Wacker RT560 and RT820 operators manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Operator’s Manual

Roller

RT 560

RT 820

0085214

D0194

0 0 8 5 2 1 4

Information Contained In

This Manual

This manual provides information and procedures to

safely operate and maintain the WACKER RT 560 and RT

820 Trench Rollers. This machine is equipped with a two-

cylinder Lombardini diesel engine.

For your own safety and protection from physical

injury, carefully read, understand, and observe the

safety instructions described in this manual.

Always operate and maintain your machine in accor-

dance with the instructions described in this manual. A

well maintained machine will provide many years of

trouble-free operation.

This book is divided into two sections:

General Operating Information

Infra-Red Remote Control Operation

Ordering Parts

A Parts Manual is available for this machine and can

be ordered using P/N 85215.

Additional Engine Information

A manual for the engine was supplied with the machine

at the time of its shipment from the factory. This

manual provides detailed maintenance procedures for

the engine.

For additional service information on the engine, order

Work Shop Manual, P/N 74232.

FOREWORD

This Manual covers machines with

Serial Numbers beginning:

6594, 6595

6784, 6785

Keep a copy of this manual with the machine. If a manual

becomes lost or additional copies are desired, please

contact WACKER Corporation.

1

2

THE INFORMATION CONTAINED IN THIS MANUAL WAS BASED ON MACHINES IN PRODUCTION AT THE TIME OF PUBLICATION.

WACKER CORPORATION RESERVES THE RIGHT TO CHANGE ANY PORTION OF THIS INFORMATION WITHOUT NOTICE.

