t-

Engine Model year

code cod*

Example (1981 through 1990 models):

X X X X XXX L X F XXXXXXX

Engln* Model year

code code

1-4

1.4 Light truck V8 engine codes

Introduction

1973

Code

X

Y

Z

C.I.

307

350

454

H.P.

(130 HP)

(155 HP)

(240 HP)

1974

L

U

V

W

Y

Z

454

350

350

350

350

454

(245 HP)

(export)

(2 barrel)

(LPgas)

(160 HP)

(230 HP)

1975

L

M

U

V

Y

Z

454

400

350

350

350

454

(245 HP)

(export)

(2 barrel)

(4 barrel)

(230 HP)

1976

L

S

U

V

Y

350

454

400

350

454

1977

L

R

S

U

Y

350

400

454

305

454

1978

Code

L

R

S

U

Y

C.I.

350

400

454

305

454

H.P.

1979

L

M

R

S

U

350

350

400

454

305

1980

G

L

M

P

R

S

W

X

305

350

350

350

400

454

454

400

1981

F

G

H

J

L

M

P

W

305

305

305

267

350

350

350

454

1982-1984

Code

F

H

L

M

P

W

C.I.

305

305

350

350

350

454

H.P.

1985-1986

F

H

K

L

M

N

W

305

305

350

350

350

262

454

1987

H

K

M

N

W

305

350

350

454

454

(TBI)

(TBI)

(4 barrel)

(TBI)

(4 barrel)

1988

H

K

N

305

350

454

(fuel

injection)

(fuel

injection)

(fuel

injection)

1989- 1990

H

K

M

N

W

305

350

350

454

454

(fuel

injection)

(fuel

injection)

(fuel

injection)

1.4 Light truck V8 engine codes (continued)

1-5

Haynes Chevrolet engine overhaul manual

Parts interchangeability

A lot of time and money can be saved if you know

which parts are interchangeable between your engine and

those available on the used market and in wrecking yards.

There is considerable interchangeability within the

Chevrolet small block and big block families. However, few

parts from one family are usable in the other; about the only

notable exception is the distributor.

Due to the vast number of Chevrolet V8 engines pro-

duced since 1955 in many versions, a complete and com-

prehensive guide would require several volumes the size of

this book. Most wrecking yards have interchange manuals

that provide a wealth of information for parts swapping. The

following information provides a basic overview, and does

not cover every possible combination of parts.

We will treat the small block and big block engines sep-

arately; refer to the appropriate Sections based on the

engine family you are working on.

