Denon MC3000 Service Manual & Repair Guide

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

START::|qzT7t3cIXfGvpSN6RPbAWw==|Nf29yLqf9ysByP/jxH09hm+vscIopbwoKUAJ5AJF9sM=|RtRIz5LbaS+BXuKmvA5t

SERVICE MANUAL

D&M Holdings Inc.

Copyright 2013 D&M Holdings Inc. All rights reserved.

WARNING: Violators will be prosecuted to the maximum extent possible.

MODEL JP E3 E2 EK EA E1 E1K E1C

MC3000 P P

Professional DJ Multi-controller

Ver. 4

S0708-1V04DM/DG1306

• Some illustrations using in this service manual are slightly different from the actual set.

• Please use this service manual with referring to the operating instructions without fail.

• For purposes of improvement, specifications and design are subject to change without notice.

Please refer to the

MODIFICATION NOTICE.

2

CONTENTS

SAFETY PRECAUTIONS ..........................................................3

NOTE FOR SCHEMATIC DIAGRAM.........................................4

TECHNICAL SPECIFICATIONS ................................................5

DIMENSION ...............................................................................5

DISASSEMBLY ..........................................................................6

1. TOP PANEL...........................................................................8

2. I/O PCB ASS'Y ....................................................................10

3. PHONE PCB ASS'Y ............................................................ 11

4. TOP PANEL ASS'Y..............................................................12

5. CONTROL PCB ASS'Y / SOFT KNOB ................................14

6. CROSS FADER PCB ASS'Y ...............................................16

7. WHEEL ASS'Y.....................................................................17

SPECIAL MODE ......................................................................19

1. Special mode setting ...........................................................19

2. Version Up mode .................................................................19

3. Version indicate mode .........................................................20

4. Adjusting mode of the touch sense sensitivity.....................21

5. Initialize mode .....................................................................21

6. MIDI transmission time mode ..............................................21

7. SW, VOLUME, ENCODER and LED TEST.........................22

WHEN THE MICROPROCESSOR IS REPLACED

WITH A NEW ONE...................................................................29

PROCEDURE FOR UPGRADING

THE VERSION OF THE FIRMWARE ......................................29

TROUBLE SHOOTING ............................................................38

WIRING DIAGRAM ..................................................................48

BLOCK DIAGRAM...................................................................49

POWER BLOCK DIAGRAM ....................................................50

Level DIAGRAM ......................................................................51

PRINTED WIRING BOARDS...................................................52

CONTROL ..............................................................................52

I/O ..........................................................................................54

CROS FADER ........................................................................54

PHONE ..................................................................................54

SENSOR ...............................................................................54

SCHEMATIC DIAGRAMS (1/2) ...............................................55

CONTROL UNIT .....................................................................55

I/O UNIT ..................................................................................56

EXPLODED VIEW....................................................................57

PARTS LIST OF EXPLODED VIEW........................................59

PACKING VIEW .......................................................................61

PARTS LIST OF PACKING & ACCESSORIES.......................61

SEMICONDUCTORS ...............................................................63

1. IC's ......................................................................................63

PARTS LIST OF P.C.B. UNIT ..................................................78

CONTROL P.C.B ASS'Y ..........................................................78

I/O P.C.B ASS'Y.......................................................................83

PHONE P.C.B ASS'Y...............................................................88

SENSOR P.C.B ASS'Y ............................................................88

CROS FADER P.C.B ASS'Y ....................................................88

3

SAFETY PRECAUTIONS

The following items should be checked for continued protection of the customer and the service technician.

LEAKAGE CURRENT CHECK

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis

resistance check. If the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the

power cord is less than 460 kohms, the set is defective.

Be sure to test for leakage current with the AC plug in both polarities, in addition, when the set's power is in each state (on,

off and standby mode), if applicable.

CAUTION Please heed the following cautions and instructions during servicing and

inspection.

◎ Heed the cautions!

Cautions which are delicate in particular for servicing

are labeled on the cabinets, the parts and the chassis,

etc. Be sure to heed these cautions and the cautions

described in the handling instructions.

◎ Cautions concerning electric shock!

(1) An AC voltage is impressed on this set, so if

you touch internal metal parts when the set is

energized, you may get an electric shock. Avoid

getting an electric shock, by using an isolating

transformer and wearing gloves when servicing

while the set is energized, or by unplugging the

power cord when replacing parts, for example.

(2) There are high voltage parts inside. Handle with

extra care when the set is energized.

◎ Caution concerning disassembly and

assembly!

Through great care is taken when parts were

manufactured from sheet metal, there may be burrs

on the edges of parts. The burrs could cause injury if

fingers are moved across them in some rare cases.

Wear gloves to protect your hands.

◎ Use only designated parts!

The set's parts have specific safety properties (fire

resistance, voltage resistance, etc.). Be sure to use

parts which have the same properties for replacement.