FOREWORD

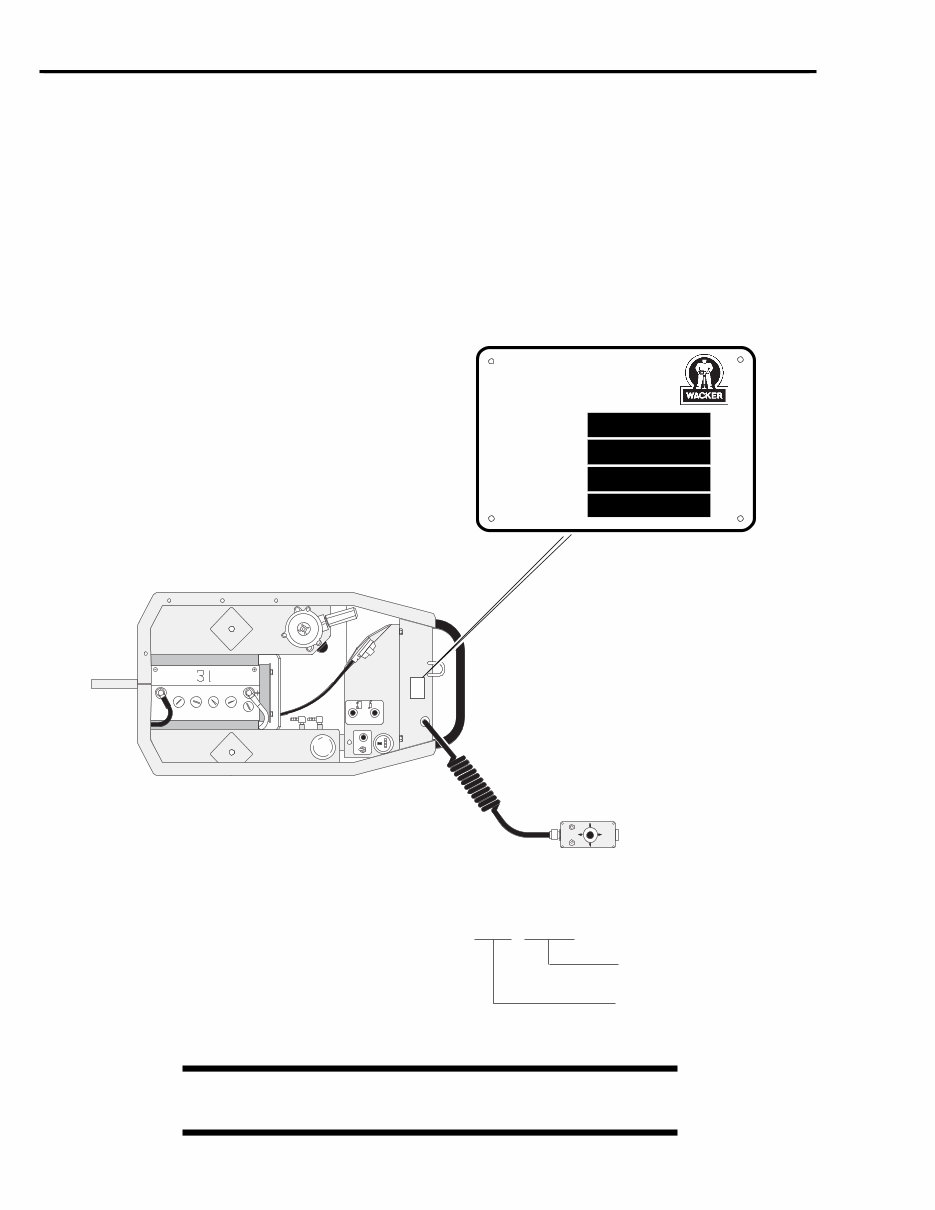

Identification Plate

Serial Number

Production Sequence

Model Identification

6594 00123 The serial number found on the identification plate is a

nine digit number. The first four digits identify the

specific machine model (Bill of Material). The last five

numbers indicate the production sequence for that

model.

An identification plate listing the Model Number and Serial Number is attached to each machine and is located

inside on the control panel. This plate should not be removed from the machine.

Please record the information found on this plate so it will be available should the identification plate become lost

or damaged. When ordering parts or requesting service information you will always be asked to specify the model

and serial number of the unit.

The serial number identifies your machine and will

ensure that you receive the correct replacement parts.

WACKER

CORPORATION

Model

Serial No.