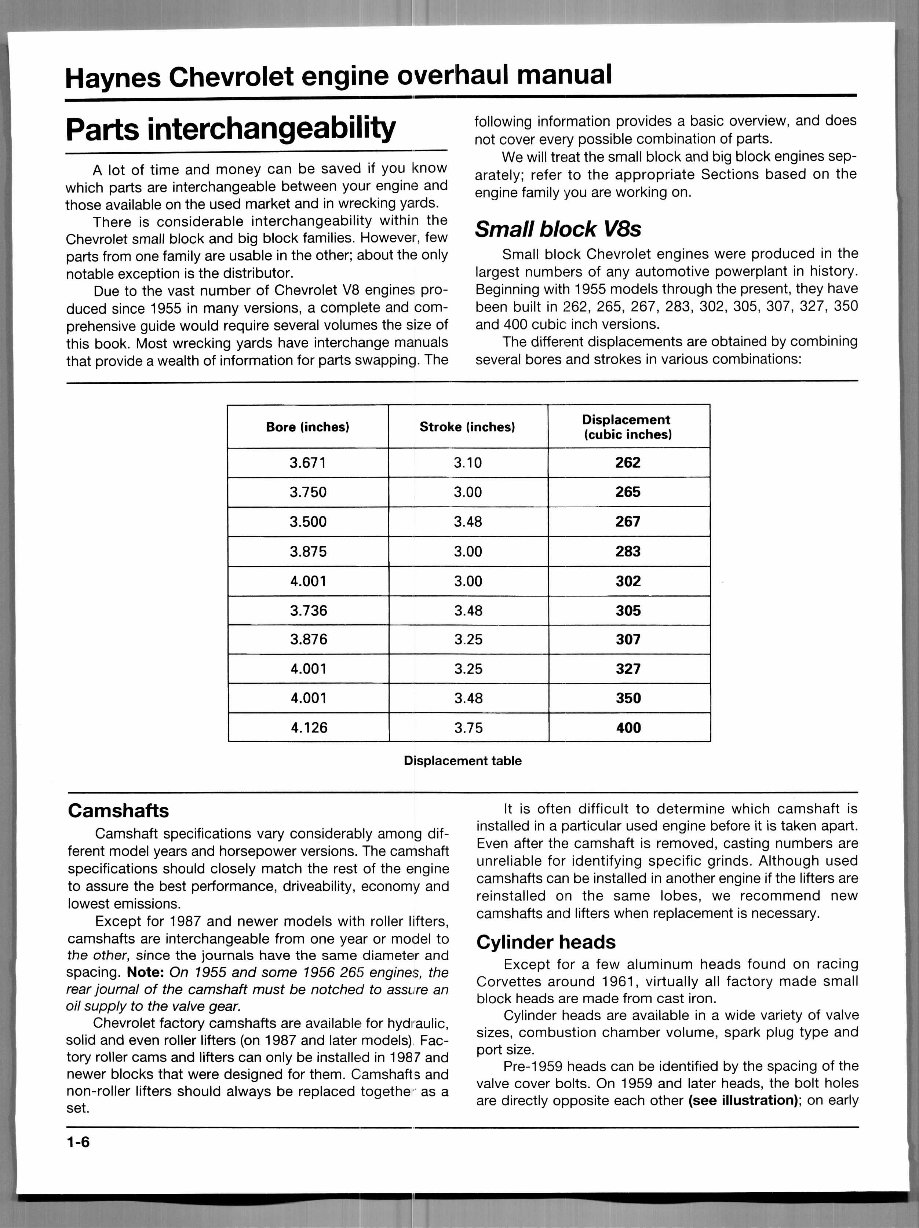

Small block V8s

Small block Chevrolet engines were produced in the

largest numbers of any automotive powerplant in history.

Beginning with 1955 models through the present, they have

been built in 262, 265, 267, 283, 302, 305, 307, 327, 350

and 400 cubic inch versions.

The different displacements are obtained by combining

several bores and strokes in various combinations:

Bore (inches)

3.671

3.750

3.500

3.875

4.001

3.736

3.876

4.001

4.001

4.126

Stroke (inches)

3.10

3.00

3.48

3.00

3.00

3.48

3.25

3.25

3.48

3.75

Displacement

(cubic inches)

262

265

267

283

302

305

307

327

350

400

Displacement table

Camshafts

Camshaft specifications vary considerably among dif-

ferent model years and horsepower versions. The camshaft

specifications should closely match the rest of the engine

to assure the best performance, driveability, economy and

lowest emissions.

Except for 1987 and newer models with roller lifters,

camshafts are interchangeable from one year or model to

the other, since the journals have the same diameter and

spacing. Note: On 7955 and some 1956 265 engines, the

rear journal of the camshaft must be notched to assure an

oil supply to the valve gear.

Chevrolet factory camshafts are available: for hydraulic,

solid and even roller lifters (on 1987 and later models) Fac-

tory roller cams and lifters can only be installed in 1987 and

newer blocks that were designed for them. Camshafts and

non-roller lifters should always be replaced togethe1 as a

set.

It is often difficult to determine which camshaft is

installed in a particular used engine before it is taken apart.

