Volvo L20B Compact Wheel Loader Service & Repair Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Service Information

Document Title: Function Group: Information Type: Date:

Description 000 Service Information 2014/3/6 0

Profile:

CWL, L20B [GB]

Description

The L20B wheel loader has a central articulating oscillating joint and four-wheel drive. The lifting frame is equipped with a

hydraulic quick-change attachment bracket. Parallel kinematics provide high breakout force and exact parallel guidance

when lifting.

The engine is a four-cylinder, four-stroke, in-line diesel engine with direct injection and oil/air cooling.

The hydrostatic transmission provides full power shift under load, both when changing direction (forward and reverse) and

between ranges. Maximum drawbar force can be achieved in all ranges. The "inch/brake pedal" provides variable machine

speed control and power transfer.

The front and rear axles are planetary rigid axles with 100% hydraulically engagable/disengagable differential locks on both

axles.

The service brake is a drum brake acting on the wheels of the front axle and is operated via the "inch/brake pedal".

The parking brake is a drum brake acting on the wheels of the front axle upon mechanical engagement.

The hydraulic system is a thermostatically regulated oil circuit with integrated cooling system. Three-spool control valve with

primary and secondary fuse protection.

Figure 1

Service Information

Document Title: Function Group: Information Type: Date:

Tightening torques 030 Service Information 2014/3/6 0

Profile:

CWL, L20B, L25B [GB]

Tightening torques

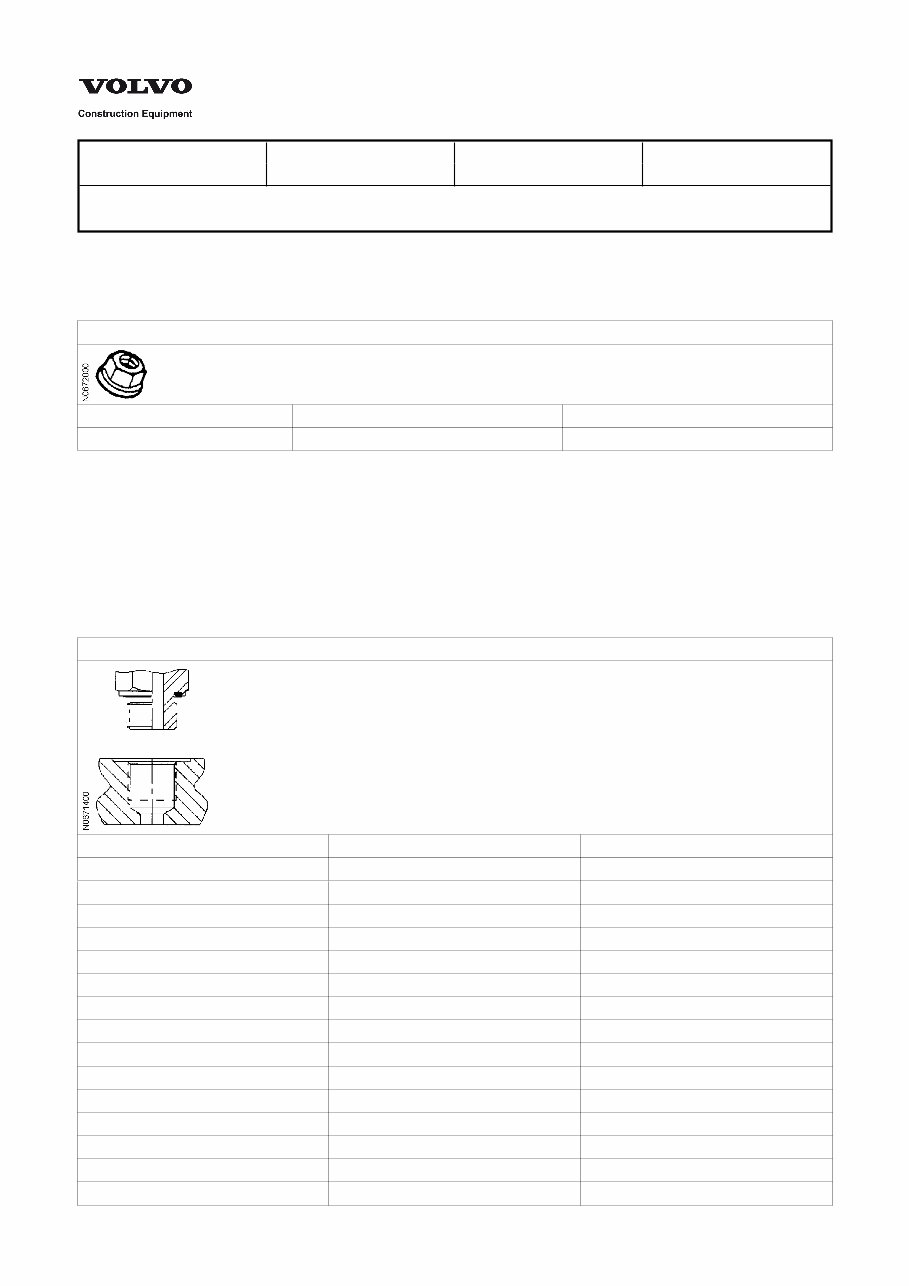

Wheel nuts

Wheel nuts

Thread M Wrench size (width across flats) Tightening torque (Nm)

M22 x 1.5 30 560 – 600

Hydraulic connections, general

Before fitting pipe couplings, plugs and hoses:

Make sure that the sealing surfaces are clean and free from pores or scratches.

