Volvo L120E Wheel Loader Full Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

VOLVO WHEEL LOADER

L120E

2

Volvo has developed and manufactured

wheel loaders for half a century. The goal

has always been to create the optimal

machine for maximum performance and

productivity, high operator comfort, and

unmatched flexibility. Now, the latest

experiences and leading technology

have resulted in the Volvo L120E. The

high performance, low emission engine

delivers close to maximum power

already at low rpm. Furthermore, the

powerful patented TP linkage, combined

with Volvo’s purpose-built range of

attachments, provides the flexibility

needed to handle a variety of tasks.

Advanced technology helps to make

this a swift, versatile and fuel efficient

production machine in any application.

Get more done

You’ll find the L120E a pleasure to

operate. In this respect, competing

loaders simply can’t compete. It’s

powerful, agile and easy to maneuver.

Sitting comfortably in an ergonomically

designed seat, you have total control

L120E - STRONG AND VERSATILE

over the machine. Engine and hydraulics

respond immediately to your commands.

Visibility is panoramic and the air in the

cab is always fresh. Both operator and

machine get more done with a lot less

waste.

A great deal for your investment

Proven reliability, excellent financing,

extremely low fuel consumption and

a high trade-in value provide the

cornerstones of a safe investment.

Add to that outstanding handling and

productivity, a market-leading operator

environment to protect the person in

the machine, quick and simple daily

maintenance and modest service

requirements.

And what do you get? The most cost

efficient loader in its class, delivering

unparalleled profitability – both now and

in years to come.

With the L120E, everybody is a winner.

Quite simply, a great deal for your money.

