JCB ROBOT 190,190HF,1110,1110HF Operator Handbook Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Operator Handbook

ROBOT 190, 190HF, 1110, 1110HF

From serial number 888000 onwards

!

THIS HANDBOOK MUST BE KEPT IN THE MACHINE AT ALL TIMES

!

Publication Number 9801/4320 January 2002 Issue 4

Purchased from www.WorkshopManuals.co.uk

Purchased from www.WorkshopManuals.co.uk

SAFETY NOTICES

!

WARNING

Study This Handbook Before Starting The Machine

You must understand and follow the instructions in this handbook. You must

observe all relevant laws and regulations. If you are unsure about anything, ask your

JCB distributor or employer. Do not guess, you or others could be killed or

seriously injured.

INT-1-1-1

!

CAUTION

Do not fit an attachment to this machine which is not JCB approved. Consult your

JCB distributor before fitting any non approved attachment.

8-4-1-6

4320-1

In this handbook and on the machine there are safety notices. Each notice starts

with a signal word. The meanings of the signal words are given below.

!

DANGER

Denotes an extreme hazard exists. If proper precautions are not taken, it is

highly probable that the operator (or others) could be killed or seriously

injured.

INT-1-2-1

!

WARNING

Denotes a hazard exists. If proper precautions are not taken, the operator

(or others) could be killed or seriously injured.

INT-1-2-2

!

CAUTION

Denotes a reminder of safety practices. Failure to follow these safety

practices could result in injury to the operator (or others) and possible

damage to the machine.

INT-1-2-3

MACHINE SECURITY

Vandalism and theft of unattended machines is an ever increasing problem and

JCB is doing everything possible to help combat this.

JCB PLANTGUARD is a comprehensive package available to help you safeguard

your machine. It includes such devices as vandal proof covers, window etching,

immobiliser, concealed serial number, battery isolator, Tracker security system

and much more.

Remember that the fitting of any one of these security devices will help to

minimise not only the damage or loss of your machine but also subsequent lost

productivity. It could also result in reduced insurance premiums.

Your JCB Distributor or Dealer will be pleased to provide information on any of

these sensible precautions. ACT NOW!

INT-1-2-4

Purchased from www.WorkshopManuals.co.uk

i i

CONTENTS

INTRODUCTION Page

About this Handbook

Machine Models ........................................................ 1

Using this Handbook ................................................. 1

Location of Handbook ............................................... 1

Units of Measurement ............................................... 1

Page Numbering ....................................................... 1

Left Side, Right Side ................................................. 1

Using the Machine .................................................... 1

The JCB Skid Steer Loader

Machine Description .................................................. 2

Safety First - Yours and Other People's ................ 3

Safety Check List

General Safety .......................................................... 3

Operating Safety ....................................................... 4

Maintenance Safety .................................................. 5

Safety Decals .......................................................... 8

Identifying Your Machine

Machine Identification Plate ..................................... 9

Typical Vehicle Identification Number (VIN) ................ 9

Unit Identification ...................................................... 9

JCB Immobiliser Option ........................................ 10

OPERATION

Introduction ............................................................ 21

Before Entering the Cab ........................................ 21

Entering/Leaving the Cab ........................................ 22

Cab Door and Vents

Opening and Closing the Cab Door ......................... 23

Ventilation of Optional Glazed Cab .......................... 23

Emergency Exits .................................................... 24

Seat and Safety Restraint

Seat Adjustment .......................................................... 25

Seat Removal and Replacement ................................ 25

Safety Restraint .......................................................... 25

Controls, Switches and Instruments

Cab Layout (servo machines) ................................ 26

Cab Layout (manual machines) ............................. 28

Switches ..................................................................... 30

Warning Indicators ................................................... 31

Seat Belt

Fastening the Seat Belt ............................................ 32

Releasing the Seat Belt ............................................ 32

Checking Seat Belt Operation .................................. 32

Page

Cab Heater Unit (optional) ..................................... 33

Cab Interior Light (optional) .................................. 34

Loader Controls (servo machines)

