Sharp MX-M623N, MX-M623U, MX-M753N, MX-M753U, Service Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

SERVICE MANUAL

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with

specified ones for maintaining the safety and performance of the set.

SHARP CORPORATION

This document has been published to be used

for after sales service only.

The contents are subject to change without notice.

NOTE FOR SERVICING

[1] PRODUCT OUTLINE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

[2] SPECIFICATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

[3] CONSUMABLE PARTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE . . . . . . . . . . . . . . . . . . . . . . . . 4-1

[5] ADJUSTMENTS AND SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

[6] SIMULATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-1

[7] SELF DIAG AND TROUBLE CODE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

[8] OPERATIONAL DESCRIPTIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

[9] MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9-1

[10] DISASSEMBLY AND ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

[11] FIRMWARE UPDATE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

[12] ELECTRICAL SECTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

[13] SERVICE WEB PAGE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

TopPage

CONTENTS

CODE: 00ZMXM753/S1E

DIGITAL MULTIFUNCTIONAL

SYSTEM

MX-M623 N/U

MX-M753 N/U MODEL

CONTENTS

NOTE FOR SERVICING

1. Precautions for servicing . . . . . . . . . . . . . . . . . . . . i

2. Warning for servicing . . . . . . . . . . . . . . . . . . . . . . . i

3. Note for installation site . . . . . . . . . . . . . . . . . . . . . i

4. Note for handling PWB and electronic parts . . . . ii

5. Note for repairing/replacing the LSU . . . . . . . . . . iii

6. Note for handling the drum unit,

the transfer unit, the developing unit,

and the fusing unit . . . . . . . . . . . . . . . . . . . . . . . . iii

7. Screw tightening torque . . . . . . . . . . . . . . . . . . . . iii

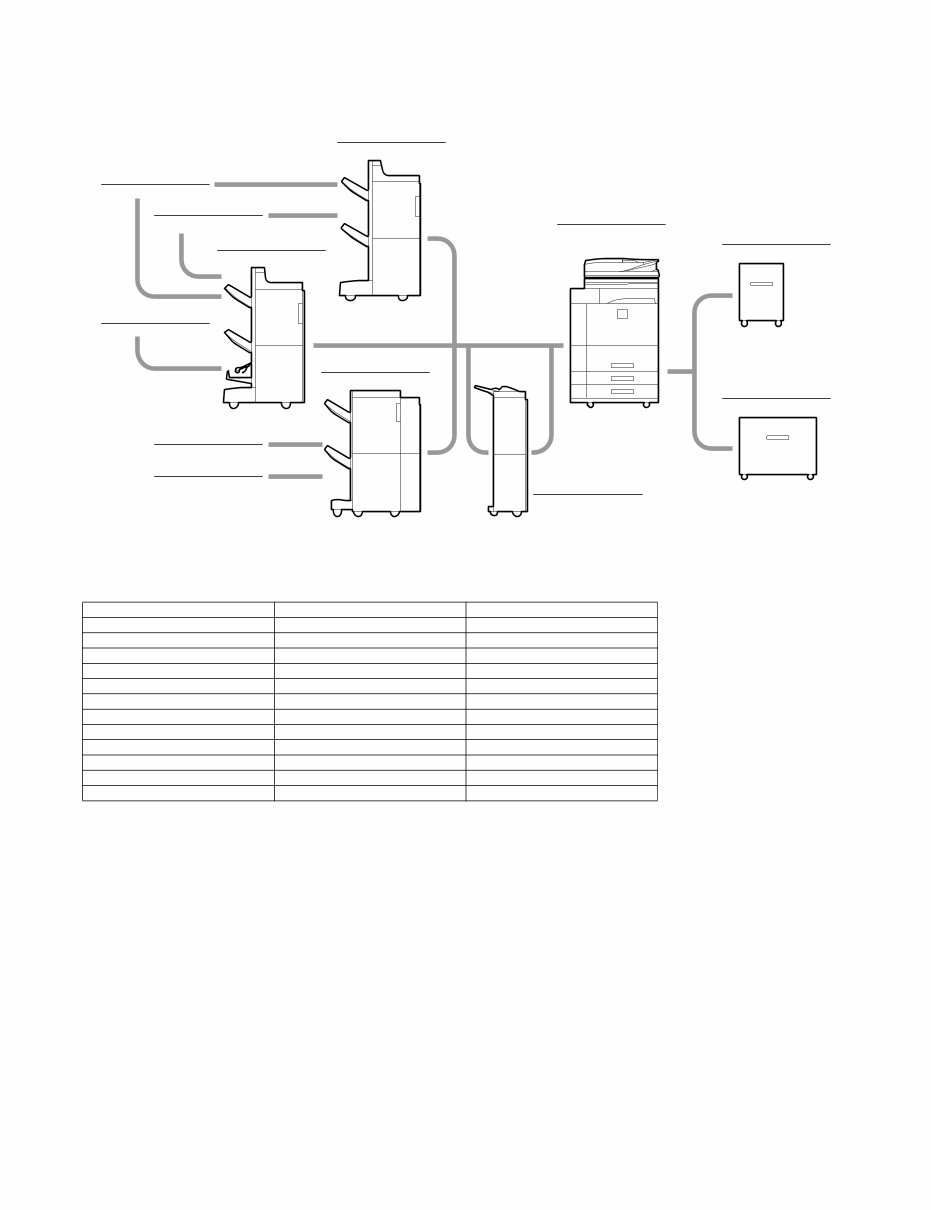

[1] PRODUCT OUTLINE

1. System configuration . . . . . . . . . . . . . . . . . . . . . 1-1

2. Machine configuration . . . . . . . . . . . . . . . . . . . . 1-1

3. Combination of options. . . . . . . . . . . . . . . . . . . . 1-2

[2] SPECIFICATIONS

1. Basic specifications . . . . . . . . . . . . . . . . . . . . . . 2-1

2. Functional specifications . . . . . . . . . . . . . . . . . . 2-4

[3] CONSUMABLE PARTS

1. Supply system table . . . . . . . . . . . . . . . . . . . . . . 3-1

2. Maintenance parts list . . . . . . . . . . . . . . . . . . . . 3-1

3. Definition of Developer and Drum life end . . . . . 3-3

4. Production number identification . . . . . . . . . . . . 3-3

[4] EXTERNAL VIEW AND INTERNAL STRUCTURE

1. Identification of each section and functions . . . . 4-1

[5] ADJUSTMENTS AND SETTINGS

1. General. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-1

2. Adjustment item list . . . . . . . . . . . . . . . . . . . . . . 5-1

3. Details of adjustment . . . . . . . . . . . . . . . . . . . . . 5-2

[6] SIMULATION

1. General (Including basic operations) . . . . . . . . . 6-1

2. List of simulation codes . . . . . . . . . . . . . . . . . . . 6-3

3. Details of simulation . . . . . . . . . . . . . . . . . . . . . . 6-7

[7] SELF DIAG AND TROUBLE CODE

1. Self diag . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-1

2. Trouble code list . . . . . . . . . . . . . . . . . . . . . . . . . 7-4

3. Details of trouble code . . . . . . . . . . . . . . . . . . . . 7-6

4. Paper JAM code . . . . . . . . . . . . . . . . . . . . . . . . 7-26

5. Necessary works when replacing

the PWB and the HDD . . . . . . . . . . . . . . . . . . . 7-30

[8] OPERATIONAL DESCRIPTIONS

1. Operation panel . . . . . . . . . . . . . . . . . . . . . . . . . 8-1

2. Scanner section . . . . . . . . . . . . . . . . . . . . . . . . . 8-3

3. Manual paper feed section . . . . . . . . . . . . . . . . . 8-5

4. Tray paper feed section . . . . . . . . . . . . . . . . . . . 8-7

5. Paper transport section, Duplex section. . . . . . 8-14