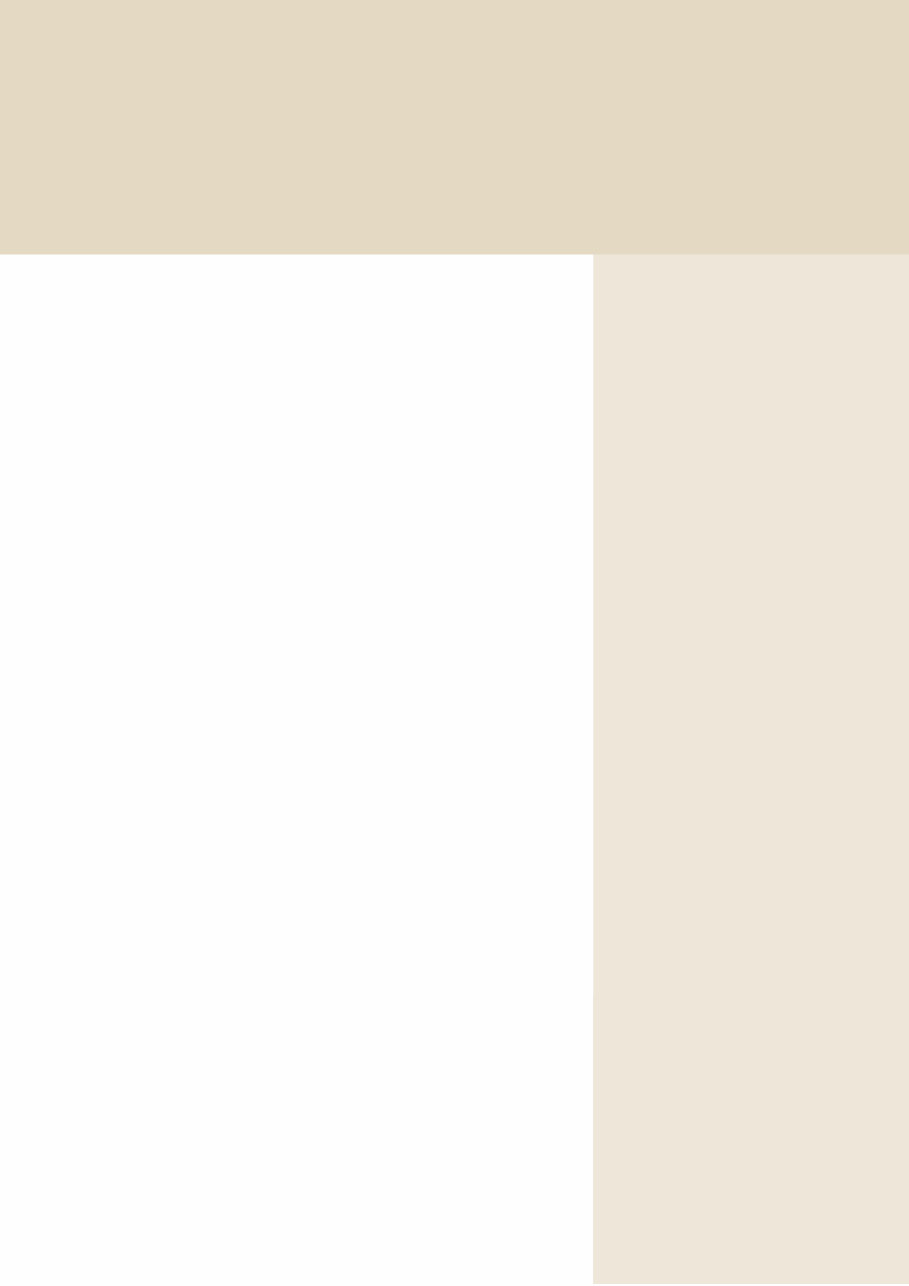

Volvo’s 20 ton wheel loader is packed with loads of

power to make your job easier everyday. The tireless

L120E represents yet another leap in the stride for

higher productivity. The versatility of this Volvo wheel

loader makes it the obvious choice in a wide range

of industries and applications, including moving

material in sand and gravel pits, loading cargo

vessels and rail cars, handling wood chips at paper

mills and unloading timber trucks.

Specifications L120E

Engine: Volvo D7D LA E2

Max power at 30,0 r/s (1800 rpm)

SAE J1995 gross: 165 kW (224 hp)

ISO 9249, SAE J1349 net: 164 kW (223 hp)

Breakout force: 149,3 kN*

Static tipping load

at full turn: 11 670 kg*

Buckets: 2,6 – 9,5 m

3

Log grapples: 1,1 – 2,4 m

2

Operating weight: 19,0 – 21,0 t

Tires: 23.5 R25

750/65 R25

* Bucket: 3,4 m

3

with bolt-on dges, tires 23.5 R25 L3,

standard boom

4

The only thing modest about this

machine is its fuel consumption

Even at low rpm, the 7-liter high

performance engine delivers full power

and maximum torque. The machine

responds quickly and forcefully with

excellent rimpull, full hydraulic power,

low fuel consumption and low emissions.

And thanks to the low rpm performance,

the service life of the engine is extended.

Responds to your commands

The Volvo fully automatic countershaft

transmission provides smooth and

effective gear shifting. All the operator

has to do is select forward or reverse and

APS automatically selects the right gear

according to both engine rpm and ground

speed. Volvo’s in-house engineered

axles and drivetrain are well matched

and designed for top dependability. And

Volvo’s oil circulation cooled wet disc

brakes provide smooth, effective braking

– and, of course, a long service life.

POWER UP YOUR PRODUCTION

Torque Parallel linkage

– a breakthrough in the industry

The reliable TP linkage, Volvo’s patented

lift-arm system, delivers high and even

breakout torque throughout the entire

lifting range. The system is exceedingly

user-friendly. The operator can easily

handle heavy materials and maintain full

control in all positions.

Hydraulics that make sense

The Volvo L120E features an intelligent

load sensing system for both the main

and steering hydraulics. Two variable

piston pumps provide the exact flow and

pressure required at any given moment,

distributing power when and where it’s

needed. In addition to rapid response,

this system facilitates smoother

operation, lower fuel consumption, and

precise control, even at low rpm.