Loader Arm/Shovel Control Lever

(single lever drive control) ........................................ 34

Loader ArmControl Lever (dual lever drive control) .... 34A

Shovel Control Lever (dual lever drive control) ........... 34A

Auxiliary Attachments Control Pedal (optional) ........... 35

Float Control Switch (optional) ................................... 35

Loader Controls (manual machines)

Loader Arm Control - Lever Option ............................ 36

Shovel Control - Lever Option .................................... 36

Loader Arm/Shovel Control - Pedal Option ................ 37

Auxiliary Attachments Control (optional) .................... 37

Before Starting the Engine .................................... 38

Starting the Engine ................................................ 39

Jump-Starting the Engine ..................................... 40

Rotating Beacon (optional) ................................... 41

Travelling Position

Travelling on Site ..................................................... 41

Travelling on Public Roads ...................................... 41

Travelling on Public Roads (UK only) ......................... 42

Driving the Machine

Drive Control Lever (servo single lever control) ........... 43

Drive Control Levers

(servo dual lever drive & manual controls) ................ 44

Getting Moving ......................................................... 45

Stopping and Parking ............................................... 45

Operating Practices .................................................. 46

Using the Attachments and Site Safety ............... 47

Quickhitch Control

Engaging the Shovel/Attachments ........................... 49

Disengaging the Shovel/Attachments ...................... 50

Working with the Loader

Filling the Shovel ...................................................... 51

Loading a Truck ....................................................... 51

Scraping and Cutting ............................................... 51

Operating in Low Temperatures ........................... 52

Operating in High Temperatures .......................... 52

Moving a Disabled Machine

Preparation for Towing/Winching ............................... 53

After Towing/Winching ................................................ 53

4320-2

Purchased from www.WorkshopManuals.co.uk

ii ii

CONTENTS

OPERATION (cont’d) Page

Transporting the Machine

Using a Trailer ......................................................... 54

Using a Truck .......................................................... 55

Transportation Safety .............................................. 55

Lifting the Machine

Safe Lifting Procedure .............................................. 57

Emergency Load Lower Procedure ....................... 56

Testing the Parking Brake ........................................ 57

MAINTENANCE

Service Requirements ........................................... 61

Lubricants - Health and Safety

Hygiene ................................................................... 62

Storage .................................................................... 62

Waste Disposal ........................................................ 62

Handling ................................................................... 62

First Aid - Oil ............................................................ 62

Spillage .................................................................... 62

Fires ......................................................................... 62

Service Schedules

Every 10 Operating Hours or Daily .......................... 63

Every 50 Operating Hours or Weekly ...................... 63

Every 100 Operating Hours or 2 Weekly ................. 63

Every 250 Operating Hours or Monthly ................... 64

Every 500 Operating Hours or 6 Monthly ................ 64

Every 1000 Operating Hours or Yearly .................... 64

Every 2000 Operating Hours or 2 Yearly ................. 64

Cleaning the Cab Floor and Rear Chassis ............. 65

ROPS/FOPS Cab/Canopy

Checking the ROPS/FOPS Cab/Canopy ................. 65

Loader Arm Safety Strut

Installing the Safety Strut ......................................... 66

Removing the Safety Strut ....................................... 66

Engine Compartment Access

Top Cover ................................................................. 67

Rear Panel ................................................................. 67

Radiator and Oil Cooler ............................................... 67

Cleaning the Radiator and Oil Cooler ....................... 67

Seat Belt

Checking Seat Belt Condition and Security .............. 68

Greasing (10 Hours)

Quickhitch Pivot Points ............................................. 68

Page

Greasing (50 Hours)

Loader Arm Pivot Point ............................................ 69

Lift Ram Pivots ......................................................... 69

Greasing and Oiling (100 Hours)

