Sony RCD-W500C COMPACT DISC RECORDER Service Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

RCD-W500C

US Model

Canadian Model

SERVICE MANUAL

COMPACT DISC RECORDER

Sony Corporation

Audio Group

Published by Sony Engineering Corporation

9-877-447-03

2004H16-1

© 2004.08

SPECIFICATIONS

Ver 1.2 2004. 08

Model Name Using Similar Mechanism NEW

CD Section

CD Mechanism Type CDM53L-30B61M

Base Unit Type BU-30BBD61M

Optical Pick-up Type A-MAX.4T

Model Name Using Similar Mechanism RCD-W100

CD-R/CD-RW

CD Mechanism Type CDM65-RBD2

Section

Base Unit Type RBD2

Optical Pick-up Type KRM-220CAA

DECK A (the CD player section)

System Compact disc digital audio

system

Laser Semiconductor laser

( = 780 nm)

Emission duration:

continuous

Playable discs CD, CD-R, CD-RW

Frequency response 20 Hz – 20,000 Hz

(±0.5 dB)

Signal to Noise Ratio Over 98 dB during play

Wow and flutter Below measurable limit

DECK B (the CD-R and CD-RW

recording section)

System Compact disc digital audio

system

Laser Semiconductor laser

( = 780 nm)

Emission duration:

continuous

Playable discs CD, CD-R, CD-RW

Recordable discs CD-R, CD-RW (for

Audio)

Frequency response 20 Hz - 20,000 Hz

(±0.5 dB)

Signal to Noise Ratio Over 98 dB during play

Wow and flutter Below measurable limit

Inputs

ANALOG IN Impedance: 47 kilohms

(Phono jacks) Rated input: 500 mVrms

Minimum input:

250 mVrms

DIGITAL OPTICAL IN

(Square optical connector jack)

Optical wavelength:

660 nm

Outputs

ANALOG OUT Rated output: 2 Vrms

(Phono jacks) Load impedance: over

10 kilohms

DIGITAL OPTICAL OUT

(Square optical connector jack)

Wavelength: 660 nm

Rated output: –18 dBm

PHONES Load impedance: 32 ohms

(Stereo phone jack) Rated output: 12mW

General

Power requirements 120 V AC, 60 Hz

Power consumption 25 W

Dimensions (approx.) (w/h/d) incl. projecting parts

and control 430 × 108 × 399 mm

( 17 × 4

3

/8 × 15

3

/4 inch)

Mass (approx.) 6.8 kg (15 lbs)

Supplied accessories

Design and specifications are subject to change

without notice.

• Audio connecting cords

Phono plug × 2 (red/white) y Phono plug ×

2 (red/white) (2)

• Remote commander (remote) (1)

• R6 (size AA) batteries (2)

λ

λ

2

Laser component in this product is capable

of emitting radiation exceeding the limit for

Class 1.

CAUTION

Use of controls or adjustments or performance of procedures

other than those specified herein may result in hazardous radiation

exposure.

Notes on chip component replacement

• Never reuse a disconnected chip component.

• Notice that the minus side of a tantalum capacitor may be

damaged by heat.

Flexible Circuit Board Repairing

• Keep the temperature of soldering iron around 270˚C

during repairing.

• Do not touch the soldering iron on the same conductor of the

circuit board (within 3 times).

• Be careful not to apply force on the conductor when soldering

or unsoldering.

RCD-W500C

SAFETY-RELATED COMPONENT WARNING!!

COMPONENTS IDENTIFIED BY MARK 0 OR DOTTED LINE WITH

MARK 0 ON THE SCHEMATIC DIAGRAMS AND IN THE PARTS

LIST ARE CRITICAL TO SAFE OPERATION. REPLACE THESE

COMPONENTS WITH SONY PARTS WHOSE PART NUMBERS

APPEAR AS SHOWN IN THIS MANUAL OR IN SUPPLEMENTS

PUBLISHED BY SONY.

ATTENTION AU COMPOSANT AYANT RAPPORT

À LA SÉCURITÉ!

LES COMPOSANTS IDENTIFÉS PAR UNE MARQUE 0 SUR LES

DIAGRAMMES SCHÉMATIQUES ET LA LISTE DES PIÈCES SONT

CRITIQUES POUR LA SÉCURITÉ DE FONCTIONNEMENT. NE

REMPLACER CES COMPOSANTS QUE PAR DES PIÈSES SONY

DONT LES NUMÉROS SONT DONNÉS DANS CE MANUEL OU

DANS LES SUPPÉMENTS PUBLIÉS PAR SONY.

After correcting the original service problem, perform the

following safety checks before releasing the set to the customer:

Check the antenna terminals, metal trim, “metallized” knobs, screws,

and all other exposed metal parts for AC leakage. Check leakage as

described below.

