Bobcat T200 Turbo Series Track Loader Complete Workshop Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

6901397 (7-10) Printed in U.S.A. ©Bobcat Company 2010

Service

Manual

S/N 518915001 & Above

S/N 516815001 & Above

S/N 517515001 & Above

EQUIPPED WITH

BOBCAT INTERLOCK

CONTROL SYSTEM (BICS™)

6901397 (4-01) Printed in U.S.A. ©Bobcat Company 2001

MAINTENANCE SAFETY

WARNING

Instructions are necessary before operating or servicing machine. Read and

understand the Operation & Maintenance Manual, Operator’s Handbook and

signs (decals) on machine. Follow warnings and instructions in the manuals

when making repairs, adjustments or servicing. Check for correct function after

adjustments, repairs or service. Untrained operators and failure to follow

instructions can cause injury or death. W-2003-0807

Maintenance procedures which are given in the Operation & Maintenance Manual can be performed by the owner/

operator without any specific technical training. Maintenance procedures which are not in the Operation & Maintenance

Manual must be performed ONLY BY QUALIFIED BOBCAT SERVICE PERSONNEL. Always use genuine Bobcat

replacement parts. The Service Safety Training Course is available from your Bobcat dealer.

Safety Alert Symbol: This symbol with a warning statement, means: “Warning, be alert! Your safety is

involved!” Carefully read the message that follows.

Never service the Bobcat Compact

Track Loader without instructions.

Stop, cool and clean engine of

flammable materials before

checking fluids.

Never service or adjust loader

with the engine running unless

instructed to do so in the

manual.

Avoid contact with leaking

hydraulic fluid or diesel fuel

under pressure. It can penetrate

the skin or eyes.

Never fill fuel tank with engine

running, while smoking or when

near open flame.

Disconnecting or loosening any

hydraulic tubeline, hose, fitting,

component or a part failure can

cause lift arms to drop. Do not go

under lift arms when raised

unless supported by an

approved lift arm support device.

Replace it if damaged.

Keep body, jewelry and clothing

away from moving parts,

electrical contact, hot parts and

exhaust.

Wear eye protection to guard

from battery acid, compressed

springs, fluids under pressure

and flying debris when engines

are running or tools are used.

Use eye protection approved for

type of welding.

Keep rear door closed except for

service. Close and latch door

before operating the loader.

Lead-acid batteries produce

flammable and explosive gases.

Keep arcs, sparks, flames and

lighted tobacco away from

batteries.

Batteries contain acid which

burns eyes or skin on contact.

Wear protective clothing. If acid

contacts body, flush well with

water. For eye contact flush well

and get immediate medical

attention.

Use the correct procedure to lift or

lower operator cab.

Cleaning and maintenance are

required daily.

B-15659

CORRECT

P-90216

CORRECT

B-15660

CORRECT

B-15664

WRONG WRONG

B-15661

WRONG

B-15662

WRONG

B-6589 B-15663

WRONG WRONG

B-15665

MSW09-0409

Never work on loader with lift

arms up unless lift arms are held

by an approved lift arm support

device. Replace if damaged.

Never modify equipment or add

attachments not approved by

Bobcat Company.

Have good ventilation when

welding or grinding painted parts.

Wear dust mask when grinding

painted parts. Toxic dust and gas

can be produced.

Avoid exhaust fume leaks which

can kill without warning. Exhaust

system must be tightly sealed.

ALPHABETICAL INDEX

ADVANCED CONTROL SYSTEM (ACS)

SELECTABLE HAND / FOOT CONTROL .............. 60-01

ADVANCED CONTROL SYSTEM (ACS)

