Volvo EC160D L Excavator OEM Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Service Information

Document Title: Function Group: Information Type: Date:

Safety concerns everybody! 191 Service Information 2015/2/28

Profile:

EXC, EC160D L [GB]

Safety concerns everybody!

Always follow the instructions in the machine's Operator's Manual.

The Operator's Manual shall always be easily accessible in the cab.

Volvo designs and manufactures machines with a high level of safety as well as effectiveness. All this work may be wasted if

anyone who is about to perform service on any of our machines does not read the safety instructions, or does not follow

them, e.g., does not replace guards, climbs on slippery machine parts instead of using a ladder, grabs a hold of hoses

instead of handles or uses the wrong tools for the job.

Always use the intended and adapted genuine Volvo spare parts for the machine in question to maintain safe and efficient

function.

Machines seldom cause accidents, instead people often do.

A safety-conscious person and a well-maintained machine make for a safe, effective and profitable combination.

Those who do not follow the safety instructions and observe the warnings in this manual must make sure that their

work method is safe. Otherwise, there is a great risk of accidents, perhaps even accidents that result in fatalities.

WARNING

WARNING SYMBOL

This symbol appears at various points throughout the manual together with a warning text. It means "Warning, stay alert!

Your safety is involved!".

Get to know the capacity and limits of your machine!

Service Information

Document Title: Function Group: Information Type: Date:

CE-marking, EMC-directive 191 Service Information 2015/2/28

Profile:

EXC, EC160D L [GB]

CE-marking, EMC-directive

CE-marking

Figure 1

(Declaration of conformity, only applies to machines marketed within the EU/EEA).

This machine is CE-marked. This means that, when delivered, the machine meets the applicable "Essential Health and Safety

Requirements" specified in EU's so-called Machine Safety Directive, 2006/42/EC.

The person making any changes that affect machine safety is also responsible for the same.

As proof that the requirements are fulfilled the machine is supplied with an EU Declaration of Conformity, issued by Volvo CE

for every individual machine. This EU declaration also covers attachments manufactured by Volvo CE. The documentation is

a valuable document that should be stored in a safe place and retained for at least ten years. The documentation shall

always accompany the machine when it is sold.

If the machine is used for other purposes or with other attachments than described in this manual, safety must be

maintained at all times and in each individual case. The person carrying out such action is also responsible for the action

which, in some cases, may require a new CE-marking and the issue of a new EU Declaration of Conformity.

EU EMC Directive

The electronic equipment of the machine may in some cases cause interference with other electronic equipment, or the

equipment may be adversely affected by external electromagnetic interference, which may constitute safety risks.

The EU EMC directive on "Electromagnetic conformity" provides a general description of what demands can be made on the

machine from a safety perspective, where permitted limits have been determined and given according to international

standards.

A machine or device which meets the requirements should be CE-marked. Our machines have been specifically tested for

electromagnetic interference. The CE marking of the machine and the declaration of conformity also cover the EMC directive.

If other electronic equipment is fitted to this machine, the equipment must be CE-marked and tested on the machine with

regard to electromagnetic interference.

EU's noise directive

Within the EU there is a noise directive stating that a machine may not have noise values that exceed a certain level. The

values are indicated on a plate on the outside of the machine. Each machine is also delivered with a noise certificate where

Volvo CE assures that the machine fulfills the governing legal requirements. It is important that this certificate accompanies

the machine when it is sold.

It is also important that no modifications are made to the machine's noise-damping components in order to fulfill the limit

values.

Service Information

Document Title: Function Group: Information Type: Date:

Safety when handling the

machine

191 Service Information 2015/2/28

Profile:

EXC, EC160D L [GB]

Safety when handling the machine

Volvo Construction Equipment is only responsible if:

the machine has been used correctly and has been maintained according to instructions in Service Manuals and

the Operator's Manual.

prescribed service and prescribed inspections have been performed at the stated intervals.

the lubricant recommendations in the manual have been followed.

no safety seals have been opened by unauthorized persons.

all modifications and repairs have been performed as prescribed by Volvo.

only Volvo genuine spare parts/accessories or attachments that meet Volvo's requirements have been used.