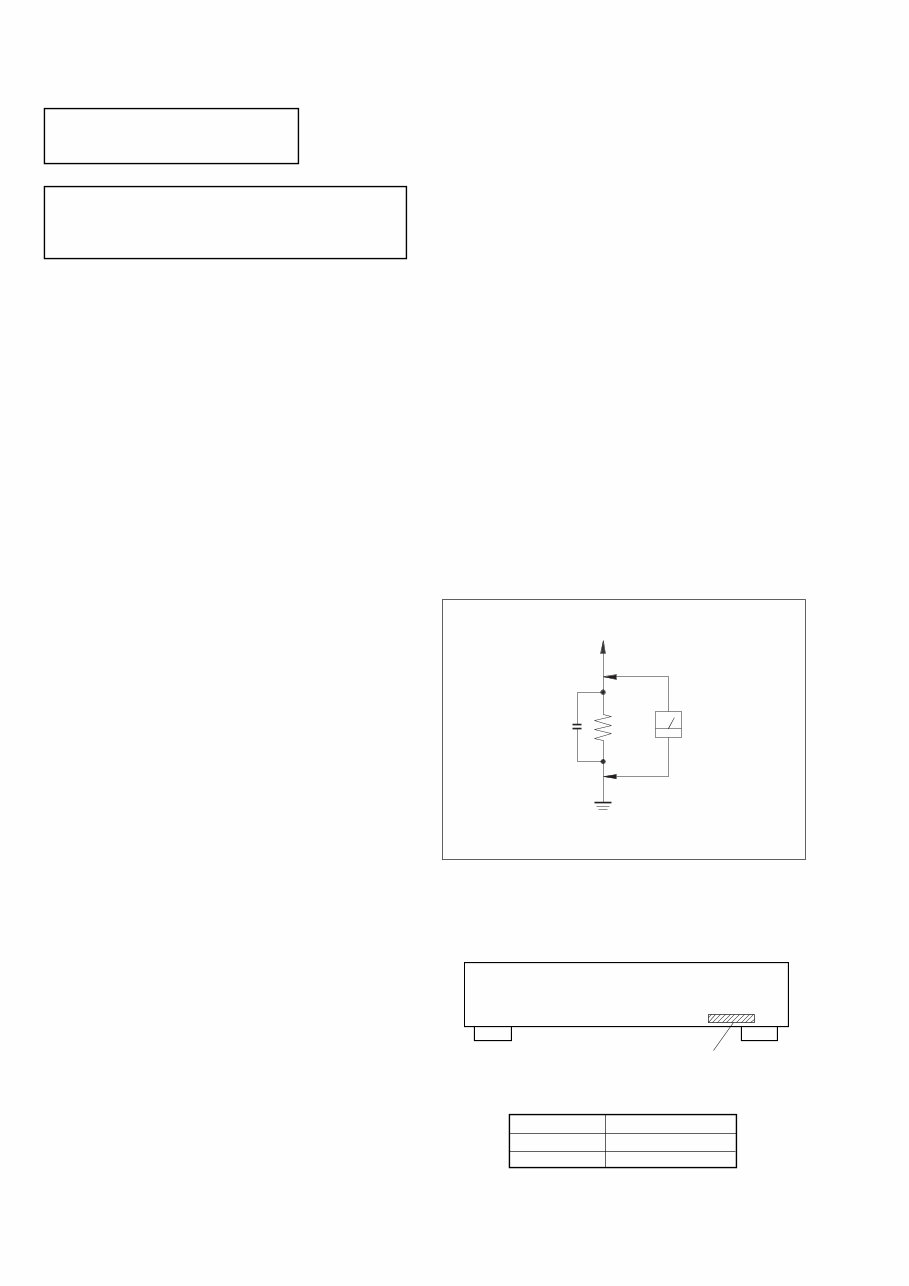

LEAKAGE

The AC leakage from any exposed metal part to earth ground and

from all exposed metal parts to any exposed metal part having a

return to chassis, must not exceed 0.5 mA (500 microamperes).

Leakage current can be measured by any one of three methods.

1. A commercial leakage tester, such as the Simpson 229 or RCA

WT-540A. Follow the manufacturers’ instructions to use these

instruments.

2. A battery-operated AC milliammeter. The Data Precision 245

digital multimeter is suitable for this job.

3. Measuring the voltage drop across a resistor by means of a

VOM or battery-operated AC voltmeter. The “limit” indication

is 0.75 V, so analog meters must have an accurate low-voltage

scale. The Simpson 250 and Sanwa SH-63Trd are examples of

a passive VOM that is suitable. Nearly all battery operated

digital multimeters that have a 2V AC range are suitable. (See

Fig. A)

SAFETY CHECK-OUT

To Exposed Metal

Parts on Set

0.15 µF 1.5 kΩ

AC

Voltmeter

(0.75 V)

Earth Ground

Fig. A. Using an AC voltmeter to check AC leakage.

MODEL IDENTIFICATION

— BACK PANEL —

Parts No.