ADVANCED HAND CONTROL............................... 60-01

AIR CLEANER ........................................................ 70-01

AIR CLEANER SERVICE ....................................... 10-01

AIR CONDITIONING SERVICE .............................. 80-01

AIR CONDITIONING SYSTEM FLOW ................... 80-01

ALTERNATOR (90 AMP) ........................................ 60-01

BASIC TROUBLESHOOTING ................................ 80-01

BATTERY ................................................................ 60-01

BICS™ SYSTEM .................................................... 60-01

BOB-TACH .................................................... 10-01,50-01

BOBCAT CONTROLLER ........................................ 60-01

BRAKE .................................................................... 40-01

BUCKET POSITION VALVE ................................... 20-01

CHARGE PRESSURE ............................................ 30-01

COMPONENTS ...................................................... 80-01

COMPRESSOR ...................................................... 80-01

CONDENSER ......................................................... 80-01

CONTROL HANDLE (ADVANCED CONTROL

SYSTEM) (ACS) SELECTABLE HAND / FOOT

CONTROL .............................................................. 50-01

CONTROL HANDLE (ADVANCED CONTROL

SYSTEM) (ACS) ADVANCED HAND CONTROL... 50-01

CONTROL PANEL .................................................. 50-01

CONTROL PEDALS ............................................... 50-01

CONTROL PEDALS (ACS) .................................... 50-01

CONVERSIONS ................................................ SPEC-01

COOLING FAN ....................................................... 70-01

CYLINDER (LIFT) ................................................... 20-01

CYLINDER (POWER BOB-TACH).......................... 20-01

CYLINDER (TILT) ................................................... 20-01

DIAGNOSTICS ................................................ 60-01

DRIVE BELT ........................................................... 30-01

DRIVE COMPONENTS .......................................... 40-01

ELECTRICAL SYSTEM INFORMATION ................ 60-01

ELECTRICAL / HYDRAULIC CONTROLS

REFERENCE .......................................................... 60-01

ENGINE & ENGINE MOUNTS ............................... 70-01

ENGINE COMPONENTS AND TESTING .............. 70-01

ENGINE COOLING SYSTEM ................................. 10-01

ENGINE LUBRICATION SYSTEM.......................... 10-01

ENGINE SPEED CONTROL .................................. 70-01

EVAPORATOR........................................................ 80-01

EVAPORATOR / HEATER UNIT ............................. 80-01

EXPANSION VALVE ............................................... 80-01

FAN GEARBOX ...................................................... 10-01

FLYWHEEL AND HOUSING................................... 70-01

FRONT AUXILIARY PRESSURE RELIEF BLOCK 20-01

FUEL SYSTEM ....................................................... 10-01

FUEL TANK ............................................................. 50-01

GENERAL AIR CONDITIONING SERVICE

GUIDELINES ........................................................... 80-01

HEATER COIL ......................................................... 80-01

HEATER VALVE ...................................................... 80-01

HEATER / AC FAN .................................................. 80-01

HYDRAULIC CONTROL VALVE (ADVANCED

CONTROL SYSTEM) (ACS) ................................... 20-01

HYDRAULIC CONNECTION

SPECIFICATIONS ............................................. SPEC-01

HYDRAULIC CONTROL VALVE (FOOT) ................ 20-01

HYDRAULIC FILTER HOUSING ............................. 20-01

HYDRAULIC FLUID RESERVOIR .......................... 20-01

HYDRAULIC PUMP ................................................ 20-01

HYDRAULIC PUMP (HI FLOW) .............................. 20-01

HYDRAULIC SYSTEM INFORMATION .................. 20-01

HYDRAULIC / HYDROSTATIC FILTER ................. 20-01

HYDRAULIC / HYDROSTATIC FLUID

SPECIFICATIONS ............................................. SPEC-01

HYDRAULIC / HYDROSTATIC SYSTEM ................ 10-01

HYDROSTATIC MOTOR ......................................... 30-01

HYDROSTATIC PUMP ............................................ 30-01

HYDROSTATIC SYSTEM INFORMATION.............. 30-01

INSTRUMENT PANEL............................................. 60-01

LIFT ARM ................................................................ 50-01

LIFT ARM BYPASS CONTROL VALVE .................. 20-01

