Volvo L120C Wheel Loader Service Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Service Information

Document Title: Function Group: Information Type: Date:

Description 000 Service Information 2014/5/27

Profile:

Description

The machine is a four-wheel drive loader with articulated frame steering.

The engine is a six-cylinder, four-stroke, direct-injection, turbocharged, diesel engine with the designation TD63KBE (L90C),

TD73KDE (L120C).

The transmission is hydro-mechanical of the power shift type, where all gears are in constant mesh, with the designation

HT131 for L90C and HT205 for L120C.

Between the engine and the transmission there is a single stage hydraulic torque converter.

Front and rear axles have fully floating drive shafts with planetary type gears in the hubs. The front axle is provided with a

differential lock.

The service brakes are wet type disc brakes, built integrally with the planetary gear in each wheel hub. The parking brake on

L90C is of the disc brake type and it is positioned externally on the transmission output shaft. The parking brake on L120C is

of the wet type disc brake and positioned inside the transmission on the output shaft.

The steering system is hydrostatic with a variable axial piston pump and two hydraulic cylinders (steering cylinders).

For further description of function and components, see the respective sections.

Figure 1

Loader L90C / L120C

Service Information

Document Title: Function Group: Information Type: Date:

Product identification

plates

000 Service Information 2014/5/27

Profile:

Product identification plates

The illustration below shows which plates should be fitted on the machine and where they are positioned.

When ordering spare parts and in all enquiries by telephone or correspondence, the model designation and Product

Identification Number, (PIN) should be stated.

When applicable, any information on the additional plate, “INCL. PARTS” should be stated.

Figure 1

Product identification plates

1.

2.

3.

4.

5.

6.

7.

8.

Engine type designation, part and serial numbers are stamped into the side of the cylinder block (left side of

machine)

Cab type, type approval and serial number are positioned by the right roof post inside the cab.

Product plate with Product Identification Number, PIN for the complete machine (shows model designation, engine

manufacturer and serial number). The plate is fitted on the left side of the front frame. Model designation and serial

number are also visibly stamped-in on the right side of the front frame.

Additional plate to product plate, which shows machine weight, engine output, year of manufacture and has a

space for the CE mark (only EU/EEA countries), is positioned below the product plate.

Rear drive axle product and serial numbers are positioned on the right side of the axle housing.

Transmission product and serial numbers are positioned on the right side of the transmission.

Front drive axle product and serial numbers are positioned on the axle housing (above the differential lock

connector).

Component plate with Component Identification Number, CIN for differential carrier assembly is positioned on the

lower part of the differential casing.

Service Information

Document Title: Function Group: Information Type: Date:

Volvo standard tightening

torques

030 Service Information 2014/5/27

Profile:

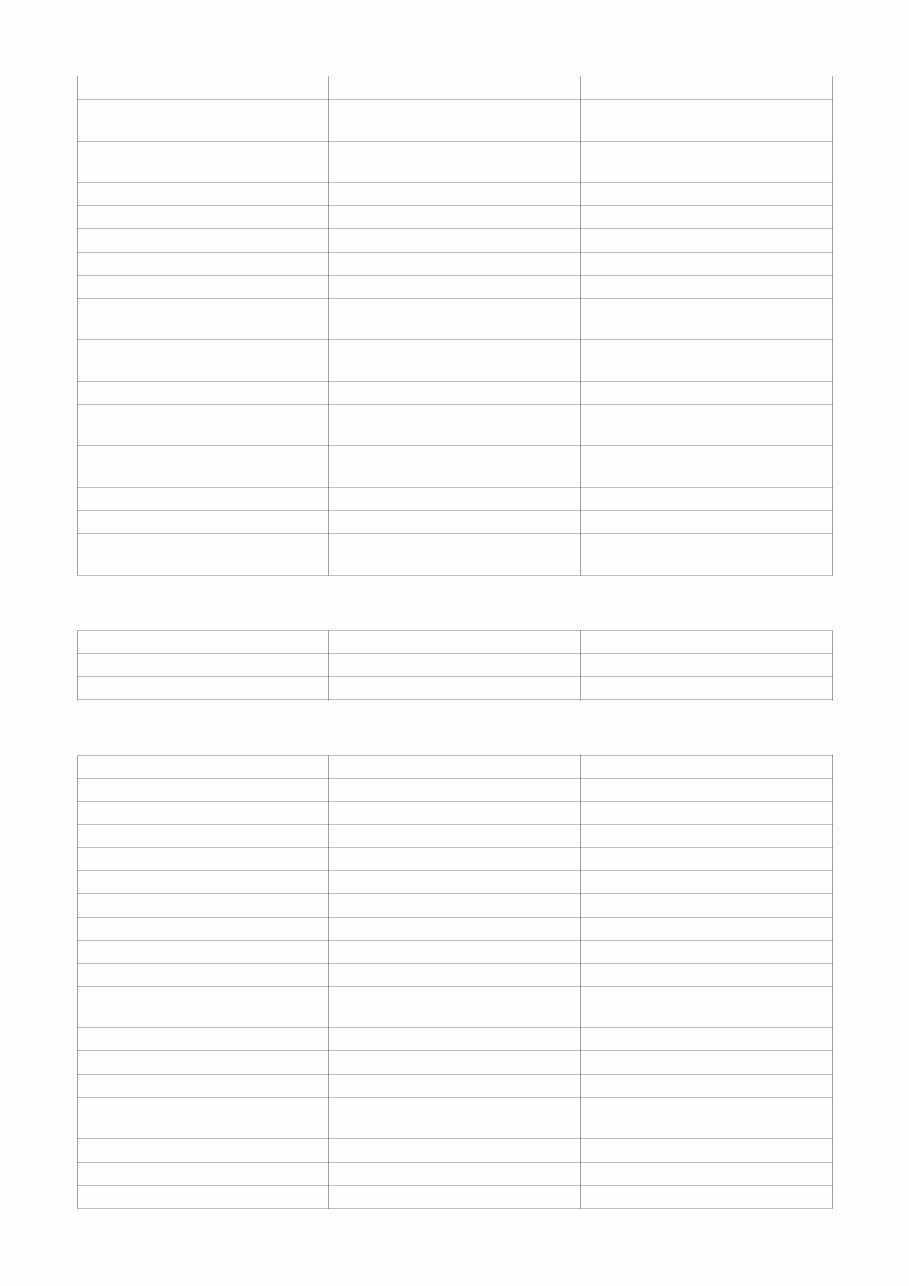

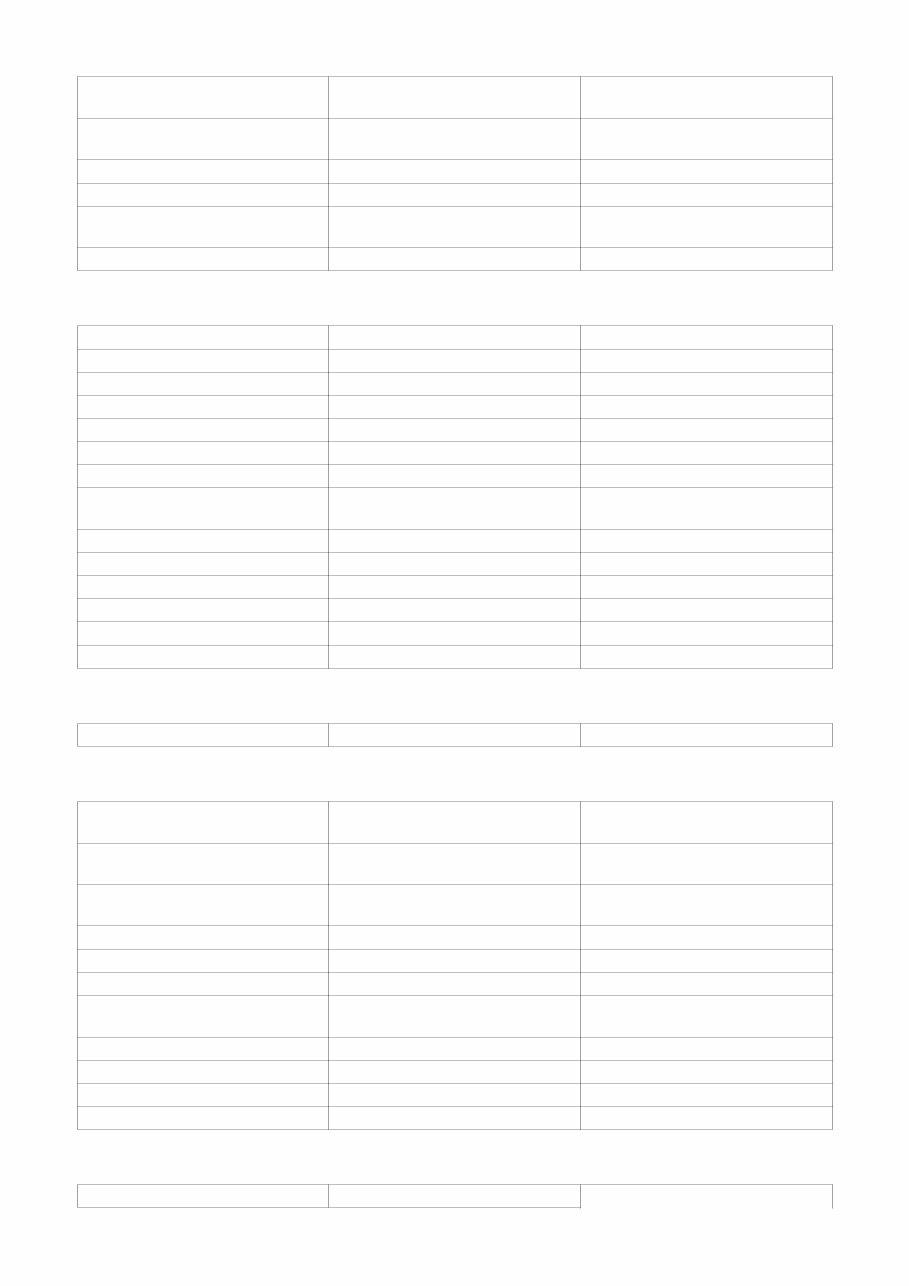

Volvo standard tightening torques

The tightening torques in the following tables apply to bolts with a tensile strength as shown below. The tables are to be

considered as a general instruction for the tightening torque of nuts and bolts unless otherwise stated.

NOTE!

For flange head bolts type U6FS the values should be increased by 10 %. Nuts and bolts must be cleaned and lubricated with

oil.

TENSILE STRENGTH 8.8 Metric coarse and fine threads

Threads N m kgf m lbf ft

M6 10 ±2 1.0 ±0.2 7.4 ±3.5

M8 24 ±5 2.4 ±0.5 18 ±3.5

M10 48 ±10 4.8 ±1.0 35 ±7.4

M12 85 ±18 8.5 ±1.8 63 ±13.0

M14 140 ±25 14.0 ±2.5 103 ±18.0

M16 220 ±45 22.0 ±4.5 160 ±33.0

M20 430 ±85 43.0 ±8.5 320 ±63.0

M24 740 ±150 74.0 ±15.0 550 ±110.0