PARTS No. MODEL

4-246-074-0s

4-246-074-1s

US

Canadian

3

RCD-W500C

TABLE OF CONTENTS

1. SERVICING NOTE ····················································· 4

2. GENERAL ··································································· 5

3. DISASSEMBLY ·························································· 6

3-1. Case (409538) ······························································· 7

3-2. Loading Panel (CDR) ··················································· 7

3-3. Front Panel Section ······················································· 8

3-4. SW Board, LED Board, DISP Board ···························· 8

3-5. CD Mechanism Deck (CDM65-RBD2) ······················· 9

3-6. Tray ··············································································· 9

3-7. CDR Board ································································· 10

3-8. Motor Assy (Loading) (M201) ··································· 10

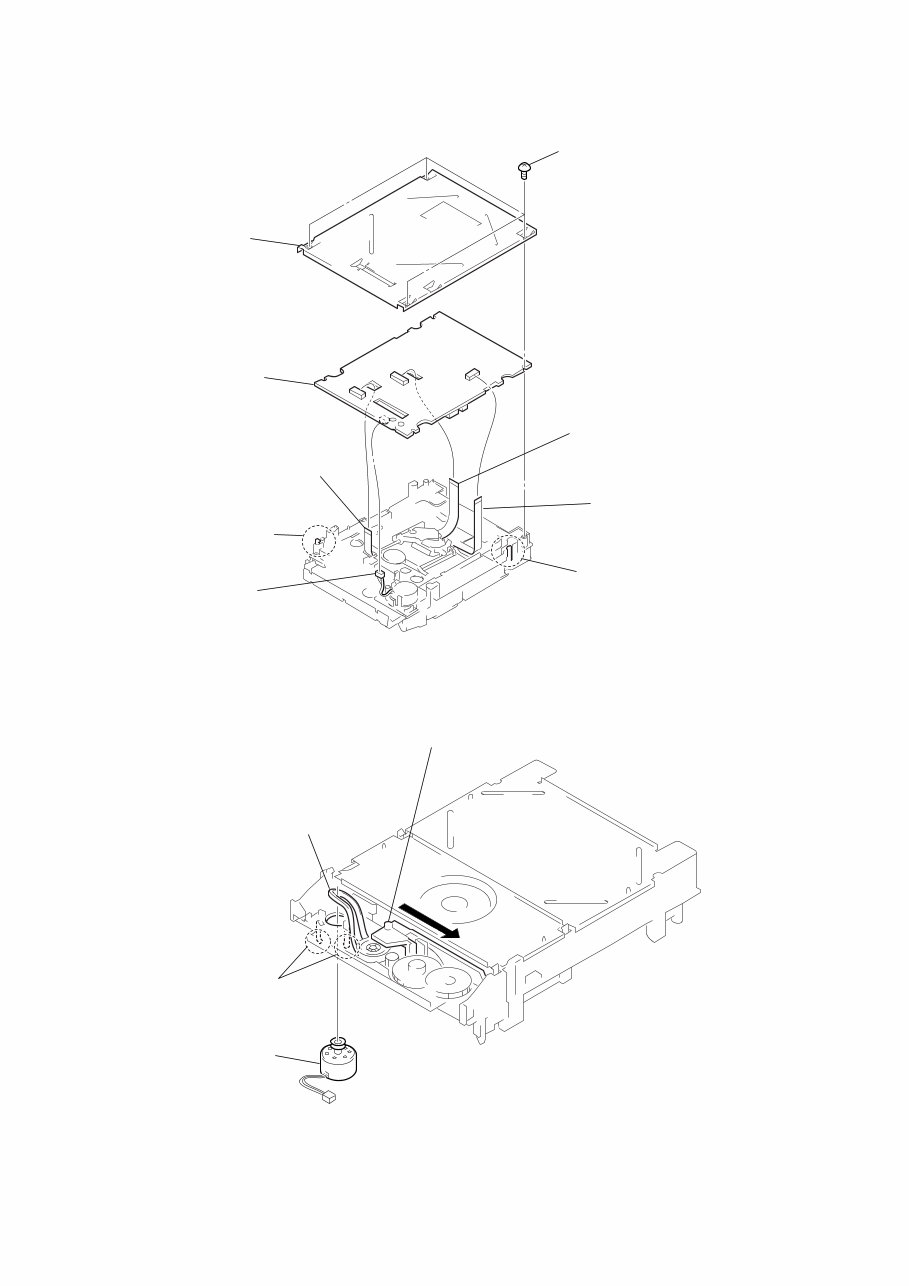

3-9. Holder (MG) Sub Assy, Dust Cover ··························· 11

3-10. Optical Pick-Up (KRM-220CAA) ······························ 11

3-11. Cam (CH) ···································································· 12

3-12. MAIN Board ······························································· 12

3-13. CD Mechanism Deck (CDM53L-30B61M) ··············· 13

3-14. Fitting Base (Magnet) Assy ········································ 13

3-15. CLAMP MOTOR Board,

Motor (Clamp) Assy (M701) ······································ 14

3-16. Fitting Base (Guide) Assy, Bracket (Chassis)············· 14

3-17. Tray (Sub) ··································································· 15

3-18. Chassis (Mold B) ························································ 15

3-19. LOAD MOTOR Board,

Motor (Loading) Assy (M702) ··································· 16

3-20. Stocker Section ··························································· 16

3-21. Slider (Selection), Tension Spring (Shutter),

Slider (Shutter) ···························································· 17

3-22. Gear (Gear A), Gear (Gear B), Gear (U/D Slider) ······ 17

Precaution During Gear (Gear U/D Slider),

Gear (Gear B), Gear (Gear A) Installation ·················· 18

3-23. Gear (Chucking) ························································· 18

3-24. BD Board ···································································· 19

