2007 W62 Chassis WSM0419

SECTION

8

PAGE

1

2007 W62 Chassis

Electrical Systems

© 2006 Workhorse Custom Chassis — All Rights Reserved

WORKHORSE CUSTOM CHASSIS

Service Manual

2007

ELECTRICAL SYSTEMS

WORKHORSE CUSTOM CHASSIS

Service Manual

2007 W62 Chassis WSM0419

SECTION

8

PAGE

2 Electrical Systems

2007 W62 Chassis

TOC

© 2006 Workhorse Custom Chassis — All Rights Reserved

TABLE OF CONTENTS

DESCRIPTION AND OPERATION .................................... 5

Diagnostic Link Connector Description ........................ 5

16-Pin DLC .................................................................. 5

9-Pin DLC .................................................................... 5

Lighting Systems Description ...................................... 5

Headlamps .................................................................. 5

Daytime Running Lamps ............................................. 6

Flash-To-Pass .............................................................. 6

Park Lamps ................................................................. 6

Turn Lamps ................................................................. 6

Hazard Lamps ............................................................. 6

Stoplamps .................................................................... 6

Backup Lamps ............................................................. 6

Windshield Wiper/Washer System Description ........... 6

LOW or MIST Position ................................................. 7

HIGH Position .............................................................. 7

DELAY Operation ........................................................ 7

Washer Pump .............................................................. 7

Horns Description ........................................................ 8

Cruise Control System Description .............................. 8

Wiring Systems Description ......................................... 8

Schematic Information ................................................. 8

CIRCUIT PROTECTION ........................................... 11

Fuses ......................................................................... 11

Circuit Breakers ......................................................... 12

Fusible Links .............................................................. 13

Wiring Repairs ........................................................... 14

Repairing Damaged Wire Insulation .......................... 14

Wiring Harness Replacement .................................... 14

Heated Oxygen Sensor (HO2S) Wiring Repairs ....... 14

Diagnosis Using The Wiring Schematics ................... 14

Schematic Icons ........................................................ 14

Connector Reference Zone Numbers ........................ 14

Underhood Fuse Panel .............................................. 15

Instrument Cluster Description and Operation .......... 15

Test at Turn On .......................................................... 22

Access to Diagnostic Menus and Menu Operation .... 22

Menu Operation ......................................................... 22

Adjusting Display Contrast ........................................ 23

Restore Default .......................................................... 23

Gauge Backlight ........................................................ 24

Software version ........................................................ 24

Part Number .............................................................. 24

Engine hours ............................................................. 24

Max Engine RPM ....................................................... 24

Max Vehicle Speed .................................................... 24

Engine Oil Life Remaining ......................................... 25

DIAGNOSTIC INFORMATION AND PROCEDURES ..... 26

General Electrical Diagnosis Procedures .................. 26

Basic Knowledge Required ....................................... 26

Electromotive Force ................................................... 26

Voltage ....................................................................... 26

Resistance ................................................................. 27

Ohms ......................................................................... 27

