Caterpillar C7 / C9 Engines Electrical and Electronic Application and Installation Guide

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

C7 & C9 Truck Engines

EPA 2004

Electrical and Electronic

Application and Installation Guide

Serial Number Prefixes

FMM

FML

KAL

YPG

9DG

CKP

LEBT2835-02 November 2008

INTRODUCTION AND PURPOSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Engine Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Engine Component Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Engine Monitoring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Power and Grounding Requirements and Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

Connectors and Wiring Harness Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

Accelerator Pedal Position Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

Vehicle Speed Input Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

ECM Speedometer and Tachometer Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Lamp Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45

OEM Installed Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Inlet Air Heater, Lamp and Relay Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Hard-wired Switch Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Cruise Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

Idle Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

J1939 Based Switch Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Dedicated PTO Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Programmable Outputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

Transmissions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Governor Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .104

Cooling Fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .106

Idle Shutdown Timer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .113

Data Links . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .114

Customer Specified Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .144

Diagnostics, Service Tools and Service Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .187

ELECTRICAL & ELECTRONIC APPLICATION AND INSTALLATION GUIDE

Caterpillar Pub # LEBT2835-02________C7 & C9 ACERT Truck Engines________EPA 2004_____ 3

INTR ODUCTION AND PURPOSE

This document is intended to provide necessary information for correct electrical & electronic application and

installation of a C7 or C9 truck engine into an on-highway truck, bus, motor coach or vocational chassis.

Caterpillar expects there will be some additions and modifications to this document as the engine program

development continues, and as OEM requests for information not currently addressed are added.The information

contained in this version of the document reflects the Caterpillar design for production C7 and C9 engines built

with March 2004 software.

General Electronic Engine Operation

1.0 Engine Functions

1.1 Electronic Governing

Two engine speed range electronic governors are available for use.These electronic governors are selectable

through a programmable parameter.

1.2 Fuel/Air Ratio Control

The control system has full authority over engine fuel delivery.The mechanical fuel/air ratio control is eliminated.

Electronic control of the fuel/air ratio provides optimum performance with reduced emissions.

1.3 Injection Timing Control

Injection timing is varied as a function of engine operating conditions to optimize engine performance for emissions,

noise, fuel consumption, and drivability.

1.4 Torque Rise Shaping

Electronic controls provide increased flexibility to tailor the torque curve over a wide speed range.

1.5 Cold Mode Operation

When the engine is started with cold coolant, the engine will operate in “Cold Mode”. The engine will operate with

reduced performance until the coolant temperature has warmed. The Caterpillar electronic service tool software will

indicate when the engine is operating in Cold Mode. The C7 engine will operate in Cold Mode below 64 Deg C and

the C9 engine will operate in Cold Mode below 40 Deg C.

ELECTRICAL & ELECTRONIC APPLICATION AND INSTALLATION GUIDE

4 Caterpillar Pub # LEBT2835-02________C7 & C9 ACERT Truck Engines________EPA 2004_____

The information herein is the property of Caterpillar Inc. and/or its subsidiaries. Without

written permission, any copying, transmittal to others, and any use except that for

which it is loaned is prohibited.