3-25. Optical Block Section ················································· 19

4. TEST MODE ···································································· 20

5. ELECTRICAL ADJUSTMENTS

CD SECTION ····························································· 23

CD-R/RW SECTION·················································· 25

6. DIAGRAMS ······································································ 55

6-1. Block Diagrams – CD-R Section – ··························· 56

– CD Section – ······························· 57

– POWER/DISPLAY Section –······ 58

6-2. Printed Wiring Boards – BD Section – ······················· 59

6-3. Schematic Diagrams – BD Section – ·························· 60

6-4. Printed Wiring Boards

– SENSER/MOTOR/SW Section – ····· 61

6-5. Schematic Diagrams

– SENSER/MOTOR/SW Section – ····· 62

6-6. Printed Wiring Boards – CD-R Section (Side A) – ···· 63

6-7. Printed Wiring Boards – CD-R Section (Side B) – ···· 64

6-8. Schematic Diagrams – CD-R Section (1/4) – ············· 65

6-9. Schematic Diagrams – CD-R Section (2/4) – ············· 66

6-10. Schematic Diagrams – CD-R Section (3/4) – ············· 67

6-11. Schematic Diagrams – CD-R Section (4/4) – ············· 68

6-12. Printed Wiring Boards – MAIN Section (Side A) – ··· 69

6-13. Printed Wiring Boards – MAIN Section (Side B) – ··· 70

6-14. Schematic Diagrams – MAIN Section (1/2) – ············ 71

6-15. Schematic Diagrams – MAIN Section (2/2) – ············ 72

6-16. Printed Wiring Boards – LED Section – ····················· 73

6-17. Schematic Diagrams – LED Section – ······················· 74

6-18. Printed Wiring Boards – DISPLAY Section – ············ 75

6-19. Schematic Diagrams – DISPLAY Section –··············· 76

6-20. IC Block Diagrams ····················································· 77

6-21. IC Pin Function Description ······································· 84

7. EXPLODED VIEWS

7-1. Case Section ·································································· 94

7-2. Front Panel Section ······················································· 95

7-3. Chassis Section ····························································· 96

7-4. Overall Section (CDM53L-30B61M) ··························· 97

7-5. Chassis (Mold) Assy Section (CDM53L-30B61M) ·········· 98

7-6. Chassis Section (CDM53L-30B61M) ·························· 99

7-7. Base Unit Section (BU-30BBD61M) ························· 100

7-8. CDM65-RBD2 ···························································· 101

8. ELECTRICAL PARTS LIST ····································· 102

Unleaded solder

Boards requiring use of unleaded solder are printed with the lead-

free mark (LF) indicating the solder contains no lead.

(Caution: Some printed circuit boards may not come printed with

the lead free mark due to their particular size.)

: LEAD FREE MARK

Unleaded solder has the following characteristics.

• Unleaded solder melts at a temperature about 40°C higher than

ordinary solder.

Ordinary soldering irons can be used but the iron tip has to be

applied to the solder joint for a slightly longer time.

Soldering irons using a temperature regulator should be set to

about 350°C.

Caution: The printed pattern (copper foil) may peel away if the

heated tip is applied for too long, so be careful!

• Strong viscosity

Unleaded solder is more viscous (sticky, less prone to flow) than

ordinary solder so use caution not to let solder bridges occur such

as on IC pins, etc.

• Usable with ordinary solder

It is best to use only unleaded solder but unleaded solder may

also be added to ordinary solder.

4

RCD-W500C

SECTION 1

SERVICING NOTE

NOTES ON HANDLING THE OPTICAL PICK-UP BLOCK

OR BASE UNIT

The laser diode in the optical pick-up block may suffer electrostatic

break-down because of the potential difference generated by the

charged electrostatic load, etc. on clothing and the human body.

During repair, pay attention to electrostatic break-down and also

use the procedure in the printed matter which is included in the

repain parts.

The flexible board is easily damaged and should be handled with

care.

NOTES ON LASER DIODE EMISSION CHECK

The laser beam on this model is concentrated so as to be focused on

the disc reflective surface by the objective lens in the optical pick-

up block. Therefore, when checking the laser diode emission,

observe from more than 30 cm away from the objective lens.

The emission check enables continuous checking of the S curve.

LASER DIODE AND FOCUS SEARCH OPERATION

CHECK

Carry out the “S curve check” in “CD section adjustment” and check

that the S curve waveform is output three times.

Message

C12/

Cannot Copy

C13/

Rec Error

C14/

TOC Error

C41/

Cannot Copy

C71/

Din Unlock

Explanation

You are trying to record a disc that

cannot be played back in DECK-A

or with an external device, such as

CD-ROM or VIDEO CD.

• Remove the disc, and then insert a

music CD for playback.

Recording has not been completed

successfully because of vibration.

• Relocate the unit in a place free of

vibration and restart the recording

again.

The disc you try to record is

excessively dirty (such as oil-

stained or finger marked) or

scratched. Or the disc is not

normal.

• Replace the disc with another one

and restart the recording again.

The unit did not read the TOC

information.

• Insert other discs.

The sound source you are trying to

record is a copy of a commercial

music software. Or you are trying

to record on a CD-R/CD-RW

digitally.

• Because of the restriction of the

Serial Copy Management System,

you cannot record a copy of a

commercial music software.

Neither can you record a CD-R/

CD-RW digitally.