Tips for Using an Ohmmeter ..................................... 27

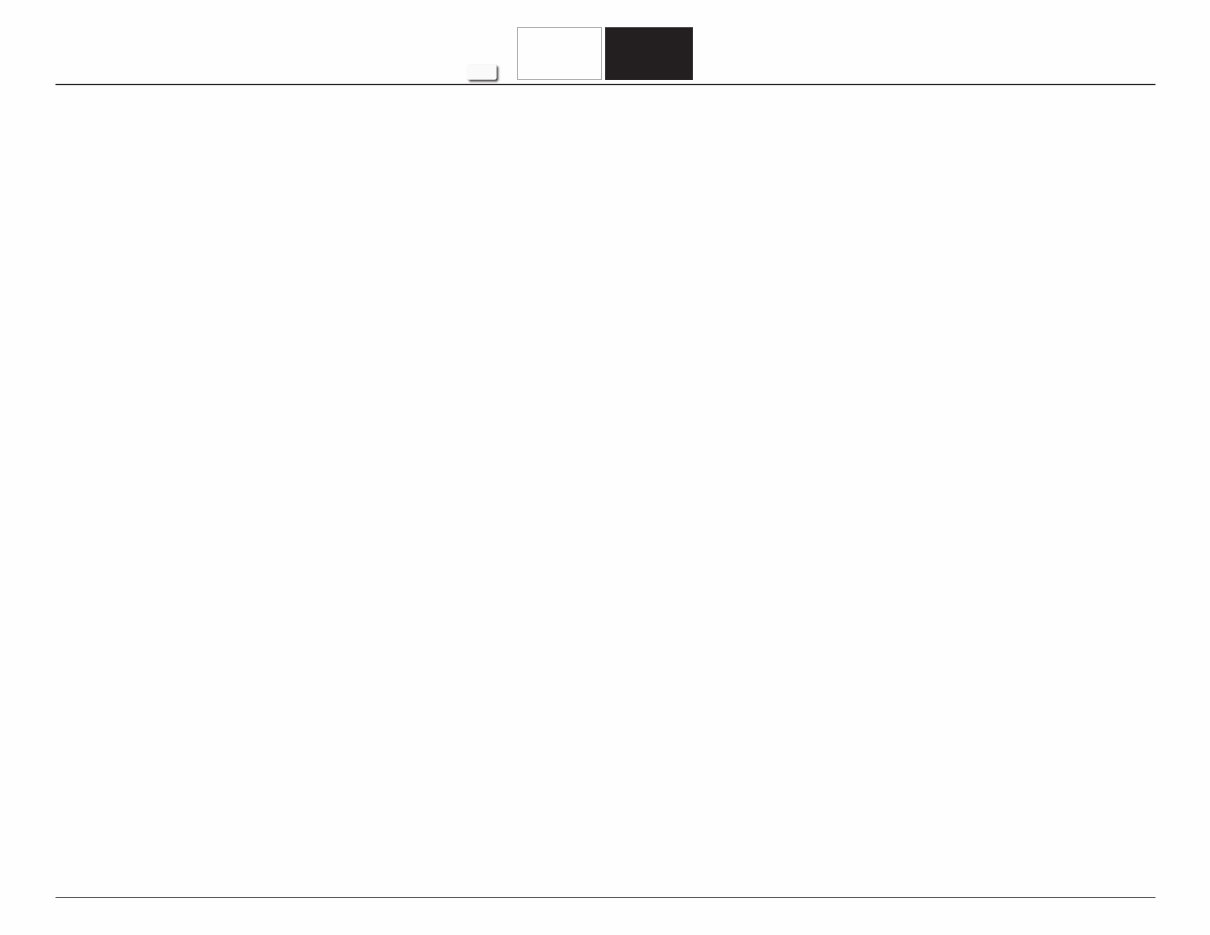

Ohm’s Law ................................................................. 28

Electrical Current ....................................................... 30

Amperage .................................................................. 30

Ammeter .................................................................... 30

The Diagnostic Process ............................................. 31

General Electrical Diagnosis ..................................... 33

Troubleshooting with a Digital Multimeter (DMM) ...... 33

Measuring Voltage ..................................................... 34

Measuring Voltage Drop ............................................ 35

Measuring Frequency ................................................ 36

TOC

WORKHORSE CUSTOM CHASSIS

Service Manual

2007 W62 Chassis WSM0419

SECTION

8

PAGE

3 Electrical Systems

2007 W62 Chassis

TOC

© 2006 Workhorse Custom Chassis — All Rights Reserved

Testing for Continuity ................................................. 36

Testing for Short to Ground ....................................... 37

Testing for a Short to Voltage .................................... 38

Troubleshooting with a Short Finder .......................... 39

Troubleshooting with a Test Lamp ............................. 39

Probing Electrical Connectors ................................... 39

Using Connector Test Adapters ................................. 40

Using Fused Jumper Wires ....................................... 40

Using Connector Test Adapters ................................. 40

Intermittents and Poor Connections .......................... 41

Testing for Intermittent Conditions and Poor

Connections ............................................................ 41

Testing for Proper Terminal Contact .......................... 42

Testing for Proper Terminal Contact in Bussed

Electrical Centers (BEC) ......................................... 42

Flat Wire (Dock and Lock) Connectors ...................... 43

Control Module/Component Voltage and Grounds .... 43

Temperature Sensitivity ............................................. 44

Electromagnetic Interference (EMI) and Electrical

Noise ...................................................................... 44

Inducing Intermittent Fault Conditions ....................... 45

Low Temperature Conditions ..................................... 46

Duplicating Failure Conditions ................................... 47

Testing for Electrical Intermittents .............................. 47

Diagnostic Link Connector Diagnostics ..................... 48

Data Link Communications System Check .............. 48

Scan Tool Does Not Communicate with

Components ............................................................ 49

Scan Tool Does Not Communicate with PCM ........... 51

Scan Tool Does Not Communicate with TCM ........... 52

Lighting Systems ....................................................... 55

Courtesy or Dome Lamps Always On ........................ 55

Courtesy or Dome Lamps Inoperative ....................... 56

Instrument Panel Lighting Issues .............................. 58

Windshield Wiper/Washer Diagnosis ........................ 59

Washer Always On .................................................... 59

Washers Inoperative .................................................. 60

Wipers Inoperative – All Modes ................................. 62

Wipers Delay Mode Inoperative ................................ 63

Wipers High Mode Inoperative .................................. 64

Wipers Low or Mist Modes Inoperative ..................... 65

Cruise Control Diagnostics ........................................ 67

Cruise Control System Check ................................... 67

Cruise Control Does Not Set or Accelerate ............... 68

Horns ......................................................................... 72