Load more tons per hour with the Volvo L120E. Its

powerful engine and the Automatic Power Shift (APS)

gear shifting system provide immediate response

even in the toughest conditions. And Volvo axles are

designed to ensure that the rimpull is there when

needed. Torque Parallel linkage (TP linkage), load

sensing hydraulics, smooth steering and stable

operation help make the L120E a precision performer.

Engine

• Volvo D7D, a turbocharged, air-to-air

intercooled low emission engine with

electronically controlled fuel injection

delivers high torque even at low rpm.

• The electronically controlled

hydrostatic fan is only activated

when necessary, thus saving fuel.

Transmission

• With Volvo’s 3rd generation of APS,

the operator can select between

four different operating modes,

including the new AUTO function,

which adaptively chooses the most

convenient shifting program for the

job at hand, equally weighing the

operator’s driving habits together

with the operating cycle.

• The 3rd generation APS now has

fully automatic shifting 1-4, meaning

all the operator has to do is choose

forward or reverse.

Axles/Brakes

• The Volvo axles are fully integrated

with the drivetrain, delivering

superior rimpull.

• Oil circulation cooled wet disc

brakes ensure effective braking

and a long service life.

• An electronic brake test in

Contronic gives you instant access

to the status of the brakes.

• A brake wear indicator on each

wheel allows you to easily check

the brake pad wear.

Steering

• Load-sensing steering only uses

power when it’s needed, thereby

saving fuel.

• E-series loaders feature an

accumulator system, providing

stable, smooth steering and

greater safety.

Frame

• Rugged frame design for secure

mounting of components increases

the service life of the machine.

• Volvo’s frame joint bearing design

is a well-proven concept that’s easy

to maintain and renowned for its

long service life.

5

TP linkage

• Unique patented lift-arm system,

which provides two solutions in

one: excellent breakout torque and

parallel action throughout the entire

lifting range.

Load-sensing hydraulics

• The load-sensing hydraulic system

ensures that hydraulic oil is pumped

around the system only when and

where it’s needed. This means

greater efficiency and lower fuel

consumption.

• Pilot-operated hydraulics allow

precise control of the attachments,

making life easier, and safer, for the

operator.