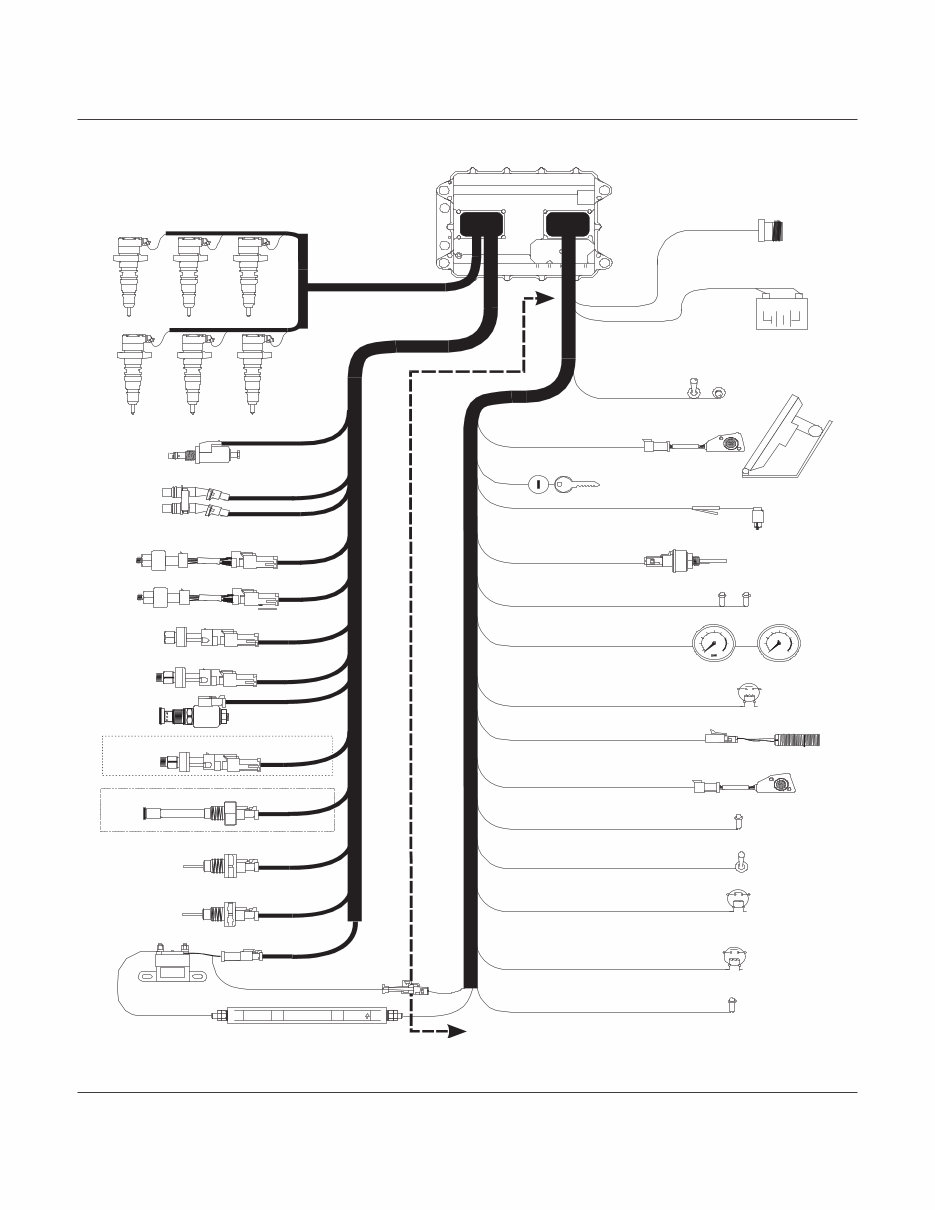

2.0 Engine Component Overview

2.1 Engine Control Module (ECM)

The ECM is located on the left rear side of the engine. The ECM has two connectors, one for the Caterpillar Engine

Harness, the other for the Vehicle OEM Harness.

2.2 Boost Pressure Sensor

The Boost Pressure Sensor is an absolute pressure sensor measuring inlet manifold pressure. Boost pressure

displayed by service tools and communicated over the data link is referenced to the Atmospheric Pressure Sensor

reading. The Boost Pressure Sensor measures gauge pressure from 0 psi (0 kPa) to 49 psi (340 kPa). The ECM

supplies the sensor with a regulated 5 Volts DC.

2.3 Atmospheric Pressure Sensor

The Atmospheric Pressure Sensor is an absolute pressure sensor. The Atmospheric Pressure Sensor measures

pressure to 16.8 psiA (116 kPaA).The ECM supplies the sensor with a regulated 5 Volts DC.

2.4 Oil Pressure Sensor

An optional Oil Pressure Sensor is available for use in applications where an actual oil pressure indication is

desired.Typical applications include vehicles with a vehicle data link capable Instrument Cluster that can display

engine information. C7 or C9 engines do not require Engine Lube Oil Pressure monitoring because the HEUI

(Hydraulically actuated Electronically controlled Unit Injector) fuel system requires oil pressure for the engine

to operate. Without sufficient oil pressure, the fuel system cannot supply fuel to the engine.

The Oil Pressure Sensor measures gauge pressure from 0 psi (0 kPa) to 165 psi (1135 kPa). Oil Pressure as

displayed by service tools and communicated over the data link is referenced to the Atmospheric Pressure Sensor

reading. The ECM supplies this sensor with the necessary voltage.