6. LSU section . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-22

7. Photo-conductor section. . . . . . . . . . . . . . . . . . 8-24

8. Toner supply section. . . . . . . . . . . . . . . . . . . . . 8-27

9. Developing section . . . . . . . . . . . . . . . . . . . . . . 8-29

10. Transfer section . . . . . . . . . . . . . . . . . . . . . . . . 8-31

11. Fusing section . . . . . . . . . . . . . . . . . . . . . . . . . 8-33

12. Paper exit section. . . . . . . . . . . . . . . . . . . . . . . 8-36

13. Automatic document feeder . . . . . . . . . . . . . . . 8-38

[9] MAINTENANCE

1. Necessary execution items

(Before and after maintenance) . . . . . . . . . . . . . 9-1

2. Contents of the maintenance codes and

countermeasures

(Relationship between various counter values

and display messages) . . . . . . . . . . . . . . . . . . . 9-2

3. Maintenance system table . . . . . . . . . . . . . . . . . 9-4

[10] DISASSEMBLY AND ASSEMBLY

1. Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-1

2. Operation panel section . . . . . . . . . . . . . . . . . . 10-2

3. Scanner section . . . . . . . . . . . . . . . . . . . . . . . . 10-5

4. Manual paper feed section . . . . . . . . . . . . . . . 10-9

5. Tray paper feed section . . . . . . . . . . . . . . . . . 10-14

6. Paper transport and duplex section . . . . . . . . 10-23

7. LSU section . . . . . . . . . . . . . . . . . . . . . . . . . . 10-39

8. Photo-conductor section . . . . . . . . . . . . . . . . 10-40

9. Toner supply section . . . . . . . . . . . . . . . . . . . 10-45

10. Developing section . . . . . . . . . . . . . . . . . . . . 10-47

11. Transfer section . . . . . . . . . . . . . . . . . . . . . . . 10-49

12. Fusing section . . . . . . . . . . . . . . . . . . . . . . . . 10-51

13. Paper exit section . . . . . . . . . . . . . . . . . . . . . 10-58

14. Drive section . . . . . . . . . . . . . . . . . . . . . . . . . 10-63

15. PWB section . . . . . . . . . . . . . . . . . . . . . . . . . 10-75

16. Fan section . . . . . . . . . . . . . . . . . . . . . . . . . . 10-80

17. Filter section . . . . . . . . . . . . . . . . . . . . . . . . . 10-85

18. Automatic document feeder . . . . . . . . . . . . . . 10-86

19. Other . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-107

[11] FIRMWARE UPDATE

1. Outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11-1

2. Update procedure . . . . . . . . . . . . . . . . . . . . . . 11-1

[12] ELECTRICAL SECTION

1. Block diagram . . . . . . . . . . . . . . . . . . . . . . . . . 12-1

2. Actual wiring chart . . . . . . . . . . . . . . . . . . . . . . 12-9

3. Signal list . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-21

[13] SERVICE WEB PAGE

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-1

2. Details and operation procedures . . . . . . . . . . 13-1

MX-M753N NOTE FOR SERVICING - i

MX-M753N

Service Manual NOTE FOR SERVICING

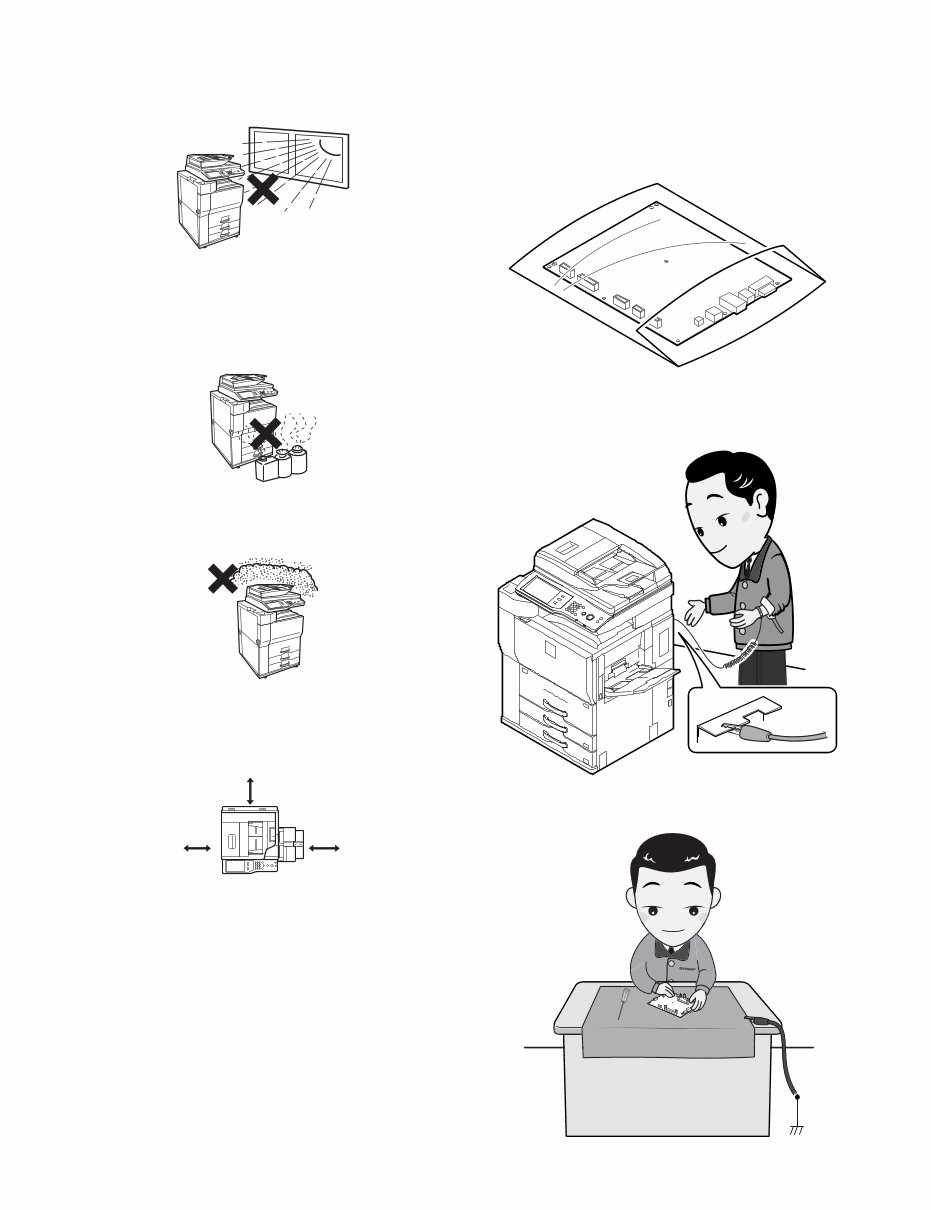

1. Precautions for servicing

1) When servicing, disconnect the power plug, the printer cable,

the network cable, and the telephone line from the machine,

except when performing the communication test, etc.

It may cause an injury or an electric shock.

2) There is a high temperature area inside the machine. Use an

extreme care when servicing.

It may cause a burn.

3) There is a high voltage section inside the machine which may

cause an electric shock. Be careful when servicing.

4) Do not disassemble the laser unit. Do not insert a reflective

material such as a screwdriver in the laser beam path.

It may damage eyes by reflection of laser beams.

5) When servicing with the machine operating, be careful not to

squeeze you hands by the chain, the belt, the gear, and other

driving sections.

6) Do not leave the machine with the cabinet disassembled.

Do not allow any person other than a serviceman to touch

inside the machine. It may cause an electric shock, a burn, or

an injury.

7) When servicing, do not breathe toner, developer, and ink

excessively. Do not get them in the eyes.

If toner, developer, or ink enters your eyes, wash it away with

water immediately, and consult a doctor if necessary.