Horns Always On ....................................................... 72

Horns Inoperative ...................................................... 73

Adjustable Pedals Diagnosis ..................................... 76

DTC U1001-U1254 .................................................... 78

DTC U1300, U1301, or U1305 .................................. 82

Instrument Cluster Diagnostic Information ................ 83

Cluster Diagnostic ..................................................... 83

Gauge Test ................................................................ 83

Warning Lamps Test .................................................. 84

LCD Test .................................................................... 84

Backlighting Test ........................................................ 85

Speaker Test .............................................................. 85

Switch Inputs ............................................................. 86

Analog Inputs ............................................................. 86

Frequency Inputs ....................................................... 87

Troubleshooting the Instrument Cluster .................... 87

Gauges ...................................................................... 87

Warning lights ............................................................ 89

Backlighting ............................................................... 91

Misc . .......................................................................... 92

WORKHORSE CUSTOM CHASSIS

Service Manual

2007 W62 Chassis WSM0419

SECTION

8

PAGE

4 Electrical Systems

2007 W62 Chassis

TOC

© 2006 Workhorse Custom Chassis — All Rights Reserved

REPAIR INSTRUCTIONS ................................................ 98

Wiring Repairs ........................................................... 98

Repairing Damaged Wire Insulation .......................... 98

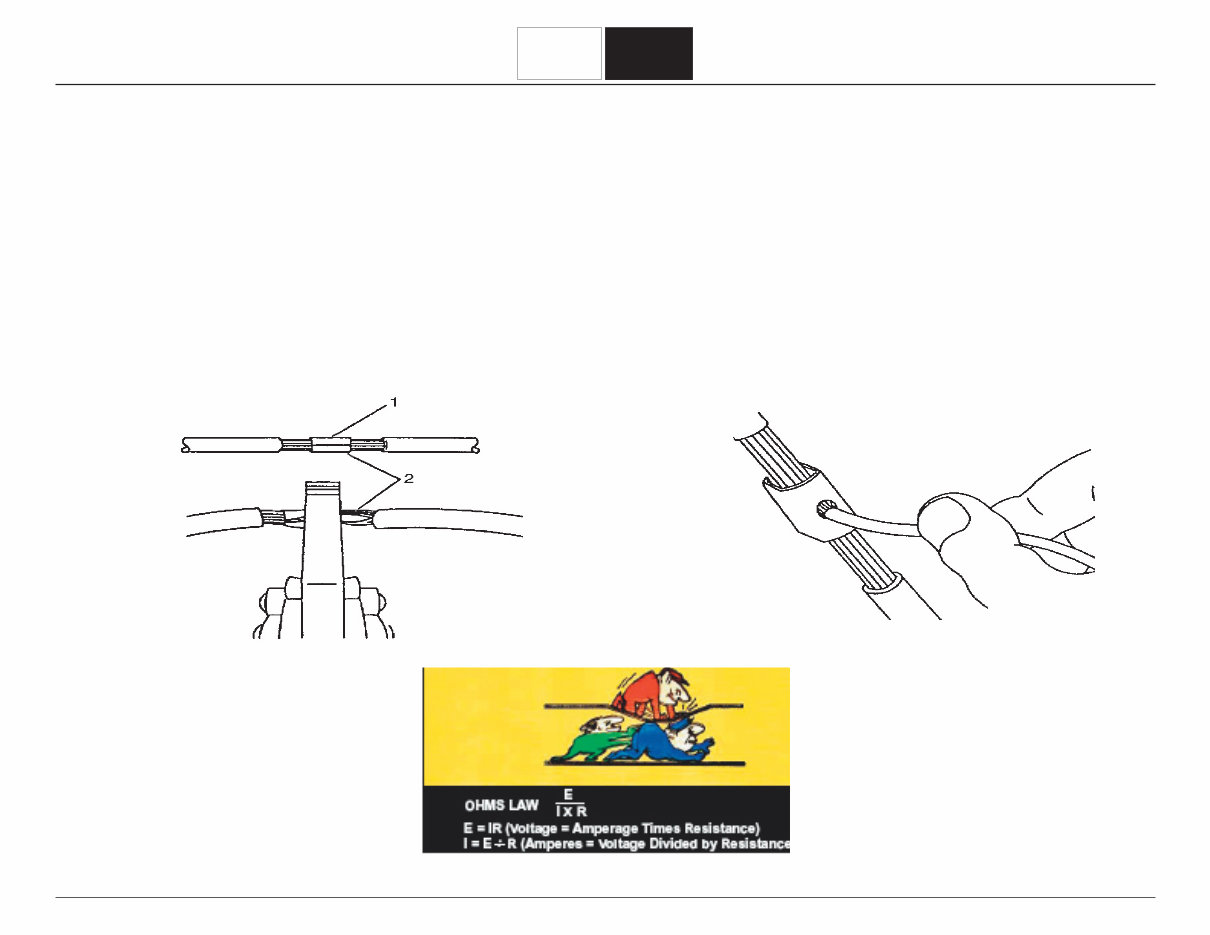

Splicing Copper Wire ................................................. 98

Splicing Twisted Pair Wiring .................................... 102

HO2S Wiring Repairs .............................................. 103

Headlamp Switch Replacement .............................. 103

WORKHORSE CUSTOM CHASSIS

Service Manual

2007 W62 Chassis WSM0419

SECTION

8

PAGE

5 Electrical Systems

2007 W62 Chassis

TOC

© 2006 Workhorse Custom Chassis — All Rights Reserved

9-Pin DLC

The 9-pin Diagnostic Link Connector (DLC) allows the

technician to access the Allison Transmission Control

Module (TCM) and/or the Electronic Control Unit (ECU)

for the WABCO anti-lock brake system (ABS).

7 of the pins in the connector are used. The pin

assignments are:

• Pin A – chassis ground via ground terminal 12

• Pin B – Battery voltage to DLC

• Pin C – J1939 Hi

• Pin D – J1939 Lo

• Pin E – J1939 Shield (ground)

• Pin F – J1587 Hi

• Pin G – J1587 Lo.

LIGHTING SYSTEMS DESCRIPTION

Headlamps

The headlamps will turn on when the headlamp switch

is placed in the ON position. When the low beam

headlamps are on, the headlamps can be switched to

the high beams by pulling the headlamp dimmer switch

toward the driver until it clicks. When the headlamp

dimmer switch is again pulled until it clicks, the

headlamps will then switch to the low beams from the

high beams.

DESCRIPTION AND OPERATION

DIAGNOSTIC LINK CONNECTOR DESCRIPTION

All 2007 Model Year (2007MY) W62 chassis are

equipped with two Diagnostic Link Connectors (DLC).

The 16-pin DLC is used to connect a scan tool or

laptop for the purpose of performing engine control

system diagnostics. The 9-pin “Deutsch” DLC is used

to connect a scan tool or laptop for the purpose of

performing transmission and/or anti-lock brake system

(ABS) diagnostics.

16-Pin DLC

The 16-pin DLC is used to connect a scan tool for

the purpose of performing engine control system

diagnostics. Establishing communication allows the

operator to monitor the systems for diagnostic purposes.

Only 4 of the 16 pins are used. The pin assignments

are:

• Pin 2 – Class 2 Serial Data link to instrument cluster/

PCM/ECM

• Pin 4 – Ground terminal 12

• Pin 5 – Ground terminal 37

• Pin 16 – Battery voltage feed to DLC.

WORKHORSE CUSTOM CHASSIS

Service Manual

2007 W62 Chassis WSM0419

SECTION

8

PAGE

6 Electrical Systems

2007 W62 Chassis

TOC

© 2006 Workhorse Custom Chassis — All Rights Reserved

Daytime Running Lamps

The optional Daytime Running Lamps (DRL) illuminate

the high beam headlamps at a reduced intensity. The

DRL will operate when the ignition switch is in the RUN

or START position and the gear selector lever is out

of the PARK position. DRL is a programmable feature

for vehicles sold in the United States. Turning on the

headlamps will disable the DRL system.

Flash-To-Pass

When the headlamp dimmer switch is pulled toward

driver, but does not click, the high beam headlamps will

light for as long as the switch is held. This will occur in

any headlamp state (off, DRL, low beams).

Park Lamps

The park lamps will turn on when the headlamp switch is

placed in the PARK or ON position.

Turn Lamps

The turn lamps can only be activated with the ignition

switch in RUN or START. When the turn signal switch is

placed in a position to indicate a left turn or a right turn,

the respective turn lamps will flash. The respective turn

indicator will flash on the Instrument Panel Cluster (IPC).