Even after the camshaft is removed, casting numbers are

unreliable for identifying specific grinds. Although used

camshafts can be installed in another engine if the lifters are

reinstalled on the same lobes, we recommend new

camshafts and lifters when replacement is necessary.

Cylinder heads

Except for a few aluminum heads found on racing

Corvettes around 1961, virtually all factory made small

block heads are made from cast iron.

Cylinder heads are available in a wide variety of valve

sizes, combustion chamber volume, spark plug type and

port size.

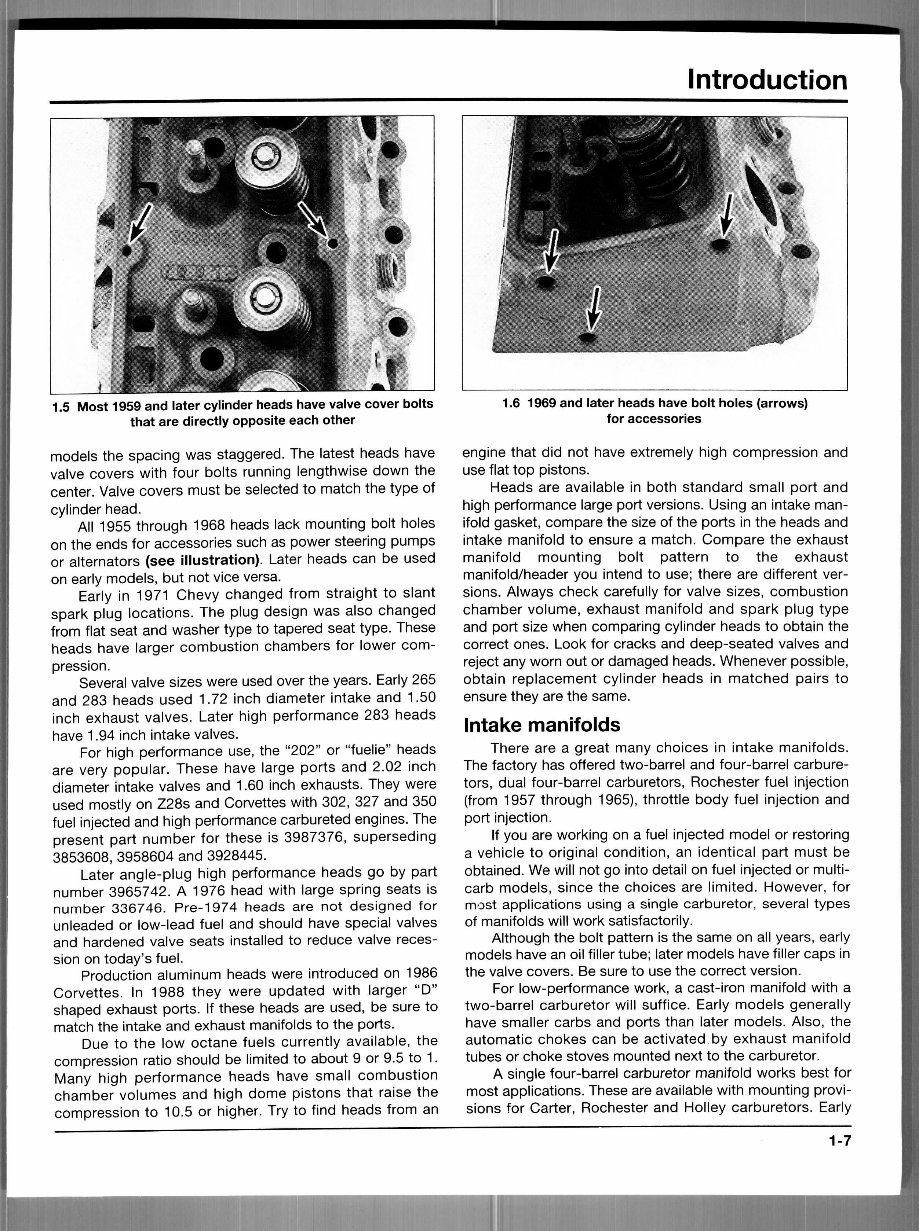

Pre-1959 heads can be identified by the spacing of the

valve cover bolts. On 1959 and later heads, the bolt holes

are directly opposite each other (see illustration); on early

1-6

Introduction

1.5 Most 1959 and later cylinder heads have valve cover bolts

that are directly opposite each other

models the spacing was staggered. The latest heads have

valve covers with four bolts running lengthwise down the

center. Valve covers must be selected to match the type of

cylinder head.

All 1955 through 1968 heads lack mounting bolt holes

on the ends for accessories such as power steering pumps

or alternators (see illustration). Later heads can be used

on early models, but not vice versa.

Early in 1971 Chevy changed from straight to slant

spark plug locations. The plug design was also changed

from flat seat and washer type to tapered seat type. These

heads have larger combustion chambers for lower com-

pression.

Several valve sizes were used over the years. Early 265

and 283 heads used 1.72 inch diameter intake and 1.50

inch exhaust valves. Later high performance 283 heads

have 1.94 inch intake valves.

For high performance use, the "202" or "fuelie" heads

are very popular. These have large ports and 2.02 inch

diameter intake valves and 1.60 inch exhausts. They were

used mostly on Z28s and Corvettes with 302, 327 and 350

fuel injected and high performance carbureted engines. The

present part number for these is 3987376, superseding

3853608, 3958604 and 3928445.

Later angle-plug high performance heads go by part

number 3965742. A 1976 head with large spring seats is

number 336746. Pre-1974 heads are not designed for

unleaded or low-lead fuel and should have special valves

and hardened valve seats installed to reduce valve reces-

sion on today's fuel.