Weight

Year

````

1002SD33

4

1-1

RT560/RT820

General Operating Information

Table of Contents

Page

SAFETY

1.1 Safety Notes ..................................... 1-2

1.2 Operating Safety ............................... 1-3

1.3 Engine Safety .................................... 1-3

1.4 Service Safety .................................. 1-4

TECHNICAL DATA

1.5 Engine ............................................... 1-5

1.6 Roller ................................................. 1-5

1.7 Lubrication ........................................ 1-5

OPERATION

1.8 Controls & Service Locations- Roller 1-6

1.9 Service Locations - Engine ............... 1-7

1.10 Before Starting .................................. 1-8

1.11 Starting .............................................. 1-8

1.12 Stopping ............................................ 1-8

1.13 Travel ................................................ 1-8

1.14 Direction & Steering Control ............. 1-8

1.15 Vibration ............................................ 1-9

1.16 Safety Bar ......................................... 1-9

1.17 Operation on Slopes ......................... 1-9

1.18 Engine Speed .................................. 1-10

1.19 Engine Oil Pressure Light ............... 1-10

1.20 Charging System Light ................... 1-10

1.21 Hour Meter ...................................... 1-10

1.22 Articulated Joint Locking Pin ........... 1-10

1.23 Automatic Engine Shut-off .............. 1-10

Page

MAINTENANCE

1.24 Engine Fuel Delivery System ......... 1-11

1.25 New Machines ................................ 1-11

1.26 Periodic Maintenance Schedule ..... 1-11

1.27 Air Cleaner ...................................... 1-12

1.28 Engine Lubrication .......................... 1-12

1.29 Articulated Joint & Steering Cyl. ..... 1-12

1.30 Drive Gearcase .............................. 1-13

1.31 Exciter ............................................. 1-13

1.32 Engine Valve Clearance ................. 1-13

1.33 Fuel Filter ........................................ 1-14

1.34 Priming Fuel System ....................... 1-14

1.35 Cleaning Engine Cylinder

Cooling Fins ..................................... 1-14

1.36 Scraper Bars .................................. 1-14

1.37 Shockmounts .................................. 1-14

1.38 Hydraulic Oil Requirements ............ 1-15

1.39 Changing Hydraulic Fluid & Filter .... 1-15

1.40 Hydraulic Fluid Level ...................... 1-15

1.41 Transporting Machine ..................... 1-16