The burrs have the same properties. In particular, for

the important safety parts that are indicated by the z

mark on schematic diagrams and parts lists, be sure to

use the designated parts.

◎ Be sure to mount parts and arrange the wires

as they were originally placed!

For safety seasons, some parts use tapes, tubes or

other insulating materials, and some parts are mounted

away from the surface of printed circuit boards.

Care is also taken with the positions of the wires by

arranging them and using clamps to keep them away

from heating and high voltage parts, so be sure to set

everything back as it was originally placed.

◎ Make a safety check after servicing!

Check that all screws, parts and wires removed or

disconnected when servicing have been put back in

their original positions, check that no serviced parts

have deteriorate the area around. Then make an

insulation check on the external metal connectors and

between the blades of the power plug, and otherwise

check that safety is ensured.

(Insulation check procedure)

Unplug the power cord from the power outlet,

disconnect the antenna, plugs, etc., and on the power.

Using a 500V insulation resistance tester, check that

the insulation resistance value between the inplug and

the externally exposed metal parts (antenna terminal,

headphones terminal, input terminal, etc.) is 1MΩ or

greater. If it is less, the set must be inspected and

repaired.

Many of the electric and the structural parts used in

the set have special safety properties. In most cases

these properties are difficult to distinguish by sight, and

the use of replacement parts with higher ratings (rated

power and withstand voltage) does not necessarily

guarantee that safety performance will be preserved.

Parts with safety properties are indicated as shown

below on the wiring diagrams and the parts list in this

service manual. Be sure to replace them with the parts

which have the designated part number.

(1) Schematic diagrams.......Indicated by the z mark.

(2) Parts lists.......Indicated by the z mark.

The use of parts other than the

designated parts could cause electric

shocks, fires or other dangerous

situations.

CAUTION Concerning important safety

parts

4

NOTE FOR SCHEMATIC DIAGRAM

WARNING:

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

CAUTION:

Before returning the set to the customer, be sure to carry out either (1) a leakage current check or (2) a line to chassis resistance check. If

the leakage current exceeds 0.5 milliamps, or if the resistance from chassis to either side of the power cord is less than 460 kohms, the set

is defective.

WARNING:

DO NOT return the set to the customer unless the problem is identified and remedied.

NOTICE:

ALL RESISTANCE VALUES IN OHM. k=1,000 OHM / M=1,000,000 OHM

ALL CAPACITANCE VALUES ARE EXPRESSED IN MICRO FARAD, UNLESS OTHERWISE INDICATED. P INDICATES MICRO-MICRO

FARAD. EACH VOLTAGE AND CURRENT ARE MEASURED AT NO SIGNAL INPUT CONDITION. CIRCUIT AND PARTS ARE SUBJECT

TO CHANGE WITHOUT PRIOR NOTICE.

Parts indicated by "nsp" on this table cannot be supplied.

When ordering a part, make a clear distinction between "1" and "I" (i) to avoid mis-supplying.

A part ordered without specifying its part number can not be supplied.

General-purpose Carbon Chip Resistors are not included are not included in the P.W.Board parts list.

(Refer to the Schematic Diagram for those parts.)

Parts indicated by the z mark have critical characteristics. Use ONLY replacement parts recommended by the manufacturer.

General-purpose Carbon Film Resistor in the P.W.Board parts list. (Refer to the Schematic Diagram for those parts.)

Part indicated by "★" mark is not illustrated in the exploded view.

WARNING:

1.

2.

3.

4.

5.

6.