2.5 Coolant Temperature Sensor

The thermistor based Coolant Temperature Sensor is used to monitor engine coolant temperature. Output from

this sensor is used for several engine functions including Inlet Air Heater Operation, Cold Mode Operation,

Cold Elevated Idle and the Engine Monitoring System.

2.6 Inlet Manifold Air Temperature Sensor

The Inlet Manifold Air Temperature Sensor is used to measure the inlet air temperature and is thermistor based like

the Coolant Temperature Sensor.This sensor output is used in controlling the Inlet Air Heater, Cold Elevated Idle,

Cooling Fan Output, and for Engine Monitoring.

2.7 Engine Speed/Timing Sensors

The engine speed/timing sensors are used to determine both engine speed and fuel injection timing. The sensors

detect this information from a wheel on the camshaft.

2.8 Coolant Level Sensor

The coolant level sensor is an option device used to monitor the engine’s coolant level.This sensor is usually

mounted in the cooling system’s surge tank. There are three types of sensors that may be used.

2.9 Injection Actuation Pressure (IAP) Sensor

The Injection Actuation Pressure Sensor measures the pressure in the high-pressure oil manifold. This oil is used

to feed the hydraulically actuated electronically controlled unit injectors. The ECM supplies the sensor with the

necessary voltage.

2.10 Injection Actuation Pressure Control Valve (IAPCV)

This valve controls the output injection actuation pressure of the high-pressure oil pump. The ECM uses the output

of the Injection Actuation Pressure Sensor to determine the required output to this valve.

ELECTRICAL & ELECTRONIC APPLICATION AND INSTALLATION GUIDE

Caterpillar Pub # LEBT2835-02________C7 & C9 ACERT Truck Engines________EPA 2004_____ 5

ELECTRICAL & ELECTRONIC APPLICATION AND INSTALLATION GUIDE

6 Caterpillar Pub # LEBT2835-02________C7 & C9 ACERT Truck Engines________EPA 2004_____

2.11 Inlet Air Heater and Relay

The Inlet Air Heater is an engine mounted, Caterpillar supplied and installed heater grid used for warming the inlet

air to aid in starting during cold ambient temperatures. Operation is based on elevation (above sea level) and the

sum of the Coolant and Inlet Manifold Air temperatures. The ECM controls the normally open relay to provide

battery power to the grid.

2.12 Fuel Pressure Sensor

A Fuel Pressure sensor is included in the engine pressure sensor package. This sensor monitors the fuel supply

pressure to the engine.

2.13 Oil Level Switch (GMT560 Trucks Only)

An Oil Level Switch is available only on General Motors engines.This switch is mounted in the oil pan and wired

to the Engine Connector (J2) of the ECM.This switch monitors the oil level in the oil pan and is checked at initial

engine power up. Proper Oil level in the engine will keep a normally open switch closed. Oil level that is too low

will allow the switch to open. If the ECM senses an open switch upon three sequential engine starts, low oil level

is indicated.

Figure 1

33

3

P2 J2

Sensor Common

Oil Level

ECM

Oil Level Switch

(Shown With Oil Level Normal)

B428-OR

G829-GN

ELECTRICAL & ELECTRONIC APPLICATION AND INSTALLATION GUIDE

Caterpillar Pub # LEBT2835-02________C7 & C9 ACERT Truck Engines________EPA 2004_____ 7