If this message is displayed

momentarily, this is not an error. It

is caused by the digital signal

during recording.

During recording of a digital sound

source, the connecting cable has

been disconnected or the player of

the sound source has turned off.

• Connect the cable or turn on the

digital player.

Self-diagnosis Function

When the self-diagnosis function is activated to

prevent the player from malfunctioning, three

character service numbers in a combination

with a message appears in the display. In this

case, check the following table.

5

RCD-W500C

SECTION 2

GENERAL

3 6

4

1

1 POWER button

2 H button

3 DISC 1 to DISC 5 A button and indicators

4 CD SYNCHRO NORMAL button

5 CD SYNCHRO HIGH button

6 OPEN/CLOSE button

7 H button

8 INPUT button

9 FINALIZE button

q; ERASE button

qa SBM button and indicator

qs REC z button

qd X button

qf REC LEVEL knob

qg x button

qh PLAY MODE button

qj TIME button

qk DISPLAY button

ql YES button

w; l AMS L knob

wa CLEAR button

ws MENU/NO button

wd l AMS L knob

wf ALBUM button

wg PLAY MODE button

wh TIME button

wj x button

wk PHONES jack

wl X button

e; PHONE LEVEL knob

2

5

9 7 8 q;

qa

qs

qd

qf qg qh qj qk ql w; wd wa wf wj wk

e;

wl

wg wh ws

6

RCD-W500C

SECTION 3

DISASSEMBLY

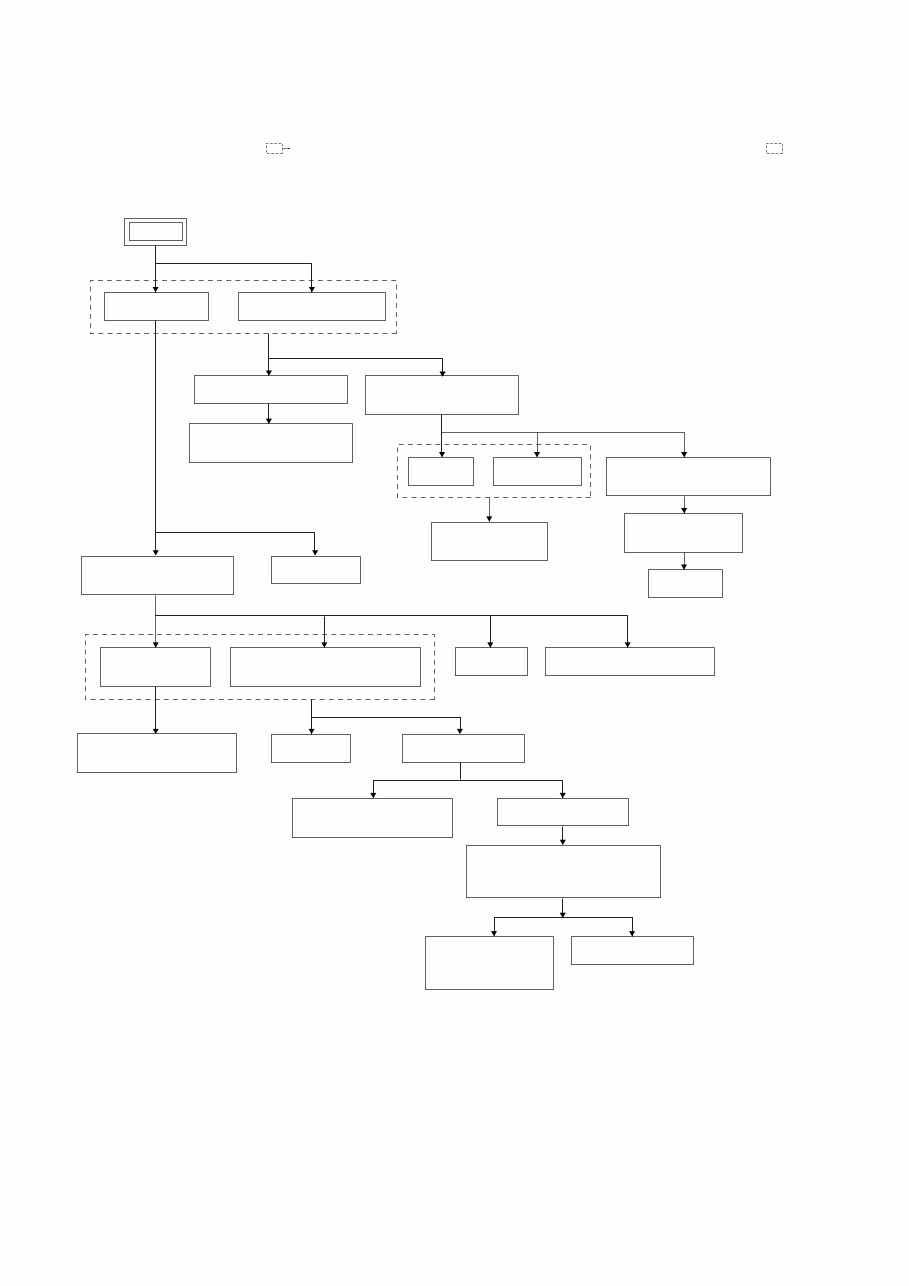

Note : • Disassemble the unit in the order as shown below.