NOTE FOR PARTS LIST

5

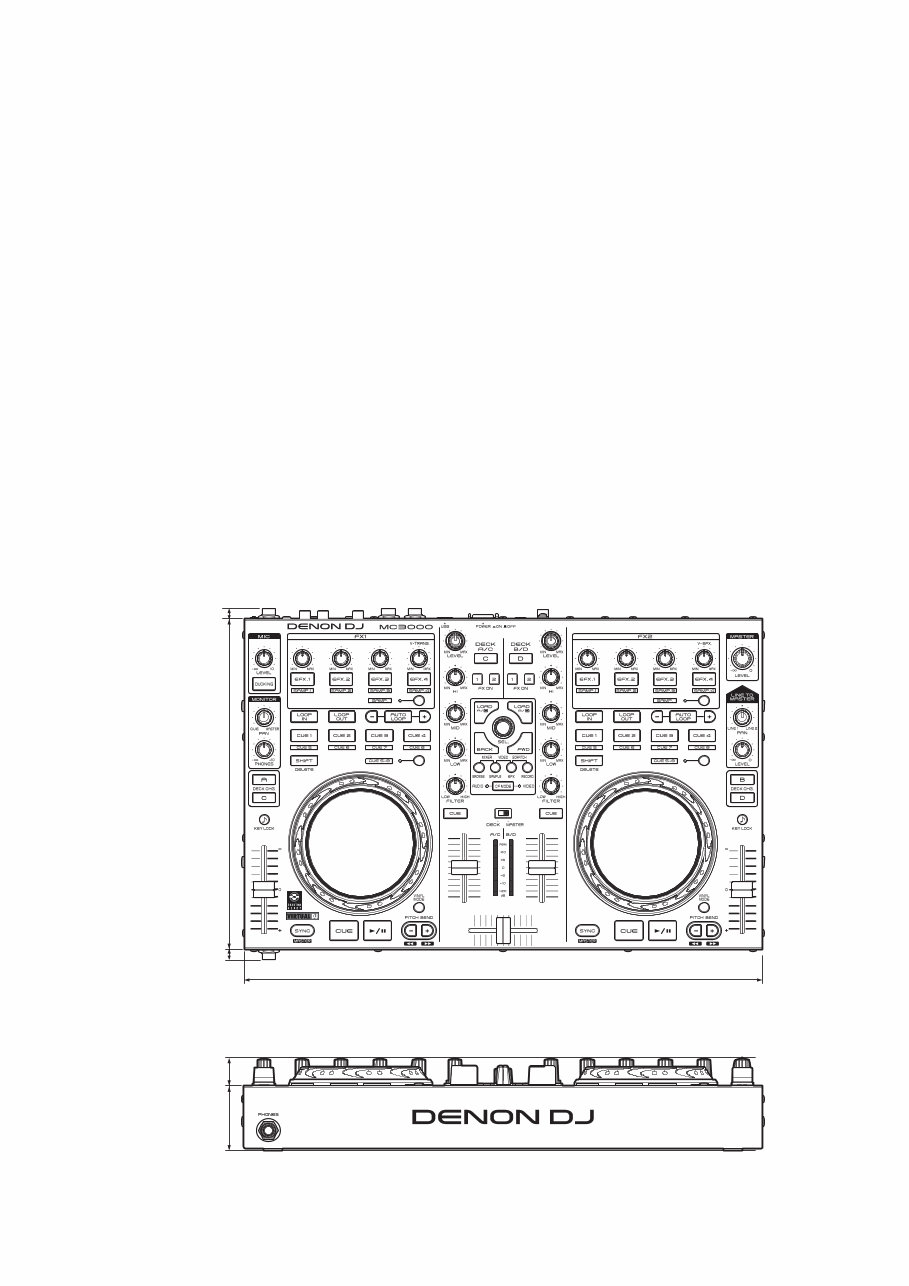

TECHNICAL SPECIFICATIONS

8.0 mm

8.0 mm

21.6 mm

50.0 mm

400.0 mm

255.0 mm

DIMENSION

n Audio (0 dBu=0.775 Vrms, 0 dBV =1 Vrms)

• LINE inputs 2 Stereo

Unbalanced RCA terminal

Input impedance: 51 kΩ

Level: 0 dBV

Signal to Noise ratio: Over 87 dB

• Microphone inputs 1 Monaural

Microphone : Balanced 1/4 in. TRS terminal

(Tip: hot, Ring: cold, Sleeve: ground)

Input impedance: 10 kΩ

Level: –52 – –20 dBu (Unity = –40 dBu)

• USB AUDIO inputs 2 Stereo (4 Monaural) 16 bit, Fs: 48 kHz USB B

• MASTER output

Balanced: Stereo, balanced 1/4 in. TRS terminal

(Tip: hot, Ring: cold, Sleeve: ground)

Load impedance: Over 600 Ω

Level: +4 dBu (Max +24 dBu)

When RL = 10 kΩ

Frequency response: 20 Hz – 20 kHz (±0.5 dB)

THD: Less than 0.05 %

Crosstalk: Less than –85 dB (1 kHz)

Unbalanced: Stereo RCA terminal

Load impedance: 10 kΩ

Level: 0 dBu (Max +20 dBu)

• Headphone output Stereo 1/4 in. (1 mm)

Load impedance: 40 Ω

Level: Over 100 mW

• USB AUDIO output 2 Stereo (4 Monaural) 16 bit, FS: 48 kHz USB B

n General

USB MIDI input/output: IN: 1ch, OUT: 1ch MIDI 1.0, USB B

MASTER meter: PPM 7 Point LED –20 – +10 dB, Peak

CH fader: 1 1/4 in. (45 mm) slim type fader

Cross fader: 1 1/4 in. (45 mm) fader

• Power voltage: DC 12 V (the unit)

AC adapter input:

U.S.A. and Canada

models:

AC 120 V, 60 Hz

European,U.K. and

Asia/Pacific models:

AC 230 V, 50 Hz

AC adapter output: DC 12 V 2 A

Power consumption: 16 W

Operating

temperature:

+5 °C – +35 °C

Operating humidity: 25 % – 85 %

Storage temperature: –20 °C – 60 °C

6

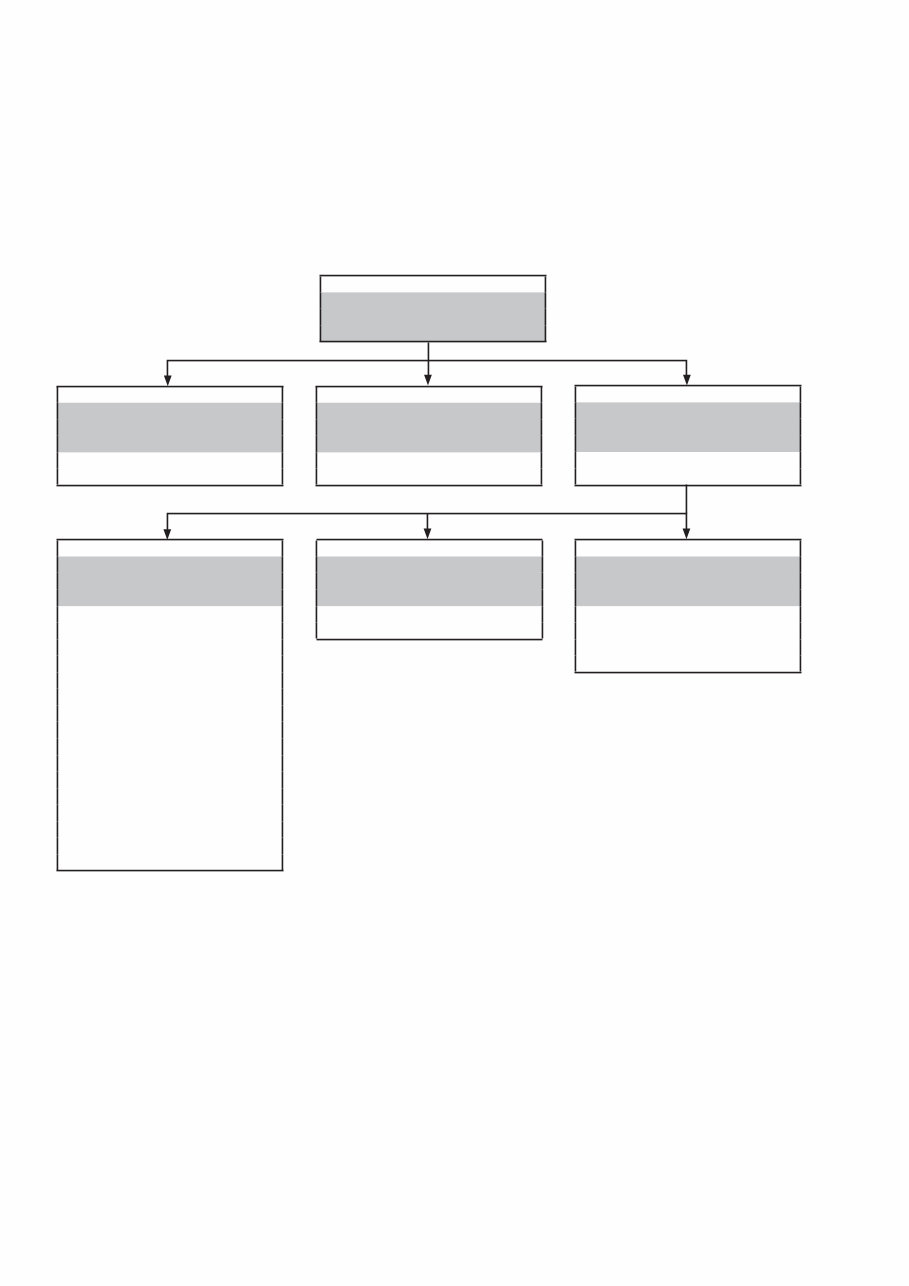

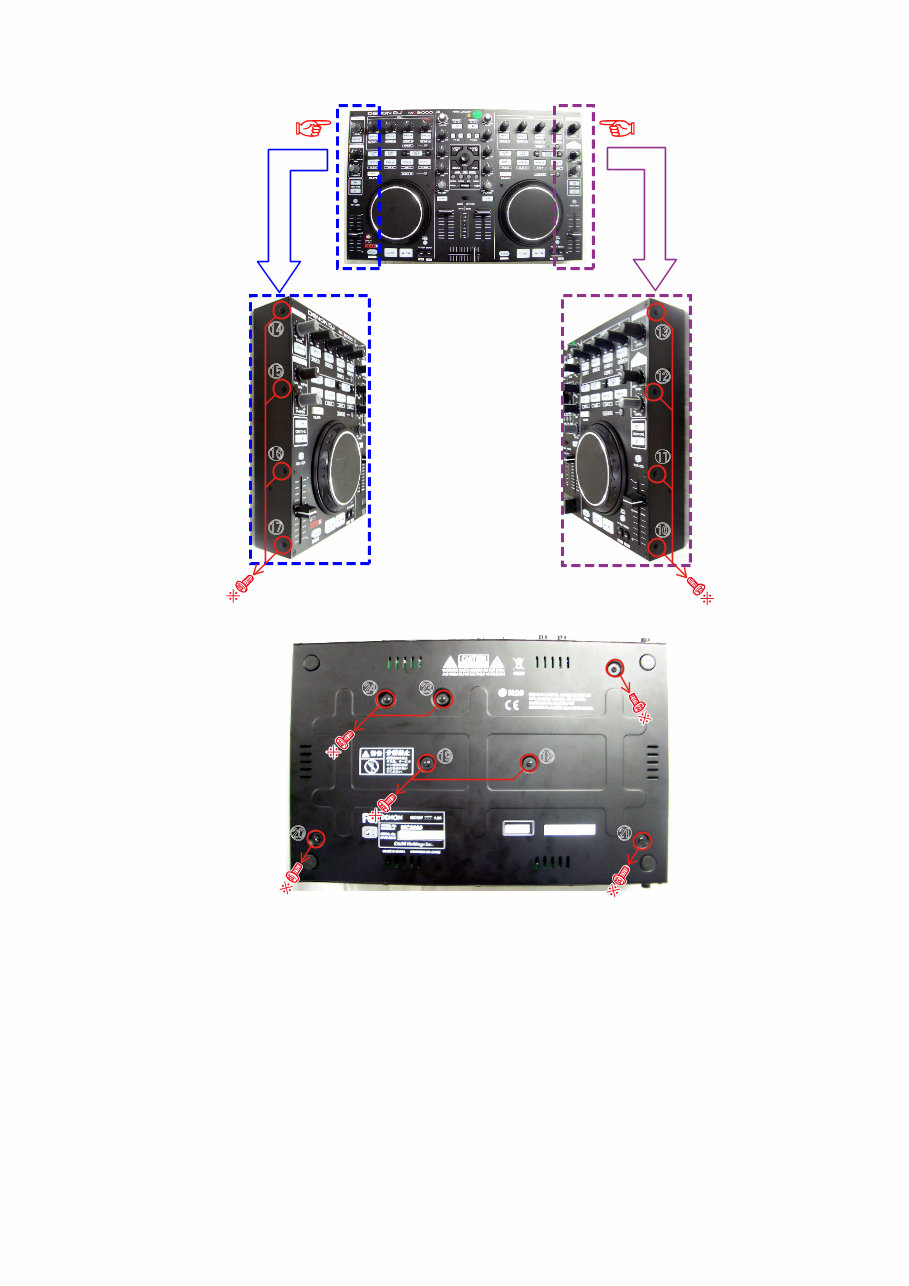

DISASSEMBLY

• Disassemble in order of the arrow in the following figure.

• In the case of the re-assembling, assemble it in order of the reverse of the following flow.

• In the case of the re-assembling, observe "attention of assembling".

• If wire bundles are untied or moved to perform adjustment or replace parts etc., be sure to rearrange them neatly as

they were originally bundled or placed afterward.

Otherwise, incorrect arrangement can be a cause of noise generation.

TOP PANEL

Refer to "DISASSEMBLY

1. TOP PANEL"

and "EXPLODED VIEW"

