Thwaites 5 6 7 8 9 tonne ton dumper workshop service manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

T0479

© Thwaites Limited

April 2006

Mach 490, Mach 550, Mach 560,

Mach 566, Mach 555, Mach 564,

Mach 568, Mach 557, Mach 565,

Mach 569

Service

manual

5-9 tonne

Mach 566 – 6 Tonne Powerswivel Mach 568 – 7 Tonne Front Tip

5-9 tonne

D

C

A

B

C

E

F

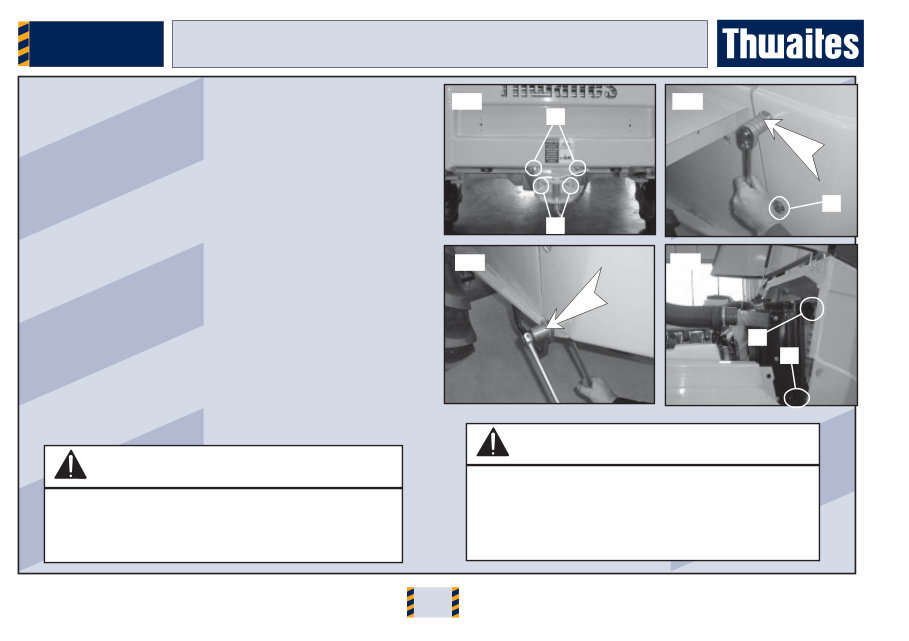

1 Park dumper on firm level surface and apply parkbrake.

2 Chock wheels

3 Push seat fully to rear of slide adjusters.

4 Open engine cover.

5 Disconnect air cleaner tube (jubilee clip).

6 Unbolt and remove towing jaw & pin (Fig. 1(B))

7 Remove towing support bracket nuts and bolts (Fig. 1(A))

8 Attach suitable crane straps to top of ROPS frame (See

component weights).

9 Remove rear grill panel (4 Bolts).

10 Loosen the bottom nuts and bolts both sides (Fig. 3(D)) DO

NOT REMOVE.

11 Remove top two nuts and bolts on both sides (Fig. 2(C)).

12 Using suitable crane and slings pull back and lower rear

panel and engine cover assembly onto safety straps (2 off).

Re-assembly

• Ensure that the air cleaner tube (Fig. 4, F) is fitted to the inlet

pipe (Fig. 4, E) when re-assembling

• Using the crane return rear panel to upright position.

Note - Ensure oil cooler pipe routings are unobstructed.

• Ensure all nuts and bolts are torqued correctly.

WARNING

• Keep hands/fingers away from hinged area of back

panel

• Heavy Components - Use suitable lifting

equipment.

WARNING

Weight of rear cover assembly will vary depending

on type of protective frame fitted to your machine. If

your machine is fitted with a ROPS/FOPS canopy, this

must be removed prior to hinging back or removing

the rear panel.

HOW TO HINGE BACK REAR COVER

Fig. 1 Fig. 2

Fig. 3 Fig. 4

5-9 tonne

This manual has been written to provide maintenance and

service information necessary to keep the Thwaites machine

operating safely and efficiently throughout its service life.

Prior to Commencing Maintenance Work You Must :

• Read and fully understand the enclosed working instructions.

• Ensure that any required safety precautions have been taken.

• Adhere to safety notices contained within this manual.

• Fully understand the risks involved and be competent to

perform the work.