1.42 Lifting Machine ................................ 1-16

1.43 Changing Drums ............................. 1-16

1.44 Battery ............................................ 1-17

1.45 Tightening Hardware ....................... 1-17

1.46 Jobsite Storage ............................... 1-17

1.47 Long Term Storage ......................... 1-17

TROUBLESHOOTING

1.48 General ........................................... 1-18

1.49 Hydraulic Schematic ....................... 1-19

1.50 Control Box Wiring .......................... 1-20

1.51 Relay Panel and Engine Wiring ...... 1-21

(W/15 Amp Vibration Relay Fuse)

1.52 Relay Panel and Engine Wiring ...... 1-22

(W/O 15 Amp Vibration Relay Fuse)

1

1-2

1

WACKER equipment is designed with user safety in mind. When

properly maintained and used by trained operators in the applica-

tions for which it was intended, this machine will provide many years

of safe, reliable service.

Should questions arise during the operation or service of this equip-

ment please contact your area WACKER Customer Support Center.

A complete listing of Support Centers appears on the front and rear

covers of this manual.

CAUTION

WARNING

Warnings warn of conditions or practices which

could lead to personal injury or death!

1.1 Safety Notes

This manual contains NOTES, CAUTIONS and WARNINGS which must be followed to prevent the possibility of improper

service, damage to the equipment or personal injury.

Notes: Notes appear in italics and contain additional

information important to a procedure.

Cautions provide information important to prevent

errors which could damage machine or components.

SAFETY

1-3

1

1.2 Operating Safety

Familiarity and proper training are required for the safe operation

of mechanical equipment !

Equipment operated improperly or by untrained personnel can be dangerous! Read the operating instructions and

familiarize yourself with the location and proper use of all controls. Inexperienced operators should receive

instruction from someone familiar with the equipment before being allowed to operate the machine.

Check that all safety devices and guards are in place before starting machine! DO NOT operate

machine if any safety devices or guards are missing or inoperative.

Disengage locking pin for the articulated joint before operating machine. The machine cannot be steered

when the locking pin is engaged.

Check that all controls are functioning properly immediately after start-up! DO NOT operate machine

unless all controls operate correctly.