• This set can be disassemble according to the following sequence.

The dotted square with arrow ( ) prompts you to move to the next job when all of the works within the dotted square ( )

are completed.

MOTOR ASSY

(LOADING) (M201)

OPTICAL PICK-UP

(KRM-220CAA)

CAM (CH)

LOADING PANEL (CDR)

CD MECHANISM DECK

(CDM53L-30B61M)

CD MECHANISM DECK

(CDM65-RBD2)

FITTING BASE

(MAGNET) ASSY

FITTING BASE (GUIDE) ASSY,

BRACKET (CHASSIS)

LOAD MOTOR BOARD,

MOTOR (LOADING) ASSY

STOCKER SECTION

GEAR (GEAR A),

GEAR (GEAR B),

GEAR(U/D SLIDER)

GEAR (CHUCKING)

SLIDER (SELECTION),

TENSION SPRING (SHUTTER),

SLIDER (SHUTTER)

TRAY (SUB)

CHASSIS (MOLD B)

BD BOARD

OPTICAL BLOCK SECTION

CLAMP MOTOR BOARD,

MOTOR (CLAMP) ASSY

SW BOARD, LED BOARD,

DISP BOARD

CDR BOARD

HOLDER (MG) SUB ASSY,

DUST COVER

TRAY

MAIN BOARD

CASE (409538)

FRONT PANEL SECTION

SET

7

RCD-W500C

Note : Follow the disassembly procedure in the numerical order given.

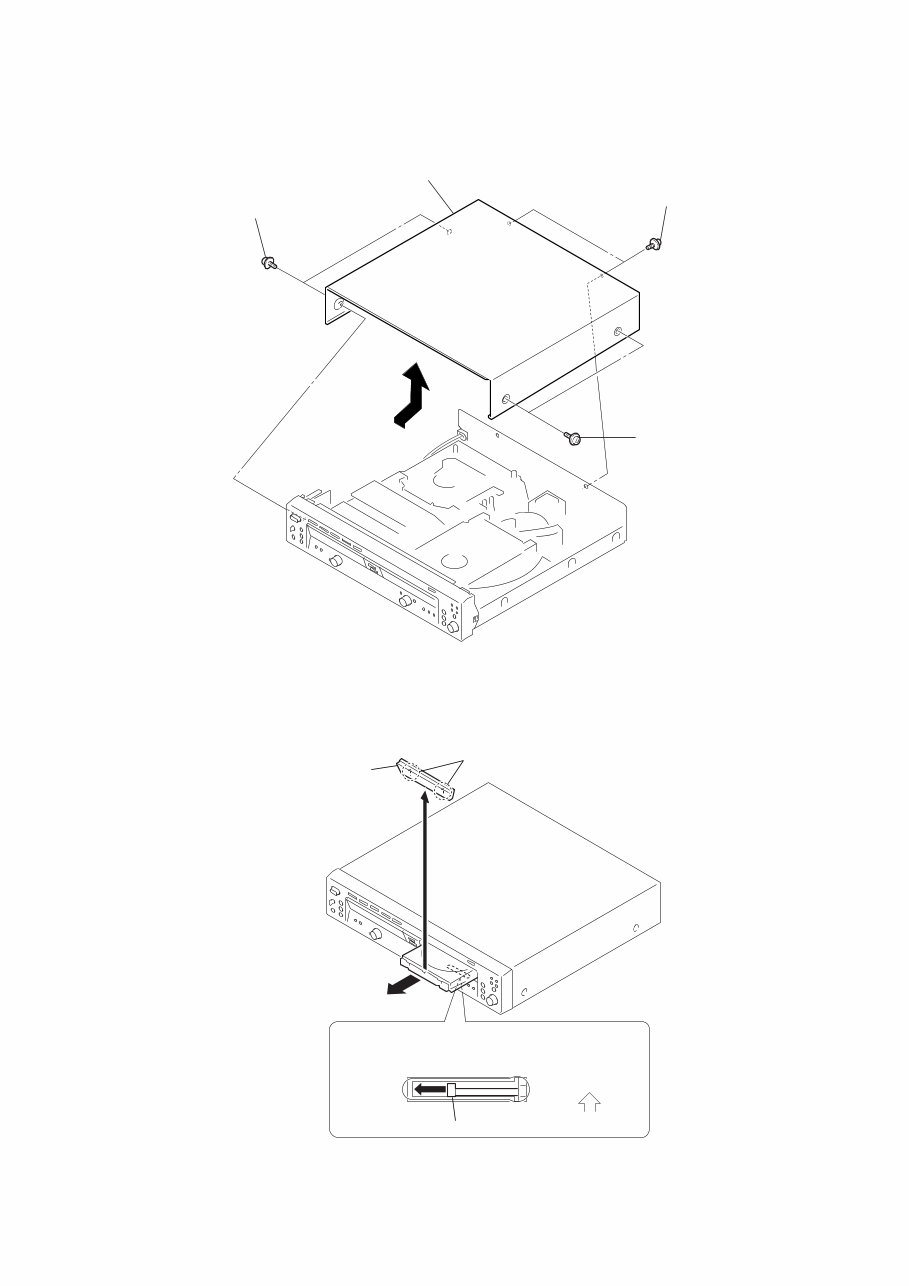

3-1. Case (409538)