8) The machine has got sharp edges inside. Be careful not to

damage fingers when servicing.

9) Do not throw toner or a toner cartridge in a fire. Otherwise,

toner may pop and burn you.

10) When replacing the lithium battery of the PWB, use a specified

one only.

If a battery of different specification is used, it may be broken,

causing breakdown or malfunction of the machine.

11) When carrying a unit with PWB or electronic parts installed to

it, be sure to put it in an anti-static-electricity bag.

It may cause a breakdown or malfunctions.

12) When the machine is moved over a bump, hold the grip on the

right side of the machine to lift and cross the bump over.

This is because the casters may be broken for a big bump.

2. Warning for servicing

1) Be sure to connect the power cord only to a power outlet that

meets the specified voltage and current requirements.

Avoid complex wiring, which may lead to a fire or an electric

shock.

It may cause a fire or an electric shock.

2) If there is any abnormality such as a smoke or an abnormal

smell, interrupt the job and disconnect the power plug.

It may cause a fire or an electric shock.

3) Be sure to connect the grounding wire. If an electric leakage

occurs without grounding, a fire or an electric shock may

result.

To protect the machine and the power unit from lightening,

grounding must be made.

4) When connecting the grounding wire, never connect it to the

following points.

It may cause an explosion, a fire or an electric shock.

• Gas tube

• Lightning conductor

• A water pipe or a water faucet, which is not recognized as a

grounding object by the authorities.

• Grounding wire for telephone line

5) Do not damage, break, or work the power cord.

Do not put heavy objects on the power cable. Do not bend it

forcibly or do not pull it extremely.

It may cause a fire or an electric shock.

6) Keep the power cable away from a heat source.

Do not insert the power plug with dust on it into a power outlet.

It may cause a fire or an electric shock.

7) Do not put a receptacle with water in it or a metal piece which

may drop inside the machine.

It may cause a fire or an electric shock.

8) With wet or oily hands, do not touch the power plug, do not

insert the telephone line jack, do not operate the machine, or

do not perform servicing.

It may cause an electric shock.

3. Note for installation site

Do not install the machine at the following sites.

1) Place of high temperature, high humidity, low tempera-

ture, low humidity, place under an extreme change in tem-

perature and humidity.

Paper may get damp and form dews inside the machine, caus-

ing paper jam or copy dirt.

For operating and storing conditions, refer to the specifications

described later.

2) Place of much vibrations

It may cause a breakdown.

3) Poorly ventilated place

An electrostatic type copier will produce ozone inside it.

The quantity of ozone produced is designed to a low level so

as not to affect human bodies. However, continuous use of

such a machine may produce a smell of ozone. Install the

machine in a well ventilated place, and ventilate occasionally.

CAUTION

DOUBLE POLE/NEUTRAL FUSING

(200V series only)

MX-M753N NOTE FOR SERVICING - ii

4) Place of direct sunlight.

Plastic parts and ink may be deformed, discolored, or may

undergo qualitative change.

It may cause a breakdown or copy dirt.

5) Place which is full of organic gases such as ammonium

The organic photo-conductor (OPC) drum used in the machine

may undergo qualitative change due to organic gases such as

ammonium.

Installation of this machine near a diazo-type copier may result

in dirt copy.

6) Place of much dust

When dusts enter the machine, it may cause a breakdown or

copy dirt.

7) Place near a wall

Some machine require intake and exhaust of air.

If intake and exhaust of air are not properly performed, copy

dirt or a breakdown may be resulted.

8) Unstable or slant surface

If the machine drops or fall down, it may cause an injury or a

breakdown.

If there are optional paper desk and the copier desk specified,

it is recommendable to use them.

When using the optional desk, be sure to fix the adjuster and

lock the casters.

4. Note for handling PWB and electronic

parts

When handling the PWB and the electronic parts, be sure to

observe the following precautions in order to prevent against dam-

age by static electricity.

1) When in transit or storing, put the parts in an anti-static bag or

an anti-static case and do not touch them with bare hands.

2) When and after removing the parts from an anti-static bag

(case), use an earth band as shown below:

• Put an earth band to your arm, and connect it to the

machine.

• When repairing or replacing an electronic part, perform the

procedure on an anti-static mat.

17-23/32"

(45cm)

11-13/16"

(30cm)

11-13/16"

(30cm)

MX-M753N NOTE FOR SERVICING - iii

5. Note for repairing/replacing the LSU

When repairing or replacing, be sure to observe the following

items.

1) When repairing or replacing the LSU, be sure to disconnect

the power plug from the power outlet.

2) When repairing or replacing the LSU, follow the procedures

described in this Service Manual.

3) When checking the operations after repairing the LSU, keep all

the parts including the cover installed and perform the opera-

tion check.

4) Do not modify the LSU.

5) When visually checking the inside of the machine for the oper-

ation check, be careful not to allow laser beams to enter the

eyes.

If the above precaution is neglected or an undesignated work is

performed, safety may not be assured.

6. Note for handling the drum unit, the

transfer unit, the developing unit, and the

fusing unit

When handling the OPC drum unit, the transfer unit, and the devel-

oping unit, strictly observe the following items.

If these items are neglected, a trouble may be generated in the

copy and print image quality.

(Drum unit)

1) Avoid working at a place with strong lights.

2) Do not expose the OPC drum to lights including interior lights

for a long time.

3) When the OPC drum is removed from the machine, cover it

with light blocking material. (When using paper, use about 10

sheets of paper to cover it.)

4) Be careful not to attach fingerprints, oil, grease, or other for-

eign material on the OPC drum surface.

(Transfer unit)

1) Be careful not to attach fingerprints, oil, grease, or other for-

eign material on the transfer roller.

(Developing unit)

1) Be careful not to attach fingerprints, oil, grease, or other for-

eign material on the developing unit.

(Fusing unit)

1) Be careful not to put fingerprints, oil, grease, or other foreign

material on the fusing roller and the external heating belt.

2) Do not leave the fusing roller in contact state for a long time.