Remain aware of changing positions and movement of other equipment and personnel on the jobsite.

Remain in visual contact with machine at all times while operating controls.

Remain aware of changing surface conditions and use extra care when operating over uneven ground,

on hills or over coarse material. The machine could shift or slide unexpectedly.

Use caution when operating near the edges of pits, trenches or platforms. Check to be sure ground

surface is stable enough to support the weight of the machine and there is no danger of the roller sliding,

falling or tipping.

Position yourself safely when operating machine in reverse or on hills. Leave enough space between

yourself and the machine so you will not be placed in a hazardous position should the machine slide

or tip.

WARNING

DO NOT run engine indoors or in an area with poor ventilation unless exhaust hoses are used.

DO NOT fill fuel tank near an open flame, while smoking or while engine is running.

DO NOT fill tank in an enclosed area with poor ventilation.

DO NOT touch or lean against hot exhaust pipes or engine cylinder.

DO NOT operate with the fuel tank cap loose or missing.

Keep area around hot exhaust pipes free of debris to reduce the chance of an accidental fire.

WARNING

1.3 Engine Safety

Internal combustion engines present special hazards during operation and fueling !

Failure to follow the safety guidelines described below could result in severe injury or death.

SAFETY

1-4

1

1.4 Service Safety

Poorly maintained equipment can become a safety hazard !

In order for the equipment to operate safely and properly over a long period of time periodic maintenance and

occasional repairs are necessary.

Replace all guards and safety devices immediately after servicing.

Turn engine off before performing maintenance or making repairs.

Secure the articulated joint using the locking pin before lifting or jacking machine up. Machine halves

could swing together unexpectedly and cause a serious injury if this is not done.

DO NOT open hydraulic lines or loosen hydraulic connections while engine is running! Hydraulic fluid

under pressure can penetrate the skin, cause burns, blind or create other potentially dangerous hazards.

Set all controls in neutral and turn engine off before loosening hydraulic lines.

Keep hands, feet and loose clothing away from moving parts.

Replace all missing and hard to read decals. See Parts Manual.

Check and tighten all external fasteners at regular intervals.