6

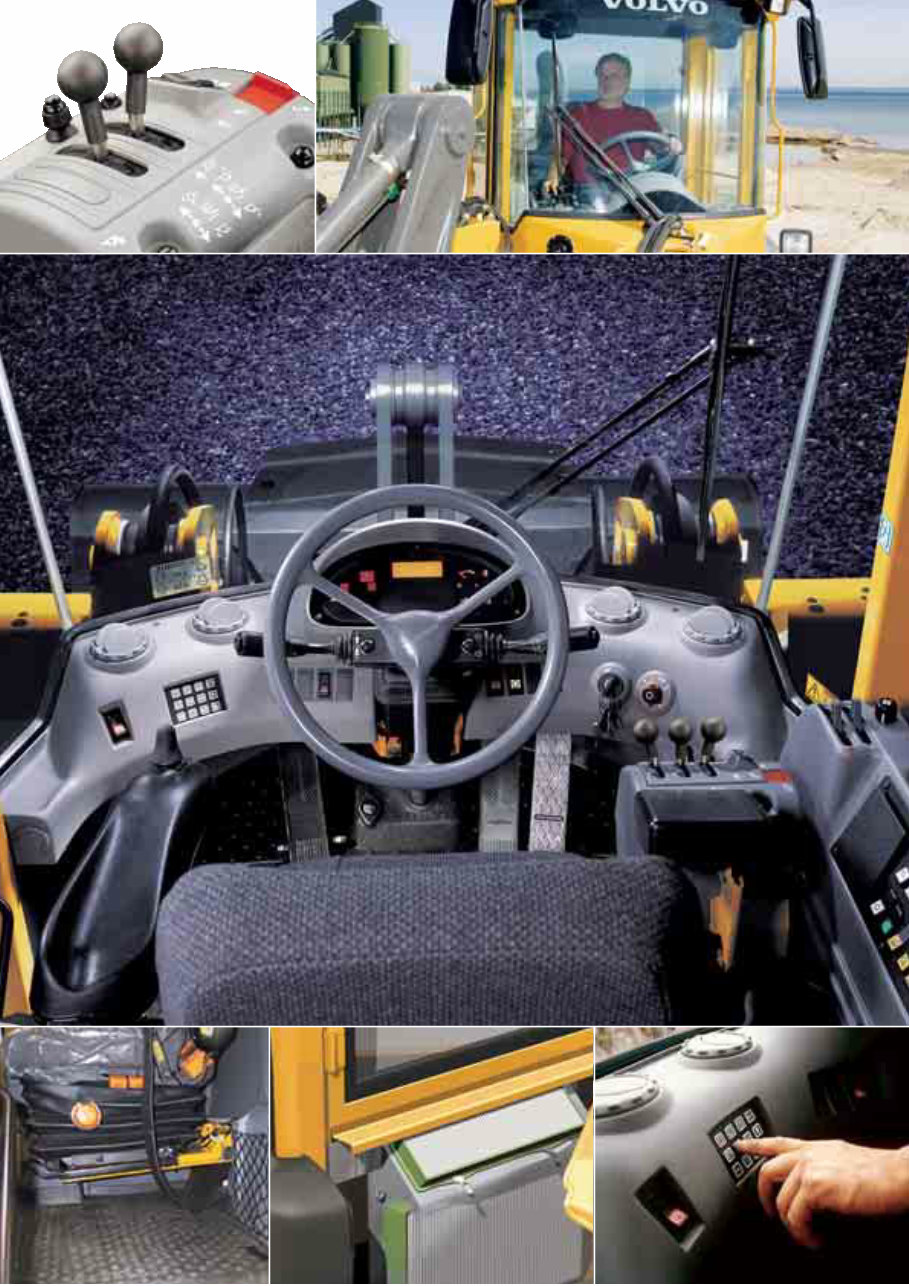

A clean and comfortable workplace

The right cab climate does wonders

for efficiency, keeping operators sharp

during long shifts. In fact, all incoming

air is filtered in two stages, making this

one of the cleanest cabs on the market.

Even the recirculated air is filtered.

Furthermore, Volvo’s state-of-the-art

air-conditioning* provides a pleasant

temperature year-round, regardless of

outdoor conditions. So even after a long

work shift, the air in the cab is still fresh

and the operator’s mind is still clear.

Comfort and productivity go hand-

in-hand

There is a range of comfortable seats,

all of them with multiple adjustment

functions for optimal individual comfort.

All instruments are visible at a glance,

and all important information is right in

front of the operator. The forward, reverse

and kick-down functions are situated

both on the lever on the left-hand side of

the steering wheel and on the hydraulic

console to the right. And thanks to

Comfort Drive Control (CDC)*, you can

steer, change directions and kickdown

to first gear with easy-to-use controls

integrated into the left-hand armrest

– an excellent way to combat fatigue and

static muscle strain. Furthermore, to avoid

monotonous arm movements, you can

shift at any time from lever steering to

using the steering wheel.

AN ALERT OPERATOR IS A PRODUCTIVE OPERATOR

Contronic keeps an eye on

everything

Contronic, the highly reliable control

and monitoring system from Volvo,

continuously monitors the machine’s

operation and performance. The system

is an electronic network made up of

three computers. Operating at three

levels, the system keeps an eye on the

machine’s various functions in real-time.

If a potential problem should occur,

the system generates an immediate

warning, making the operator aware

of the condition. All operating data is

saved and can be used to analyze how

the machine performs and also to trace

its history since the latest service. The

machine’s functions can be updated for

optimal adaptation to new and changing

operating conditions via the Contronic

service display tool. With VCADS Pro,

it’s also possible to check and adjust the

machine’s functions and performance

characteristics.

Low noise levels

Thanks to its ingenious rubber mounting

system and heavy-duty insulation, the

Care Cab is one of quietest cabs on the

market. By reducing tiresome earfuls and

annoying vibrations, the operator will stay

sharp throughout the shift. In short, it’s a

great place to work.