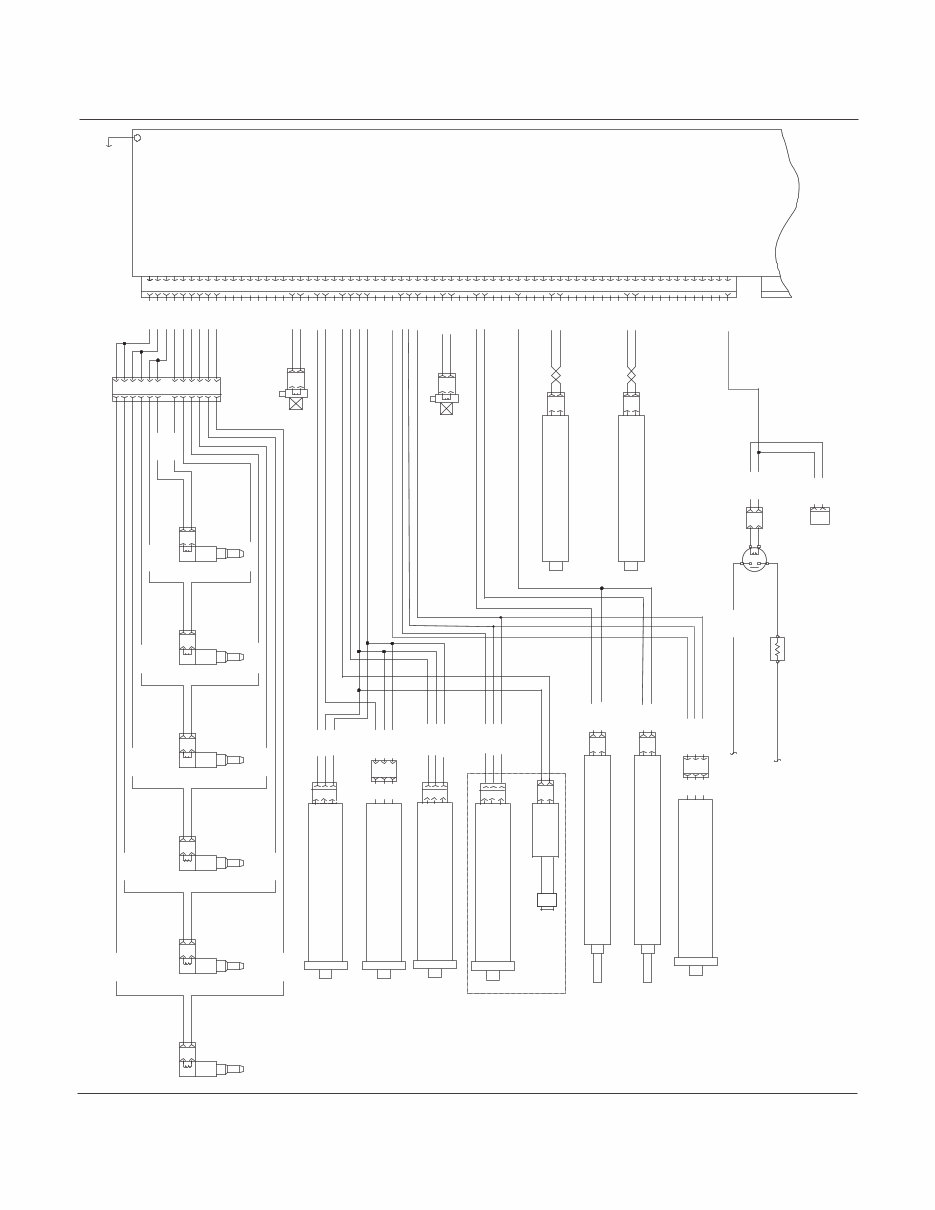

Figure 2

Boost Pressure Sensor

Top Camshaft Position Sensor

Bottom Camshaft Position Sensor

12V

ñ

+

BATTERIES

6 HEUI Injectors

Injection Actuation Pressure Control Valve

Injection Actuation Pressure Sensor

Atmospheric Pressure Sensor

Coolant Level Sensor

Coolant Temperature Sensor

Intake Manifold Air Temperature Sensor

109-3000

12 V

AIR FLOW

Intake Air Heater

Intake Air Heater Relay

Intake Air Heater Lamp

Vehicle Speed Sensor

Cooling Fan

SAE J1939/13 OFF-BOARD

DIAGNOTSIC CONNECTOR

Ignition Key Switch

2 +Battery & 9 Ground Switch Inputs

3, 1.5A Outputs

3, 1.0A Outputs

2, 0.3A Lamp Outputs

Clutch and Service Brake Switches

Check Engine & Warning Lamps

MPH

15

5

0

25

45

35 55

65

75

85 RPM X 100

5

10

15

20

25

30

Speedometer & Tachometer

Throttle Position Sensor

PTO Throttle Position Sensor

OEM Installed

Caterpillar Installed

Cruise Control On/Off

& Set/Resume Switches

ADEM 2000

Engine

Control

Module

Engine Oil Pressure Sensor (Optional)

Oil Level Switch (GMT560 Trucks Only)