Production aluminum heads were introduced on 1986

Corvettes. In 1988 they were updated with larger "D"

shaped exhaust ports. If these heads are used, be sure to

match the intake and exhaust manifolds to the ports.

Due to the low octane fuels currently available, the

compression ratio should be limited to about 9 or 9.5 to 1.

Many high performance heads have small combustion

chamber volumes and high dome pistons that raise the

compression to 10.5 or higher. Try to find heads from an

1.6 1969 and later heads have bolt holes (arrows)

for accessories

engine that did not have extremely high compression and

use flat top pistons.

Heads are available in both standard small port and

high performance large port versions. Using an intake man-

ifold gasket, compare the size of the ports in the heads and

intake manifold to ensure a match. Compare the exhaust

manifold mounting bolt pattern to the exhaust

manifold/header you intend to use; there are different ver-

sions. Always check carefully for valve sizes, combustion

chamber volume, exhaust manifold and spark plug type

and port size when comparing cylinder heads to obtain the

correct ones. Look for cracks and deep-seated valves and

reject any worn out or damaged heads. Whenever possible,

obtain replacement cylinder heads in matched pairs to

ensure they are the same.

Intake manifolds

There are a great many choices in intake manifolds.

The factory has offered two-barrel and four-barrel carbure-

tors, dual four-barrel carburetors, Rochester fuel injection

(from 1957 through 1965), throttle body fuel injection and

port injection.

If you are working on a fuel injected model or restoring

a vehicle to original condition, an identical part must be

obtained. We will not go into detail on fuel injected or multi-

carb models, since the choices are limited. However, for

most applications using a single carburetor, several types

of manifolds will work satisfactorily.

Although the bolt pattern is the same on all years, early

models have an oil filler tube; later models have filler caps in

the valve covers. Be sure to use the correct version.

For low-performance work, a cast-iron manifold with a

two-barrel carburetor will suffice. Early models generally

have smaller carbs and ports than later models. Also, the

automatic chokes can be activated by exhaust manifold

tubes or choke stoves mounted next to the carburetor.