Volvo Care Cab with the Contronic monitoring

system reinforces Volvo’s reputation as a leader

in operator environments and cab comfort. We

never forget the operator inside the machine. A

comfortable, operator-friendly and safe environment

makes the workday easier and more productive.

Care Cab

• Unrivalled operator environment

with one of the market’s best cab

filtration systems.

• Pleasant interior with superior finish

makes it easy to maintain and keep

clean.

• Adjustable seat, armrest, hydraulic

lever console and steering wheel*

for optimal operator comfort and

high production.

• Contronic, a superior control and

monitoring system, designed to

increase safety and productivity.

• All service platforms and entry

ladders boast improved anti-slip

surfaces. Sloped entry ladder for

easy cab access.

• Large windscreens, narrow pillars

and a sloped engine hood ensure

good panoramic visibility, thus

further increasing safety.

• Powerful halogen lighting to the

front and rear provides good visibility

over the entire work area.

* Optional equipment

8

A winner for years to come

Your Volvo L120E has to be a winner

– both in day-to-day and long-term

operations, always operating economically

with maximum consideration of the

environment. The machinery has to be

trusted in all aspects. It must deliver the

anticipations of productivity and economy.

High quality and easy maintenance

are imperative for keeping up the work

process. The high performance low

emission engine is both good for your

business and for the environment.

Comfortable and quiet operator´s

environment

The operator inside deserves a

comfortable, reliable and safe machine

to work with. A good environment helps

to spare operator, equipment and nature

for years to come. The Volvo L120E is a

super competitive wheel loader that puts

the operator right in the middle, literally

speaking. Tedious vibrations and noise

have been heavily reduced. If the operator

feels comfortable and secure, it’s easier

to stay attentive.

VOLVO’S COMMITMENT TO NATURE AND MANKIND

More than 95% recyclable

The L120E is almost completely

recyclable. We see it as a natural step in

our commitment. Components such as

the engine, transmission and hydraulics

are re-engineered and re-used in our

Parts Exchange program. The equipment

has to be as trustworthy, service-friendly,

productive and as cost-effective as

possible. Choose this wheel loader for

maximum productivity and minimal impact

on operator, machinery and environment.

Feel free to feel secure in a Volvo L120E.

Quality, safety, and care for the environment are

Volvo’s core values. Indeed, we see our commitment

as an integral part of our operation. Few machines

have to work in tougher conditions. The ultimate

goal is maximized productivity and efficiency for the

lowest cost per hour, with minimized environmental

impact. For instance, plants and manufacturing

processes are certified in accordance with ISO

14001. This is but one example of our tangible

commitments and high quality standards. And

that’s why Volvo customers get one of the most

environmentally considerate and dependable wheel

loaders on the market.

Quality

• The air is vented from all major

components with easy to replace

breather filters, used to prevent dirty

air from entering the transmission,

axles, fuel tank, and hydraulic tank.

• All electrical wires are routed

through sturdy conduits, protected

from water, dust, and abrasion with

rubberized connectors and terminal

caps.

• The L120E is designed from the

beginning for easy service and

maintenance. Easy access to all

components lays the foundation for

shorter service and maintenance

time and longer life.

Safety

• A dual-circuit service brake

system that fulfills all requirements

according to ISO 3450, electronic

brake test in Contronic and easy to

check brake wear indicators are all

ways to ensure safe and effective

braking.

• Volvo Care Cab is tested and

approved according to ROPS

ISO 3471 and FOPS ISO 3449

standards.

• Optimized panoramic visibility gives

effective control over the entire work

area.

• The L120E has steps and platforms

that are equipped with anti-slip

surfaces and well positioned hand

rails.

Environment

• The low rpm, high performance D7D

engine meets all current emission

requirements according to step 2

legislation in Europe and the US.

• The L120E is manufactured in

environmentally certified factories

according to ISO 14001.