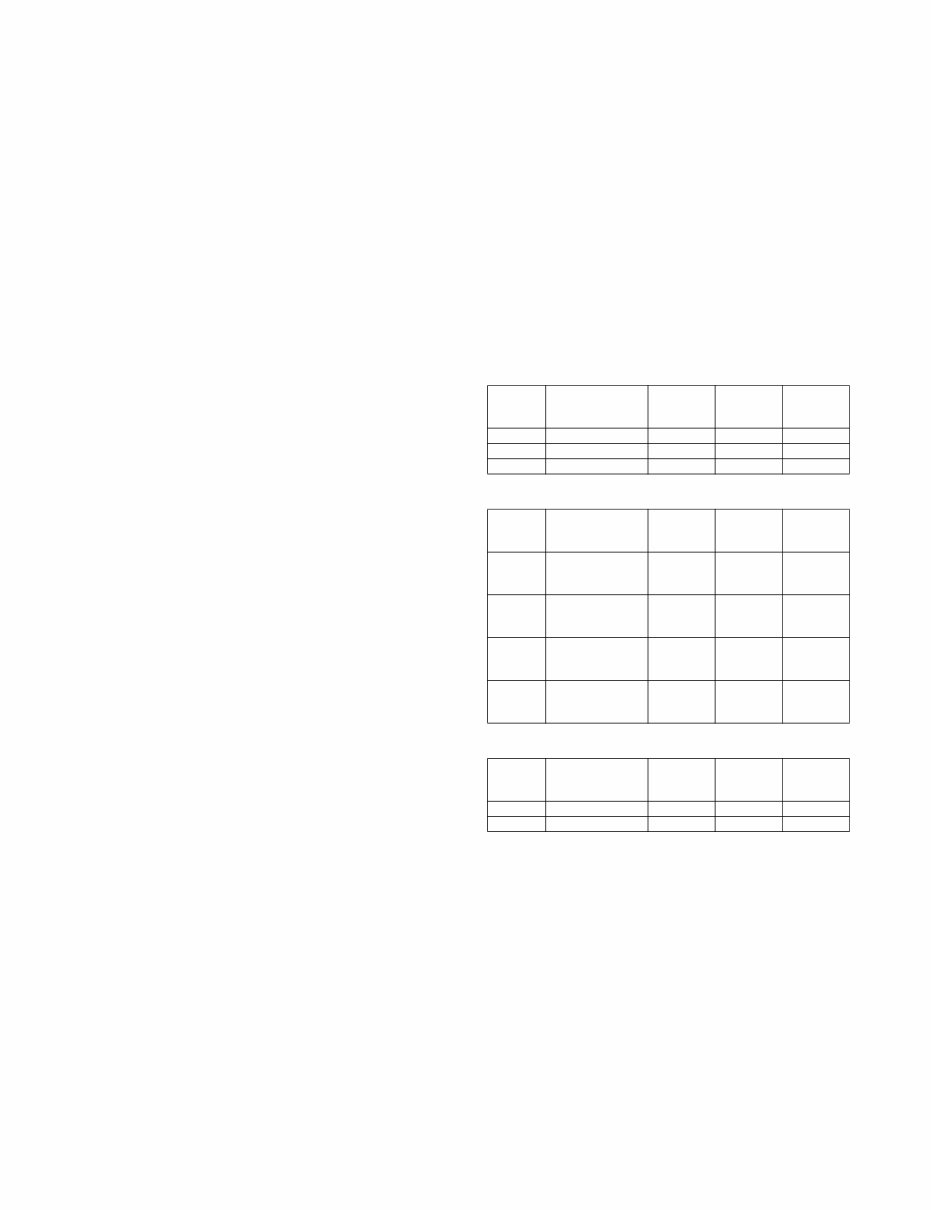

7. Screw tightening torque

The screws used in this machine are largely classified into three

kinds.

These kinds are classified according to the shape of the screw

grooves and use positions.

The table below shows the kinds of the screws and the tightening

torques depending on the use position.

When tightening the screws for repair or maintenance, refer to the

table.

However, for the other conditions of tightening screws than speci-

fied on this table, or when a special care is required, the details are

described on the separate page. Refer to the descriptions on such

a case.

NOTE: Especially for the screw fixing positions where there is an

electrode or a current flows, use enough care to tighten

securely to avoid loosening.

Screw kinds and tightening torques

Normal screws, set screws (including step screws)

Tapping screws (for iron)

Tapping screw (for plastic)

Screw

diameter

Material to be

fixed

Tightening

torque

(Nm)

Tightening

torque

(kgfcm)

Tightening

torque

(lbft)

M2.6 Steel plate 0.8 - 1.0 8 - 10 0.6 - 0.7

M3 Steel plate 1.0 - 1.2 10 - 12 0.7 - 0.9

M4 Steel plate 1.6 - 1.8 16 - 18 1.2 - 1.3

Screw

diameter

Material to be

fixed

Tightening

torque

(Nm)

Tightening

torque

(kgfcm)

Tightening

torque

(lbft)

M3 Steel plate

(Plate thickness

0.8mm or above)

1.0 - 1.2 10 - 12 0.7 - 0.9

M4 Steel plate

(Plate thickness

0.8mm or above)

1.6 - 1.8 16 - 18 1.2 - 1.3

M3 Steel plate

(Plate thickness

less than 0.8mm)

0.6 - 0.8 6 - 8 0.4 - 0.6

M4 Steel plate

(Plate thickness

less than 0.8mm)

1.2 - 1.4 12 - 14 0.9 - 1.0

Screw

diameter

Material to be

fixed

Tightening

torque

(Nm)

Tightening

torque

(kgfcm)

Tightening

torque

(lbft)

M3 Plastic resin 0.6 - 0.8 6 - 8 0.4 - 0.6

M4 Plastic resin 1.0 - 1.2 10 - 12 0.7 - 0.9

MX-M753N PRODUCT OUTLINE 1 – 1

MX-M753N

Service Manual [1] PRODUCT OUTLINE

1. System configuration

2. Machine configuration

STD: Standard provision. OPT: Option

OPT*1: Product key target.

MX-M623N/M753N MX-M623U/M753U

Copier STD STD

PCL printer STD OPT*

1

PS printer OPT*

1

OPT*

1

Main body LCD COLOR WVGA 8.5" COLOR WVGA 8.5"