Safety Restraint mechanism ...................................... 70

Control Linkage (manual machines) ........................... 70

Throttle Pedal (if fitted) ............................................. 70

Engine Air Filter

Changing the Elements ........................................... 71

Engine Oil and Filter

Checking the Oil Level ............................................. 72

Changing the Oil and Filter ...................................... 72

Engine Cooling System

Coolant Mixtures ...................................................... 74

Checking the Coolant Level ..................................... 74

Changing the Coolant .............................................. 75

Cleaning the Coolant Radiator and Oil Cooler ......... 75

Engine Alternator Belt

Checking the Alternator Belt Tension ........................ 76

Adjusting the Alternator Belt ..................................... 76

Drive Chain Lubrication

Checking the Oil Level ............................................. 77

Changing the Oil ...................................................... 77

Fuel System

Types of Fuel ........................................................... 78

Fuel Standards ........................................................ 78

Low Temperature Fuels ........................................... 78

Petrol ....................................................................... 78

Advice ...................................................................... 78

Fatty Acid Methyl Ester Fuels .................................... 78

Filling the Tank ........................................................ 78

Draining the Fuel Sediment Bowl .............................. 79

Changing the Fuel Filter Element .............................. 80

Bleeding the Fuel System .......................................... 80

Hydraulic System

Checking the Oil Level ............................................ 81

Changing the Filter .................................................. 81

Changing the High-flow Filter .................................... 82

Battery

Safety ...................................................................... 83

Checking the Electrolyte Level ................................ 84

Warning Symbols ..................................................... 84

Electrical System

Fuses .......................................................................... 85

Primary Fuses ............................................................ 86

Relays ........................................................................ 86