I/O PCB ASS'Y

Refer to "DISASSEMBLY

2. I/O PCB ASS'Y"

and "EXPLODED VIEW"

I/O PCB ASS'Y

(Ref. No. of EXPLODED VIEW : 7)

PHONE PCB ASS'Y

Refer to "DISASSEMBLY

3. PHONE PCB ASS'Y"

and "EXPLODED VIEW"

PHONE PCB ASS'Y

(Ref. No. of EXPLODED VIEW : 8)

TOP PANEL ASS'Y

Refer to "DISASSEMBLY

4. TOP PANEL ASS'Y"

and "EXPLODED VIEW"

TOP PANEL ASS'Y

(Ref. No. of EXPLODED VIEW : 4)

WHEEL ASS'Y

Refer to "DISASSEMBLY

7. WHEEL ASS'Y"

and "EXPLODED VIEW"

WHEEL ASS'Y

(Ref. No. of EXPLODED VIEW : 2)

SENSOR PCB ASS'Y

(Ref. No. of EXPLODED VIEW : 9)

CROSS FADER PCB ASS'Y

Refer to "DISASSEMBLY

6. CROSS FADER PCB ASS'Y"

and "EXPLODED VIEW"

CROSS FADER PCB ASS'Y

(Ref. No. of EXPLODED VIEW : 5)