Check elastic seal rings for defects.

Oil in threads, sealing surfaces and contact surfaces except for ORFS-connections (ORFS = O-Ring Face Seal).

Valve connections

Valve connections, ORFS-connections with ED seals (DIN 3852 form E)

Connection thread (mm) Wrench size, width across flats (mm) Tightening torque (Nm)

M10 x 1.0 19

M12 x 1.5 17 37

M14 x 1.5 22 58

M16 x 1.5 22 74

M18 x 1.5 24 94

M20 x 1.5 130

M22 x 1.5 27 140

M27 x 2.0 32 190

M33 x 2.0 41 330

M42 x 2.0 50 470

M48 x 2.0 55 570

Connection thread (inches) Wrench size, width across flats (mm) Tightening torque (Nm)

G 1/8 17 alt. 19 19

G 1/4 19 alt. 22 58

G 3/8 22 alt. 27 84

G 1/2 27 alt. 32 120

G 3/4 32 alt. 41 190

G 1 41 alt. 46 330

G 1 1/4 50 470

G 1 1/2 55 570

Valve connections, ORFS-connections with O-ring seals (ISO 6149)

Connection thread (mm) Wrench size, width across flats (mm) Tightening torque (Nm)

M8 x 1.0 11

M10 x 1.0 21

M12 x 1.5 17 alt. 19 37

M14 x 1.5 19 alt. 22 47

M16 x 1.5 22 58

M18 x 1.5 24 alt. 27 74

M22 x 1.5 27 alt. 32 110

M27 x 2.0 32 180

M33 x 2.0 32, 41 alt. 46 330

M42 x 2.0 50 350

M48 x 2.0 55 440

Connection thread (inches) Wrench size, width across flats (mm) Tightening torque (Nm)