Machine operators must have sufficient skills and knowledge of the content in the Operator's Manual before operating the

machine.

It is important that the operator reads and follows the instructions in the machine's Operator's Manual.

An untrained operator may cause serious injuries and fatalities.

Never operate a excavators for which there is no Operator's Manual available.

Learn to understand the warning plates, symbols and operating instructions for the machine before you start operating.

A few simple safety rules

General

Repair malfunctions or defects that affect safety as soon as possible.

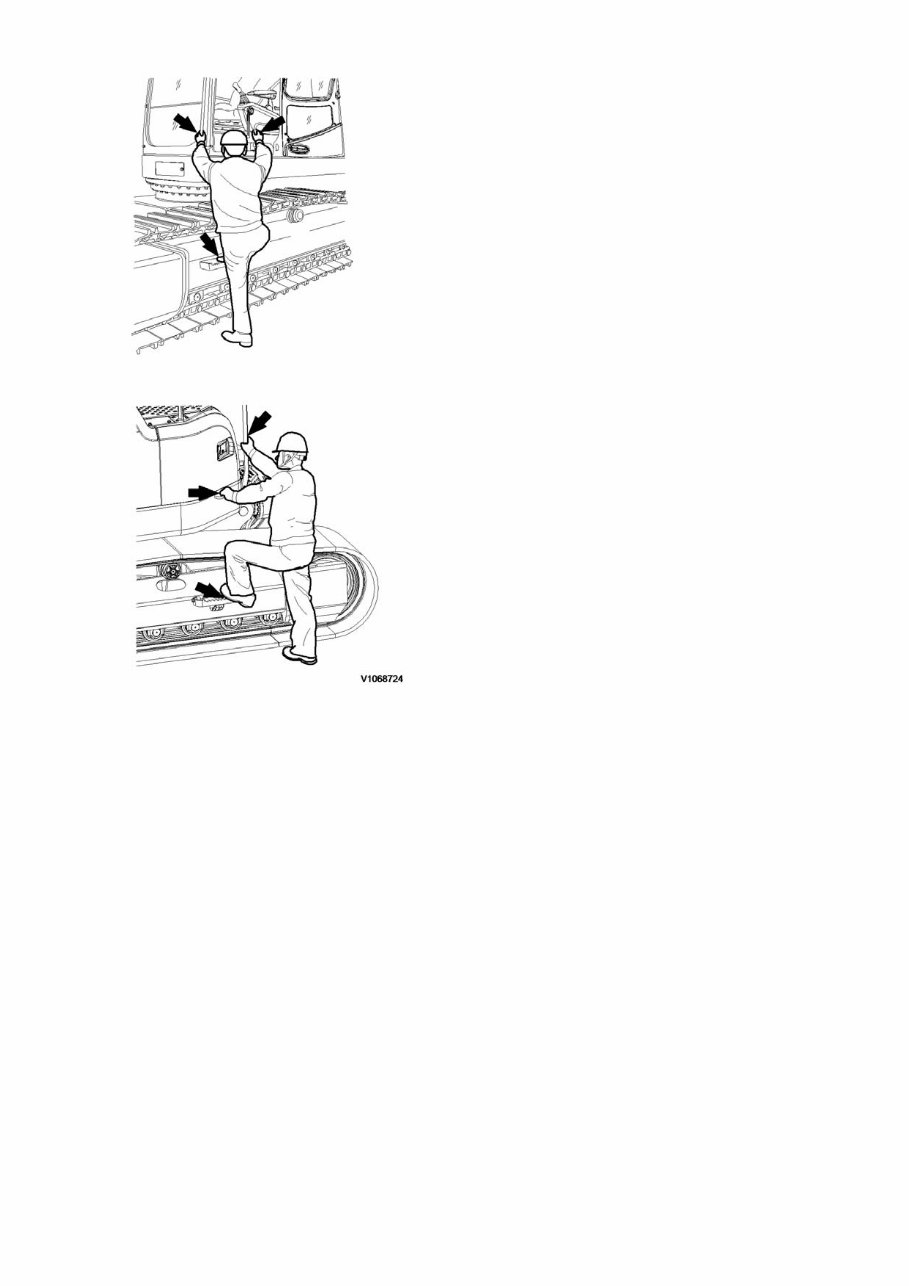

Figure 1

Always maintain a three point contact with the steps and handrails

Always use a hard hat, safety glasses, gloves, protective work shoes and other protective items as required by the

work situation.