FAX OPT OPT

Scanner STD OPT*

1

Filing (Print hold function) STD STD

HDD STD STD

DSPF STD STD

Automatic duplex STD STD

Security OPT*

1

OPT*

1

Internet Fax OPT*

1

OPT*

1

MX-FN16

SADDLE STITCH FINISHER

SF-SC11

STAPLE CARTRIDGE

AR-SC3

STAPLE CARTRIDGE

AR-PN4A/B/C/D

PUNCH MODULE

MX-PN10A/B/C/D

PUNCH MODULE

MX-SC10

STAPLE CARTRIDGE

MX-FN15

FINISHER

MX-FN14

FINISHER

MX-CF10

INSERTER

MX-LC10

LARGE CAPACITY TRAY

MX-LCX3N

LARGE CAPACITY TRAY

MX-M623N/M753N

MX-M623U/M753U

DIGITAL MULTIFUNCTIONAL

SYSTEM

MX-M753N PRODUCT OUTLINE 1 – 2

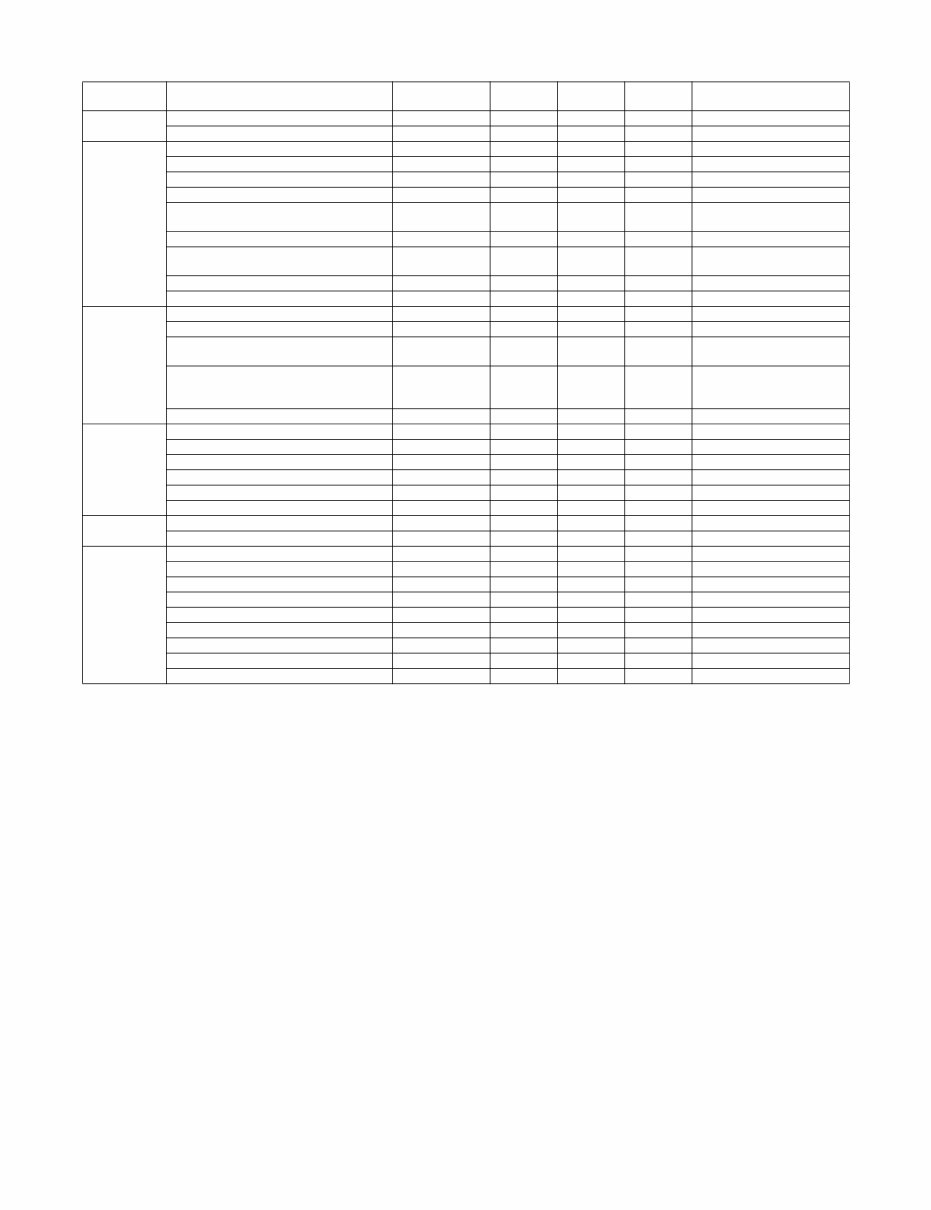

3. Combination of options

STD: Standard provision. : Installable. *1: The printer expansion kit is required. *2: No support for some destinations.

*3: The SharpOSA Utility CD-ROM is not provided. *4: Standard for North America.

Section Name Model name

MX-M623N

MX-M753N

MX-M623U

MX-M753U

Product

key target

Remarks

Paper feed

system

LARGE CAPACITY TRAY MX-LC10

LARGE CAPACITY TRAY MX-LCX3N

Paper exit

system

INSERTER MX-CF10

FINISHER MX-FN15

SADDLE STITCH FINISHER MX-FN16

FINISHER MX-FN14 100 sheets staple

PUNCH MODULE AR-PN4A/B/C/D For finisher and saddle stitch

finisher

PUNCH MODULE MX-PN10A/B/C/D For 100 sheets staple finisher

STAPLE CARTRIDGE SF-SC11 For Finisher and

Saddle Finisher

STAPLE CARTRIDGE AR-SC3 For saddle

STAPLE CARTRIDGE MX-SC10 For 100 sheets staple finisher

Printer

expansion

PRINTER EXPANSION KIT MX-PB13 STD

PS3 EXPANSION KIT MX-PKX1

XPS EXPANSION KIT MX-PUX1 *

1

The expansion memory board

is required.

EXPANSION MEMORY BOARD MX-SMX3 1GB

Required when the XPS

expansion kit is used.

BARCODE FONT KIT AR-PF1

Image send

expansion

FACSIMILE EXPANSION KIT MX-FXX2 *

2

*

2

STAMP UNIT AR-SU1 *

2

*

2

STAMP CARTRIDGE AR-SV1 *

2

*

2

INTERNET FAX EXPANSION KIT MX-FWX1

NETWORK SCANNER EXPANSION KIT MX-NSX1 STD

ENHANCED COMPRESSION KIT MX-EBX3

Authentication/

Security

DATA SECURITY KIT MX-FR22U Commercial version

DATA SECURITY KIT MX-FR22 Authentication version

Application/

Solution

SHARPDESK 1 LICENSE KIT MX-USX1

SHARPDESK 5 LICENSE KIT MX-USX5

SHARPDESK 10 LICENSE KIT MX-US10

SHARPDESK 50 LICENSE KIT MX-US50

SHARPDESK 100 LICENSE KIT MX-USA0

APPLICATION INTEGRATION MODULE MX-AMX1

APPLICATION COMMUNICATION MODULE MX-AMX2 STD*

3

/

EXTERNAL ACCOUNT MODULE MX-AMX3 STD*

3

/

KEYBOARD MX-KBX2 STD/*

4

MX-M753N SPECIFICATIONS 2 – 1

MX-M753N

Service Manual [2] SPECIFICATIONS

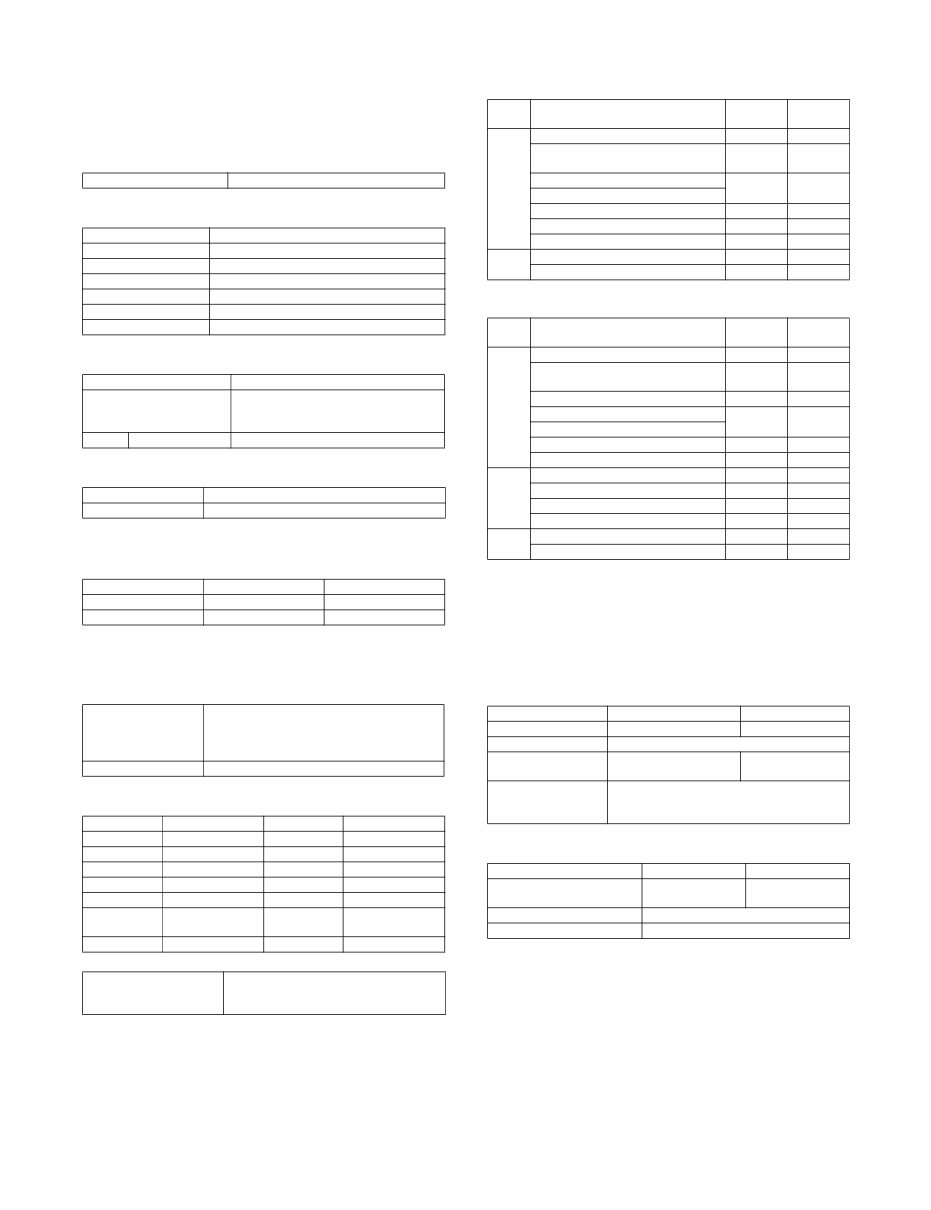

1. Basic specifications

A. Base engine

(1) Type

(2) Engine composition

(3) Dimension / Weight

(4) Warm-up

* It may differ depending on the machine conditions.