TENSILE STRENGTH 10.9 Metric coarse and fine threads

Threads N m kgf m lbf ft

M6 12 ±2 1.2 ±0.2 9 ±1.5

M8 30 ±5 3.0 ±0.5 22 ±3.5

M10 60 ±10 6.0 ±1.0 44 ±7.5

M12 105 ±20 10.5 ±2.0 78 ±14.5

M14 175 ±30 17.5 ±3.0 130 ±22

M16 275 ±45 27.5 ±4.5 204 ±33

M20 540 ±90 54.0 ±9.0 400 ±66

M24 805 ±160 80.5 ±16.0 594 ±118

UNC threads, coarse pitch

Threads N m kgf m lbf ft

1/4" 9 ±2 0.9 ±0.2 6.6 ±1.5

5/16" 18 ±4 1.8 ±0.4 13 ±3.0

3/8" 33 ±8 3.3 ±0.8 24 ±5.9

7/16" 54 ±14 5.4 ±1.4 40 ±10

1/2" 80 ±20 8.0 ±2.0 59 ±15

9/16" 120 ±30 12.0 ±3.0 89 ±22

5/8" 170 ±40 17.0 ±4.0 130 ±30

3/4" 300 ±70 30.0 ±7.0 220 ±52

7/8" 485 ±115 48.5 ±11.5 360 ±85

1" 725 ±175 72.5 ±17.5 530 ±130

Service Information

Document Title: Function Group: Information Type: Date:

Time Guide 070 Service Information 2014/5/27

Profile:

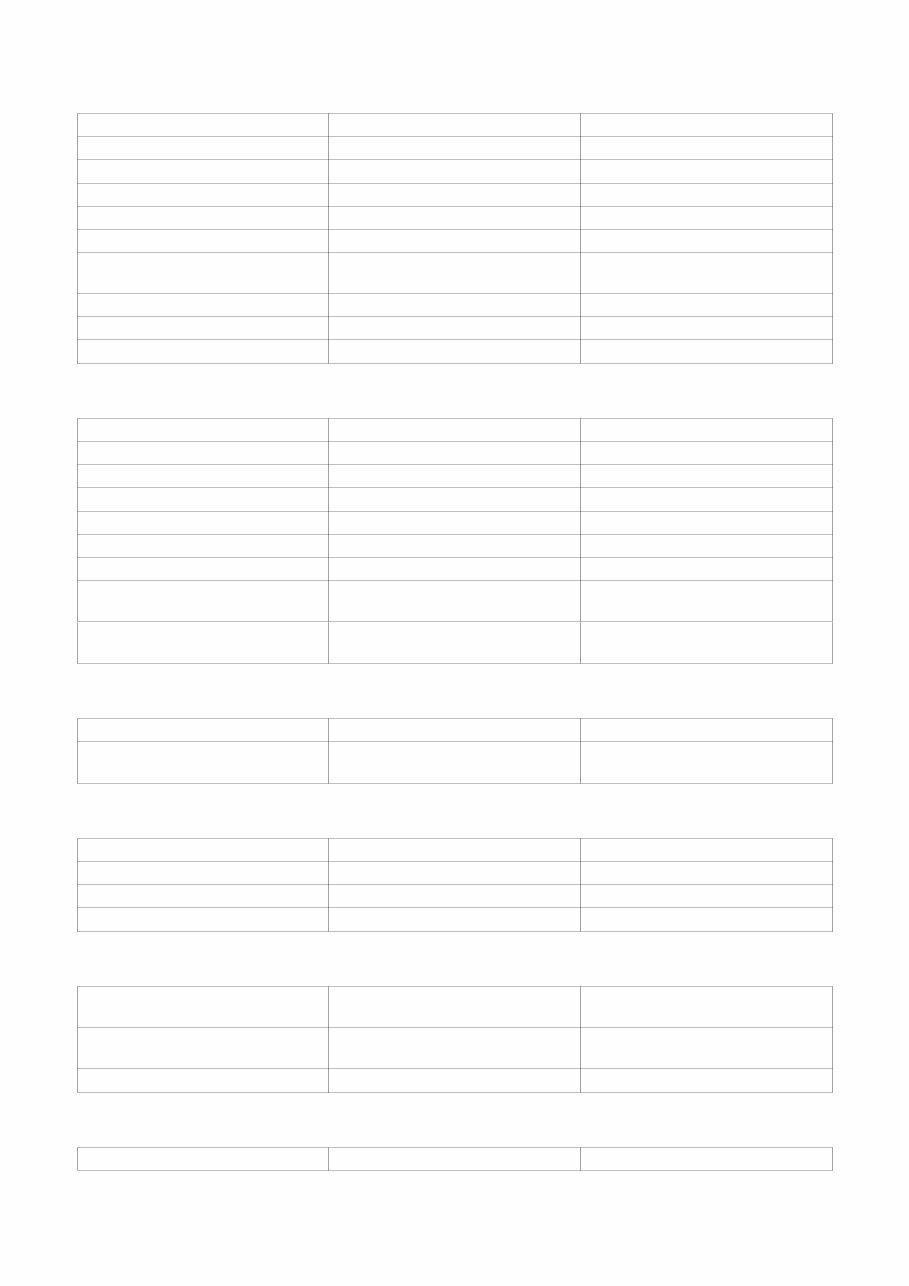

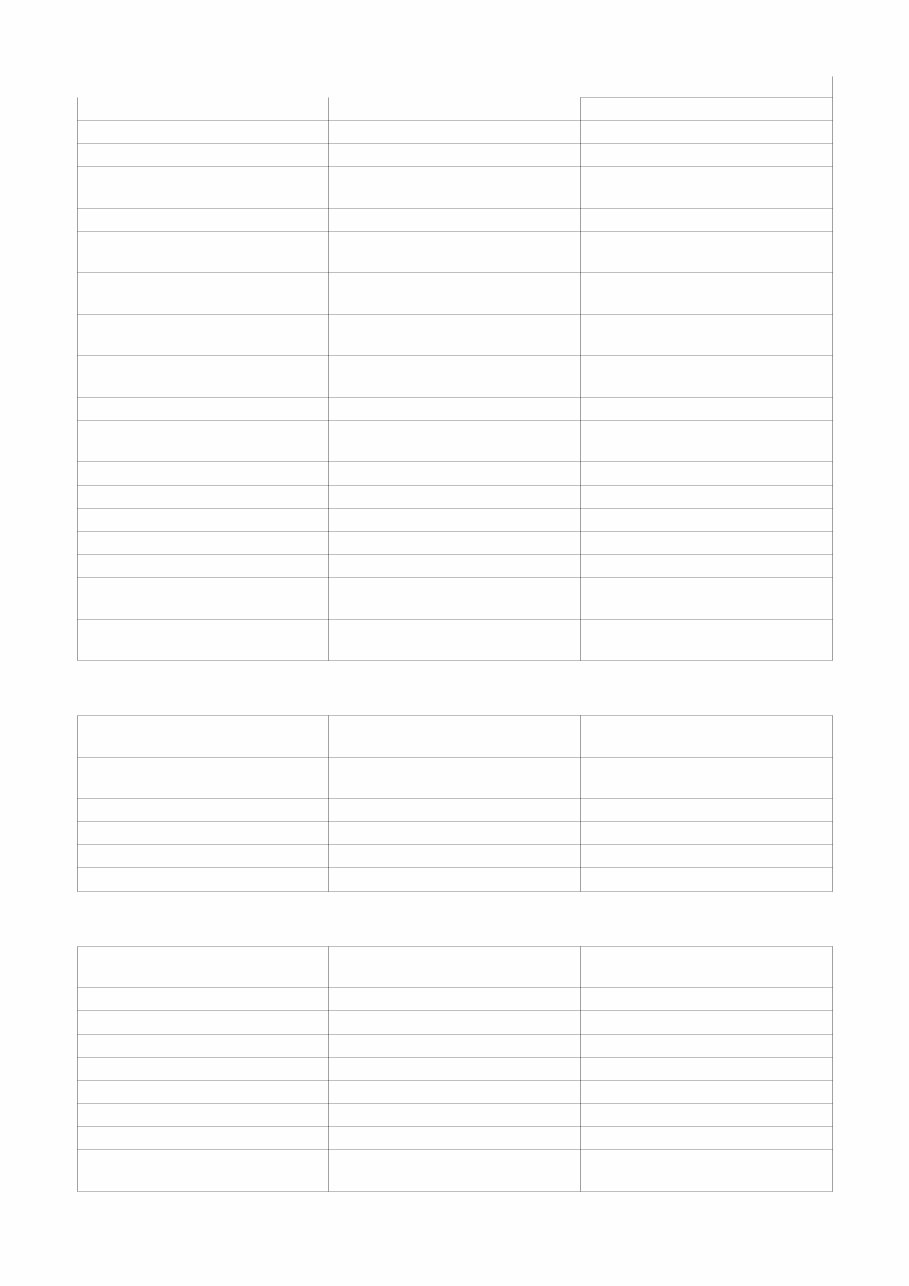

Time Guide

Regarding: L120C

16 Lubricants, fuels and other liquids

Op.no. Time (h) Operation

16234 1,75 Hydraulic oil tank, changing oil and

filter excl. cleaning tank

16236 2,5 Hydraulic oil tank, changing oil and

filter incl.cleaning tank

16238 1,5 Transmission, changing oil and filter

and cleaning suction strainer

16250 1,5 Drop box, changing oil/cleaning suction

strainer

16259 1,5 Axles, changing oil

17 General

17101 0,5 Arrival inspection, according to

programme

17102 1,5 Delivery inspection, according to

programme

17202 3,5 Warranty inspection 100 hours,

according to service programme

17204 8 Warranty inspection 1000 hours,

according to service programme

17307 1,5 Maintenance service, every 250 hours

17310 3 Maintenance service, every 500 hours

17312 5 Maintenance service, every 1000 hours

17314 8 Maintenance service, every 2000 hours

21 Engine, general

21002 1,75 Compression test, engine at operating

temperature

21070 7 Engine, removing

21071 40 Engine removed, general overhaul

21072 8 Engine, fitting