Make sure slings, chains, hooks, ramps, jacks and other types of lifting devices are attached securely

and have enough weight bearing capacity to lift or hold the machine safely. Always remain aware of

the position of other people around you when lifting the machine.

DO NOT modify the equipment without expressed written approval from WACKER Corporation.

WARNING

SAFETY

1-5

1

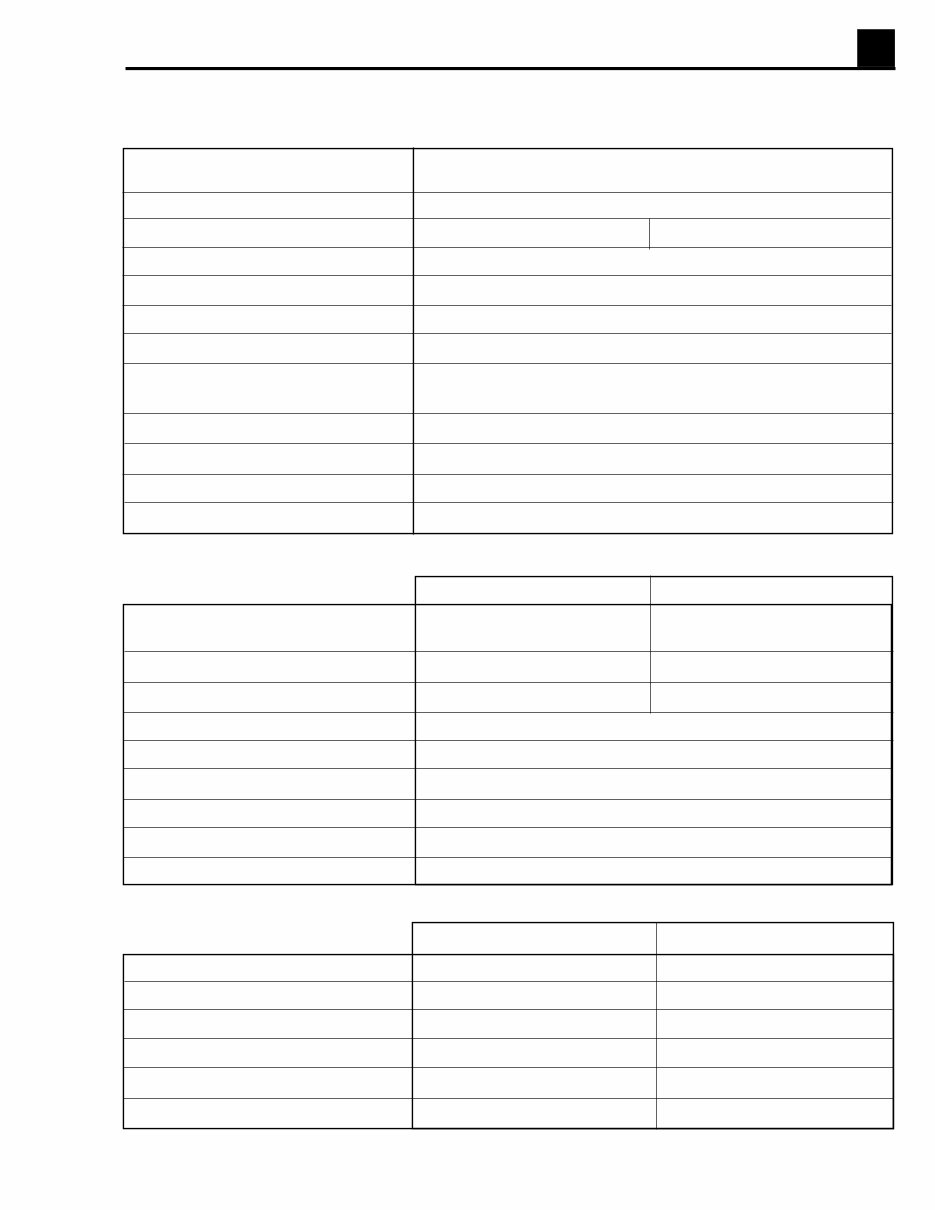

Engine Type Two cylinder,4-cycle

air cooled, diesel engine

Engine Make Lombardini

Engine Model 12LD435-2

1

12LD475-2

1

Power @ 2500 rpm Hp (kW) 16 (12)

Operating Speed rpm 2600 ± 100

Alternator V / Amp 12 / 14

Battery V/ A hr/size 12 / 160 / 31

Air Cleaner Type Dry pleated paper element

with pre-cleaner

Valve Clearance - in/ex in.(mm) .006 -.008 (0.15-0.20)

Fuel Type No.2 Diesel

Fuel Consumption gal.(l)/hr 1.1 (4.2)

Fuel Tank Capacity gal. (l) 5.6 (21)

1.5 Engine

Type Quantity

Engine Crankcase SAE 15W40, CD rated 2.5 qts (2.5 litres)

Hydraulic System *SAE 10W30 - Hydraulic Fluid 10.5 gal. (40 litres)

Exciter SAE 10W 32 oz. (.95 litres)

Drum Drive Gearcase SAE 10 W 8 oz. (240 ml)

Articulated Joint Shell Alvania No. 2 As required

Steering Cylinder Shell Alvania No. 2 As required

1.7 Lubrication

* See Section 1.38 Hydraulic Oil Requirements.

TECHNICAL DATA

1

Refer to identification plate on engine.

RT 560 RT 820

Overall Dimensions (l x w x h) in 80 x 22 x 48 80 x 32 x 48

(mm) (2030 x 560 x 1220) 2030 x 820 x 1220

Operating Weight lbs.(Kg) 2830 (1283 ) 2960 (1345)

Area Capacity ft

2

(m

2

) / hr 7500 (690) 10900 (1016)

Inside Turning Radius in (m) 58 (1.5)

Low Speed ft (m)/min. 68 (21)

High Speed ft (m)/min. 136 (41)

Vibration Frequency vpm (Hz) 2400 (40)

Gradeability with vibration % 50

Gradeability without vibration % 55

1.6 Roller

1-6

1

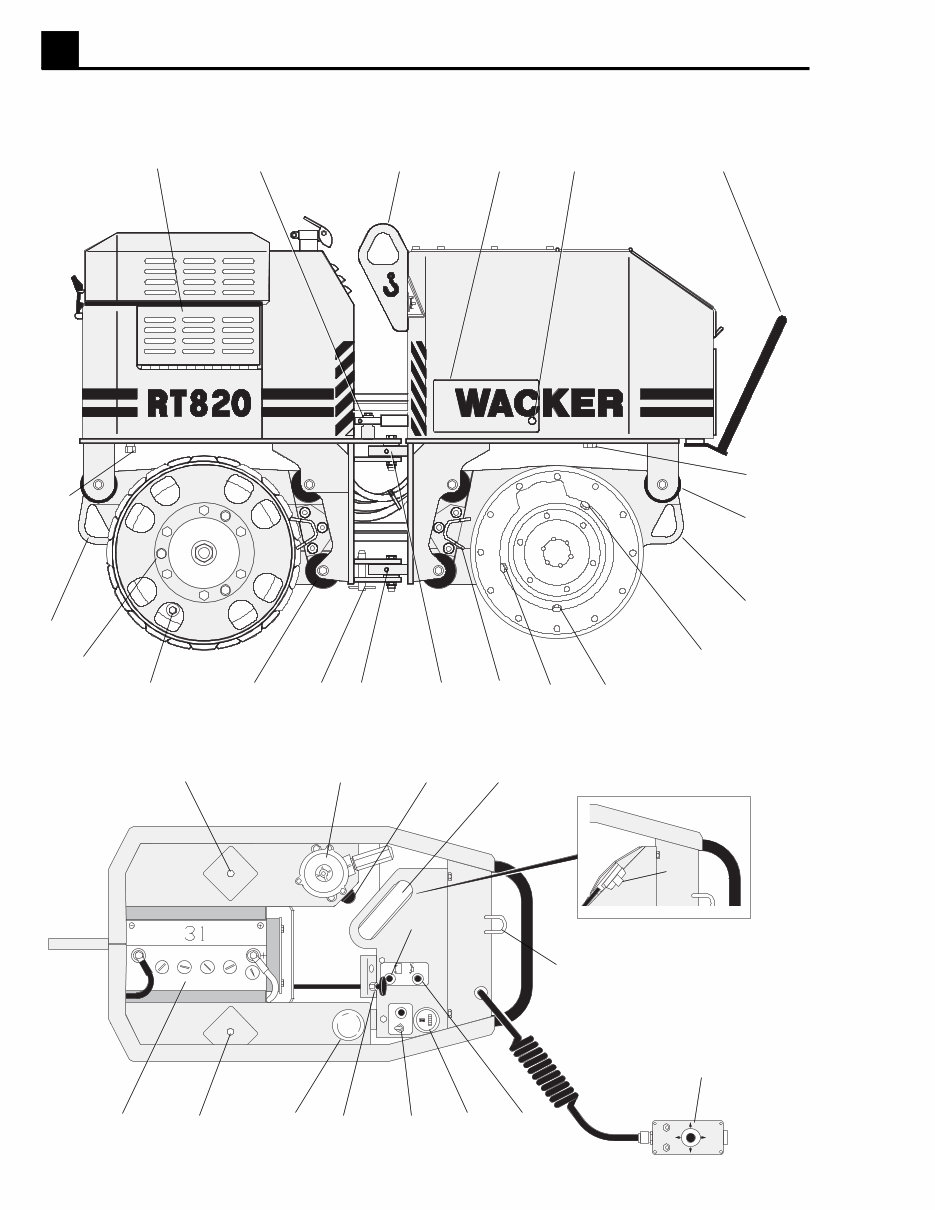

c d e

f

g

j k i f

g

b a

1.8 Controls & Service Locations - Roller

x

y h i

b

aa

bb

z

cc

OPERATION

1002SD34

l m u

o

v w t q n

2

s

SEE

NOTE *

r

dd

1006SD32

LEVER TYPE THROTTLE CONTROL

[AVAILABLE WITH PULL TYPE

THROTTLES (n

2

) ONLY]

n

1

p

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

Viewed 41 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$27.99

Get the operators manual for the Wacker RT560 and RT820. This factory manual spans 40 pages and contains essential technical information for both professional mechanics and DIY enthusiasts. Whether you're working on routine maintenance or complex repairs, this manual provides the detailed guidance you need.