7/16 – 20 UNF 16 21

1/2 – 20 UNF 26

9/16 – 18 UNF 19 37

3/4 – 16 UNF 22 74

7/8 – 14 UNF 27 110

1 1/16 – 12 UNF 41 180

1 5/16 – 12 UNF 41 284

1 5/8 – 12 UNF 50 300

1 7/8 – 12 UNF 55 390

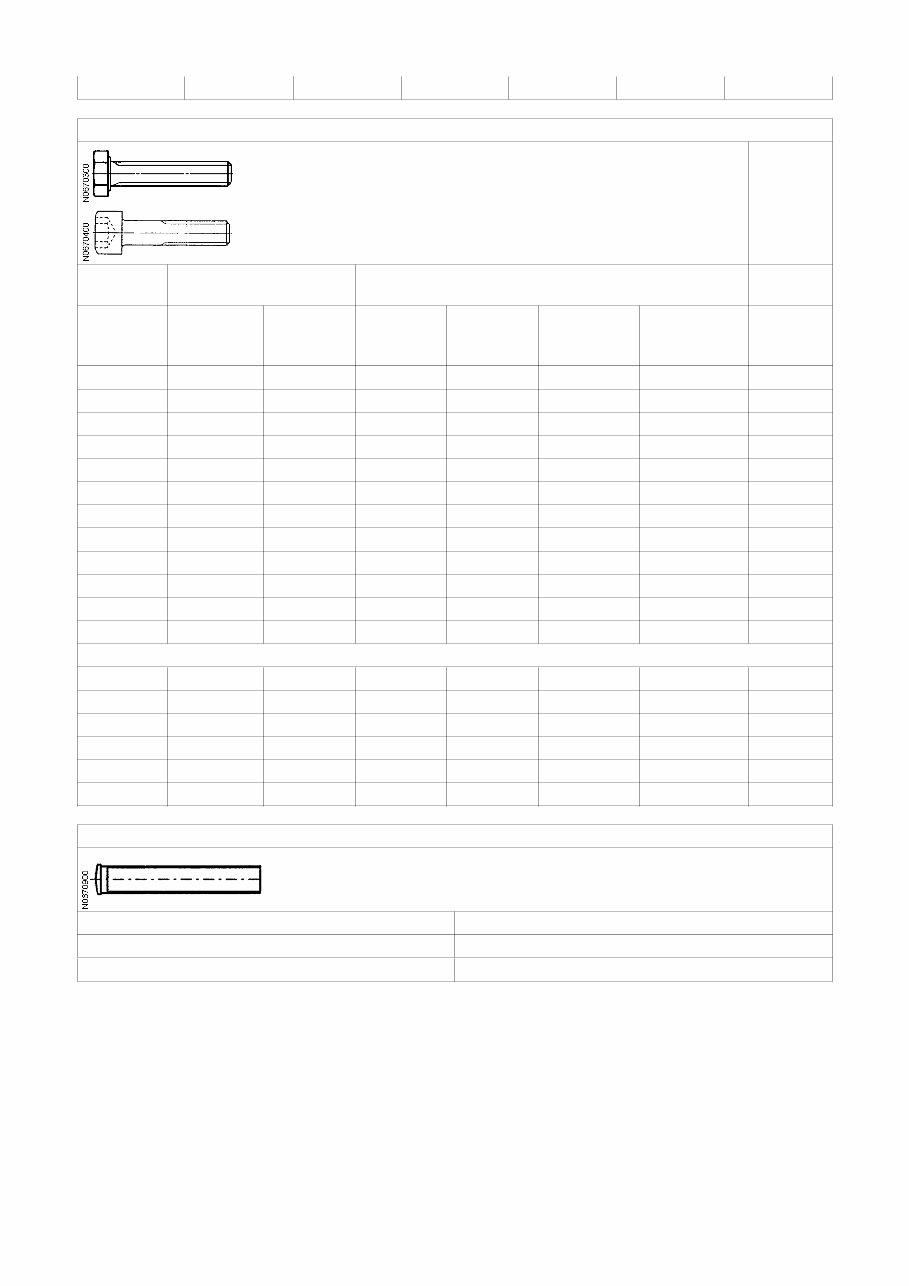

Blanking plugs

Blanking plugs with ED seal

Connection thread (mm) Allen key dim. (mm) Tightening torque (Nm)

M10 x 1.0 5 12

M12 x 1.5 6 25

M14 x 1.5 6 35

M16 x 1.5 8 55

M18 x 1.5 8 65

M20 x 1.5 10 80

M22 x 1.5 10 90

M26 x 1.5 12 100

M27 x 2.0 12 140

M33 x 2.0 17 230

M42 x 2.0 22 360

M48 x 2.0 24 360

Connection thread (inches) Allen key dim. (mm) Tightening torque (Nm)

G 1/8 5 13

G 1/4 6 30

G 3/8 8 60

G 1/2 10 80

G 3/4 12 140

G 1 17 200

G 1 1/4 22 400

G 1 1/2 24 450

Blanking plugs with O-ring seal (ISO 6149)

Connection thread (mm) Allen key dim. (mm) Tightening torque (Nm)

M10 x 1.0 5 20

M12 x 1.5 6 35

M14 x 1.5 6 45

M16 x 1.5 8 55

M18 x 1.5 8 70

M20 x 1.5 10 80

M22 x 1.5 10 100

M26 x 1.5 12 130

M27 x 2.0 12 170

M33 x 2.0 14 310

M42 x 2;0 22 330

ORFS-connections

ORFS-connections (ISO 8434-3)

Thread (inches) Wrench size, width across flats (mm) Tightening torque (Nm) *

9/16 – 18 UNF 17 alt. 19 25

11/16 – 16 UN 22 35

13/16 – 16 UN 24 55

1 – 14 UNS 30 85

1 3/16 – 12 UN 36 120

1 7/16 – 12 UN 41 alt. 46 160

1 11/16 – 12 UN 50 200

2 – 12 UN 60 260

* Threads and sealing surface must not be oiled in before tightening.