Avoid standing in front of or behind the machine when the engine is running.

Always use a rubber window scraper or brush with a long handle when cleaning the outside of the windows in

order to avoid unnecessary climbing on the machine.

When servicing the machine, for example when changing light bulbs, a ladder may be needed.

Make sure that stepping surfaces, handles, service areas and anti-slip surfaces are free from oil, diesel, dirt and ice

and that they are changed if they are damaged or missing.

Check at regular intervals that all anti-slip surfaces are securely fastened. If not, fasten or replace as required.

Always face the machine and use the steps and handrails when entering or leaving the machine. Use two hands and

one foot, or two feet and one hand. Do not jump!

Before operating

Read the Operator's Manual before you operate the machine! Follow the operating instructions and perform

actions according to the instructions in the manual before operating.

A few important rules are given below:

Figure 2

Read the operator's manual before you operate the machine

Perform a control light test before starting the engine by turning the ignition key to position I, see Operator's

Manual.

Perform all recommended safety checks as outlined in the Operator's Manual.

WARNING

Never operate the machine if you are tired or under the influence of alcohol, medicine or other drugs.

Before starting the engine indoors, make sure that the extraction capacity of the ventilation system is sufficient. The

machine is equipped with a diesel engine and the exhausts may be hazardous to your health. Make sure that

ventilation is sufficient, and avoid running the engine indoors for longer than necessary where ventilation is

insufficient.

Read all plates and instructions on the machine and in the Operator's Manual before operating or servicing the

machine. Each of these instructions contains important information about safety, handling and service.

Use the seat belt during all operation.

Always sit in the operator's seat when starting the engine.

The machine must be fully operational before it is put into work, that is, all malfunctions that may cause an accident

must be repaired.

Do not operate the machine for long periods without ventilation or with a completely closed cab without running

the cab fan (risk of lack of oxygen).

Only step and stand on surfaces with slip-protected treads and hold on to the available handles and handrails.