• The L120E is more than 95%

recyclable according to material

weight.

• Low external and internal sound

levels.

10 (L120E)

VOLVO L120E IN DETAIL

Engine

7 liter, 6-cylinder straight turbocharged

diesel engine with electronically

controlled unit pumps and conventional

injectors. The engine has wet replaceable

cylinder liners and replaceable valve

guides and valve seats. The throttle

application is transmitted electrically

from the throttle pedal or the optional

hand throttle. Air cleaning: three-stage.

Cooling system: Air-to-air intercooler and

hydrostatic, electronically controlled fan.

Brake system

Service brake: Volvo dual-circuit system

with nitrogen charged accumulators.

Outboard mounted hydraulically operated,

fully sealed oil circulation cooled wet

disc brakes. The operator can select

automatic declutch of the transmission

when braking through Contronic. Parking

brake: Fully sealed, wet multi-disc brake

built into the transmission. Applied by

spring force and electro-hydraulically

released with a switch on the instrument

panel. Secondary brake: Dual brake

circuits with rechargeable accumulators.

Either one circuit or the parking brake

fulfills all safety requirements. Standard:

The brake system complies with the

requirements of ISO 3450.

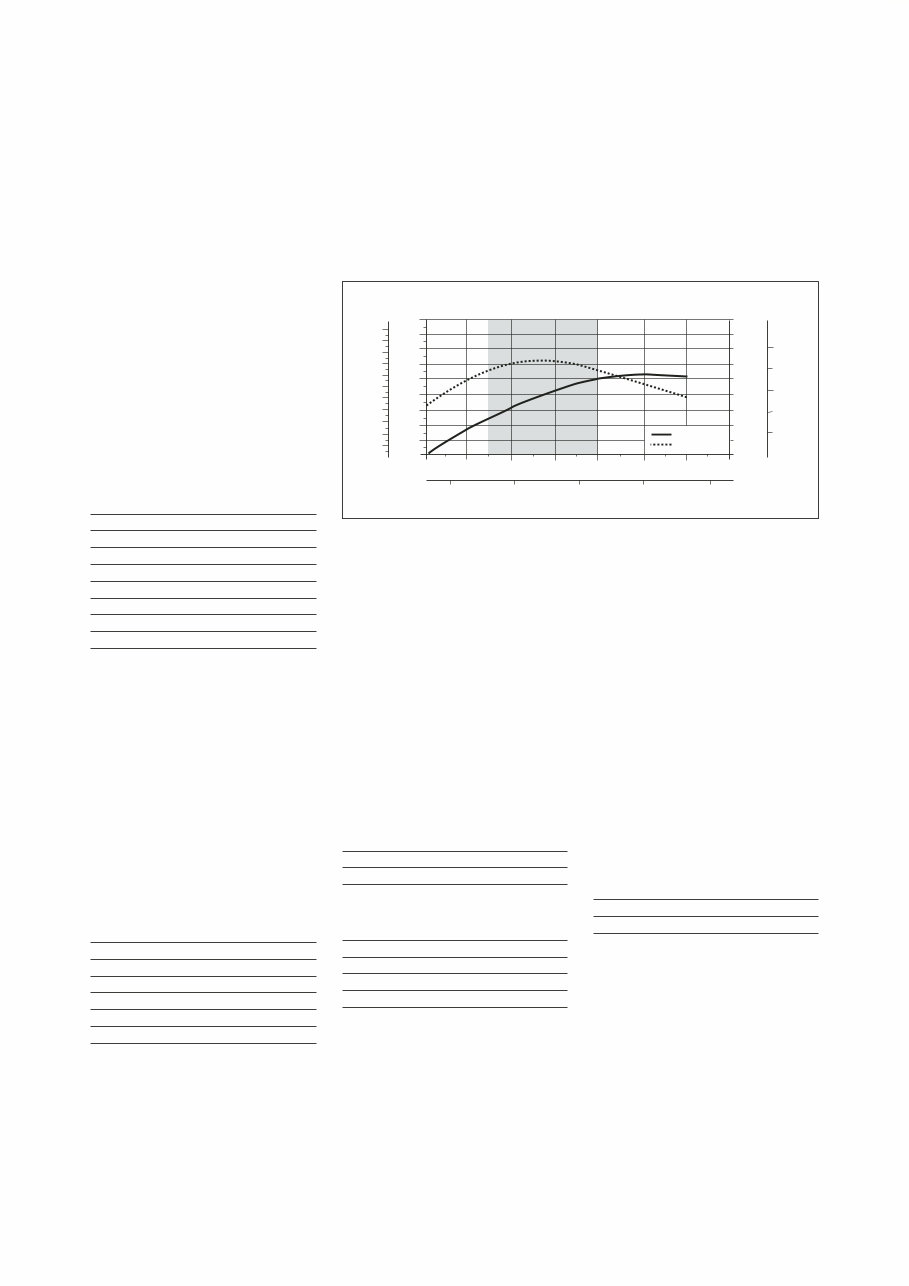

800 1000 1200 1400 1600 1800 2000 r/min

15 20 25 30 35 r/s

Torque

Torque

Economic working range

hp

Power

Power

lbf ft

700

600

500

400

800

1200

1000

800

600

400

Nm

kW

220

200

180

160

140

120

100

80

300

250

200

150

100

Engine Volvo D7D LA E2

Max power at 30,0 r/s (1800 r/min)

SAE J1995 gross 165 kW (224 hp)

ISO 9249, SAE J1349 164 kW (223 hp)

Max torque at 23,3 r/s (1400 r/min)

SAE J1995 gross 1020 Nm

ISO 9249, SAE J1349 1015 Nm

Economic working range 1100–1600 r/min

Displacement 7,1 l

Drivetrain

Torque converter: single-stage.

Transmission: Volvo countershaft

transmission with single lever control.

Fast and smooth shifting of gears

between forward and reverse with Pulse

Width Modulation (PWM) valve. Gear