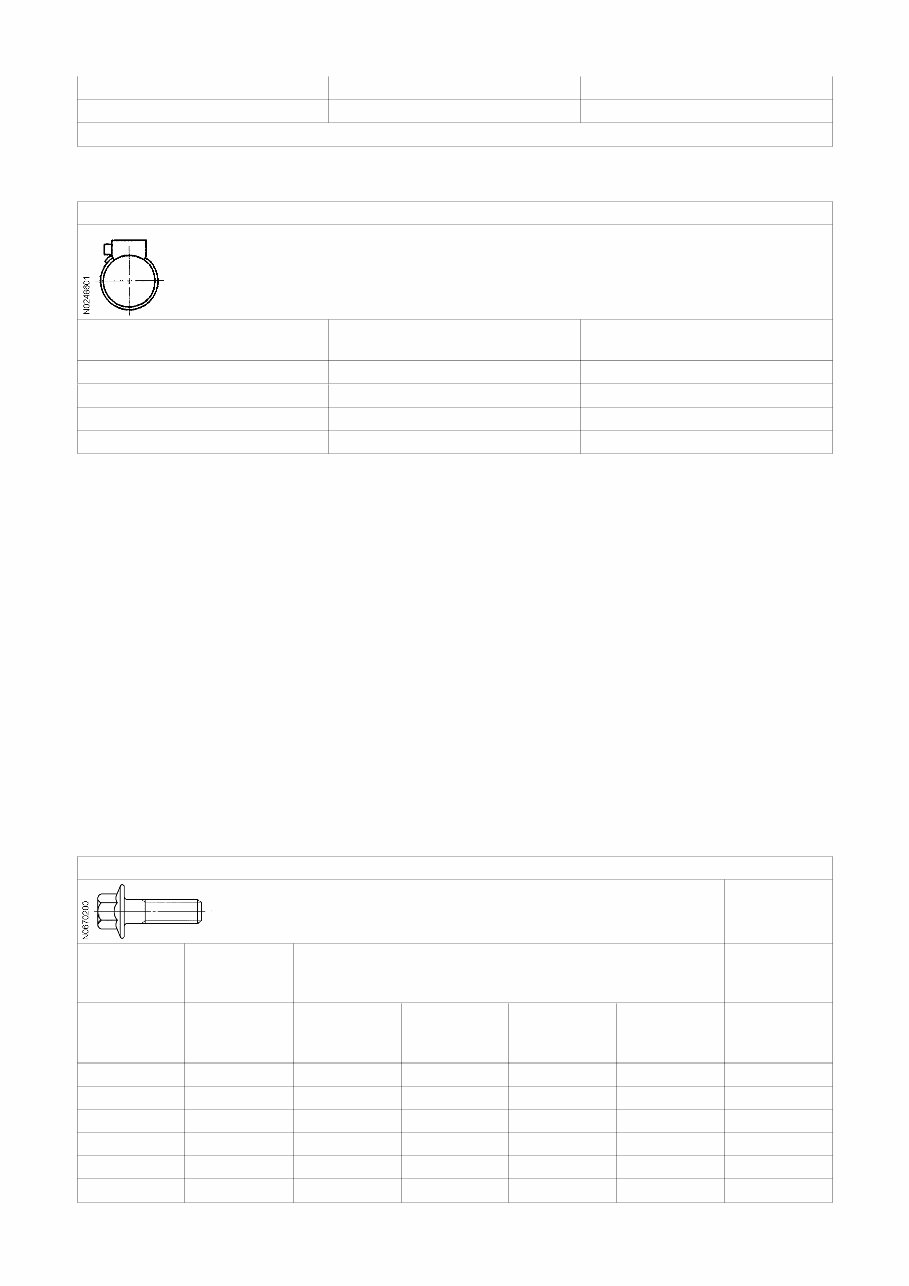

Hose clamps

Hose clamps with worms

Intended for hose outside diameter

(mm)

Wrench size, width across flats (mm) Tightening torque (Nm)