Light Bulbs ................................................................. 86

4320-4

Purchased from www.WorkshopManuals.co.uk

iii iii

CONTENTS

MAINTENANCE (cont’d) Page

Windscreen Washer ............................................... 87

Tracks

Track Adjustment ....................................................... 87

Tyres and Wheels

Inflating the Tyres ..................................................... 88

Renewing Segments of Optional Non-Inflatable Tyres 88

Checking the Wheel Nut Torques ............................ 88

Fluids, Capacities and Lubricants ........................ 89

Obtaining Replacement Parts ................................ 89

Storage

Storing the Machine ................................................... 90

OPTIONAL ATTACHMENTS Page

Introduction ........................................................... 101

Quick Release Couplings ..................................... 102

Connecting/Disconnecting Hydraulic Hoses ..... 103

Attachments Controls ............................................ 104

Shovels .................................................................... 105

6-in-1 Shovel ............................................................ 105

Pallet Forks .............................................................. 108

Manure/Silage Fork with Top Grab ........................ 109

Attachment Frame ................................................... 110

Wheel Mounted Tracks ........................................... 111

SPECIFICATION

General Specification ............................................. 131

Tyre Specification ................................................... 131

Static Dimensions - Wheeled Machines ................ 132

Static Dimensions - Tracked Machines ................ 134

Noise and Vibration Data

Machines up to serial no. 888055 ............................. 136

Machines from serial no. 888056 .............................. 137

4320-3

Purchased from www.WorkshopManuals.co.uk

1 1

INTRODUCTION

ABOUT THIS HANDBOOK

Machine Models

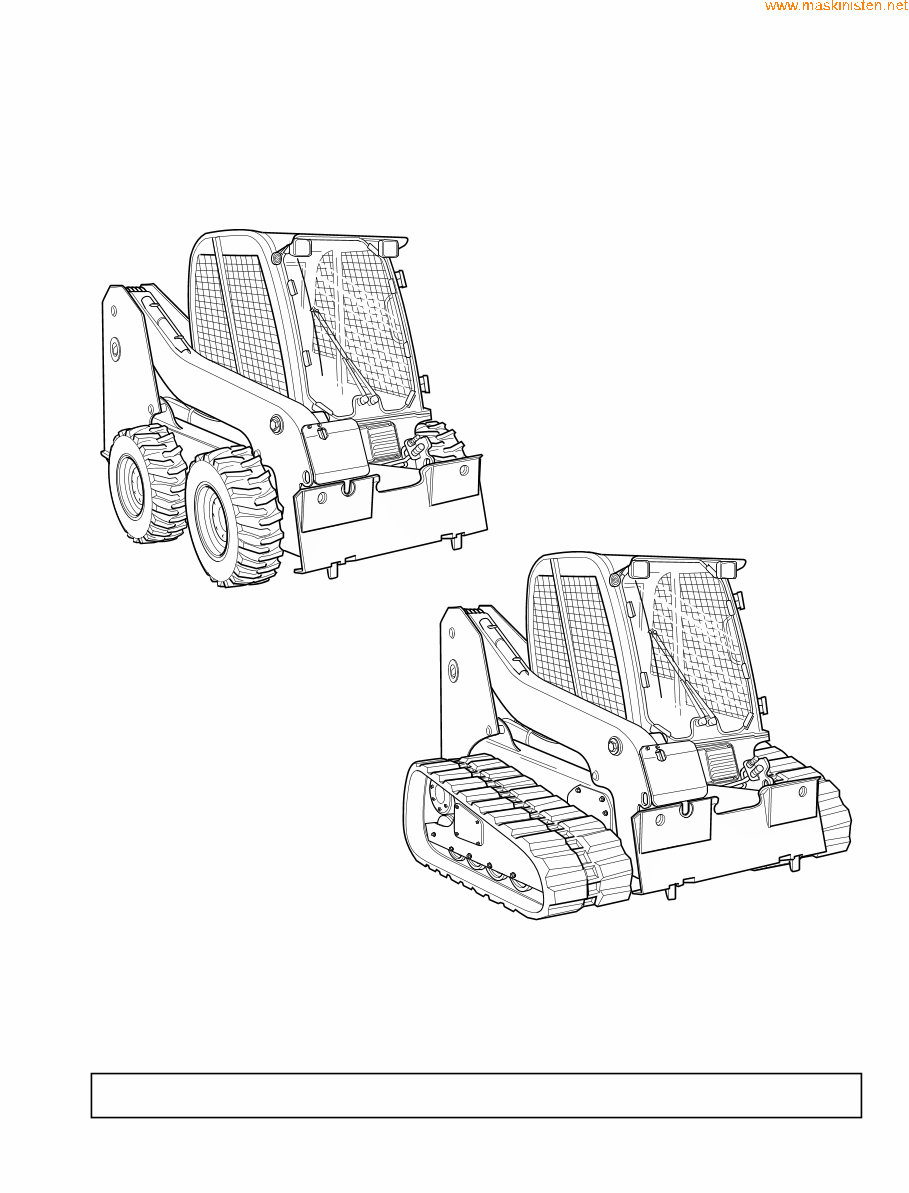

This handbook provides information for the following

models in the JCB Skid Steer Loader range:

Robot 190, 190HF, 1110 and 1110HF

from serial no. 888000

The handbook covers both servo and manual controls

although some illustrations may show only one type.

Information also covers both wheeled and tracked

machines unless otherwise stated.

Using this Handbook

The illustrations in this handbook are for guidance only.

Where the machines differ, the text and/or the illustration

will specify.

This handbook is arranged to give you a good

understanding of the machine and its safe operation. It also

contains maintenance information and specification data.

Read this handbook from front to back before using the

machine for the first time. Particular attention must be given

to all the safety aspects of operating and maintaining the

machine.

General warnings in this chapter are repeated throughout

the book, as well as specific warnings. Read all the safety

statements regularly, so you do not forget them. Remember

that the best operators are the safest operators.

Finally, treat this handbook as part of the machine. Keep it

clean and in good condition. Do not operate the machine

without a handbook in the cab. If there is anything you are

not sure about, ask your JCB distributor or employer. Do

not guess, you or others could be killed or seriously injured.