• Use only genuine spare parts as replacement items.

• Ensure that prior to the machine being used, after

maintenance work has been completed, all safety checks and

tests have been completed.

Any problems please contact your local distributor

In compiling this document we have endeavoured to provide

the most up to date and accurate information.

Due to Thwaites continual product development we reserve the

right to amend information contained within this manual without

prior notice.

INTRODUCTION

5-9 tonne

Technical Specification ................................................... 1

Maintenance .................................................................... 2

CONTENTS

5-9 tonne

1.0

CONTENTS

Machine Identification .................................................. 1.1

Location of Major Components ................................... 1.2

Torque Settings/Capacities .......................................... 1.3

5-9 tonne

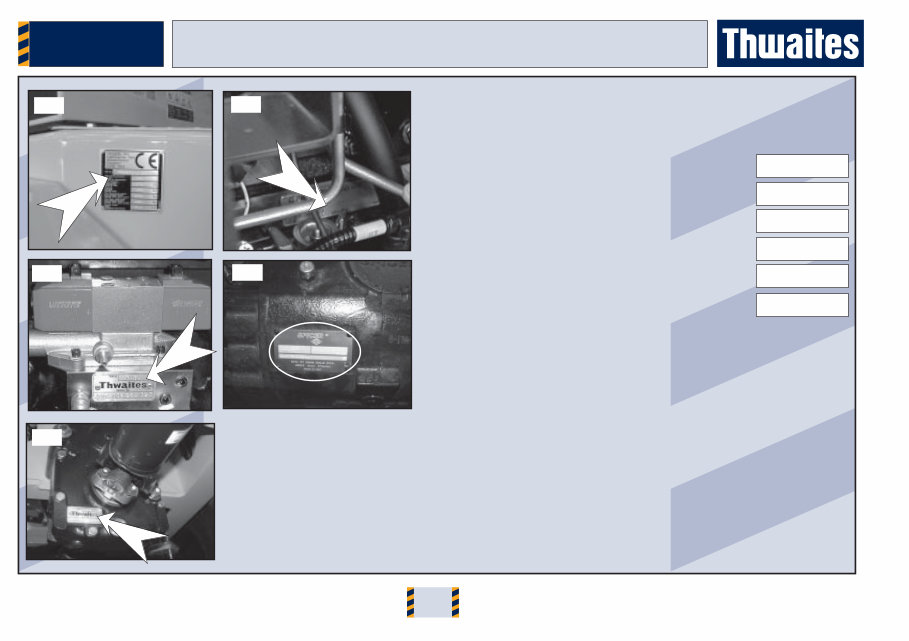

1.1

Serial Numbers

Note machine serial numbers. Always quote them in

communication with Thwaites dealer or Head Office.

Model Type (Fig 1.)

Vin Nº (Fig 1.)

Engine Serial Nº (Fig 2.)

Gearbox Serial Nº (Fig 3.)

Axle Serial Nº (Fig 4.)

Transfer Box Serial Nº (Fig 5.)