10 – 19 7 2.5

20 – 30 7 3.5

31 – 49 7 4.5

50 – 231 7 5.5

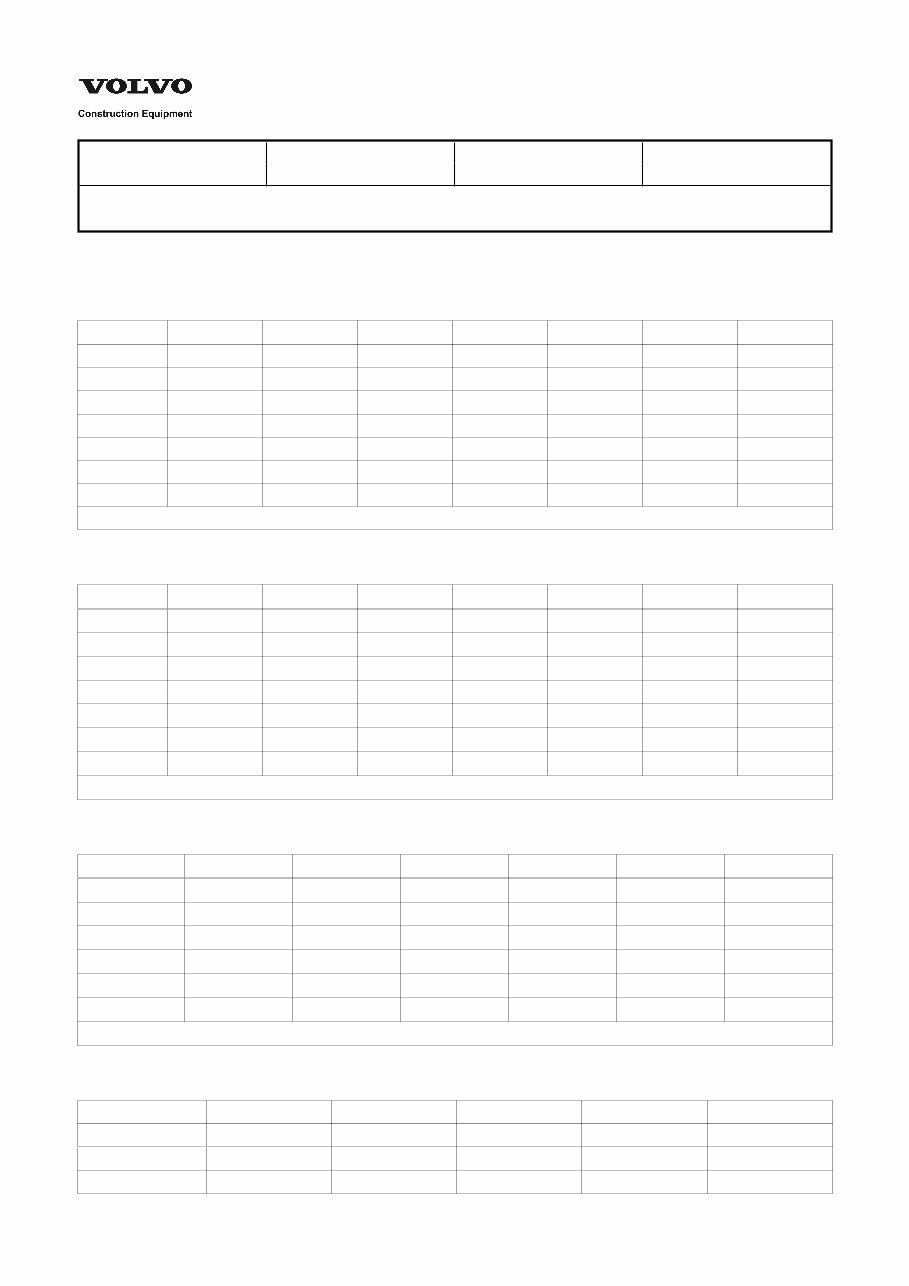

Bolts and nuts

The pretensioning force achieved at a given tightening torque depends on the coefficient of friction of the bolted joint.

The coefficient of friction in turn depends on the surface texture, surface treatment and lubricated condition. The values are

calculated assuming a coefficient of friction of 0.2 for a dry chromated flange bolt and 0.15 for a lubricated chromated

flange bolt. The lower torque for Allen bolts and traditional hex bolts, in relation to flange bolts, is due to the shorter torque

arm for the frictional force under the bolt head (smaller diameter of bolt head).

The following abbreviations for surface treatment are used in the tables:

Fe/Zn-Fe = Black chromated zinc - iron

FZB = Blank chromated

NOTE!

In some body parts, there are weld bolts with much lower strength than normal bolts of the same dimension.

NOTE!

When Nordloc washer is used, increase the torque by 20%.

NOTE!

Bolts provided with liquid alt. micro-capsuled thread locker or thread sealant shall be tightened with the same torque as a

lubricated bolt of the same type.

Flange bolts

Blind rivet nut

Thread (mm) Wrench size,

width across

flats (mm)

Torque (Nm) Torque (Nm)

8.8 Fe/Zn-Fe

Dry

8.8 Fe/Zn-Fe

Lubricated

10.9

Phosphated

10.9

Phosphated

Lubricated

Dry

M5 8 7 6 6

M6 10 12 10 10

M8 12 28 24 24

M10 14 56 48 70 60 48

M12 17 100 85 125 105 82

M14 18 160 140 200 175

M16 21 250 220 320 275

Hex bolts and Allen head bolts

Blind rivet

nut

Wrench size (width across

flats)

Torque (Nm) Torque

(Nm)

Thread

(mm/inch)

Hex bolt

(mm/inch)

Allen head

bolt (mm/

inch)

8.8 FZB &

Fe/Zn-Fe

Dry

8.8 FZB &

Fe/Zn-Fe

Lubricated

10.9

Phosphated

Lubricated

12.9 Untreated

Lubricated

Dry

M5 8 4 6 5 6

M6 10 5 10 9 20 10

M8 13 6 25 22 40 24

M10 16 8 50 44 60 80 48

M12 18 10 90 75 105 140 82

M14 21 12 140 125 175 220

M16 24 14 220 190 275 340

M20 30 17 450 380 540 650

M24 36 19 770 660 900 1 120

M27 41 – 1 100 940 1 350 1 620

M30 46 22 1 500 1 280 1 840 2 210

M36 55 2 500 2 300 3 210 3 850

1/4 UNC 7/16 3/16 12 10 15 20

5/16 UNC 1/2 1/4 25 21 30 40

3/8 UNC 9/16 5/16 45 38 55 70

7/16 UNC 5/8 65 55 90

1/2 UNC 3/4 3/8 100 85 130 170

9/16 UNC 13/16 145 123 190

Nuts on weld bolts (material S235JRG2-EN 10025)

Thread Torque (Nm)

M6 5

M8 12

Tolerances

Modern high-quality torque wrenches normally give a variation of ± 5 % of the indicated value. This, together with variations

in friction coefficient, gives a range in the pretensioning force of approximately ± 16 % for lubricated bolted joints and ± 29

% for dry bolted joints.