The manufacturer's policy is one of continuous

improvement. The right to change the specification of the

machine without notice is reserved. No responsibility will be

accepted for discrepancies which may occur between

specifications of the machine and the descriptions

contained in this publication.

INT-1-2-5/1

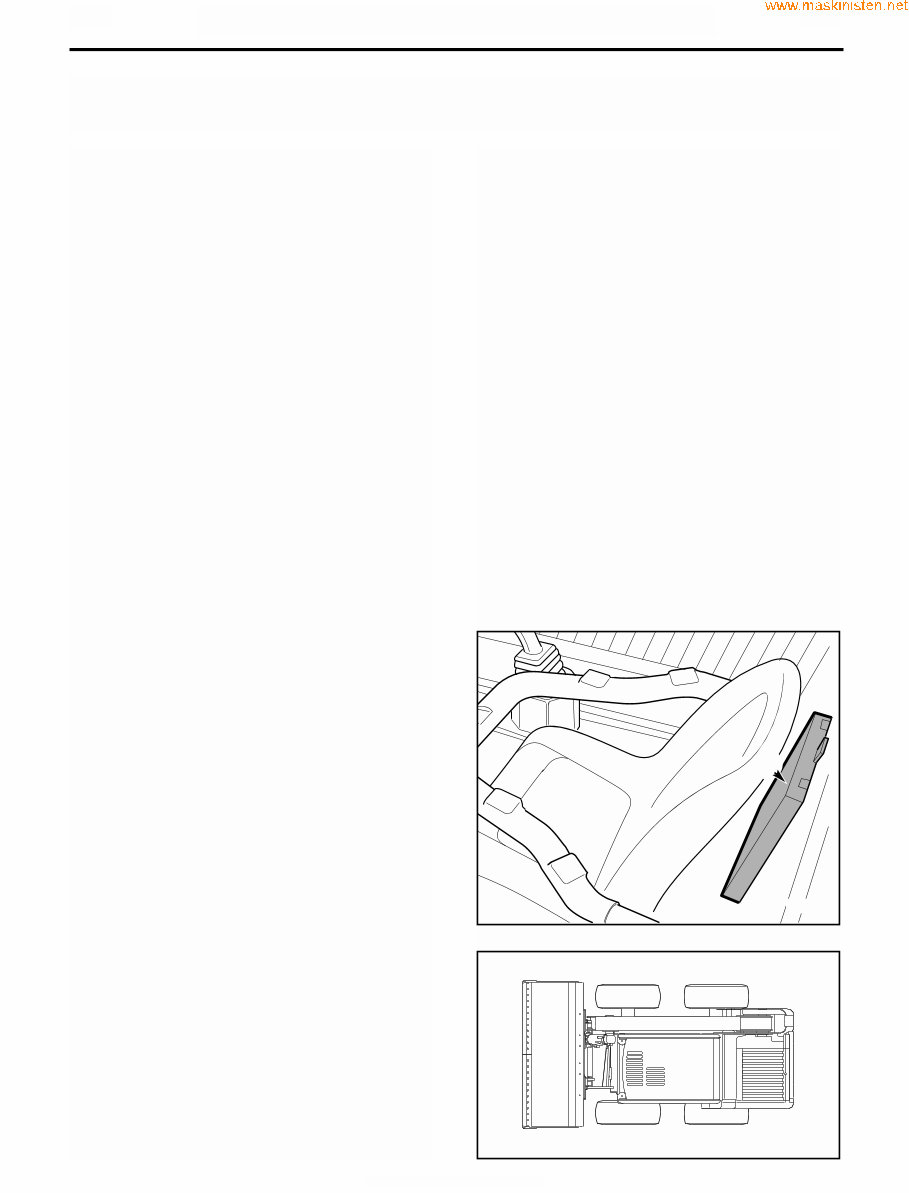

Location of Handbook

The handbook is located in the case provided which is

behind the seat, as shown at A. The handbook should

always be returned to its correct stowage.