(5) First copy time

* It may differ depending on the environment.

* Measuring conditions: A4 (8.5" x 11")

(6) Engine resolution

(7) Printable area

(8) Engine speed (ppm)

a. Tray (1-4, LCC)

b. Manual paper feed tray

*1: Switched by the service simulation setting. Postcard is set Low

before shipment.

*2: After completion of discharge of paper outside of the machine,

the next paper is fed. (The values are reference values.)

(9) Power source

NOTE: Check the shape of the power plug of the machine, and

insert it into a power outlet of the acceptable shape.

(10) Power consumption

*1: When the power supply is turned on, when the dehumidification

heater is OFF.

Type Desktop

Photo-conductor kind OPC (Drum diameter: 80mm)

Copying method Electronic photo (Laser)

Developing system Dry, 2-component magnetic brush development

Charging system Charged saw-tooth method

Transfer system Transfer belt

Cleaning system Counter blade

Fusing system Heat roller

Outer dimension (W x D x H) 728 x 683 x 1213mm

Machine dimension with the

bypass tray extended

(W x D).

1026 x 683mm

Weight Main unit Approx. 190kg

Warm-up time 30 seconds or less

Pre-heat Yes

Engine 62 CPM model 75 CPM model

Platen 4.0 second 3.5 second

DSPF 6.4 second 5.9 second

Resolution Writing

Copy: 600 x 600dpi

Print: 600 x 600dpi

1200 x 1200dpi

Gradation Equivalent to 256 gradation

A3 289 x 412mm 11" x "17 271 x 424mm

B4 242 x 356mm 8.5" x "14 208 x 348mm

A4 202 x 289mm 8.5" x "13.5 208 x 335mm

B5 174 x 249mm 8.5" x "13.4 208 x 332mm

A5 140 x 202mm 8.5" x "13 208 x 322mm

Postcard 92 x 140mm 8.5" x "11 208 x 271mm

8K 262 x 382mm Executive

(7.25" x "10.5)

183 x 259mm

16K 187 x 262mm 5.5" x "8.5 132 x 208mm

Void area Image loss Lead edge: 4mm or less

Rear edge: 4 mm or less

FR total: 8mm or less

Paper

type

Paper size

62 CPM

model

75 CPM

model

Plain

paper

A3, 11" x 17", 8K 34 39

B4, 8.5" x 14", 8.5" x 13", 8.5" x 13.4",

8.5" x 13.5"

39 45

A4R, 8.5" x 11"R, 16KR 45 48

B5R, 7.25" x 10.5"R

A5R, 5.5" x 8.5"R 45 48

A4, B5, 8.5" x 11", 16K 62 75

Extra 34 39

Heavy

paper

A4, B5, 8.5" x 11", 16K (Tray 3, 4) 43 43

Extra (Tray 4) 22 22

Paper

type

Paper size

62 CPM

model

75 CPM

model

Plain

paper

A3, 11" x 17", 8K 34 39

B4, 8.5" x 14", 8.5" x 13", 8.5" x 13.4",

8.5" x 13.5"

39 45

A4, 8.5" x 11", 16K, B5 62 75

B5R, 7.25" x 10.5"R 45 48

A4R, 16KR, 8.5" x 11"R

A5R, 5.5" x 8.5"R 45 48

Extra 34 39

Heavy

paper

A4, 8.5" x 11", 16K, B5 43 43

Extra 22 22

Postcard HIGH *

1

32 32

Postcard LOW *

2

21 21

OHP A4, 8.5" x 11" 43 43

A4R, 8.5" x 11"R 31 31

100V series 200V series

Voltage / Current 100 - 127V 16A USA:20A 220 - 240V 8A

Frequency 50/60Hz

Power source code Fixed type

(Direct connection)

Inlet

Power switch 2 switches

(Primary switch: in the front cover; Secondary

switch: the operation panel)

100V series 200V series

Max. Rated Power

Consumption *1

1.8kW 1.84kW

Moving time to Pre-heat mode 1 minutes (default)

Moving time to Sleep mode 1 minutes (default)

MX-M753N SPECIFICATIONS 2 – 2

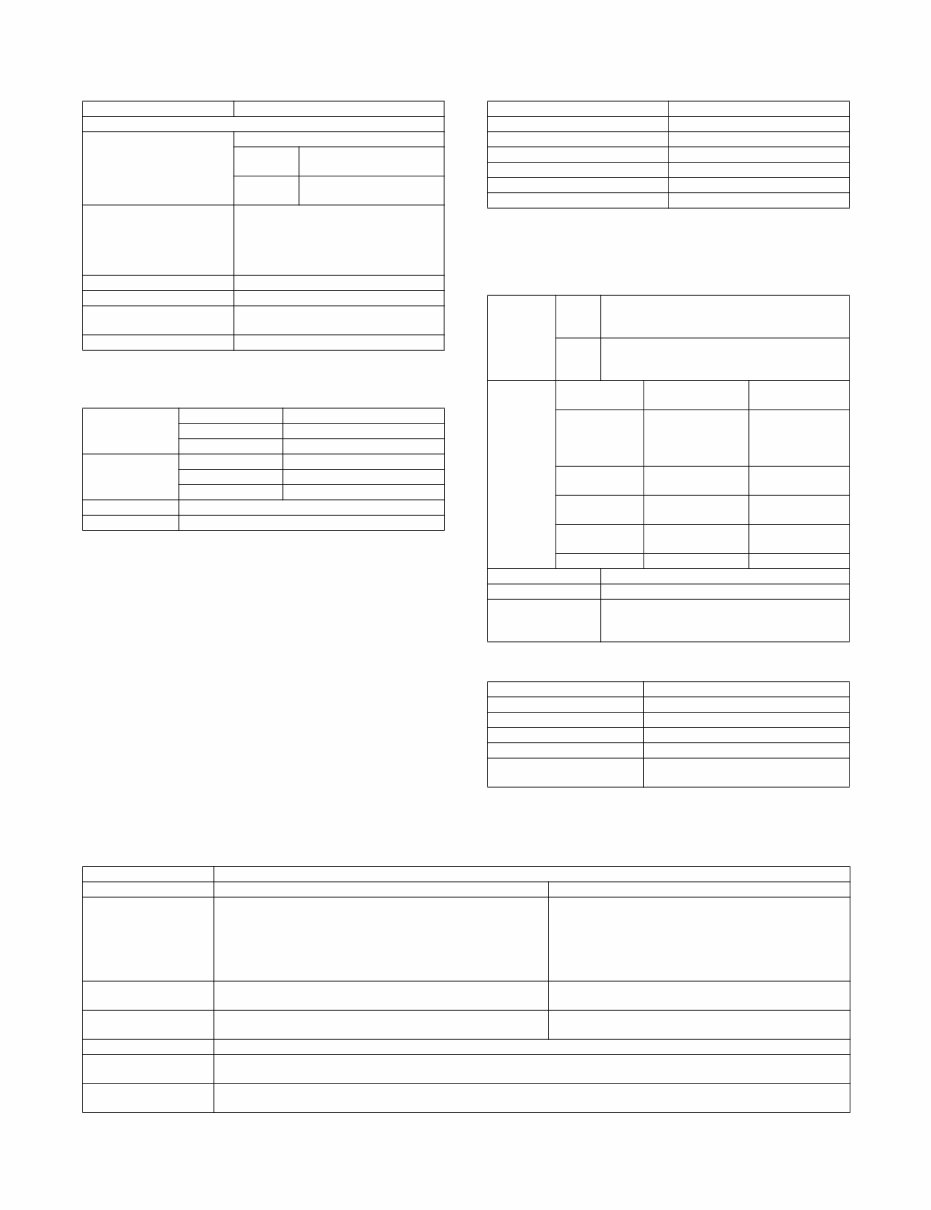

B. Controller board

(1) Controller board

(2) Memory, hard disk

Memory capacity, HDD capacity

*1: The HDD capacity may vary depending on the production date.