A single four-barrel carburetor manifold works best for

most applications. These are available with mounting provi-

sions for Carter, Rochester and Holley carburetors. Early

1-7

Haynes Chevrolet engine overhaul manual

1.7 If you're swapping manifolds, make sure there are

provisions for all your vacuum fittings (arrow)

models and/or lower horsepower engines can use manifold

part number 3888886 with a small Carter or Holley four-bar-

rel. From 1966 on, most four-barrel models used Rochester

Quadrajets on a manifold with part number 3987361.

Relatively few aluminum four-barrel manifolds were

installed at the factory. Exchanging a cast-iron manifold for

an aluminum one is an easy way to shave weight off the

front end of a vehicle.

For high-performance street use, the factory aluminum

high-rise is hard to beat. It mounts a square-flange Holley

four-barrel or Carter AFB and goes under part number

3958627 superseded to 3972114.

Always compare the port sizes of the heads and mani-

folds by holding a gasket up to both openings. For optimum

performance, the sizes must match. Larger ports favor high

rpm and larger displacements. Small ports tend to improve

low rpm torque and driveability.

On 1973 and later models, look for Exhaust Gas Recir-

culation (EGR) valve provisions. Always compare the old

and new manifolds to determine if sufficient vacuum fittings

are present (see illustration).

Exhaust manifolds

The choice of exhaust manifolds is limited to a few

basic designs; none of these are exceptional from a perfor-

mance standpoint. Many enthusiasts convert to tubular

headers if they are looking for more performance.

Generally, the "ram's horn" shape manifolds used on

early Corvettes and high-performance passenger cars pro-

duce more power than the log shape designs. However,

clearance between body and frame determines which

exhaust manifolds can be used in a given situation.

There are several types of exhaust outlet flanges from 2

to 2 1/2 inches in diameter, using both two and three studs.

Heat risers or EFE valves, if used, must fit the manifold cor-

rectly. Also, accessory mounts and the length and angle of

exhaust outlet must match the engine and vehicle. Be sure

to check the number of cylinder head-to-manifold mounting

bolt holes; these vary on different models.