Units of Measurement

In this handbook, the S.I. system of units is used. For

example, liquid capacities are given in litres. The Imperial

units follow in parenthesis () eg 28 litres (6 UK gal).

Page Numbering

The page numbering system in this handbook is not

continuous. There is a gap between sections. This allows

for the insertion of new pages in later issues of the

handbook.

Left Side, Right Side

In this handbook, 'left' B and 'right' C mean your left and

right when you are seated correctly in the machine.

Using the Machine

To use the Skid Steer Loader efficiently and safely you

must know the machine and have the skill to use it. This

handbook instructs you on the machine, its controls and its

safe operation. It is not a training manual on the art of

loading. If you are a new operator, get yourself trained in

the skills of using a Skid Steer Loader before trying to work

with it. If you do not, you will not do your job well, and you

will be a danger to yourself and others.

4320-1

378210

C

B

332720

A

Purchased from www.WorkshopManuals.co.uk

2 2

INTRODUCTION

THE JCB SKIDSTEER LOADER

4320-1

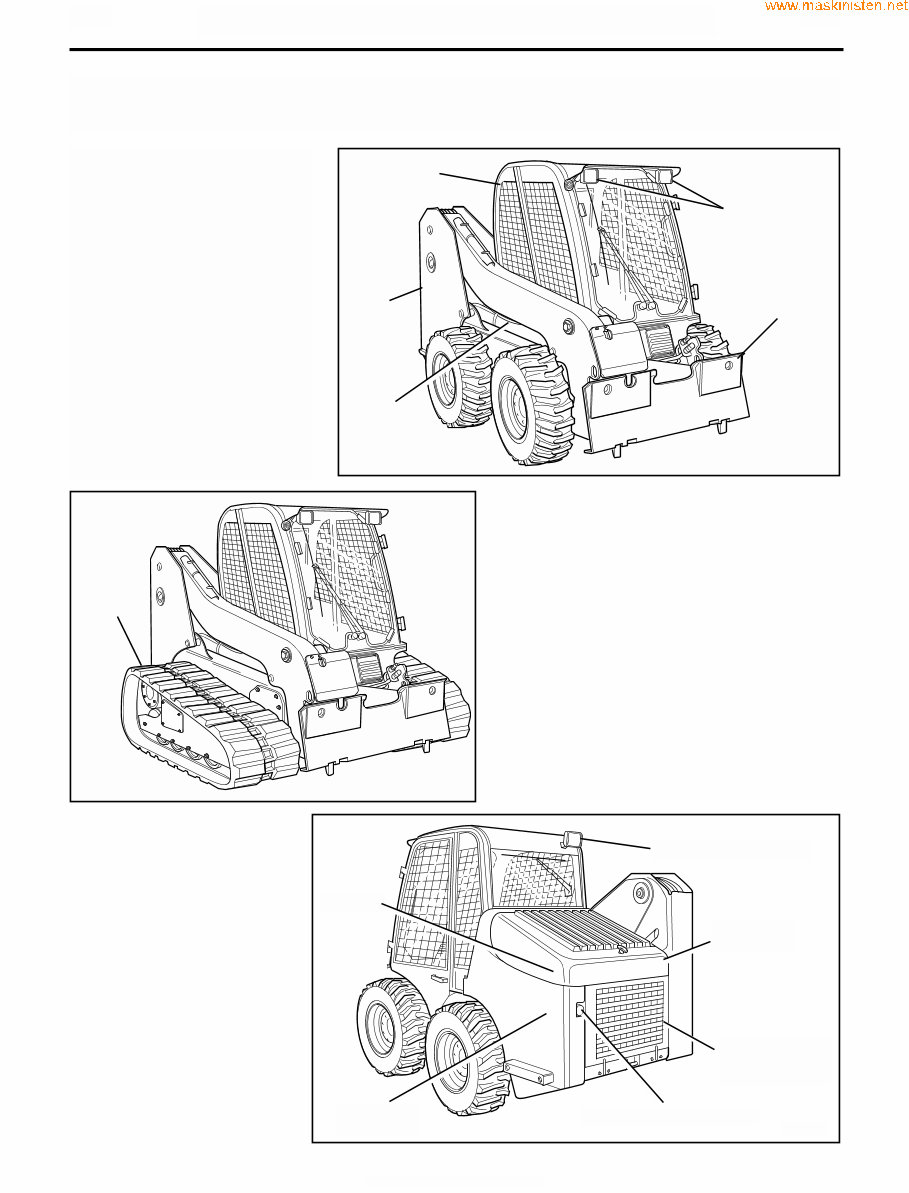

Machine Description

The Robot is a self propelled skid steer

machine fitted with either wheels or

tracks. The main structural support is

designed to carry a front mounted

carriage onto which a shovel or an

approved attachment can be fitted.

When used normally with a shovel

fitted, the machine loads or excavates

through forward motion of the machine

and lifts, transports and discharges

material.

ROPS/FOPS

CAB

LOADER

ARM

QUICKHITCH

FRONT

WORKING

LIGHTS

378230

378220

ENGINE

COMPARTMENT

REAR COVER

HYDRAULIC SIGHT GLASS

HYDRAULIC

TANK

ENGINE

TOP COVER

REAR WORKING LIGHT

BATTERY

FUEL

TANK

378240

RUBBER

TRACKS

Purchased from www.WorkshopManuals.co.uk

3 3

INTRODUCTION

SAFETY FIRST - YOURS AND OTHER PEOPLE'S

All construction and agricultural equipment can be

hazardous. When a Skid Steer Loader is correctly operated

and properly maintained, it is a safe machine to work with.

But when it is carelessly operated or poorly maintained it

can become a danger to you (the operator) and others.

In this handbook and on the machine you will find warning

messages. Read and understand them. They tell you of