MACHINE IDENTIFICATION

Fig. 1 Fig. 2

Fig. 3 Fig. 4

Fig. 5

5-9 tonne

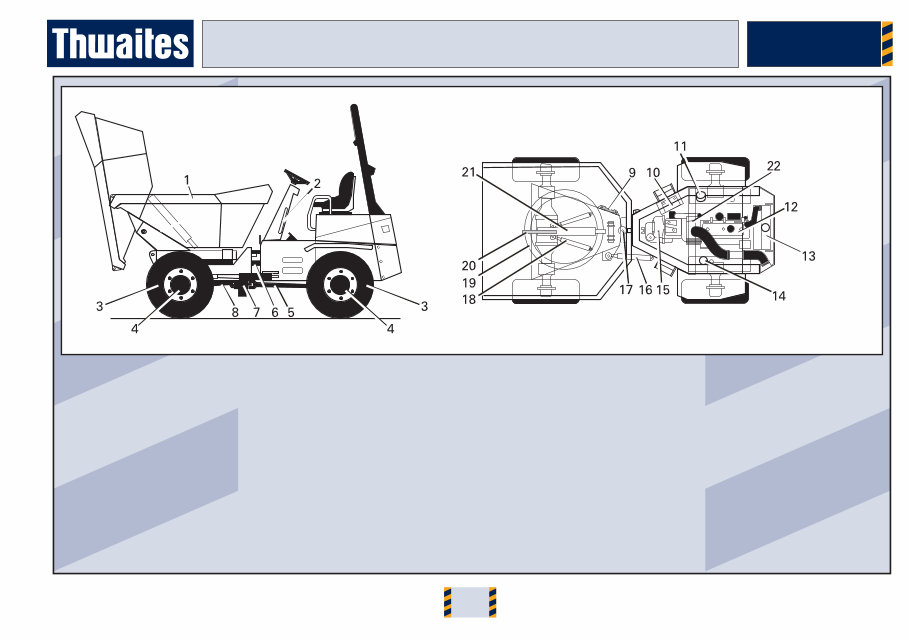

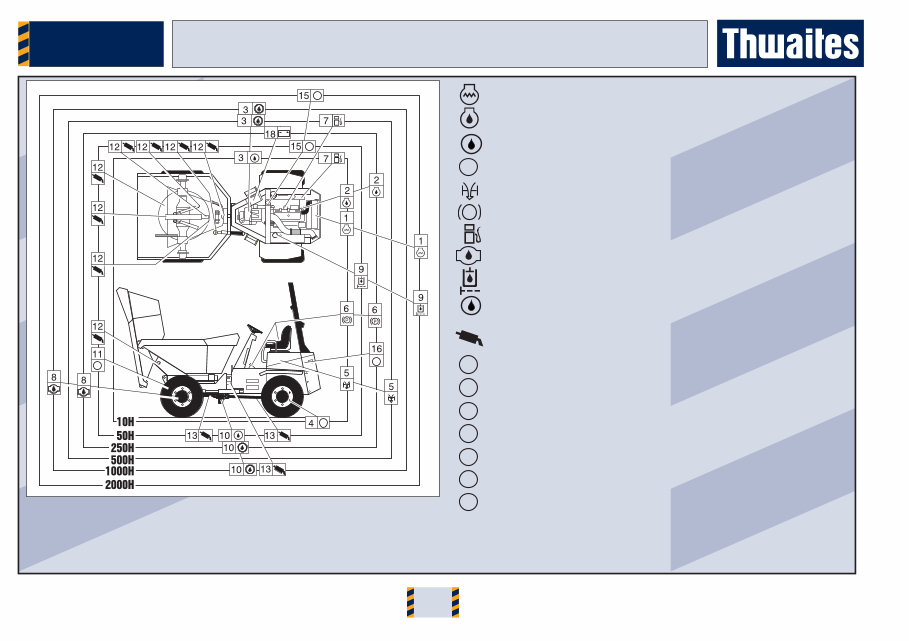

1.2

LOCATION OF MAJOR COMPONENTS

1 Skip

2 Operator Manual Pocket

3 Wheel

4 Axle

5 Propshaft Lower Rear

6 Propshaft Top Rear

7 Tranfer Box

8 Propshaft Front

9 Chassis Locking Bar

10 Battery Box

11 Fuel Tank

12 Engine

13 Radiator/Oil Cooler

14 Hydraulic Tank

15 Gearbox

16 Steering Ram

17 Kinglink

18 Slew Ram

19 Slew Ring

20 Skip Prop

21 Tipping Ram

5-9 tonne

1.3

System Fluid Capacities Ltrs

Engine oil (with filter) ............................................................. 08.5

Transmission .......................................................................... 18.5

Axle Front/Rear (5-7t) ............................................................ 11.5

Axle Front/Rear (9t) ............................................................... 15.0

Transfer case ............................................................................ 0.6

Cooling system ...................................................................... 23.0

Hydraulic system ................................................................... 74.0

Brake reservoir ......................................................................... 0.3

Fuel tank ................................................................................. 68.0

Recommended Lubricants – see page 2.23

Torque Settings Nm

Axle Bolts ................................................................................ 650

Bearing mounting plate bolts .................................................... 80

Centre pivot ............................................................................. 550

Diesel/ hyd tank drain plugs ..................................................... 25

Engine/Gearbox .............................................. (+ Loctite 243) 55

Eng Brkt/rubber mounts .......................................................... 250

Eng/Brkt/engine ...................................................................... 190

Kinglink bearing pins upper .................................................... 480

Prop bolts straps ........................................................................ 75