Hazard Lamps

When the hazard switch is pressed, all turn lamps will

flash. Both turn indicators will flash on the Instrument

Panel Cluster (IPC).

Stoplamps

When the brake pedal is pressed, all stoplamps

illuminate.

Backup Lamps

When the ignition switch is in RUN and the gear selector

lever is in REVERSE, the backup lamps light. Instrument

Cluster Dimming The instrument cluster lamps light

when the park lamps are on. The brightness of the

instrument cluster lamps is controlled by the instrument

cluster dimmer switch located on the instrument panel.

WINDSHIELD WIPER/WASHER SYSTEM

DESCRIPTION

Voltage is supplied to the wiper motor via the WIPER

fuse when the ignition switch is in the ACC or RUN

position. Different speeds and functions of the wiper

motor are achieved by completing different ground paths

through the wiper pulse control module. The windshield

wiper relay feed coil is used to keep the wiper motor

running. When the windshield wiper relay feed coil circuit

is not grounded, the motor will not turn. Closing the

various contacts in the wiper/washer switch will provide

ground for this circuit and allow the motor to turn.

WORKHORSE CUSTOM CHASSIS

Service Manual

2007 W62 Chassis WSM0419

SECTION

8

PAGE

7 Electrical Systems

2007 W62 Chassis

TOC

© 2006 Workhorse Custom Chassis — All Rights Reserved

LOW or MIST Position

With the wiper/washer switch in the LOW or MIST

position:

• Power is supplied to the Pulse Wiper Control Module via

circuit 143 (YEL)

• Ground is provided to the Pulse Wiper Control Module

via circuit 150 (BLK)

• Low signal is supplied by the Pulse Wiper Control

Module to the body builder wiper system via circuit 97

(LT BLU)

• Coil feed signal is supplied by the Pulse Wiper Control

Module to the body builder wiper system via circuit 91

(GRA)

• Multifunction switch signal is provided to the Pulse Wiper

Control Module via circuit 112 (GRA)

HIGH Position

With the wiper/washer switch in the HIGH position:

• Power is supplied to the Pulse Wiper Control Module via

circuit 143 (YEL)

• Ground is provided to the Pulse Wiper Control Module

via circuit 150 (BLK)

• Low signal is supplied by the Pulse Wiper Control

Module to the body builder wiper system via circuit 97

(LT BLU)

• Coil feed signal is supplied by the Pulse Wiper Control

Module to the body builder wiper system via circuit 91

(GRA)

• Multifunction switch signal is provided to the Pulse Wiper

Control Module via circuit 112 (GRA)

• High signal is supplied by the multifunction switch to the

body builder wiper system via circuit 92 (PPL).

DELAY Operation

With the multifunction switch in one of the delay

positions:

• Power is supplied to the Pulse Wiper Control Module via

circuit 143 (YEL)

• Ground is provided to the Pulse Wiper Control Module

via circuit 150 (BLK)

• Coil feed signal is supplied by the Pulse Wiper Control

Module to the body builder wiper system via circuit 91

(GRA)

• Multifunction switch signal is provided to the Pulse Wiper

Control Module via circuit 112 (GRA).

Washer Pump

When the contacts of the wash switch in the wiper

washer switch close:

• Power is supplied to the Pulse Wiper Control Module via

circuit 143 (YEL)

• Ground is provided to the Pulse Wiper Control Module

via circuit 150 (BLK)

• Low signal is supplied by the Pulse Wiper Control

Module to the body builder wiper system via circuit 97

(LT BLU)

WORKHORSE CUSTOM CHASSIS

Service Manual

2007 W62 Chassis WSM0419

SECTION

8

PAGE

8 Electrical Systems

2007 W62 Chassis

TOC

© 2006 Workhorse Custom Chassis — All Rights Reserved

Depressing the SET and the R/A switches

simultaneously will cancel the cruise control operation.

Canceling the cruise control operation will not cancel the

speed memory.