CONTROL PCB ASS'Y / SOFT KNOB

Refer to "DISASSEMBLY

5. CONTROL PCB ASS'Y / SOFT KNOB"

and "EXPLODED VIEW"

CONTROL PCB ASS'Y

(Ref. No. of EXPLODED VIEW : 6)

MASTER SOFT KNOB

(Ref. No. of EXPLODED VIEW : 33)

EFX SOFT KNOB

(Ref. No. of EXPLODED VIEW : 34)

PLAY/CUE SOFT KNOB

(Ref. No. of EXPLODED VIEW : 35)

DECK/AC SOFT KNOB

(Ref. No. of EXPLODED VIEW : 36)

DECK/BD SOFT KNOB

(Ref. No. of EXPLODED VIEW : 37)

CUE SOFT KNOB

(Ref. No. of EXPLODED VIEW : 38)

DUCKING SOFT KNOB

(Ref. No. of EXPLODED VIEW : 39)

7

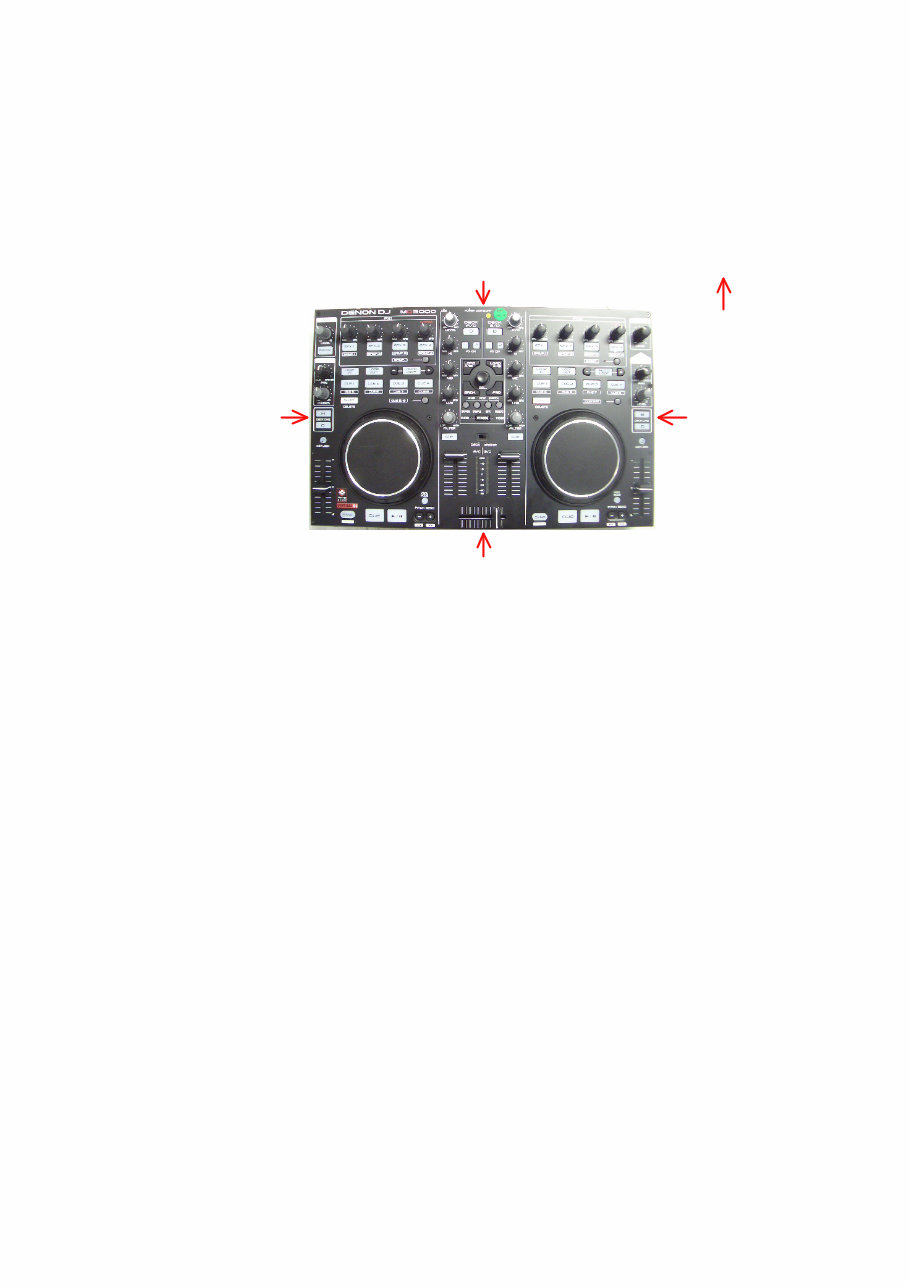

About the photos used for "descriptions of the DISASSEMBLY" section

• The shooting direction of each photograph used herein is indicated on the left side of the respective photograph as

"Shooting direction: ***".