LIFT ARM SUPPORT DEVICE................................ 10-01

LIFTING AND BLOCKING THE LOADER............... 10-01

LIGHTS.................................................................... 60-01

LOADER SPECIFICATIONS ............................. SPEC-01

LOADER TORQUE............................................ SPEC-01

LUBRICATION OF THE BOBCAT LOADER ........... 10-01

MAIN RELIEF VALVE .............................................. 20-01

MUFFLER................................................................ 70-01

OIL COOLER........................................................... 30-01

OPERATOR CAB .......................................... 10-01,50-01

OPERATOR SEAT................................................... 50-01

OPERATOR SEAT (SUSPENSION) ........................ 50-01

POWER BOB-TACH ................................................ 50-01

POWER BOB-TACH (OPTION)............................... 10-01

POWER BOB-TACH BLOCK................................... 20-01

PRESSURE RELIEF VALVE ................................... 80-01

PRESSURE SWITCH.............................................. 80-01

ALPHABETICAL INDEX

RADIATOR............................................................... 70-01

REAR AUXILIARY DIVERTER VALVE

(DUAL SHUTTLE) ................................................... 20-01

REAR DOOR ........................................................... 50-01

REAR GRILL ........................................................... 50-01

RECEIVER / DRIER ................................................ 80-01

RECONDITIONING ................................................. 70-01

REGULAR MAINTENANCE .................................... 80-01

REMOTE START ..................................................... 10-01

RPM SENSOR .....................................................70-01

SAFETY ................................................................... 80-01

SEAT BAR ............................................................... 50-01

SEAT BAR SENSOR ............................................... 60-01

SELECT VALVE....................................................... 20-01

SERVICE SCHEDULE ............................................ 10-01

SPARK ARRESTOR MUFFLER .............................. 10-01

STARTER ................................................................ 60-01

SYSTEM CHARGING AND RECLAMATION .......... 80-01

SYSTEM TROUBLESHOOTING CHART ............... 80-01

TEMPERATURE / PRESSURE ............................... 80-01

THERMOSTAT......................................................... 80-01

TORQUE SPECIFICATIONS FOR BOLTS........ SPEC-01

TOWING THE LOADER .......................................... 10-01

TRACTION LOCK.................................................... 60-01

TRANSPORTING THE BOBCAT LOADER ............. 10-01

TROUBLESHOOTING............................................. 70-01

TURBOCHARGER .................................................. 70-01

ACS-ADVANCED CONTROL SYSTEM

AHC-ADVANCED HAND CONTROL SYSTEM

BICS-BOBCAT INTERLOCK CONTROL SYSTEM

T200 Bobcat Loader

I Service Manual

CONTENTS

FOREWORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . II

SAFETY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . V

FIRE PREVENTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . VII

SERIAL NUMBER LOCATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . IX

DELIVERY REPORT. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . X

BOBCAT LOADER IDENTIFICATION. . . . . . . . . . . . . . . . . . . . . . . . XI

SAFETY AND MAINTENANCE. . . . . . . . . . . . . . . . . . . . . . . . . . 10-01

HYDRAULIC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-01

HYDROSTATIC SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-01

DRIVE SYSTEM . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40-01

MAINFRAME . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50-01

ELECTRICAL SYSTEM & ANALYSIS. . . . . . . . . . . . . . . . . . . . . 60-01

ENGINE SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70-01

HEATING, VENTILATION, AIR CONDITIONING . . . . . . . . . . . . 80-01

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . SPEC-01

SAFETY &

HYDROSTATIC

MAINFRAME

SYSTEM

SYSTEM

DRIVE

ELECTRICAL

MAINTENANCE

SYSTEM

ENGINE

SERVICE

ENGINE

SPECIFICATIONS

HVAC

SPECIFICATIONS

HYDRAULIC

SYSTEM

T200 Bobcat Loader

II Service Manual

FOREWORD

This manual is for the Bobcat loader mechanic. It provides necessary servicing and adjustment

procedures for the Bobcat loader and its component parts and systems. Refer to the Operation &

Maintenance Manual for operating instructions, starting procedure, daily checks, etc.

