1990-1994 VW POLO Service Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Contents

LIVING WITH YOUR VW POLO

Introduction Page 0.4

Safety first! Page 0.5

Roadside repairs

Introduction Page 0.6

If your car won’t start Page 0.6

Jump starting Page 0.7

Wheel changing

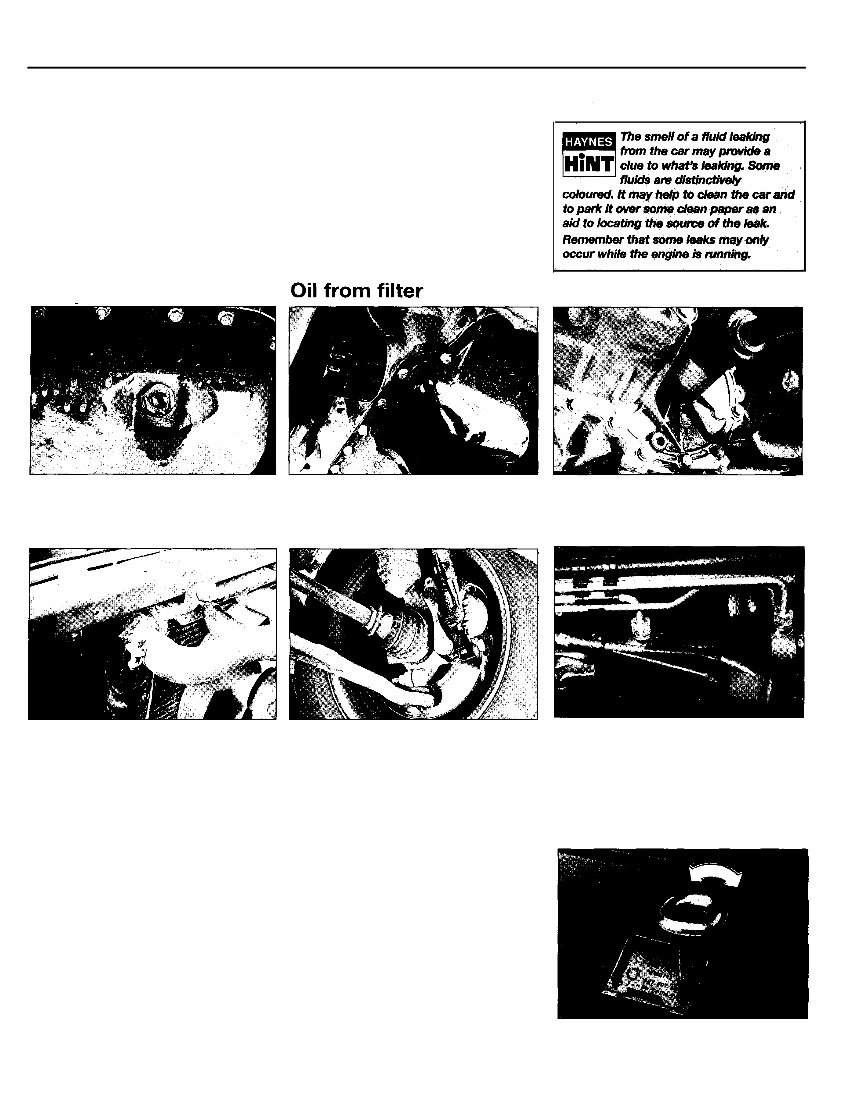

Identifying leaks

Towing

Page 0.8

Page 0.9

Page 0.9

Weekly checks

Introduction Page 0.10

Underbonnet check points

Engine oil level

Page 0.10

Page 0.11

Coolant level Page 0.11

Brake fluid level Page 0.12

Screen washer fluid level Page 0.12

Wiper blades

Battery

Tyre condition and pressure

Bulbs and fuses

Page 0.13

Page 0.13

Page 0.14

Page 0.15

Lubricants, fluids and tyre pressures Page 0.16

MAINTENANCE

Routine maintenance and servicing Page 1.1

Maintenance schedule Page 1.3

Maintenance procedures Page 1.5

Contents

REPAIRS & OVERHAUL

Engine and associated systems

Petrol engine in-car repair procedures Page 2A.1

Engine removal and overhaul procedures

Cooling, heating and ventilation systems

Fuel/exhaust systems - single-point petrol injection models

Fuel/exhaust systems - multi-point petrol injection models

Page 2B.1

Page 3.1

Page 4A.1

Page 4B.1

Exhaust and emission control systems Page 4C.1

Engine electrical - starting and charging systems

Engine electrical - Ignition system

Page 5A.1

Page 5B.1

Transmission

Clutch Page 6.1

Manual transmission Page 7.1

Driveshafts Page 8.1

Brakes and suspension

Braking system Page 9.1

Suspension and steering Page 10.1

Body equipment

Bodywork and fittings

Body electrical systems

Page 11.1

Page 12.1

Wiring diagrams Page 12.12

REFERENCE

Dimensions and weights Page REF.1

Conversion factors Page REF.2

Buying spare parts and vehicle identification

General repair procedures

Jacking and vehicle support

MOT test checks

Page REF.3

Page REF.4

Page REF.5

Page REF.5

Fault finding

Glossary of technical terms

Page REF.12

Page REF.19

Index Page REF.24

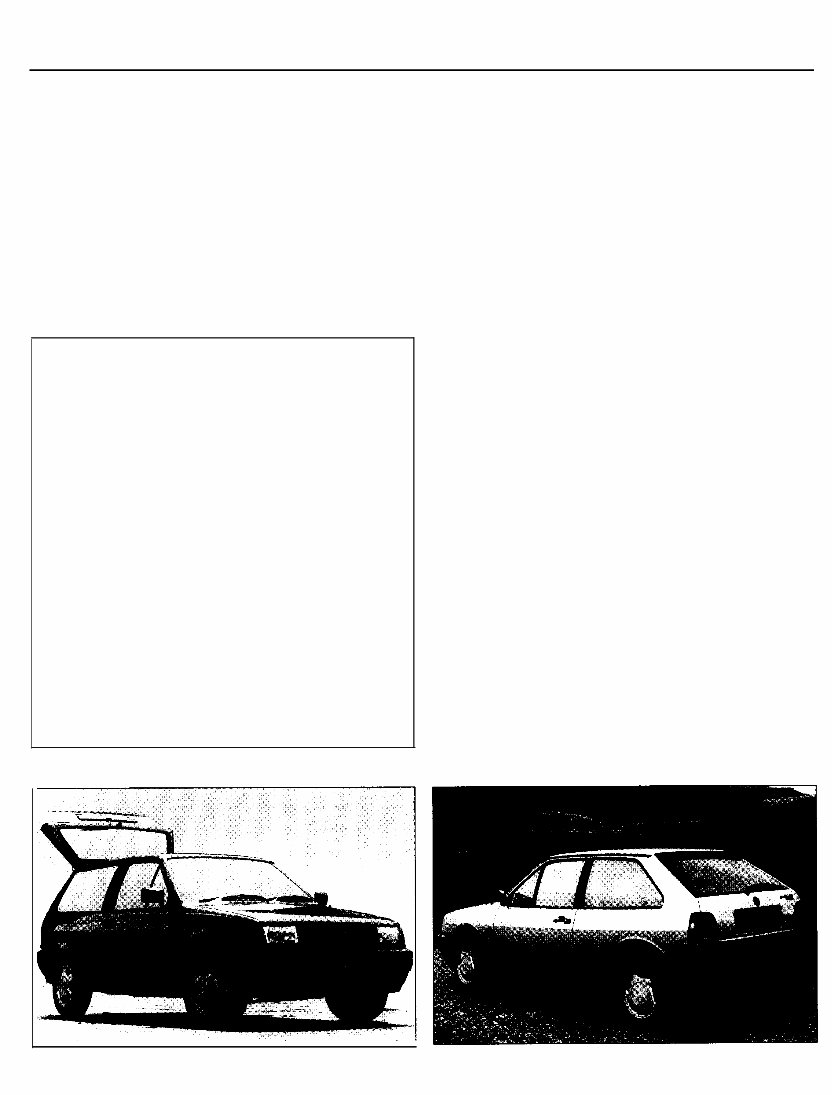

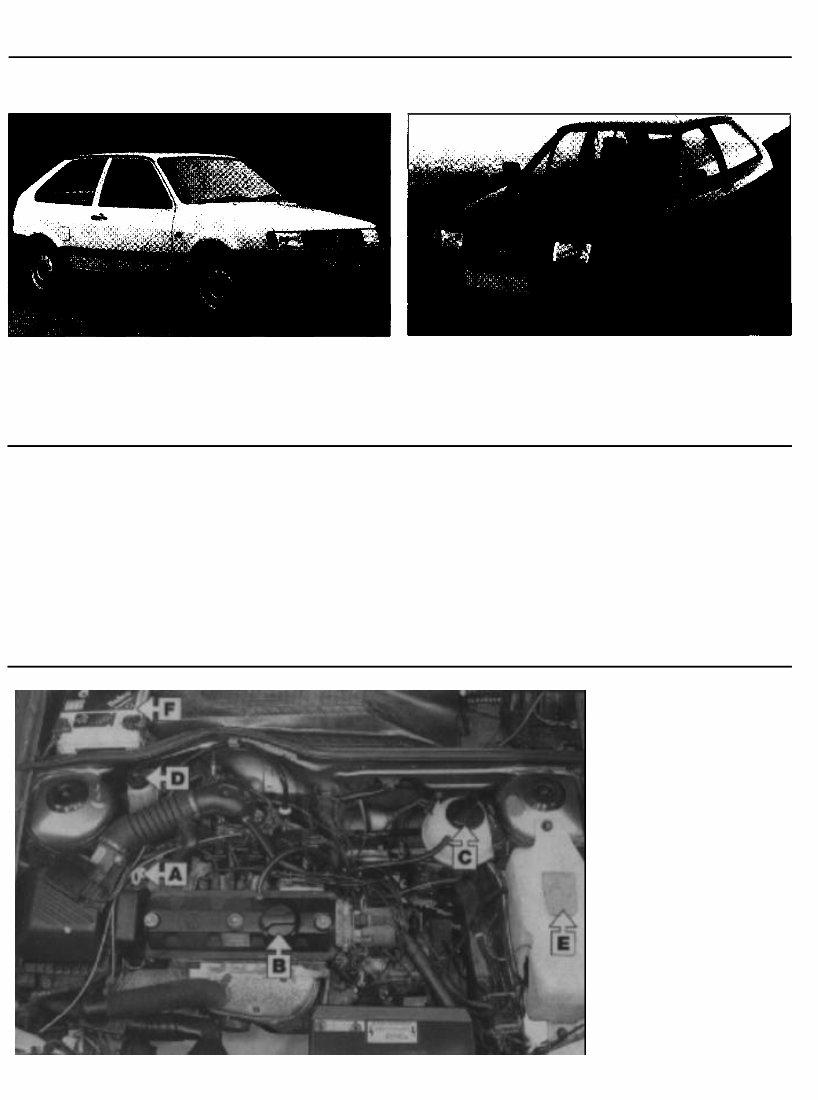

0.4 Introduction

The updated VW Polo range was introduced in November of

A wide range of standard and optional equipment is available within

1990, with a choice of 1.05 litre (1043 cc) or 1.3 litre (1272 cc) petrol