Service Information

Document Title: Function Group: Information Type: Date:

Conversion tables 030 Service Information 2014/3/6 0

Profile:

CWL, L20B, L25B [GB]

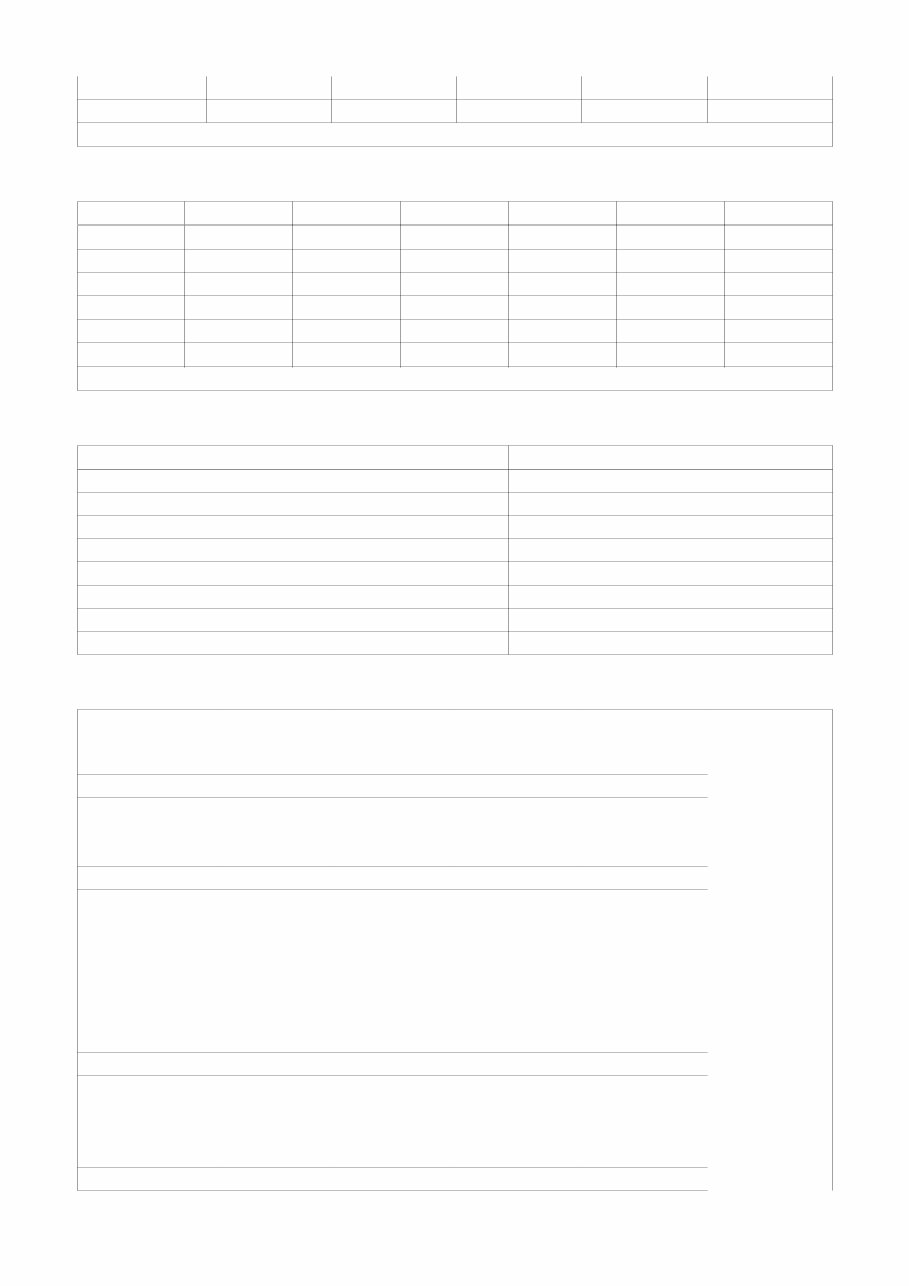

Conversion tables

Length

Unit cm m km in ft yd mile

cm 1 0.01 0.00001 0.3937 0.03281 0.01094 0.000006

m 100 1 0.001 39.37 3.2808 1.0936 0.00062

km 100000 1000 1 39370.7 3280.8 1093.6 0.62137

in 2.54 0.0254 0.000025 1 0.08333 0.02777 0.000015

ft 30.48 0.3048 0.000304 12 1 0.3333 0.000189

yd 91.44 0.9144 0.000914 36 3 1 0.000568

mile 160930 1609.3 1.6093 63360 5280 1760 1

1 mm = 0.1 cm - 1 mm = 0.001 m

Area

Unit cm2 m2 km2 a ft2 yd2 in2

cm2 1 0.0001 - 0.000001 0.001076 0.000012 0.155000

m2 10000 1 0.000001 0.01 10.764 1.1958 1550.000

km2 - 1000000 1 10000 1076400 1195800 -

a 0.01 100 0.0001 1 1076.4 119.58 -

ft2 - 0.092903 - 0.000929 1 0.1111 144.000

yd2 - 0.83613 - 0.008361 9 1 1296.00

in2 6.4516 0.000645 - - 0.006943 0.000771 1

1 ha = 100 a - 1 mile2 = 259 ha = 2.59 km2

Volume

Unit cm3 = cc m3 l in3 ft3 yd3

cm3 = ml 1 0.000001 0.001 0.061024 0.000035 0.000001

m3 1000000 1 1000 61024 35.315 1.30796

dm3(l) 1000 0.001 1 61.024 0.035315 0.001308

in3 16.387 0.000016 0.01638 1 0.000578 0.000021

ft3 28316.8 0.028317 28.317 1728 1 0.03704

yd3 764529.8 0.76453 764.53 46656 27 1

1 gal (US) = 3785.41 cm3 = 231 in3 = 0.83267 gal (UK)

Weight

Unit g kg t oz lb

g 1 0.001 0.000001 0.03527 0.0022

kg 1000 1 0.001 35.273 2.20459

t 1000000 1000 1 35273 2204.59

oz 28.3495 0.02835 0.000028 1 0.0625

lb 453.592 0.45359 0.000454 16 1

1 ton (metric) = 1.1023 ton (US) = 0.9842 ton (UK)