21102 8 Cylinder head, replacing gasket

21118 10 Cylinder heads all, replacing gaskets

21168 4 Cylinder heads all removed,

decarbonizing and grinding in valves

21171 0,5 Cylinder head removed, pressure

testing each

21180 4,5 Cylinder heads all, removing

21182 7 Cylinder heads all, fitting

21207 4 Cylinder block, liners removed, milling

of all liner locations

21211 0,5 Cylinder, cylinder heads removed,

measuring wear in all cylinders

21310 14 Cylinder liner and piston, replacing one

21318 24 Cylinder liners and pistons, replacing all

21412 1,5 Valves, adjusting

21427 0,5 Inspection cover, fitting new gasket

21436 14 Valve covers all, fitting new gasket

21493 0,5 Rocker arm mechanism removed,

reconditioning

21502 6 Timing gear cover, fitting new gasket in

machine

21530 7 Timing gear, replacing in machine

21532 8 Timing gear case, fitting new gasket in

machine

21540 2 Injection pump, drive shaft, replacing

seal

21614 2,5 Crankshaft, replacing front oil seal

21618 12 Crankshaft, replacing rear oil seal

21702 5 Sump gasket, replacing incl cleaning oil

strainer

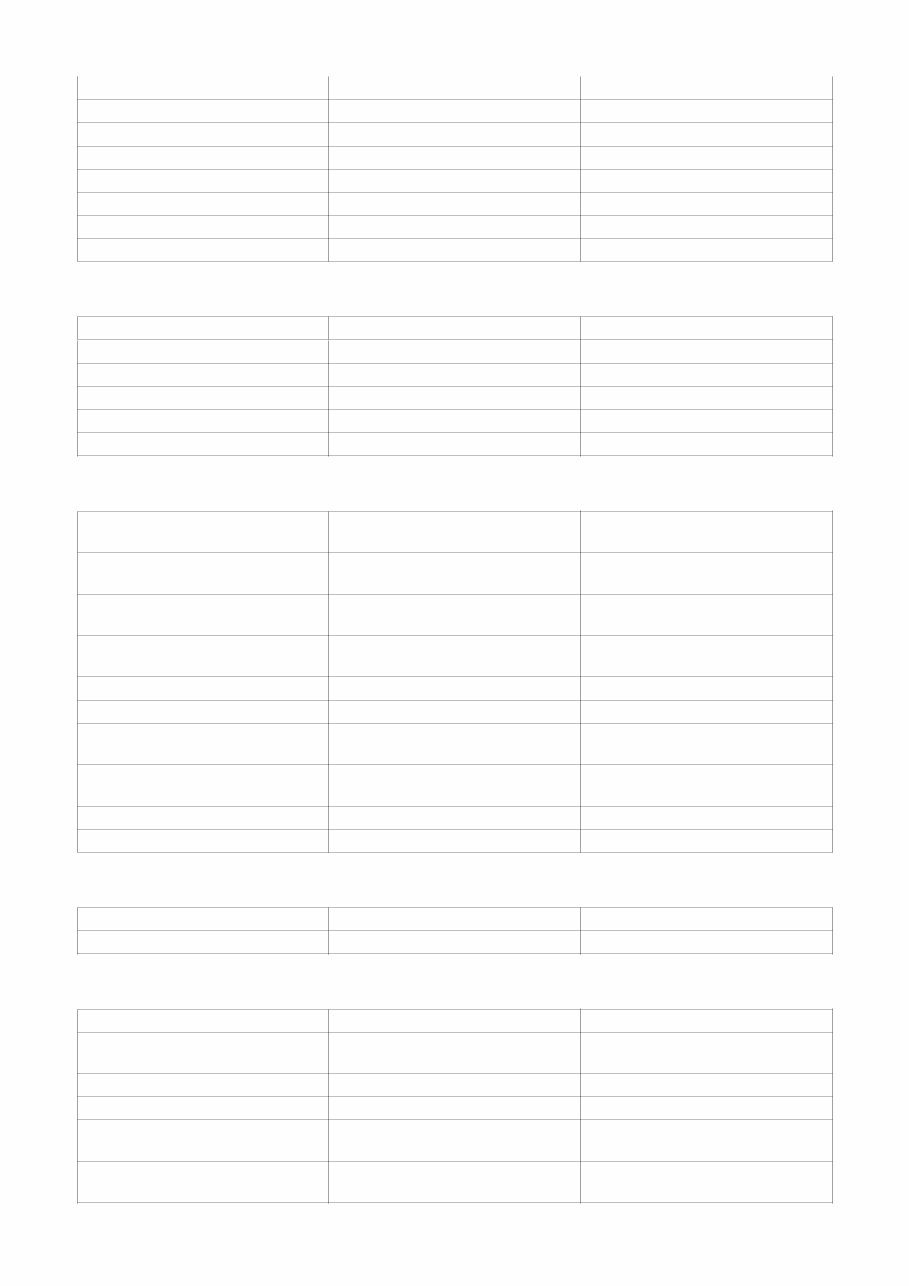

22 Lubrication and oil system

22106 0,25 Oil pressure relief valve, replacing

22114 6 Oil pump, replacing

22306 3 Oil cooler, replacing

23 Fuel system, general

23301 0,25 Fuel system, bleeding

23302 0,75 Feed pump, replacing

23304 0,5 Feed pump, checking feed pressure

23314 0,5 Fuel filters all, replacing

23315 0,25 Fuel filter extra, replacing

23410 4 Fuel tank, replacing

23601 0,5 Idling speed, checking and adjusting

23602 0,25 Stall speed, checking

23630 1,5 Injection timing, checking and adjusting

23644 1 Injection timing, checking

23673 2 Injection pump, replacing incl setting

injection timing

23702 1,5 Injectors, replacing all

23704 0,75 Injector, replacing one

23707 0,25 Overflow valve, replacing

23716 1,5 Injectors, replacing copper sleeve in

machine

23718 0,5 Delivery pipe, replacing one

23720 0,5 Pressure equalizer, replacing

23780 2 Injectors removed, reconditioning all

25 Inlet and exhaust systems

25102 1 Induction manifold, replacing gasket

25104 2 Exhaust manifold, replacing gasket

25220 1,5 Silencer, replacing

25221 0,5 Exhaust pipe, flexible tube, replacing

25571 1 Turbo charger, replacing

25573 2 Turbo charger removed, reconditioning

25602 0,25 Air cleaner, checking prssure drop

indicator

25603 0,25 Air cleaner, primary filter replacing

25604 0,25 Air cleaner, secondary filter replacing

25606 0,75 Pre-heating coil, replacing

26 Cooling system

26104 1 Coolant, changing

26108 3 Radiator, replacing

26112 1 Radiator hose upper, replacing

26114 1 Radiator hoses lower, replacing

26202 1,5 Coolant pump, replacing

26271 1,5 Coolant pump removed, reconditioning

26298 1 Thermostat, replacing

26312 0,75 Fan belt and/or alternator belt,

replacing

26322 1 Fan belt and/or alternator-, compressor

belt, replacing all belts

27 Engine control

27321 0,75 Stop magnet, replacing

27323 0,5 Electrical engine shut down, check and

adjusting

31 Battery and mounting parts

31101 1 Batteries, checking charging capacity

31103 0,5 Main switch, replacing

31106 0,5 Earth lead to battery, replacing

31108 1 Starter motor lead to battery, replacing

32 Alternator and charge regulator

32102 1 Alternator, replacing incl function check

(no measuring instrument)