3-2. Loading Panel (CDR)

4 case (409538)

2 two screws

(case 3 TP2 3 × 8)

3 two screws

(case 3 TP2 3 × 8)

1 two screws

(case 3 TP2 3 × 8)

1 Slide the lever (cam (CH)) to the direction of arrow.

Front panel side

CD mechanism deck (CDM65-RBD2)

3

2

lever (cam (CH))

two hooks

4 loading panel (CDR)

8

RCD-W500C

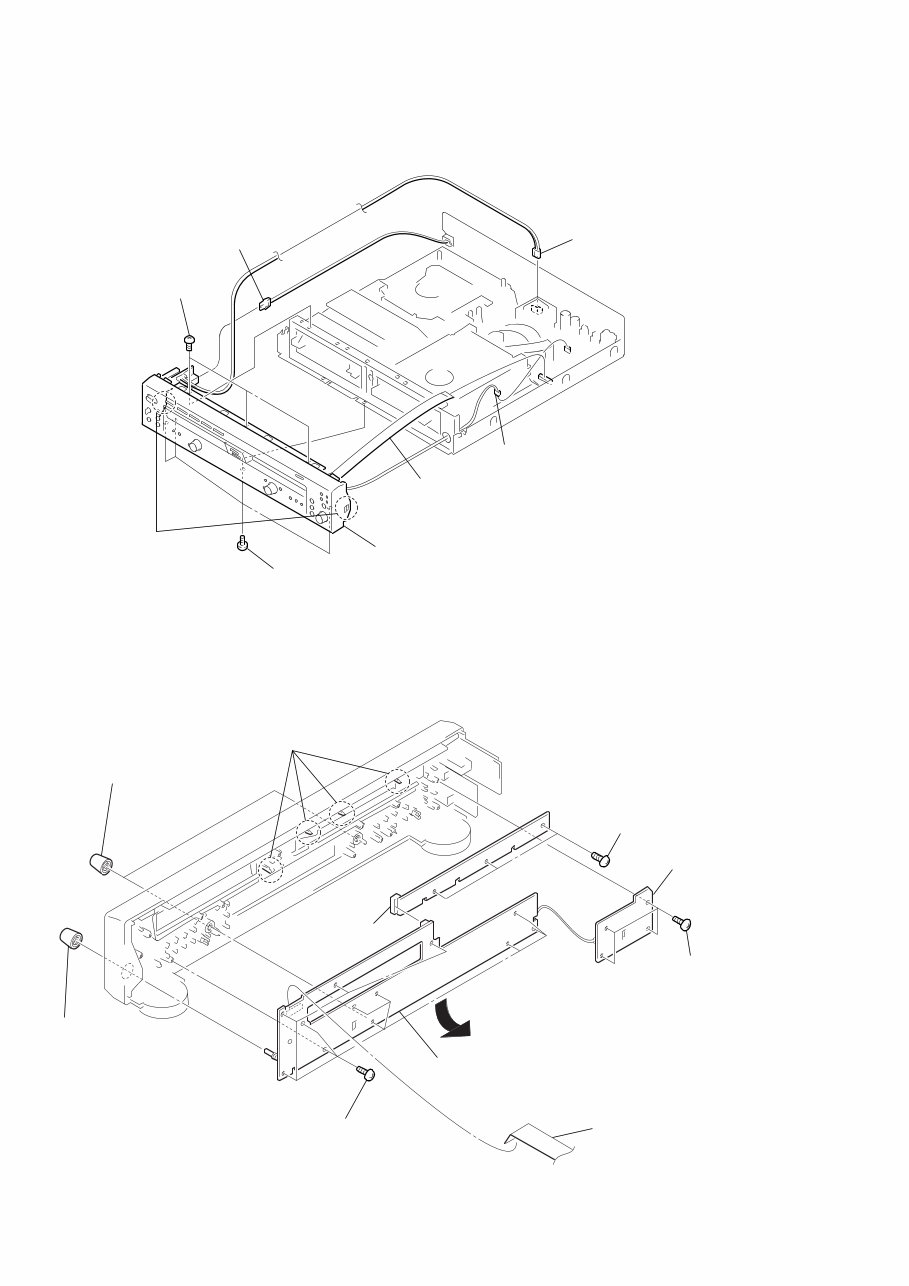

3-3. Front Panel Section

3-4. SW Board, LED Board, DISP Board

7 two claws

8 front panel section

1 connector (2pin) (CN900)

2 connector (3pin) (CN690)

4 connector (2pin) (CN920)

5 three screws

(+BVTP 3 × 8)

6 four screws

(+BVTP 3 × 8)

3 wire (flat type)

(21core) (CN671)

5 three screws

(+BVTP 2.6 × 8)

7 four claws

2 two knobs (AMS)

1 knob (AMS)

6 twelve screws

(+BVTP 2.6 × 8)

3 four screws

(+BVTP 2.6 × 8)

4 SW board

8 LED board

q; DISP board

9 wire (flat type)

(21core) (CN700)