Prop bolts G/box ..................................................................... 120

Ram Pin Nuts (continue around to next split-pin hole) .......... 450

ROPS Frame ............................................................................ 250

Slew Ring Bolts ....................................................................... 170

Transfer Box ............................................................................ 250

Wheel nuts .............................................................................. 330

Weight of Components kg

Rigid ROPS ............................................................................ 70kg

Hinged ROPS ......................................................................... 90kg

ROPS/FOPS ......................................................................... 240kg

Rear Cover ........................................................................ 143.5kg

Engine Cover c/w Seat ....................................................... 67.5kg

Rear Grill Panel ................................................................... 16.5kg

Towing jaw & pin ................................................................... 4.0kg

Torque Setting Nm

Rear Cover/Chassis ................................................................. 250

ROPS frames/Cover ................................................................ 250

Towing Bracket .......................................................................... 55

Support Bracket ......................................................................... 55

SECTION 1 - TECHNICAL DATA

5-9 tonne

2.0

Note:

The following service period recommendations are the

maximum permissable and should never be exceeded.

Lubrication And Maintenance Chart ........................... 2.1

Lubrication And Maintenance Schedule ..................... 2.2

Safe Working Practice .................................................. 2.3

Every 10 Hours - Cooling ............................................. 2.5

Every 10 Hours - Transmission/Engine oil .................. 2.6

Every 10 Hours - Fuel system/Air filter ........................ 2.7

Every 10 Hours - brake test .......................................... 2.8

Every 50 Hours - Hydraulic Oil ..................................... 2.9

Every 50 Hours - Brake Oil ......................................... 2.10

Every 50 Hours - Drivebelt ......................................... 2.11

Every 50 Hours - Park brake & caliper adjustment .... 2.12

Brake pad replacement .............................................. 2.13

First 100 Hours - Hydraulic oil filter ............................ 2.14

First 100 Hours - Transmission oil filter ..................... 2.15

First 100 Hours - Engine oil/filter ................................ 2.16

Every 250 Hours - Engine Oil & Filter ......................... 2.17

Every 250 Hours - Axles and Transfer Case .............. 2.18

500 Hour Service - Transmission ............................... 2.19

500 Hour Service - Fuel Filter/Air Filter ...................... 2.20

500 Hour Service - Hydraulic Oil Filter ...................... 2.21

1000 Hour Service - Transmission ............................. 2.22

1000 Hour Service - Axle and transfer box oil .......... 2.23

2000 Hour Service - Cooling system ......................... 2.24

2000 Hour Service - Hydraulic oil .............................. 2.25

Recommended Lubricants ......................................... 2.26

SECTION 2 - MAINTENANCE

5-9 tonne

2.1

IMPORTANT NOTE

After first 100 hours - Change engine oil - Change engine oil

filter - Change hydraulic oil filter element - Change transmission

oil filter - Check idle speed.

LUBRICATION AND MAINTENANCE CHART

COOLANT 1 H²0 + 50% Antifreeze

ENGINE OIL 2 BP Vanellus C5 Global 15W 40

TRANSMISSION OIL 3 BP Autran MBX

OTHER SERVICES 4 Wheel Nut Tightness

INDUCTION 5 Clean Filters

BRAKES 6 Operation of Brakes

FUEL 7 Diesel

AXLE OIL (including hubs) 8 TRACTELF SF3

HYDRAULIC OIL 9 BP Energol HLP HM32

TRANSFER BOX 10 BP Energear Hypo 80W-90

11 Tyre Pressure

GREASE 12/13 BP Energrease L21M

BRAKE SYSTEM 14 BP Bartran HV32

OTHER SERVICES 15 Drive Belts

OTHER SERVICES 16 Hoses

OTHER SERVICES 17 Bolt tighness (Ref Page 1.3)

BATTERY 18 Battery Cable Connections

LAP BELTS 19 Replace

WIRING/LIGHTS 20 Inspect

ROPS 21 Inspect

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

Viewed 69 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

Our 300 Series manual is designed to offer essential maintenance and service details to ensure the safe and efficient operation of your Thwaites machine. Whether you're a professional mechanic or a DIY enthusiast, this manual provides the necessary information for upkeep.

- Provides maintenance and service information

- Ensures safe and efficient operation

- Useful for professional mechanics and DIY enthusiasts

For UK models.