• Refer to the diagram below about the shooting direction of each photograph.

• Photographs with no shooting direction indicated were taken from the top of the set.

The viewpoint of each photograph

(Shooting direction)

[View from the top]

Front side

Shooting direction: B

Shooting direction: D Shooting direction: C

Shooting direction: A

8

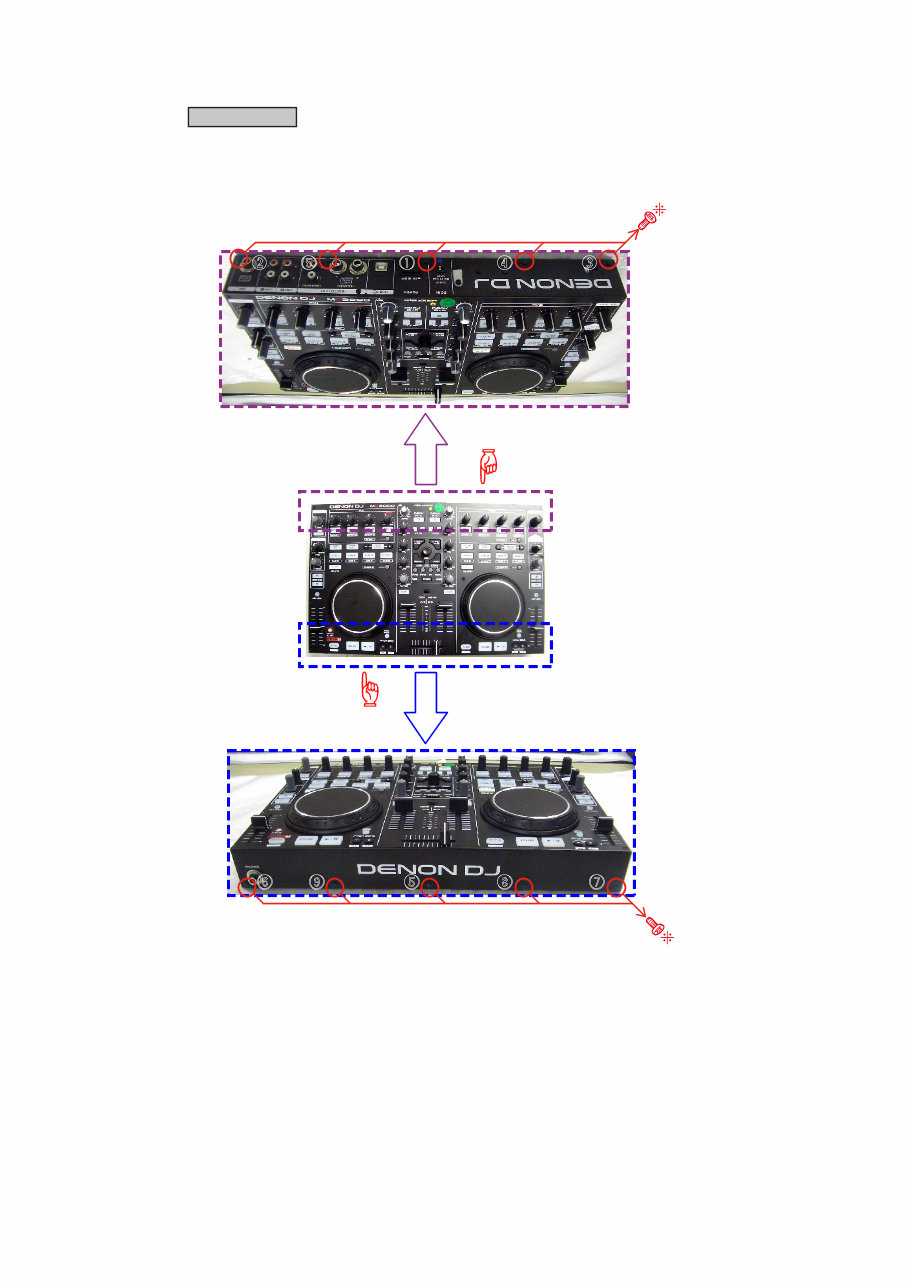

1. TOP PANEL

(1) Remove the screws.

NOTE: Turn to tighten a screws q...W4.