32125 0,5 Alternator, replacing carbon brush kit in

machine

32205 0,5 Charging regulator, replacing

33 Starting system, general

33118 0,75 Starter motor, replacing

35 Lighting

35144 0,5 Control lamp on instrument board,

replacing

35224 0,5 Head lamp assy, replacing one incl

adjusting

35316 0,5 Rear lamp, replacing one

35318 0,25 Rear lamp, replacing glass or bulb

35656 0,5 Work lighting, replacing one head lamp

assy

35657 0,5 Work lighting, replacing one insert

36 Other electrical equipment, general

36102 0,25 Flasher unit, replacing relay

36110 0,75 Flasher switch, replacing

36117 0,25 Flasher lamp, replacing glass or bulb

36202 0,25 Horn, replacing

36203 0,5 Reverse alarm, replacing

36216 0,75 Horn switch, replacing

36301 0,5 Windscreen wiper rear, replacing motor

36302 0,75 Windscreen wiper front, replacing

motor

36303 0,75 Windscreen wiper, replacing switch

36304 0,25 Windscreen flusher pump, replacing

36404 0,25 Switch, replacing

36408 0,25 Brake light switch, replacing

36720 0,5 ECU, replacing

36721 0,5 CU 8, replacing

37 Cables and fuses, general

37201 1 Printed cercuit board, replacing

38 Instruments, sender units, warning systems

38603 0,5 Transmission oil pressure sensor,

replacing

38604 0,5 Transmission temperature sensor,

replacing

38605 0,5 Transmission, revolution sensor,

replacing

38606 0,5 Engine temperature sensor, replacing

38607 0,5 Engine oil pressure sensor, replacing

38611 0,75 Fuel level sender, replacing

38704 0,5 Transmission temperature gauge,

replacing

38705 0,5 Information display, replacing

38706 0,5 Engine temperature gauge, replacing

38711 0,5 Fuel level gauge, replacing

38720 0,5 Tachometer, replacing

42 Transmission, general

42102 0,75 Hydraulic transmission, check oil

pressure

42104 2 Oil pump, replacing

42106 1,5 Oil cooler, replacing

42108 3 Gear selector valve, replacing

42109 1 Gear selector valve removed,

reconditioning

42118 16 Converter, replacing

42123 1 Lubrication and converter pressure

valve, replacing

42141 1 Oil distributor and seals, replacing f and

r or 1:st and f or 3:rd and f

42142 2 Oil distributor and seals, replacing 1st

and 2nd or 2nd and reverse

42143 3 Oil distributor and seals, replacing 3rd

and 4th or 4th and reverse

42147 0,75 Gear selector, replacing

42148 0,75 Gear selector valve, replacing one

solenoid

42152 1 Seal for front output shaft, replacing

42154 1 Seal for rear output shaft, replacing

42168 7,5 Transmission, removing (upwards)

42169 8 Transmission, fitting (from above)

42171 32 Transmission removed, reconditioning

42173 9 Transmission, removing (together with

engine)

42174 10 Transmission, fitting (together with

engine)

45 Propeller shaft incl. bearings and mounting

45101 0,25 Propeller shaft and intermediate

bearing, checking radial clearance

45102 2 Support or intermediate bearing,

replacing

45104 1,5 Propeller shaft, rear, replacing

45107 1,5 Propeller shaft, in frame joint, replacing

45110 2 Propeller shaft, front, replacing

45113 1,5 Propeller shaft, removed reconditioning

46 Drive axles, general

46001 0,75 Axle suspension, measuring axial and

radial clearanse

461 Null Front axle

46101 4 Axle, replacing

46111 5 Centre gear , removing and fitting

46112 6 Centre gear removed, reconditioning

46114 2 Pinion front, fitting new gasket

46142 6 Hub retainer, reconditioning one side

46143 4 Hub, replacing seal

46152 0,25 Differential lock front, repacking excl

adjusting

46153 1 Differential lock, adjusting engagement

463 Null Rear axle

46301 5 Axle, replacing

46305 2 Drive shaft, replacing one side

46312 6 Centre gear removed, reconditioning

46314 2 Pinion rear, fitting new gasket

46342 6 Hub retainer, reconditioning one side

46343 4 Hub, replacing seal

51 Wheel brake, all

516 Null Front axle

51601 0,5 Brake linings, checking wear

517 Null Rear axle

51701 0,5 Brake linings, checking wear

51704 4 Brake disc, replacing both sides

51750 3 Brake piston, replacing seals

52 Hydraulic brake system

52001 0,5 Brake system, checking function,

hydraulic

52002 0,5 Brake system, checking function,

retardation

52004 0,5 Brake system, adjusting unloading

pressure

52005 0,5 Brake system, check and adjusting

pressure in circuit

52037 1 Brake system, bleeding

52508 1,75 Foot brake valve, replacing

52509 1,25 Foot brake valve removed,

reconditioning

52701 0,5 Accumulator removed, checking

charging pressure

52702 0,5 Accumulator, replacing

52704 2 Hydraulic pump, replacing

55 Parking brake incl.control system

55006 3,5 Parking brake, replacing discs and seals

55008 1 Parking brake, replacing control valve

64 Steering

64121 1,5 Adjustable steering column, replacing

64503 0,25 Steering system, checking working

pressure

64506 1,75 Steering cylinder, replacing

64510 2 Hydraulic pump, replacing

64515 0,5 Steering system, checking and

adjusting standby pressure

64520 1,75 Steering system, checking and

adjusting shock and anti-cavitation-

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$42.99

Viewed 67 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$42.99

This manual provides comprehensive maintenance and repair procedures for the Volvo L120C Wheel Loader.

- Service Repair Factory Manual is an electronic version offering the advantage of zooming in anywhere on your computer for clear visibility.

- Parts correspond with the number of pages printed on it in this manual, making it very easy to use.

- Contains a lot of information covering General Information, Specifications, Technical Features and Description, Rigging Information, Troubleshooting, Electrical System, Fuel System, Power Unit, Lower Unit, Bracket Unit, Maintenance, Index, Appendix, and more.

- Written step by step in detail, facilitating easy repairs by oneself and potentially saving expenses.

Upon payment, the manual is immediately accessible. It is available in a file format compatible with all versions of Windows & Mac and requires Adobe Reader for access. The language used is English.