Turbo Wastegate

Control Valve

(Not All Ratings)

Fuel Pressure Sensor

ELECTRICAL & ELECTRONIC APPLICATION AND INSTALLATION GUIDE

8 Caterpillar Pub # LEBT2835-02________C7 & C9 ACERT Truck Engines________EPA 2004_____

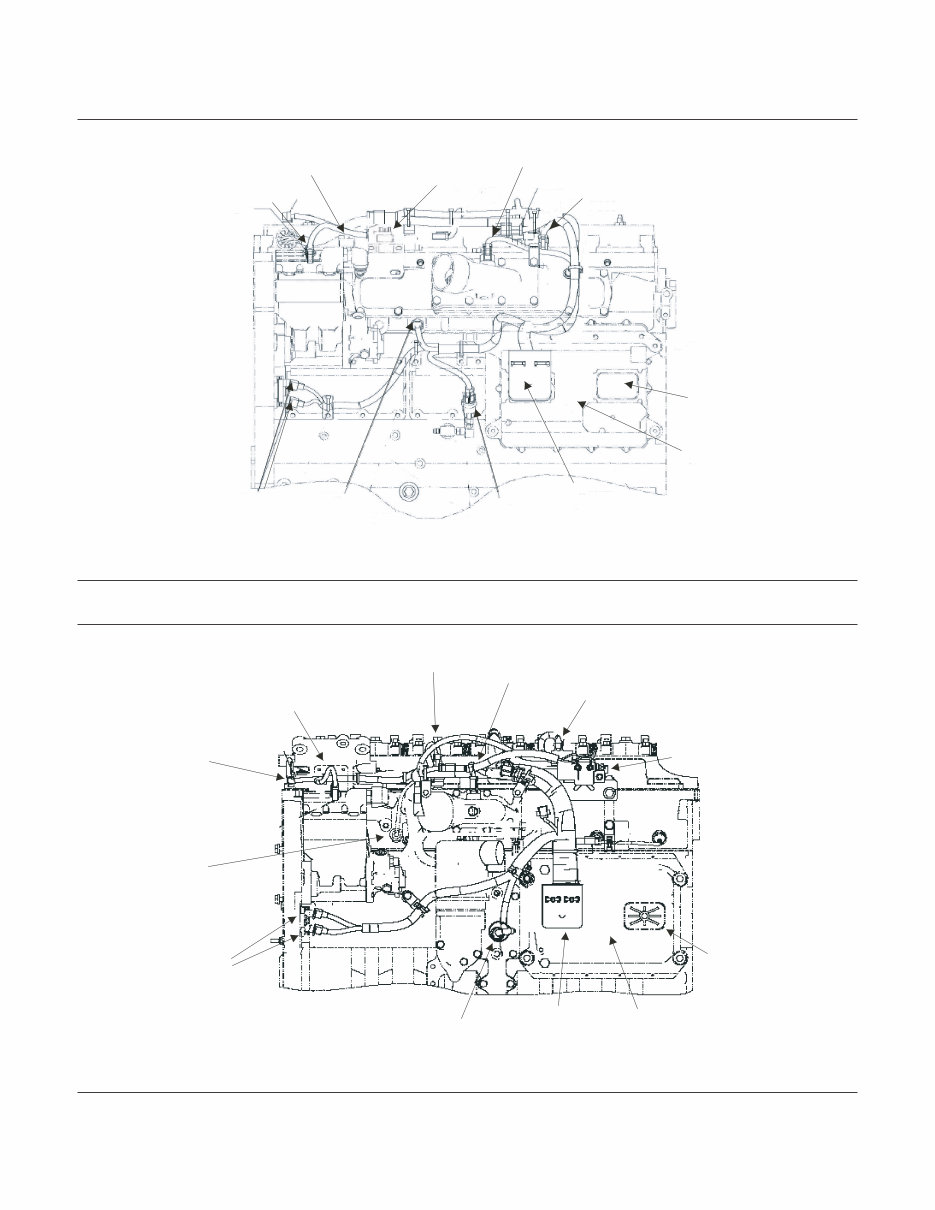

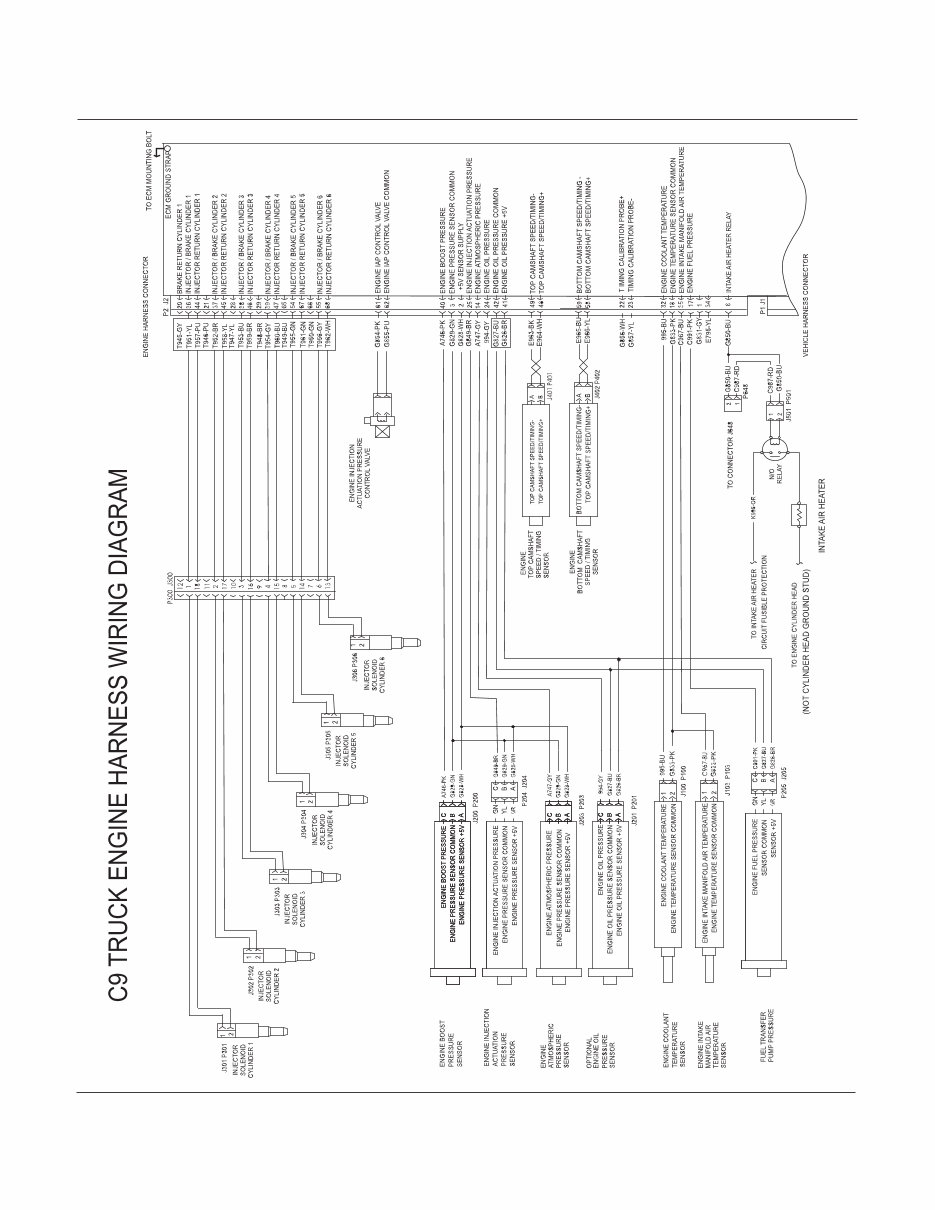

Engine

Oil

Pressure

Sensor

(Optional)

Coolant

Temperature

Sensor

Engine

Speed/Timing

Sensors

Injection Actuation

Control Valve

Injection Pressure

Sensor

Boost Pressure

Sensor

Inlet Air

Temperature

Sensor

Inlet Air

Heater

Relay

OEM

Connector

J1/P1

ECM

Engine

Connector

J2/P2

ECM

Inlet Air

Heater Relay

Atmospheric Pressure Sensor

Inlet Air

Temperature

Sensor

Boost Pressure

Sensor

Injection Actuation

Pressure

Control Valve

Coolant

Temperature

Sensor

Injection

Actuation

Pressure

Sensor

Speed/Timing

Sensors

Oil

Pressure

Sensor

(Optional)