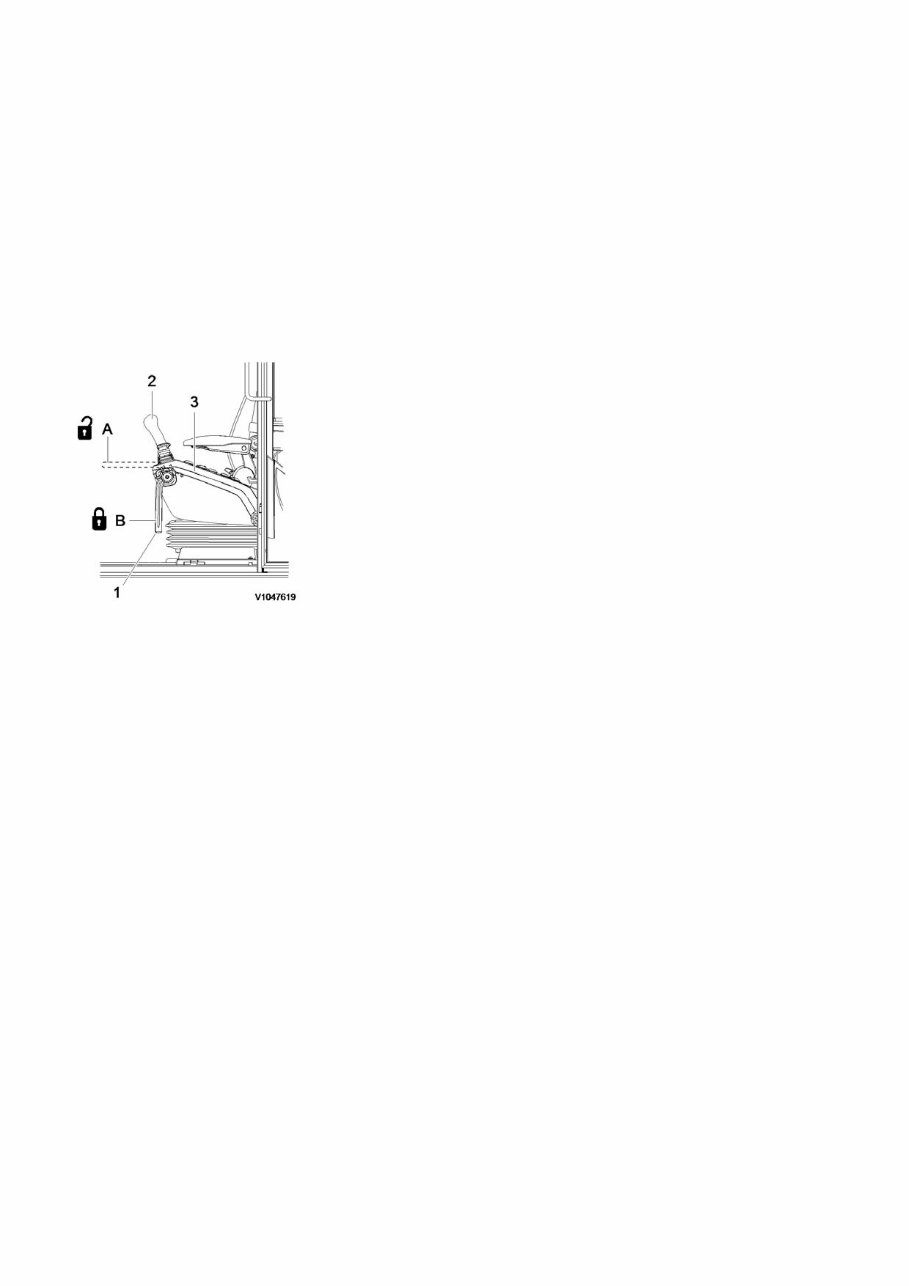

Seat belt

If the seat belt needs to be washed: Use a mild soap solution when washing and allow the belt to dry while it is fully

pulled out, before rolling it up. Make sure that the belt is fitted correctly.

Figure 3

Use the seat belt during all operation

A.

B.

C.

Strap lap type (2 inches)

Strap lap type (3 inches)

Retractable type (2 inches)

Change the belt immediately if it is worn, damaged or if the machine has been involved in an accident where the

belt had to take some strain.

Never make changes to the belt or its mounts.

Keep the belt rolled up when not in use.