Pressure

Unit kp/cm2 bar Pa=N/m2 kPa lbf/in2 lbf/ft2

kp/cm2 1 0.98067 98066.5 98.0665 14.2233 2048.16

bar 1.01972 1 100000 100 14.5037 2088.6

Pa=N/m2 0.00001 0.001 1 0.001 0.00015 0.02086

kPa 0.01020 0.01 1000 1 0.14504 20.886

lbf/in2 0.07032 0.0689 6894.76 6.89476 1 144

lbf/ft2 0.00047 0.00047 47.88028 0.04788 0.00694 1

kg/cm2 = 735.56 Dry (mmHg) = 0.96784 atm

Unit explanations

Unit abbreviation

Newton meter Nm

Kilopoundmeter kpm

Kilopascal kPa

Megapascal MPa

Kilowatt kW

kilojoule kJ

British thermal unit Btu

Calorie ca

Approx. conversion

SI unit Conversion

factor

Non SI Conversion factor SI

Torque

Nm x10.2 =kg/cm x0.8664 =lb in

Nm x0.74 =lbf·ft x1.36 =Nm

Nm x0.102 =kg/m x7.22 =lbft

Pressure (Pa = N/m2)

kPa x4.0 =in.H2O x0.249 =kPa

kPa x0.30 =in.Hg x3.38 =kPa

kPa x0.145 =psi x6.89 =kPa

bar x14.5 =psi x0.069 =bar

kp/cm2 x14.22 =psi x0.070 =kp/cm2

N/mm2 x145.04 =psi x0.069 =bar

MPa x145 =psi x0.00689 =MPa

Power (W = J/s)

kW x1.36 =hp(cv) x0.736 =kW

kW x1.34 =bhp x0.746 =kW

kW x0.948 =Btu/s x1.055 =kW

W x0.74 =ft·lb/s x1.36 =W

Energy (J = Nm)

kJ x0.948 =Btu x1.055 =kJ

Figure 1

J x0.239 =calorie x4.19 =J

Speed and acceleration

m/s2 x3.28 =ft/s2 x0.305 =m/s2

m/s x3.28 =ft/s x0.305 =m/s

km/h x0.62 =mph x1.61 =km/h

Horsepower/torque

Bhp x5252 rpm= TQ (lb·ft) TQ x rpm 5252=bhp

Temperature

ºC =(ºF-32)/1.8 ºF =(ºC x1.8) +32

Flow factor

l/min (dm3/min) x0.264 = US gal/min x3.785 =liter/min

Service Information

Document Title: Function Group: Information Type: Date:

Machine, transporting 050 Service Information 2014/3/6 0

Profile:

CWL, L20B [GB]