the Polo range to suit most tastes, including a sliding sunroof, tinted

engines, with either single-point or multi-point fuel injection. During

glass, alloy wheels and remote adjustable door mirrors.

Spring 1991, the G40 model was launched, equipped with a

Provided that regular servicing is carried out in accordance with the

supercharged version of the 1.3 litre engine. Three body shells are

manufacturer’s recommendations, the VW Polo should prove reliable

available - a three-door hatchback, a two-door saloon and a three-

and very economical. The engine compartment is well-designed, and

door Coupe. most of the items requiring frequent attention are easily accessible.

All engines are derived from the well-proven units which have

appeared in previous versions of the VW Polo. The engine is of four-

cylinder overhead camshaft design, mounted transversely, with the

transmission mounted on the left-hand side. All models have a four or

five-speed manual transmission.

Your Polo manual

All models have fully-independent front suspension and employ coil-

over-damper struts, transverse lower arms and an anti-roll bar. The

rear suspension is semi-independent, utilising coil-over-damper struts

and incorporating trailing arms located by a torsion beam axle. A rear

anti-roll bar is fitted to certain models.

The aim of this manual is to help you get the best value from your

vehicle. It can do so in several ways. It can help you decide what work

must be done (even if you choose to get it done by a garage). It will

also provide information on routine maintenance and servicing, and

give a logical course of action and diagnosis when random faults

occur. However, it is hoped that you will use the manual by tackling the

work yourself. On simpler jobs it may even be quicker than booking the

car into a garage and going there twice, to leave and collect it. Perhaps

most important, a lot of money can be saved by avoiding the costs a

garage must charge to cover its labour and overheads.

The WV Polo Team

Haynes manuals are produced by dedicated and

enthusiastic people working in close co-operation. The

team responsible for the creation of this book included:

Authors

Sub-editor

Editor & Page Make-up