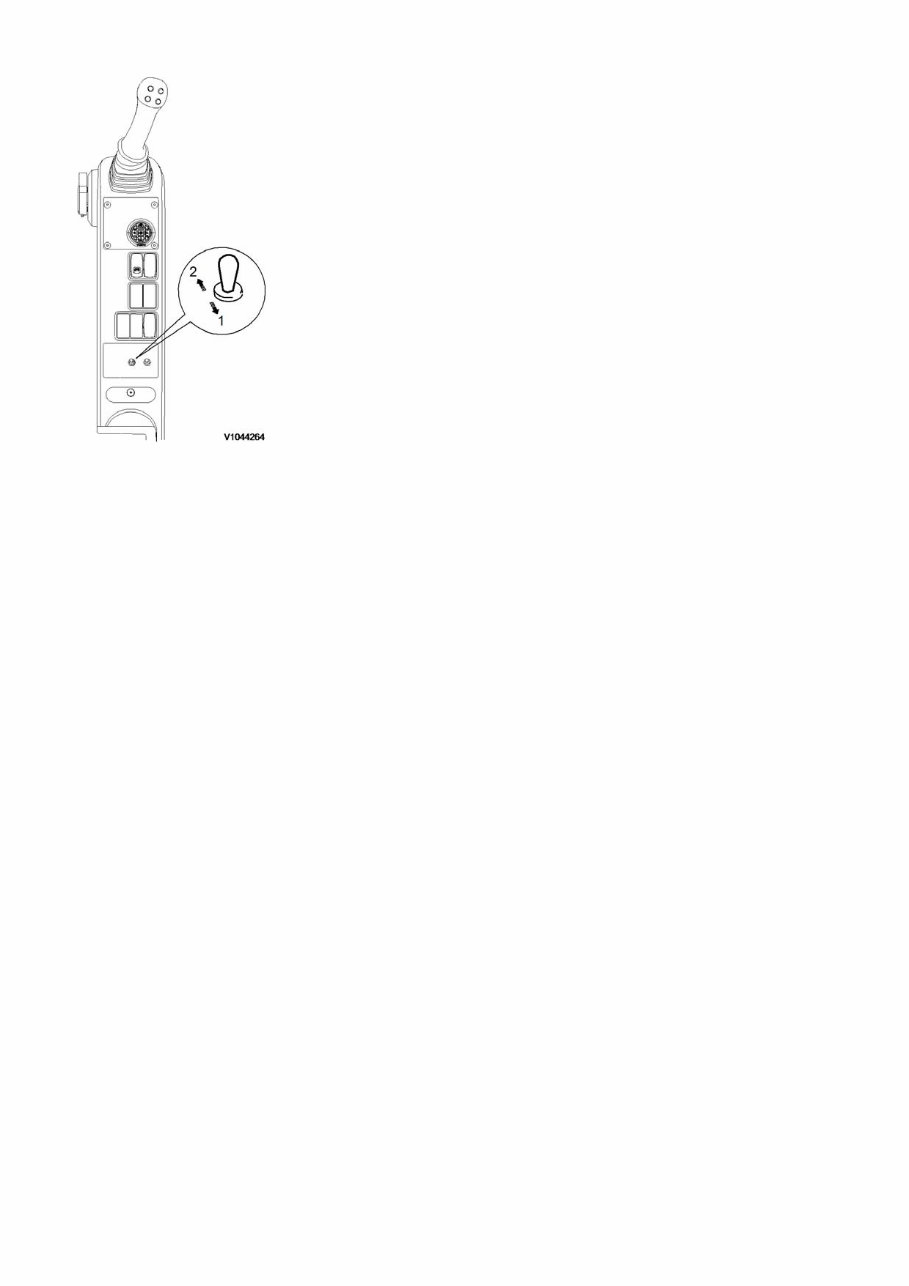

Control lockout system

Move the control lockout lever down to lock the hydraulic system securely. Unless the control lockout lever is on the

“Locked” position (B), operating levers can be operated by careless touch, which could cause serious injury.

Figure 4

Control lockout lever

1 Control lockout lever

2 Left control lever

3 Left control console

A Unlocked position

B Locked position

Unlocked position (A)

The control lockout lever is in “Unlocked” position (A) for working and travelling operations.

When the control lockout lever is in this position the engine can not be started.

Locked position (B)

The control lockout lever is used to lock-out the attachment, slew and travel unit.

Place this lever on the left control console to “Locked” position (B) to lock out the hydraulic control levers and

pedals.

When the control lockout lever is in this position the engine can be started.

NOTE!

In manual control mode, the engine can be started using the ignition switch even if the control lockout lever is in the

unlocked (up) position. Place the control lockout lever in locked position to lock the hydraulics before starting the

engine, otherwise the control levers can be activated inadvertently, which could cause serious injury.