Machine, transporting

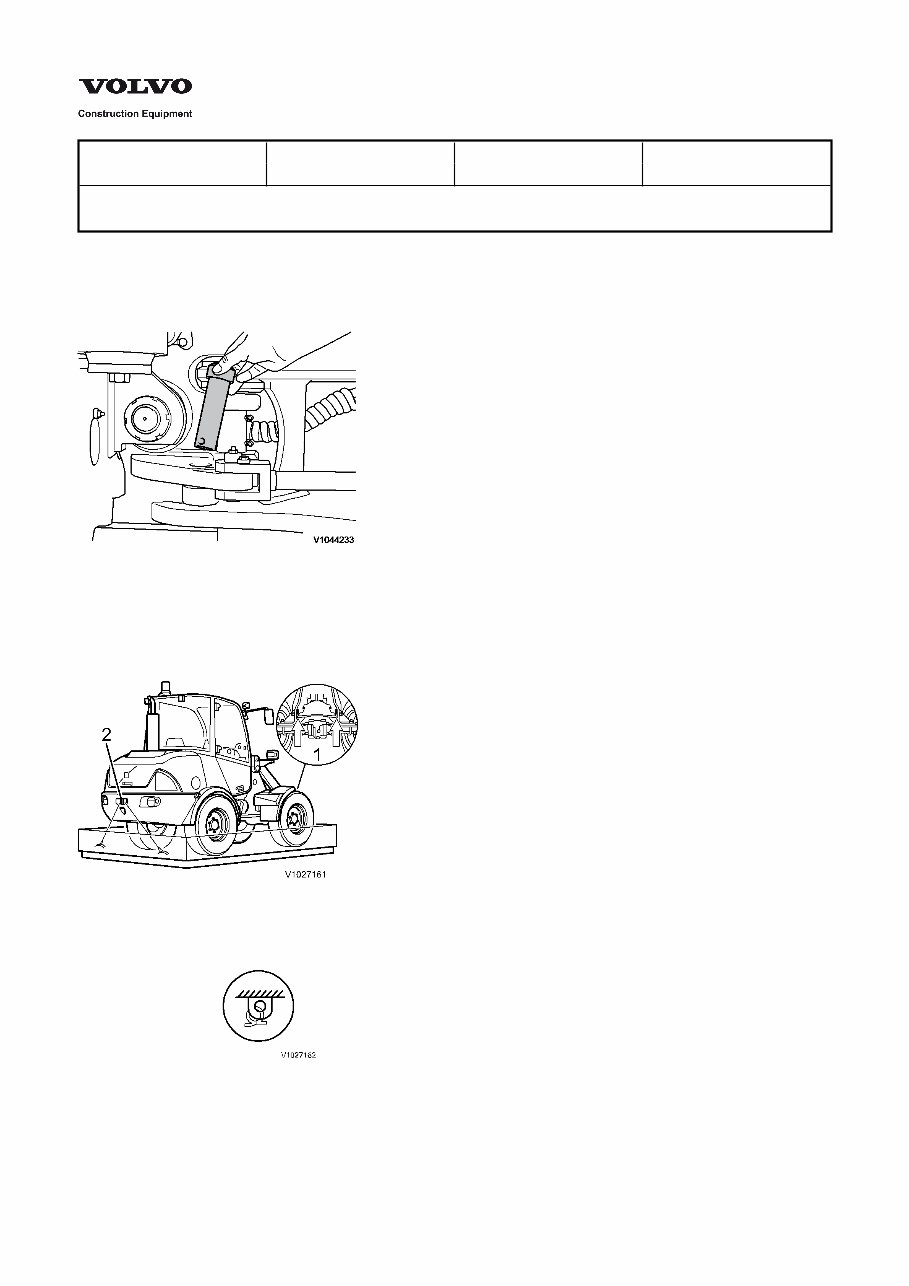

Steering joint lock

When transporting the machine on a trailer or by rail, the articulated steering joint must be locked with the steering lock.

Figure 1

Steering joint lock

Also, the machine must be lashed down to the loading surface of the transport vehicle so that it cannot tip over or roll away.

Block the wheels with chocks.

Figure 2

Lashing the machine

Marker plate for lashing

1.

2.

Fixing eyes on front frame

Fixing eyes on rear frame (towing device)

Lifting of machine

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 27 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

The Volvo L20B Compact Wheel Loader Service & Repair Manual is a comprehensive factory workshop manual designed for instant access on your computer, tablet, or smartphone. This professional manual is an invaluable resource for both professional mechanics and DIY enthusiasts, covering all repair, servicing, and troubleshooting procedures with detailed step-by-step instructions, exploded diagrams, and photographs.

Key Features:

- Complete factory service repair workshop manual

- No extra fees or expiry dates

- Printable pages with no limitations

- Multi-computer usage

- Full compatibility with Windows & MAC computers

With no trial periods or renewal fees, this full manual provides lifetime access for all your repair and maintenance needs. Click the button to get your hands on this invaluable resource.