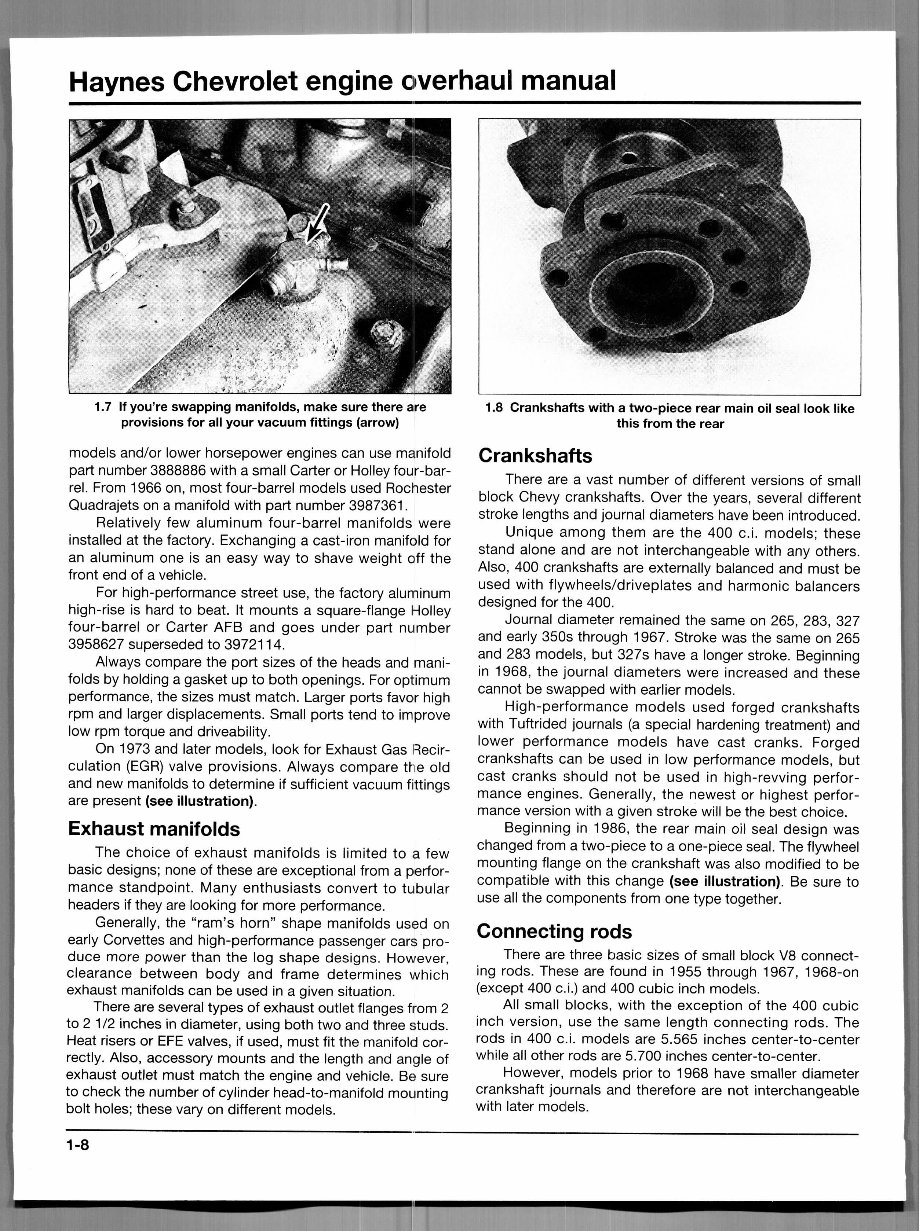

1.8 Crankshafts with a two-piece rear main oil seal look like

this from the rear

Crankshafts

There are a vast number of different versions of small

block Chevy crankshafts. Over the years, several different

stroke lengths and journal diameters have been introduced.

Unique among them are the 400 c.i. models; these

stand alone and are not interchangeable with any others.

Also, 400 crankshafts are externally balanced and must be

used with flywheels/driveplates and harmonic balancers

designed for the 400.

Journal diameter remained the same on 265, 283, 327

and early 350s through 1967. Stroke was the same on 265

and 283 models, but 327s have a longer stroke. Beginning

in 1968, the journal diameters were increased and these

cannot be swapped with earlier models.

High-performance models used forged crankshafts

with Tuftrided journals (a special hardening treatment) and

lower performance models have cast cranks. Forged

crankshafts can be used in low performance models, but

cast cranks should not be used in high-revving perfor-

mance engines. Generally, the newest or highest perfor-

mance version with a given stroke will be the best choice.

Beginning in 1986, the rear main oil seal design was

changed from a two-piece to a one-piece seal. The flywheel

mounting flange on the crankshaft was also modified to be

compatible with this change (see illustration). Be sure to

use all the components from one type together.

Connecting rods

There are three basic sizes of small block V8 connect-

ing rods. These are found in 1955 through 1967, 1968-on

(except 400 c.i.) and 400 cubic inch models.

All small blocks, with the exception of the 400 cubic

inch version, use the same length connecting rods. The

rods in 400 c.i. models are 5.565 inches center-to-center

while all other rods are 5.700 inches center-to-center.

However, models prior to 1968 have smaller diameter

crankshaft journals and therefore are not interchangeable

with later models.

1-8

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

Viewed 27 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

Get your hands on the 1972-1990 Chevrolet V8 Engine Overhaul Manual. This manual covers a range of engines including the 262, 267, 305, 307, 350, 400, 402, and 454. Whether you're a professional mechanic or a DIY enthusiast, this manual is an invaluable resource for all your repair needs.