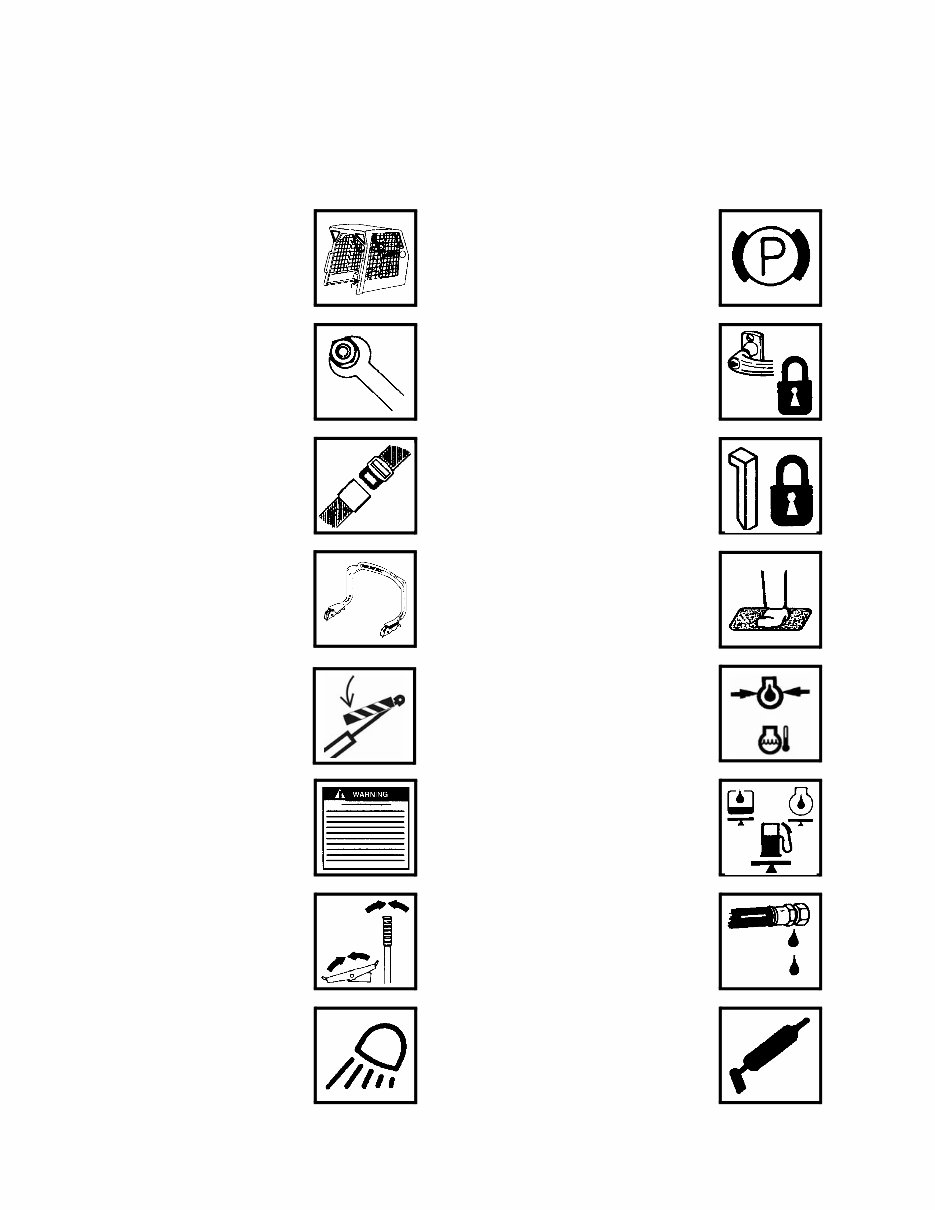

A general inspection of the following items must be made after the loader has had service or repair:

FW SSL-1008 SM

1. Check that the ROPS/FOPS

(Including side screens) is in

good condition and is not

modified.

9. The parking brake must

function correctly.

2. Check that ROPS mounting

hardware is tightened and is

Bobcat approved.

10. Enclosure door latches must

open and close freely.

3. The seat belt must be

correctly installed, functional

and in good condition.

11. Bob-Tach wedges and

linkages must function

correctly and be in good

condition.

4. The seat bar must be

correctly adjusted, clean and

lubricated.

12. Safety treads must be in good

condition.

5. Check lift arm support device,

replace if damaged.

13. Check for correct function of

indicator lamps.

6. Machine signs (decals) must

be legible and in the correct

location.

14. Check hydraulic fluid level,

engine oil level and fuel

supply.

7. Steering levers, hand controls

and foot pedals must return to

neutral (as applicable).

15. Inspect for fuel, oil or

hydraulic fluid leaks.

8. Check for correct function of

the work lights.