potential hazards and how to avoid them. If you do not fully

understand the warning messages, ask your employer or

JCB distributor to explain them.

But safety is not just a matter of responding to the

warnings. All the time you are working on or with the

machine you must be thinking what hazards there might be

and how to avoid them.

General Safety

!

WARNING

Handbook

You and others can be injured if you operate or maintain

the machine without first studying this handbook. Read the

safety instructions before operating the machine. If you do

not understand anything, ask your employer or JCB

distributor to explain it. Keep this handbook clean and in

good condition. Do not operate the machine without a

handbook in the cab, or if there is anything on the machine

you do not understand.

INT-1-3-2

!

CAUTION

Regulations

Obey all laws, work site and local regulations which affect

you and your machine.

INT-1-3-3

!

WARNING

Decals

You can be injured if you do not obey the decal safety

instructions. Keep decals clean. Replace unreadable or

missing decals with new ones before operating the

machine. Make sure replacement parts include warning

decals where necessary.

INT-1-3-4

!

WARNING

Care and Alertness

All the time you are working with or on the machine, take

care and stay alert. Always be careful. Always be alert for

hazards.

INT-1-3-5

Do not work with the machine until you are sure that you

can control it.

Do not start any job until you are sure that you and those

around you will be safe.

If you are unsure of anything, about the machine or the job,

ask someone who knows. Do not assume anything.

Remember

BE CAREFUL

BE ALERT

BE SAFE

INT-1-3-1/1

!

WARNING

Raised Attachments

Raised attachments can fall and injure you. Do not walk or

work under raised attachments unless they are safely

blocked.

INT-1-3-8

!

WARNING

Clothing

You can be injured if you do not wear the proper clothing.

Loose clothing can get caught in the machinery. Wear

protective clothing to suit the job. Examples of protective

clothing are: a hard hat, safety shoes, safety glasses, a well

fitting overall, ear-protectors and industrial gloves. Keep

cuffs fastened. Do not wear a necktie or scarf. Keep long

hair restrained.