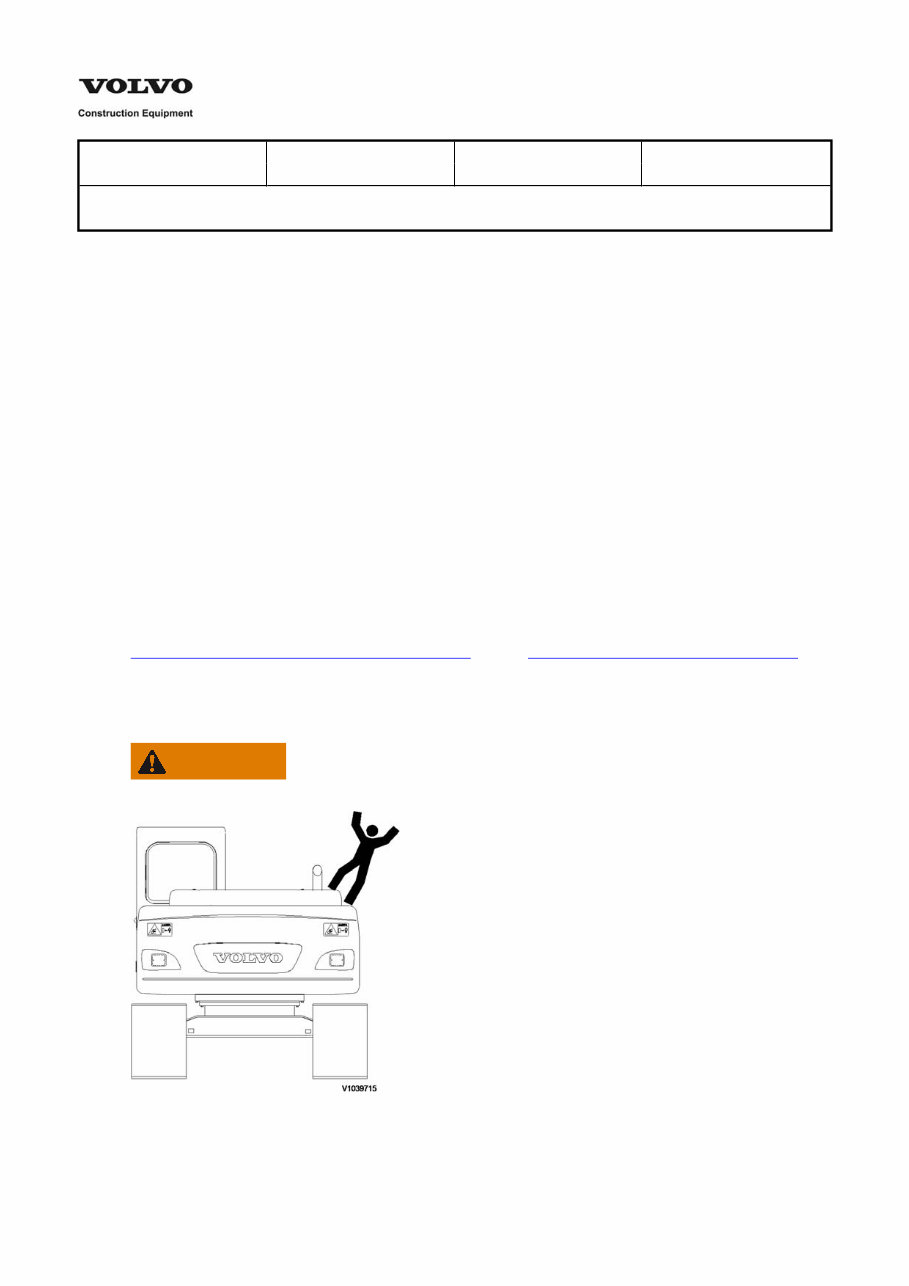

Figure 5

Automatic/manual pump control switch

1.

2.

Manual control

Automatic control

Theft protection system

The machine can be equipped with theft protection in the form of a code lock (See Operator's Manual) which prevents start

of the machine without the correct four-digit code. Do not forget the code. It can only be programmed and changed via

VCADS Pro. If you forget the code, contact your dealer.

Service Information

Document Title: Function Group: Information Type: Date:

Safety rules when servicing 191 Service Information 2015/2/28

Profile:

EXC, EC160D L [GB]

Safety rules when servicing

This section covers general safety rules when checking and servicing. Other rules, information and warning texts are

given in the Operator's Manual.

CE-marking

This machine is CE-marked. This means that, when delivered, the machine meets the applicable "Essential Health and Safety

Requirements", which are given in the EU Machine Safety Directive. If changes are made that affect the safety of the

machine, the person making the changes is responsible for the same.

Before you begin any service work:

Service work done incorrectly is dangerous.

Make sure that you have sufficient knowledge, correct information, the right tools and the correct equipment to perform the

service in a correct manner.

Repair or replace damaged tools and defective equipment.

Park the machine on a level surface and prepare it for service by placing it in the service position according to figure:

NOTE!

No work may be done on the machine until you have the correct skills and knowledge of the machine to do the work.

General

Machine working in a environmentally contaminated area, See

.See also .

191 Working in environmentally contaminated areas 191 Checklist after a fire or heat exposure

If someone is to take over the job that you have started, make sure that this person is informed about what part of

the work has been completed and what remains to be done.