TOP PANEL Proceeding :

Shooting direction: B

Shooting direction: A

e r q t w

u i t o y

9

Shooting direction: D Shooting direction: C

View from bottom

Q3

Q2

Q1

Q0

Q4

Q5

Q6

Q7

W3 W4

Q9

W0

W2

W1

Q8

10

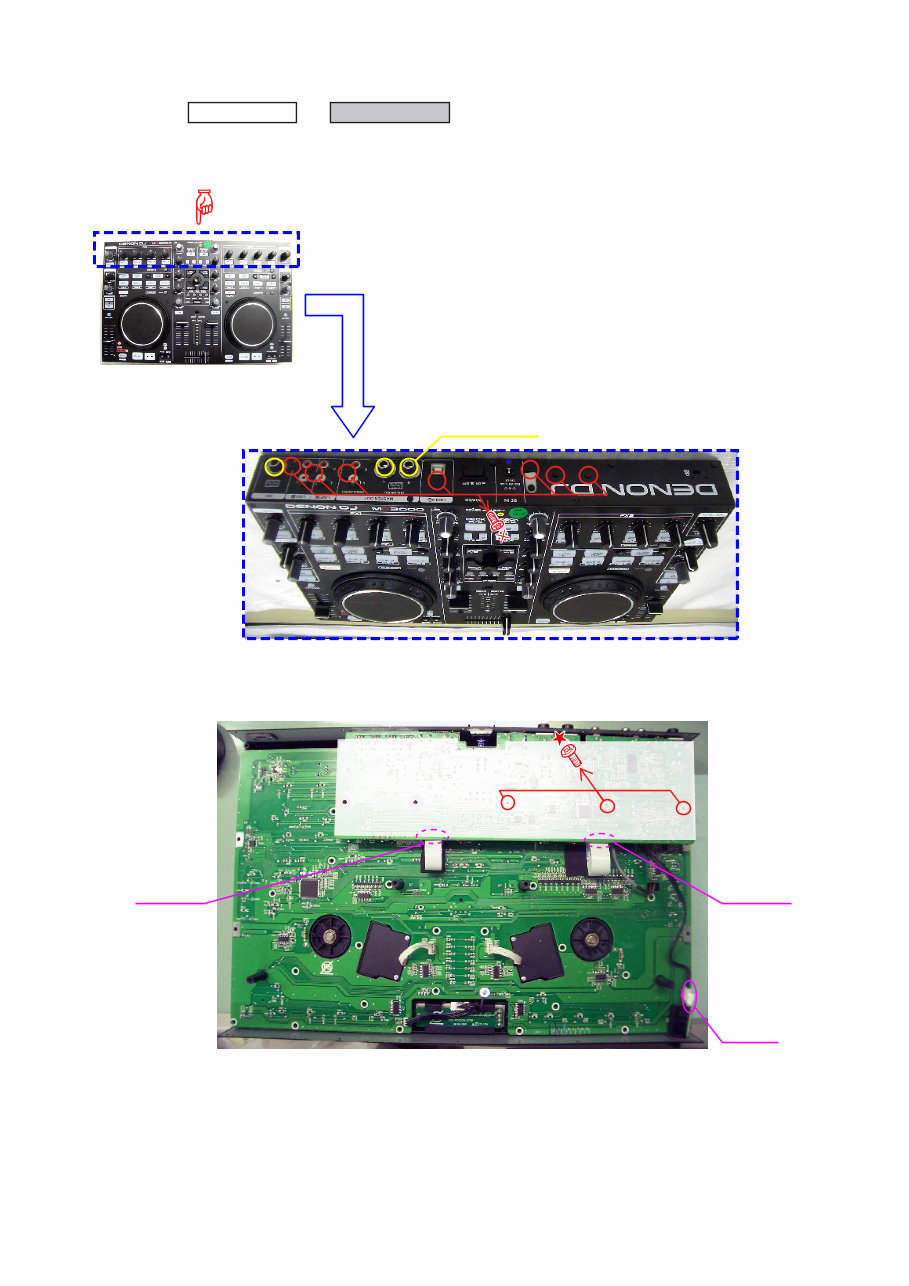

2. I/O PCB ASS'Y

(1) Remove the screws, nuts and washers.

NOTE: Varnish washer surface is visible.

(2) Disconnect the FFC cables and connector wire, then remove the screws.

TOP PANEL I/O PCB ASS'Y

→

Proceeding :

Shooting direction: B

NUT,WASHER

CN300A

FFC cable FFC cable

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 43 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

This service and repair manual for the Denon MC3000 DJ Controller is an essential resource for both professional technicians and DIY enthusiasts. It provides detailed instructions and information to troubleshoot and repair the DJ system, helping you save on costly repairs or replacements.

- Safety & Precautions

- Product Specifications

- Disassembly & Assembly Instructions

- Semiconductors

- Troubleshooting

- Service Mode

- Printed Wiring Boards

- Block Diagram

- Level Diagram

- Wiring Diagram

- Schematic Diagrams

- Exploded Views

- Replacement Parts list

This comprehensive manual is illustrated with high-resolution pictures and provides step-by-step guidance for servicing and repairing the device effectively. It is available in PDF format, ensuring instant access without any shipping delays, allowing you to commence repairs promptly.

Specifications:

- Language: English

- Format: PDF

- Pages: 88