C. Operation panel

(1) Display device

D. Scanner section

(1) Resolution/Gradation

(2) Document table

(3) Automatic document feeder

CPU Power QUICC III-MPC8533E (800MHz)

Interface

Ethernet 1 port

Interface 10Base-T, 100Base-TX,

1000Base-T

Support

Protocol

TCP/IP (IPv4, IPv6), IPX/

SPX, NetBEUI, EtherTalk

USB 2.0 (Host)

* Simultaneous connection

is inhibited. The total

current consumption must

not exceed 500mA.

The ports on the front and on the side of

the rear section cannot be used

simultaneously. (Exclusive use)

USB 2.0 (high speed) Device 1 port

Scanner expansion I/F Yes

Memory Refer to the section on “(2) Memory, hard

disk”.

Memory slot 2 slots (one is empty slot)

Copier memory

(Local Memory)

Standard Memory 512MB

Expansion Memory No

Max. 512MB

Printer memory

(System Memory)

Standard Memory 1GB

Expansion Memory 1GB

Max. 2GB

Codec memory 256MB

HDD *

4

80GB *

1

Size/resolution 8.5inch WVGA

Type Dot matrix LCD, touch panel

Display dot number 800 x 480 (WVGA)

Color Color

LCD drive display area (W x D) 184.8 x 110.88mm

LCD back-light Fluorescent lamp back-light system

LCD brightness adjustment Yes

Scanning

Resolution

(dpi)

Platen 600 x 600 dpi

600 x 400 dpi

600 x 300 dpi (Default)

DSPF 600 x 600 dpi

600 x 400 dpi

600 x 300 dpi (Default)

In sending

Resolution

(dpi)

Scanner

Internet Fax /

Direct SMTP

Fax

100dpi x 100dpi

200dpi x 100dpi

(halftone not

allowed)

Standard

(203.2 x 97.8 dpi)

(halftone not

allowed)

200dpi x 200dpi 200dpi x 200dpi

Fine

(203.2 x 195.6 dpi)

300dpi x 300dpi 200dpi x 400dpi

Super Fine

(203.2 x 391 dpi)

400dpi x 400dpi 400dpi x 400dpi

Ultra Fine

(406.4 x 391 dpi)

600dpi x 600dpi 600dpi x 600dpi ---

Exposure lamp Xenon

Reading gradation 10bits

Output gradation B/W: 1bit

Grayscale: 8bit

Full color: RGB colors are 8bit each

Type Document table fixed system (Flat bed)

Scanning area 297 x 432mm

Original standard position Left bottom reference

Detection Yes

Detection size Automatic detection

Dehumidifying heater

(Scanner section)

Supplied as a service part

Type DSPF (Duplex single pass feeder)

Scan speed Monochrome (A4 / 8.5" x 11") Color (A4 / 8.5" x 11") only

Copy Single: 75-sheet/min. (600 x 300 dpi)

53-sheet/min. (600 x 400 dpi)

41-sheet/min. (600 x 600 dpi)

Duplex: 75-page/min. (600 x 300 dpi)

53-page/min. (600 x 400 dpi)

41-page/min. (600 x 600 dpi)

N/A

Fax / Internet Fax Single: 75-sheet/min. (200 x 200 dpi)

Duplex: 75-page/min. (200 x 200 dpi)

N/A

Scanner Single: 75-sheet/min. (200 x 200 dpi)

Duplex: 75-page/min. (200 x 200 dpi)

Single: 75-sheet/min. (200 x 200 dpi, 8 bit)

Duplex: 75-page/min. (200 x 200 dpi, 8 bit)

Original setup direction Upward standard (1 to N feeding standard)

Original standard

position

Center standard (Rear one-side standard for random feeding)

Face Up (1 to N Feeding standard)

Original transport

method

Sheet-through method

MX-M753N SPECIFICATIONS 2 – 3

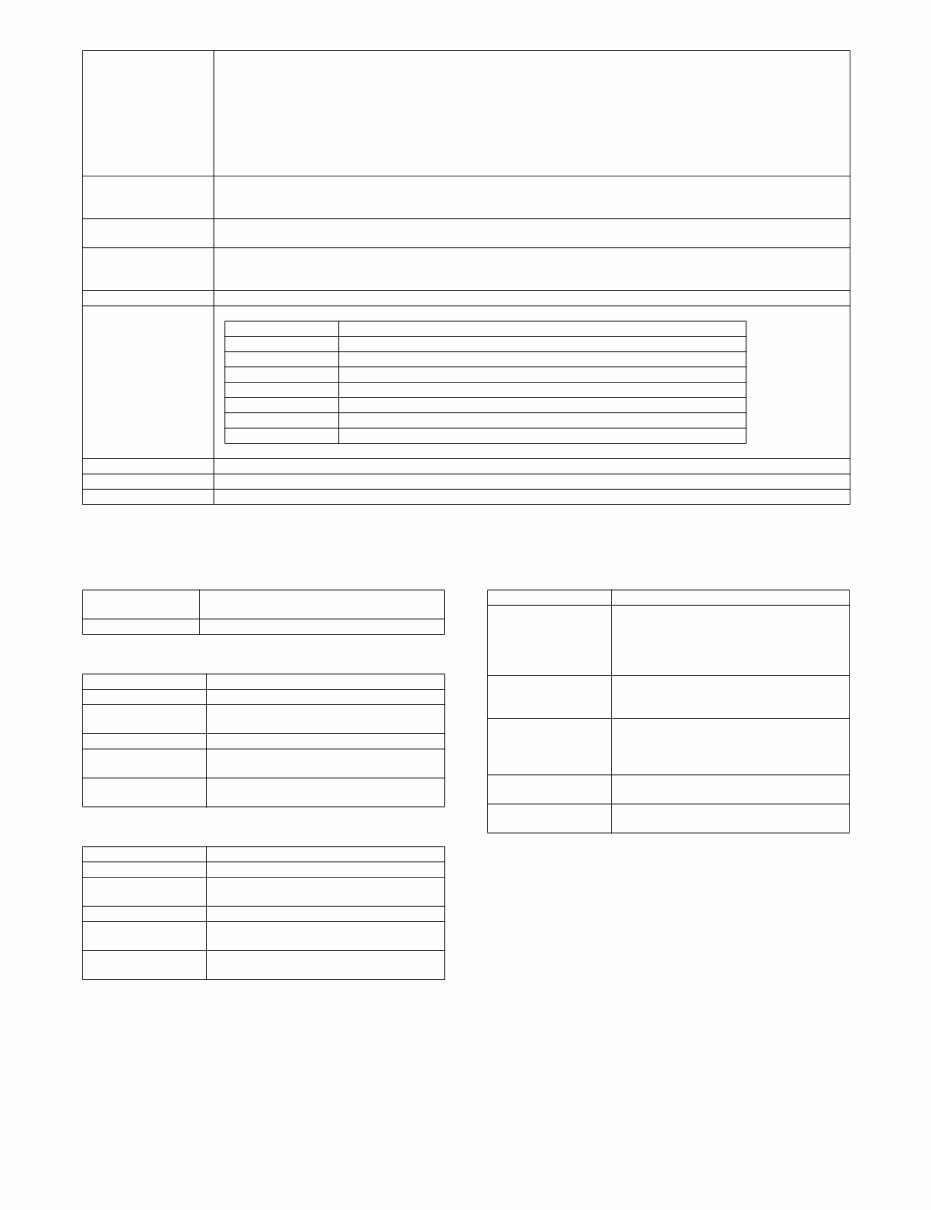

E. Paper feed section

(1) Type

(2) Tray 1 (Main unit: LCC left tray)

(3) Tray 2 (Main unit: LCC right tray)

(4) Tray 3 (Main unit: multi-purpose tray)

*1: 8.5" x 11", A4, B5 only

*2: 8.5" x 11", A4 only

Original size Standard size: (Refer to the "paper detection size")

Long paper: 1000 mm (Monochrome binary only)

Internet Fax 600 x 600 dpi: Max. 800 mm. When scan 400 dpi or more, long paper is not available.