shifting system: Volvo Automatic Power

Shift (APS) with fully automatic shifting

1-4 and mode selector with 4 different

gear shifting programs, including AUTO.

Axles: Volvo fully floating axle shafts

with planetary hub reductions and cast

steel axle housings. Fixed front axle and

oscillating rear axle. 100% differential

lock on the front axle.

Transmission Volvo HTE 205

Torque multiplication 2,85:1

Maximum speed, forward/reverse

1 7,1 km/h

2 13,1 km/h

3 24,7 km/h

4 35,1 km/h

Measured with tires 23.5 R25 L3

Front axle/rear axle Volvo/AWB 31/30

Rear axle oscillation ±13°

Ground clearance at 13° oscillation 460 mm

Number of brake discs per wheel

front/rear 1/1

Accumulators 3x1,0 l

Accumulator for parking brake 1x1,0 l

Voltage 24 V

Batteries 2x12 V

Battery capacity 2x140 Ah

Cold cranking capacity, approx 1050 A

Reserve capacity, approx 270 min

Alternator rating 1540 W/55 A

Starter motor output 5,4 kW (7,3 hp)

Electrical system

Central warning system: Central

warning light for the following functions,

(buzzer with gear engaged): Engine

oil pressure, transmission oil pressure,

brake pressure, parking brake applied,

hydraulic oil level, axle oil temperature,

steering system pressure, low coolant

level, coolant temperature, transmission

oil temperature, hydraulic oil temperature,

overspeeding in engaged gear, brake

charging, fuel temperature, charge air

temperature.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 17 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Get the complete factory service repair workshop manual for the Volvo L120E Wheel Loader. This professional manual is essential for all repairs, servicing, and troubleshooting procedures. It contains detailed photos, diagrams, and step-by-step instructions, making it useful for both professional mechanics and DIY enthusiasts.

Print out a single page or the entire manual as per your preference. The manual can be used on multiple computers without any limitations or trial periods. There's no expiry date, renewal fee, or additional charges. It is compatible with Windows and MAC computers.