WIRING SYSTEMS DESCRIPTION

Schematic Information

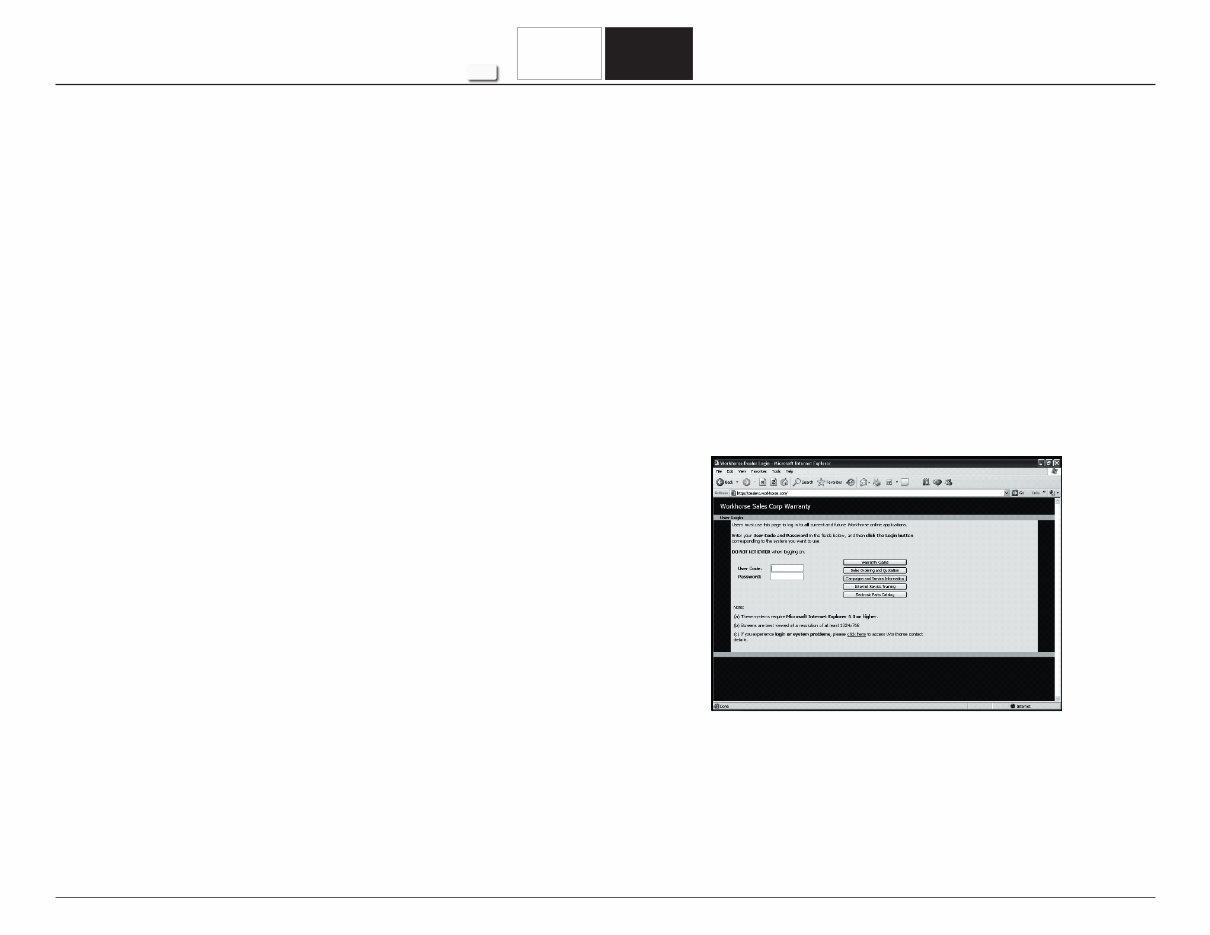

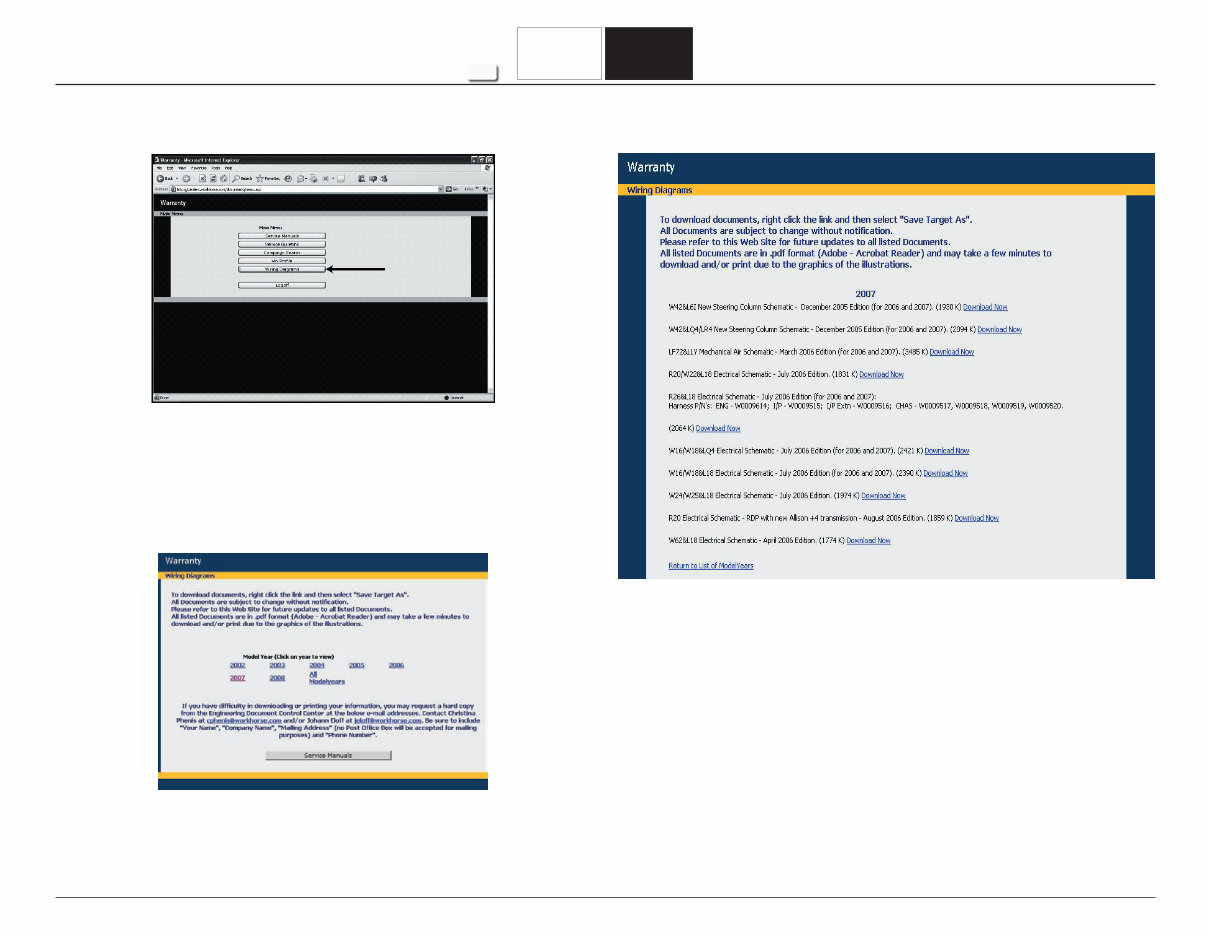

Where to Find Schematics

The electrical schematics for the 2007 W-Series are

not included in the service manual itself. Instead, the

schematics reside on the Workhorse Dealers website

(www.dealers.workhorse.com).

Using the dealer’s user code and password, the

technician can access the engineering drawings. Type

the user code into the User Code field and the password

into the Password field. DO NOT press the enter key.

Use the mouse, and left click on the Campaigns and

Service Information box in the center of the screen.

• Coil feed signal is supplied by the Pulse Wiper Control

Module to the body builder wiper system via circuit 91

(GRA)

• Multifunction switch signal is provided to the Pulse Wiper

Control Module via circuit 112 (GRA)

• Output signal is supplied by the Pulse Wiper Control

Module to the body builder wiper/washer system via

circuit 94 (PNK).

HORNS DESCRIPTION

The HORN fuse applies voltage at all times to the horn

relay. When the horn button is depressed, the contacts

for the horn switch close to ground. The horn relay

energizes and the contacts for the horn relay switch

close. This supplies voltage directly to the right and left

horns. Both horns are grounded through ground terminal

19.

CRUISE CONTROL SYSTEM DESCRIPTION

The cruise control system maintains the desired vehicle

speed under normal driving conditions. The cruise

control system has the following capabilities:

CRUISE

RESUME SPEED

ACCELERATE

COAST

WORKHORSE CUSTOM CHASSIS

Service Manual

2007 W62 Chassis WSM0419

SECTION

8

PAGE

9 Electrical Systems

2007 W62 Chassis

TOC

© 2006 Workhorse Custom Chassis — All Rights Reserved

After selecting the 2007MY link, a page will be displayed

that shows all of the drawings available for the 2007MY.