9

RCD-W500C

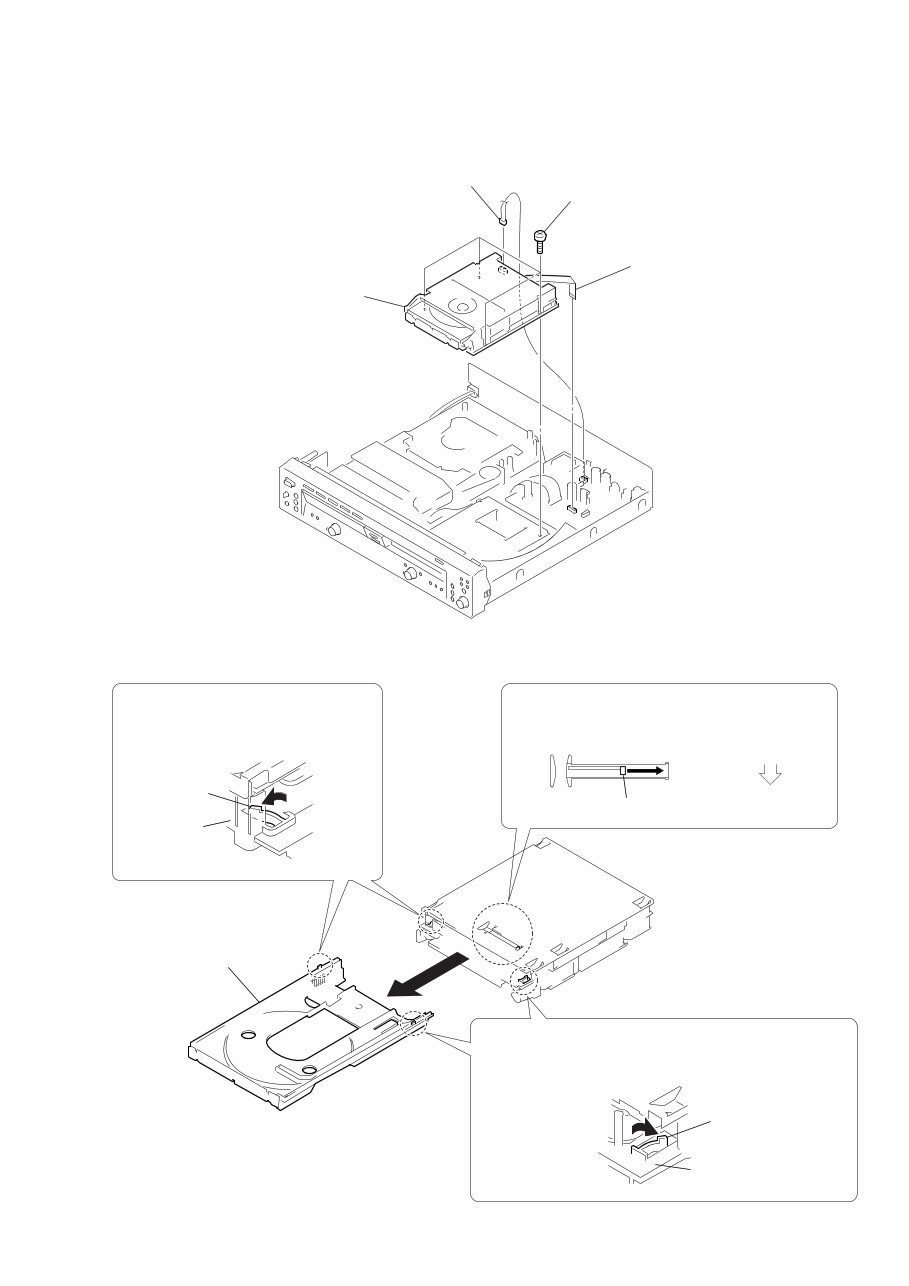

3-5. CD Mechanism Deck (CDM65-RBD2)

3-6. Tray

3 four screws (+BVTP 3 × 8)

2 wire (flat type)

(11core) (CN630)

1 connector

(4pin) (CN111)

4 CDR mechanism deck

(CDM65-RBD2)

1 Slide the lever (cam (CH)) to the direction of arrow.

4 tray

2 Pull the tray while pressing the claw of

the chassis in the direction of the arrow.

3 Pull the tray while pressing the claw of the chassis and the claw

of the tray in the direction of the arrow.

front panel side

lever (cam (CH))

claw

claw

chassis

chassis

10

RCD-W500C

3-8. Motor Assy (Loading) (M201)

3-7. CDR Board

7 claw

6 claw

8 connector

(2pin) (CN104)

3 flexible flat cable

(32core) (CN101)

4 flexible flat cable

(11core) (CN102)

5 flexible flat cable

(11core) (CN103)

9 CDR board

2 bottom plate

1 four screws

(+BVTP 2.6 × 8)

1 Slide the cam (CH) to the direction of arrow.

2 Remove the belt (loading) from the

pulley of the motor assy.

3 two claws

4 motor assy

(loading) (M201)

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 53 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

This service manual for the Sony RCD-W500C Compact Disc Recorder provides essential technical information for servicing and repair. It includes detailed sections on disassembly, test mode, electrical adjustments, diagrams, exploded views, and an electrical parts list. The manual spans 114 pages and is presented in English. It is available in a format suitable for both Windows and MAC platforms.