16. Lubricate the loader.

T200 Bobcat Loader

III Service Manual

FW SSL-1008 SM

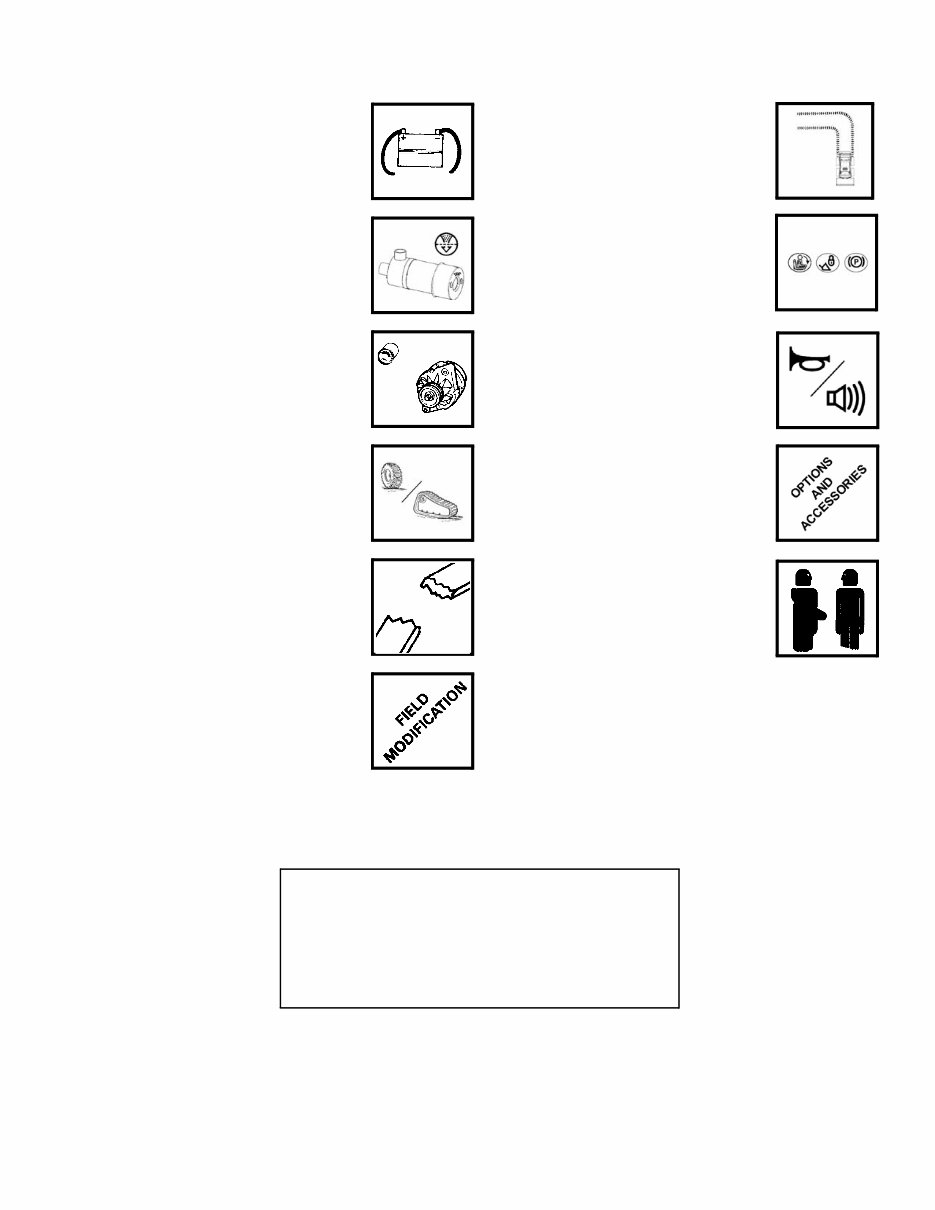

17. Check the condition of the

battery and cables.

23. Operate the machine and

check all functions.

18. Inspect the air cleaner for

damage or leaks. Check the

condition of the element.

24. Check for correct function of

the Bobcat Interlock Control

System (BICS™) before the

machine is returned to the

customer.

19. Check the electrical charging

system.

25. Check for proper function of

front horn and back-up alarm

(if equipped).

20. Check tires for wear and

pressure. Check tracks for

wear and tension. Use only

approved tires or tracks.

26. Check function or condition of

all equipped options and

accessories (examples: fire

extinguisher, rotating beacon,

lift kits, etc.).

21. Inspect for loose or broken

parts or connections.

27. Recommend to the owner

that all necessary corrections

be made before the machine

is returned to service.

22. Check for any field

modification not completed.

CALIFORNIA

PROPOSITION 65 WARNING

Diesel engine exhaust and some of its

constituents are known to the state of California

to cause cancer, birth defects and other

reproductive harm.

T200 Bobcat Loader

IV Service Manual

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Viewed 12 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Thank you for considering this comprehensive Service Repair Workshop Manual for the Bobcat T200 Turbo Series Track Loader.

This manual is an invaluable resource covering every Service & Repair Procedure necessary for professional mechanics and DIY enthusiasts alike.

DESCRIPTION:

- This manual provides easy-to-follow step-by-step instructions and detailed pictures for all servicing and repairs, enabling significant cost savings by performing repairs independently.

- Once downloaded, the manual is yours to keep forever. You have the flexibility to print individual pages, chapters, or the entire manual. It can also be saved to your tablet or smartphone for easy access.

MODELS COVERED:

- All Models/Engines/Trim/Transmissions Types are comprehensively covered in this manual.

CONTENTS:

- This high-quality Service Repair Workshop Manual encompasses all repair procedures from A to Z, ensuring that every repair and service procedure is thoroughly addressed.

COMPUTER REQUIREMENTS:

- This downloadable Manual is compatible with all PC & MAC Computers, tablets, and mobile phones. The only software required is Adobe Reader, which is typically pre-installed on most computers or can be downloaded for free.

INSTANT DELIVERY:

- Upon payment confirmation via Visa, MasterCard, or PayPal, the manual will be instantly emailed to the address provided during checkout.

Customer Satisfaction Guaranteed.