OEM Harness

Connector

J1/P1

Engine

Harness

Connector

J2/P2

Figure 3 - C7 Sensor Locations

Figure 4 - C9 Sensor Locations

ELECTRICAL & ELECTRONIC APPLICATION AND INSTALLATION GUIDE

Caterpillar Pub # LEBT2835-02________C7 & C9 ACERT Truck Engines________EPA 2004_____ 9

Figure 5 - C7 Engine Wiring Diagram

1

2

INJECTION ACTUATION

PRESSURE CONTROL VALVE

J500 P500

E963-BK

E964-WH

E965-BU

E966-YL

49

48

13

19

20

21

28

29

30

59

58

31

43

51

22

23

56

57

65

60

69

8

A

B

TOP CAMSHAFT

POSITION SENSOR

TOP CAMSHAFT POSITION -

TOP CAMSHAFT POSITION +

J401 P401

J402 P402

B

A

BOTTOM CAMSHAFT POSITION -

BOTTOM CAMSHAFT POSITION +

BOTTOM CAMSHAFT

POSITION SENSOR

995-BU

C967-BU

G833-PK

C

B

A

G849-BR

G829-GN

G828-WH

A746-PK

G849-BR

A747-GY

G829-GN

G828-WH

P204 J204

ENGINE ATMOSPHERIC PRESSURE

ENGINE PRESSURE SENSOR COMMON

ENGINE PRESSURE SENSOR +5V

ENGINE ATMOSPHERIC

PRESSURE

NOTE A

ENGINE INJECTION

ACTUATION

PRESSURE

ENGINE INJECTION ACTUATION PRESSURE

ENGINE PRESSURE SENSOR COMMON

ENGINE PRESSURE SENSOR +5V

P203

A747-GY

G829-GN

G828-WH

A

B

C

P200

A746-PK

G829-GN

G828-WH

SENSOR

ENGINE BOOST

PRESSURE

ENGINE BOOST PRESSURE

ENGINE PRESSURE SENSOR COMMON

ENGINE PRESSURE SENSOR +5V

GN

YL

0R

INTAKE AIR HEATER RELAY

ENGINE COOLANT TEMPERATURE

ENGINE INTAKE MANIFOLD AIR TEMP.

ENGINE TEMPERATURE SENSOR COMMON

ENGINE ATMOSPHERIC PRESSURE

ENGINE PRESSURE SENSOR COMMON

ENGINE PRESSURE SENSOR +5V

IAP CONTROL VALVE

IAP CONTROL VALVE COMMON

ENGINE BOOST PRESSURE

ENGINE INJECTION ACTUATION PRESSURE

P1 J1

ECM GROUND STRAP

G854-PK

G855-PU

TO ECM

MOUNTING

BOLT

ENGINE HARNESS CONNECTOR

VEHICLE HARNESS CONNECTOR

C987-RD

G850-BU

P648

TO CONNECTOR J648

(OEM HARNESS)

A

B

K995-OR

G850-BU

C987-RD

1

2

ENGINE TIMING CALIBRATION PROBE+

ENGINE TIMING CALIBRATION PROBE-

TO INTAKE AIR HEATER

CIRCUIT PROTECTION

(BATTERY +)