When high-pressure washing the machine, do not aim the water jet directly at anti-slip surfaces or decals that are

glued on.

WARNING

Only walk or step on the machine's prepared stepping surfaces, see operator's manual.

Figure 1

Do not step on engine covers

Never wear loose fitting clothing, for example, a scarf or jewelry, that can get caught and cause injury when working

on the machine.

Figure 2

Protective equipment

Always use a hard hat, safety glasses, gloves, protective work shoes and other protective items as required by the

work situation.

Always stop the engine when servicing the machine unless instructions on plates or in this manual state otherwise.

Turn off the engine before opening engine covers, radiator casing, etc. Make sure that no tools or other objects

that can cause damage are forgotten in the machine.

Pay attention when removing or installing the tracks of track type machines. When removing the track pin, the track

separates suddenly, so never let anyone stand at either end of the track.

Always blocks both ends of the track to prevent any sudden uncontrolled movement.

Figure 3

Pay attention when removing or installing the tracks

Pay attention when removing or installing the master pin of the track using a press, the master pin may pop out

suddenly, so never let anyone stand at either end of the master pin.

Figure 4

Pay attention when removing or installing the master pin

Service Information

Document Title: Function Group: Information Type: Date:

Fire prevention measures 191 Service Information 2015/2/28

Profile:

EXC, EC160D L [GB]

Fire prevention measures

General

There is always a risk of fire. Find out which type of fire extinguisher to use, where it is located and how to use it.

The fire extinguisher in the machine should be located according to the figure or in an external box that can be

locked.

Fire-fighting equipment installed in or on the machine must be maintained in working order. Such equipment

should be regarded as a complement to the operator's own efforts in case of a fire.

The equipment should not be considered as a replacement of the operator's own fire fighting efforts.

Fire extinguishers mounted on the machine or used when working on the machine must fulfil certain requirements.

See the Operator's Manual.

At the slightest sign of fire, if the situation allows it and keeping in mind your own safety, take the following action:

drive the machine away from the danger area.

stop the engine by turning the ignition key to the "0" position.

leave the cab.

turn off the battery disconnect switch.

start fighting the fire and call the fire department if necessary.

Figure 2

Smoking and open flames are absolutely forbidden when filling fuel or any time diesel fuel is in contact with

the open air.

Smoking or open flames are absolutely forbidden close to the machine when filling fuel or at any time the fuel

system is in contact with the open air.

Diesel fuel is flammable and must not be used for cleaning. Use an approved solvent instead.

Remember that certain solvents can cause skin rashes and are usually flammable. Avoid inhaling solvent vapour.

Engine starting aids are flammable. Store such items in cool and adequately ventilated areas. Remember that such

aids must not be used in combination with electric preheating of induction air.

Cleanliness

Cleanliness is a decisive factor for operational reliability of the machine's systems. Therefore, keep the servicing area

clean. Oil or water make floors and steps slippery and are also dangerous in combination with electrical systems or

tools. Oily clothes or clothes drenched in grease constitute a serious fire hazard.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

Viewed 89 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$41.99

- The Volvo EC160D L Excavator Service & Repair Manual is a comprehensive technical guide that includes service, maintenance, troubleshooting, and replacement procedures for the excavator.

- It features step-by-step instructions, clear images, and exploded-view illustrations, making it suitable for both professional mechanics and DIY enthusiasts.

- The manual contains comprehensive diagrams, detailed illustrations, and all the manufacturer's specifications and technical information necessary for servicing and repairing the excavator.

- Accessible on electronic devices such as smartphones and laptops, the manual ensures that repair procedures can be easily accessed and utilized, minimizing downtimes.

- Please note: This is not a generic repair manual but the manufacturer-sourced guide used by professional technicians, providing detailed troubleshooting and replacement procedures, step-by-step instructions, and clear images.

- It eliminates the need to search through numerous pages and offers the convenience of electronic access, allowing for easy searching, bookmarking, and even printing if desired.

- Printable: Yes

Language: English

Compatibility: Compatible with various electronic devices including PC, Mac, Android, and Apple smartphones and tablets.

Requirements: Adobe Reader (free)