INT-1-3-6

!

WARNING

Lifting Equipment

You can be injured if you use faulty lifting equipment. Make

sure that lifting equipment is in good condition. Make sure

that lifting tackle complies with all local regulations and is

suitable for the job. Make sure that lifting equipment is

strong enough for the job.

INT-1-3-7

4230-1

SAFETY CHECK LIST

Purchased from www.WorkshopManuals.co.uk

4 4

INTRODUCTION

SAFETY CHECK LIST

(continued)

General Safety (continued)

!

WARNING

Alcohol and Drugs

It is extremely dangerous to operate machinery when

under the influence of alcohol or drugs. Do not consume

alcoholic drinks or take drugs before or whilst operating

the machine or attachments. Be aware of medicines which

can cause drowsiness.

INT-1-3-9

Operating Safety

!

WARNING

Practice

You or others can be killed or seriously injured if you do

unfamiliar operations without first practising them.

Practise away from the work site on a clear area. Keep

other people away. Do not perform new operations until

you are sure you can do them safely.

INT-2-1-1

!

WARNING

Machine Condition

A defective machine can injure you or others. Do not

operate a machine which is defective or has missing parts.

Make sure the maintenance procedures in this handbook

are completed before using the machine.

INT-2-1-2

!

WARNING

Controls

You or others can be killed or seriously injured if you

operate the control levers from outside the cab. Operate

the controls levers only when you are correctly seated

inside the cab.

INT-2-1-3

!

WARNING

Machine Limits

Operating the machine beyond its design limits can

damage the machine, it can also be dangerous. Do not

operate the machine outside its limits. Do not try to

upgrade the machine performance with unapproved

modifications.

INT-2-1-4

!

WARNING

Passengers

Passengers in or on the machine can cause accidents. The

JCB Skid Steer Loader is a one man machine. Do not carry

passengers.

INT-2-2-2

!

CAUTION

Machine Modifications

This machine is manufactured in compliance with

legislative and other requirements. It should not be altered

in any way which could affect or invalidate any of these

requirements. For advice consult your JCB Distributor.

Reference should also be made to Optional Attachments

section where appropriate.

INT-1-3-10

!

WARNING

Rollover

Should the machine start to roll over, you can be crushed

if you try to leave the cab. If the machine starts to roll over,

DO NOT TRY TO JUMP FROM THE CAB. STAY IN THE

CAB, WITH YOUR SEAT BELT FASTENED.

INT-2-1-12

!

WARNING

ROPS/FOPS Structure

The machine is fitted with a Roll Over Protection Structure

(ROPS) and a Falling Objects Protection Structure (FOPS).

You could be killed or seriously injured if you operate the

machine with a damaged or missing ROPS/FOPS. If the

ROPS/FOPS has been in an accident, do not use the

machine until the structure has been renewed.

Modifications and repairs that are not approved by the

manufacturer may be dangerous and will invalidate the

ROPS/FOPS certification.

INT-2-1-9/3

!

WARNING

Seat Belts

The ROPS/FOPS cab is designed to give you protection in

an accident. If you do not wear your seat belt, you could

be thrown around inside the cab or thrown out of the

machine and crushed. You must wear a seat belt when

using the machine. Fasten the seat belt before starting the

engine.

2-2-1-9

!

CAUTION

Cold Starting

Do not use ether or other starting fluids to assist cold

starting. Using these fluids may result in an explosion

causing possible injury and/or damage to the engine.

3-2-1-9

4230-1

Purchased from www.WorkshopManuals.co.uk

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Viewed 17 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Get your hands on the JCB Skid-Steer Operator Handbook for models 190, 190HF, 1110, and 1110HF. This professional manual comes in a version (in format) and spans 112 pages in English. Packed with crucial tips and advice, this manual is indispensable for both professional mechanics and DIY enthusiasts. Every machine operator should have access to these essential instructions!