TO ENGINE CYLINDER HEAD

INTAKE AIR

HEATER

G850-BU

P2 J2

J501 P501

N/O

RELAY

32

35

7

34

26

18

10

11

12

15

16

17

24

27

41

42

50

52

53

66

9

40

25

6

33

14

3

2

B

A

INJECTOR

CYLINDER

NO.5

1

63

64

4

5

61

62

70

INJECTOR

CYLINDER

NO.6

B

A

J306 P306 J305 P305

J304 P304 J303 P303

J302 P302

L984-OR

B

A

INJECTOR

CYLINDER

NO.4

J301 P301

INJECTOR

CYLINDER

NO.1

A704-GN

B

A

A705-BU

A703-BR

A702-PU

A701-GY

L985-YL

L984-OR

A706-GY

L985-YL

L983-WH

L983-WH

INJECTOR

CYLINDER

NO.3

B

A

B

A

INJECTOR

CYLINDER

NO.2

P300 J300

L983-WH

L984-OR

L985-YL

A706-GY

A705-BU

A704-GN

A703-BR

A702-PU

A701-GY

INJECTOR COMMON CYLINDERS 1 & 2

INJECTOR COMMON CYLINDERS 3 & 4

INJECTOR COMMON CYLINDERS 5 & 6

INJECTOR CYLINDER 6

INJECTOR CYLINDER 5

INJECTOR CYLINDER 4

INJECTOR CYLINDER 3

INJECTOR CYLINDER 2

INJECTOR CYLINDER 1

44

45

46

55

54

39

38

37

36

47

67

68

12

11

10

9

8

7

6

5

4

3

2

1

SENSOR

1

2

ENGINE COOLANT

TEMPERATURE

995-BU

G833-PK

J100 P100

ENGINE COOLANT TEMPERATURE

ENGINE TEMPERATURE SENSOR COMMON

ENGINE INTAKE MANIFOLD AIR TEMPERATURE

ENGINE TEMPERATURE SENSOR COMMON

J103 P103

C967-BU

G833-PK

ENGINE INTAKE

MANIFOLD AIR

TEMPERATURE

1

2

SENSOR

SENSOR

SENSOR

NOTE A: INDICATES AN OPTIONAL COMPONENT NOT INSTALLED ON ALL ENGINES

ENGINE OIL PRESSURE

ENGINE OIL PRESSURE SENSOR COMMON

ENGINE OIL PRESSURE SENSOR +5V

P201

994-GY

G827-BU

G826-BR

994-GY

G827-BU

G826-BR

ENGINE OIL

PRESSURE

NOTE A

SENSOR

ENGINE OIL PRESSURE

ENGINE OIL PRESSURE SENSOR COMMON

ENGINE OIL PRESSURE SENSOR +5V

TOP CAMSHAFT POSITION -

TOP CAMSHAFT POSITION +

BOTTOM CAMSHAFT POSITION -

BOTTOM CAMSHAFT POSITION +

A

B

C

A

B

C

ENGINE OIL

LEVEL

SWITCH

(GMT560 Only)

G458-GY

OIL LEVEL SWITCH

1

2

M 795-WH

C211-BK

TURBO WASTEGATE SOL NEGATIVE

TURBO WASTEGATE SOL POSITIVE

TURBO WASTEGATE SOLENOID

*** Not On All Ratings ***

OIL Level -

OIL Level -

A

B

C

B

A

C991-PK

G827-BU

G826-BR

P205 J205

ENGINE FUEL PRESSURE

SENSOR COMMON

SENSOR +5V

GN

YL

0R

C991-PK

FUEL PRESSURE

FUEL TRANSFER

PUMP PRESSURE

ELECTRICAL & ELECTRONIC APPLICATION AND INSTALLATION GUIDE

10 Caterpillar Pub # LEBT2835-02________C7 & C9 ACERT Truck Engines________EPA 2004_____

A

B

J500 P500

Figure 6 - C9 Engine Wiring Diagram

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$55.99

Viewed 58 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$55.99

Caterpillar C7 & C9 Truck Engines | Electrical and Electronic Application and Installation Guide

Serial Number Prefixes:

- FMM

- FML

- KAL

- YPG

- 9DG

- CKP

This manual provides essential information for the correct electrical and electronic application and installation of a C7 or C9 truck engine into on-highway trucks, buses, motor coaches, or vocational chassis.

The content reflects the Caterpillar design for production C7 and C9 engines built with March 2004 software.

Table of Contents:

- Introduction and Purpose

- Engine Functions

- Engine Component Overview

- Engine Monitoring

- Power and Grounding Requirements and Considerations

- Connectors and Wiring Harness Requirements

- Accelerator Pedal Position Sensors

- Vehicle Speed Input Circuit

- ECM Speedometer and Tachometer Outputs

- Lamp Outputs

- OEM Installed Sensors

- Inlet Air Heater, Lamp and Relay Operation

- Hard-wired Switch Inputs

- Cruise Control

- Idle Functions

- J1939 Based Switch Messages

- Dedicated PTO Operation

- Programmable Outputs

- Transmissions

- Governor Type

- Cooling Fan

- Idle Shutdown Timer

- Data Links

- Customer Specified Parameters

- Diagnostics, Service Tools and Service Information