Mix paper feed (Same series, same width paper) enabled

Random paper feed combination

Mix feeding available. (same system, same width)

Random feeding (feeding of different types / different widths)

Only the following combinations of 2 size types are allowed:

either A3 or A4 and either B4 or B5; either B4 or B5 and either A4R or A5 and 11-inch and 8.5-inch. AMS available.

Original copy weight Single: (Thin paper) 9 - 13 lb bond (35 - 49 g/m

2

), (plain paper) 13 - 34 lb bond (50 - 128 g/m

2

)

* Thin paper mode (36 pages/minute (A4, 8.5" x 11", 600dpi)) is set up for the thin paper.

Duplex: 13 - 28 lb bond (50 - 34 g/m

2

)

Max. loading capacity of

documents

Max. 150 sheets (21lbs Bond, 80g/m

2

), or Max. height: 1/2 inch, 19.5mm or less

Un-acceptable originals

for feeding.

OHP, second original paper, tracing paper, carbon paper, thermal paper, paper with wrinkles, folds, or breakage, pasted paper, cutout

document, document printed with ink ribbon, documents with perforation other than 2- or 3-holes (Perforated document by punch unit

is allowed.)

Detection Yes

Paper detection size

(DSPF)

Auto detection (Switching one type of detection unit)

Inch-1 11" x 17", 8.5" x 14", 8.5" x 11", 8.5" x 11"R, 5.5" x 8.5", A3, A4

Inch-2 11" x 17", 8.5" x 13", 8.5" x 11", 8.5" x 11"R, 5.5" x 8.5", A3, A4

Inch-3 11" x 17", 8.5" x 13.4", 8.5" x 11", 8.5" x 11"R, 5.5" x 8.5", A3, A4

AB-1 A3, B4, A4, A4R, B5, B5R, A5, 11" x 17", 8.5" x 14", 8.5" x 11"

AB-2 A3, B4, A4, A4R, B5, B5R, A5, 11" x 17", 8.5" x 13", 8.5" x 11"

AB-3 8K, 16K, 16KR, A3, B4, A4, A4R, A5, 11" x 17", 8.5" x 13", 8.5" x 11"

AB-4 A3, B4, A4, A4R, B5, B5R, A5, 11" x 17", 8.5" x 13.4", 8.5" x 11"

AB-5 A3, B4, A4, A4R, B5, B5R, A5, 11" x 17", 8.5" x 13.5", 8.5" x 11"

* 5.5" x 8.5"R, A5R cannot be detected.

Paper feeding direction Right hand feeding

Finish stamp Option

Power source Provided from main unit

Type 4-stage paper feed tray

(Parallel LCC + 2 tray + Multi manual paper feed)

Dehumidifying heater Service parts (Supported by kit)

Paper capacity Plain paper: 800 sheets (80 g/m

2

)

Paper size 8.5" x 11", A4

Paper type Plain paper, printed paper, recycled paper,

letter head, punched paper, colored paper

Feedable paper weight Plain paper: 16 - 28 lb bond (60 - 105g/m

2

)

Paper size setting

when shipping

AB series: A4

Inch series: 8.5" x 11"

Paper remaining

detection

Yes (Paper empty and 3 levels)

Paper capacity Plain paper: 1200 sheets (80 g/m

2

)

Paper size A4, 8.5" x 11", B5 (Setting by parts)

Paper type Plain paper, printed paper, recycled paper,

letter head, punched paper, colored paper

Feedable paper weight Plain paper: 16 - 28 lb bond (60 - 105g/m

2

)

Paper size setting

when shipping

AB series; A4

Inch series; 8.5" x 11"

Paper remaining

detection

Yes (Paper empty and 3 levels)

Paper capacity Plain paper: 500 sheets (80 g/m

2

)

Paper size A3, B4, A4, A4R, B5, B5R, A5R

11" x 17", 8.5" x 14" (216 x 356),

8.5" x 13.5 (216 x 343), 8.5" x 13.4" (216 x 340),

8.5" x 13" (216 x 330), 8.5" x 11", 8.5" x 11"R,

7.25" x 10.5"R, 5.5" x 8.5"R, 8K, 16K, 16KR

Paper type Plain paper, printed paper, recycled paper,

letter head, punched paper, colored paper,

heavy paper*

1

, OHP, label sheet*

1

, tab paper*

2

Feedable paper weight Plain paper:

16 - 28 lb bond (60 - 105g/m

2

)

Heavy paper:

28 lb bond - 110 lb index (106 - 209g/m

2

)

Paper size setting

when shipping

AB series: A3

Inch series: 11" x 17"

Paper remaining

detection

Yes (Paper empty and 3 levels)

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

Viewed 84 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

This manual for the Sharp MX-M623N, MX-M623U, MX-M753N, MX-M753U copier is available in PDF format. It contains detailed diagrams, pictures, and comprehensive procedures for diagnosing and repairing the copier. Whether you are a professional mechanic or a DIY enthusiast, this manual provides valuable information.

You can easily print, zoom, or read any diagram, picture, or page from this Service Manual. Each chapter is fully detailed and includes simulation codes, trouble codes, maintenance procedures, reset procedures, and diagnostic procedures for the Sharp MX-M623N, MX-M623U, MX-M753N, MX-M753U photocopier.

The manual includes the following sections:

- NOTE FOR SERVICING

- Precautions for servicing

- Warning for servicing

- Note for installation site

- Note for handling PWB and electronic parts

- Note for repairing/replacing the LSU

- Note for handling the drum unit, the transfer unit, the developing unit, and the fusing unit

- Screw tightening torque

- PRODUCT OUTLINE

- System configuration

- Machine configuration

- Combination of options

- SPECIFICATIONS

- Basic specifications

- Functional specifications

- CONSUMABLE PARTS

- Supply system table

- Maintenance parts list

- Definition of Developer and Drum life end

- Production number identification

- EXTERNAL VIEW AND INTERNAL STRUCTURE

- Identification of each section and functions

- ADJUSTMENTS AND SETTINGS

- General

- Adjustment item list

- Details of adjustment

- SIMULATION

- General (Including basic operations)

- List of simulation codes

- Details of simulation

- SELF DIAG AND TROUBLE CODE

- Self diag

- Trouble code list

- Details of trouble code

- Paper JAM code

- Necessary works when replacing the PWB and the HDD

- OPERATIONAL DESCRIPTIONS

- Operation panel

- Scanner section

- Manual paper feed section

- Tray paper feed section

- Paper transport section, Duplex section

- LSU section

- Photo-conductor section

- Toner supply section

- Developing section

- Transfer section

- Fusing section

- Paper exit section

- Automatic document feeder

- MAINTENANCE

- Necessary execution items (Before and after maintenance)

- Contents of the maintenance codes and countermeasures (Relationship between various counter values and display messages)

- Maintenance system table

- DISASSEMBLY AND ASSEMBLY

- Exterior

- Operation panel section

- Scanner section

- Manual paper feed section

- Tray paper feed section

- Paper transport and duplex section

- LSU section

- Photo-conductor section

- Toner supply section

- Developing section

- Transfer section

- Fusing section

- Paper exit section

- Drive section

- PWB section

- Fan section

- Filter section

- Automatic document feeder

- Other

- FIRMWARE UPDATE

- Outline

- Update procedure

- ELECTRICAL SECTION

- Block diagram

- Actual wiring chart

- Signal list

- SERVICE WEB PAGE

- General

- Details and operation procedures

Number of pages: 428