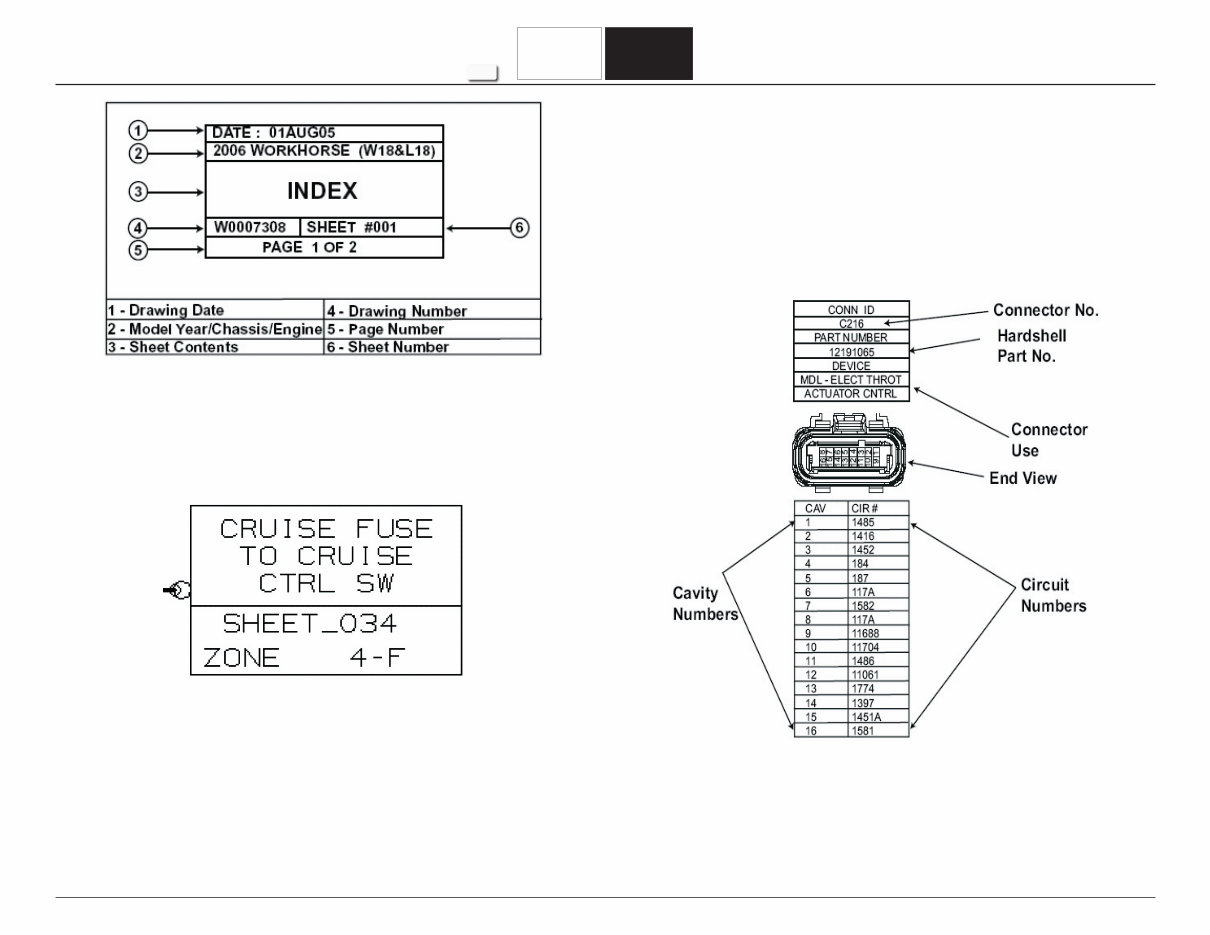

How to Use Schematics

In the lower right corner of each page of the wiring

diagram is a box containing information on the page’s

contents.

Note: As with other engineering documents a “sheet”

contains information specific to a system or

subsystem. Sheets may have more than one

page.

When the main menu screen appears, click on the

Wiring Diagrams button.

After clicking on the Wiring Diagrams button, the

technician will be presented with a screen showing with

several model year links. Clicking on the 2007 link, will

result in the page with the links for all of the electrical

schematics for the 2007 MY being displayed.

WORKHORSE CUSTOM CHASSIS

Service Manual

2007 W62 Chassis WSM0419

SECTION

8

PAGE

10 Electrical Systems

2007 W62 Chassis

TOC

© 2006 Workhorse Custom Chassis — All Rights Reserved

Navigation Box

When a circuit continues elsewhere on the same page

or on another page, a Navigation Box is shown to help

you locate the continuation of the circuit.

The top portion of the box gives you the details of

the circuit. Below the line, the point where the circuit

continues is shown along with the grid locator. Use the

grid locator in the same way that a road map is used to

pinpoint the location.

Connector End Views

Connector End Views show the cavity or terminal

locations for all the related connectors shown in the

system schematics. The drawings show the connector

face as seen after the harness connector has been

disconnected from a component or mating connector.

Unused cavities are left blank in the table.

You're Reading a Preview

What's Included?

Lifetime Access

Access Contents & Bookmarks

Print one or all pages of your manual