Andy Legg

Spencer Drayton

Carole Turk

Bob Jex

Pete Shoemark

Workshop manager

Photo Scans

Paul Buckland

John Martin

Paul Tanswell

Steve Tanswell

Cover illustration & Line Art Roger Healing

Wiring diagrams Matthew Marke

W e hope the book will help you to get the maximum

enjoyment from your car. By carrying out routine

maintenance as described you will ensure your car’s

reliability and preserve its resale value.

The manual has drawings and descriptions to show the function of

the various components so that their layout can be understood. Tasks

are described and photographed in a clear step-by-step sequence.

This manual is not a direct reproduction of the vehicle

manufacturer’s data, and its publication should not be taken as

implying any technical approval by the vehicle manufacturers or

importers.

Acknowledgements

Thanks are due to Champion Spark Plugs, who supplied the

illustrations showing spark plug conditions. Special thanks to Loders

of Yeovil who provided several of the project vehicles used in the

origination of this manual. Thanks are also due to Sykes-Pickavant

Limited, who provided some of the workshop tools, and to all those

people at Sparkford and Newbury Park who helped in the production

of this manual.

We take great pride in the accuracy of information given in this

manual, but vehicle manufacturers make alterations and design

changes during the production run of a particular vehicle of which

they do not inform us. No liability can be accepted by the authors

or publishers for loss, damage or injury caused by any errors in, or

omissions from, the information given.

VW Polo Boulevard

WV Polo GT Coupe

Safety first! 0.5

W orking on your car can be dangerous.

This page shows just some of the potential

risks and hazards, with the aim of creating a

safety-conscious attitude.

General hazards

l Mains voltage is also dangerous. Make

sure that any mains-operated equipment is

correctly earthed. Mains power points should

be protected by a residual current device

(RCD) circuit breaker.

Scalding

l Don’t remove the radiator or expansion

tank cap while the engine is hot.

. Engine oil, automatic transmission fluid or

power steering fluid may also be dangerously

hot if the engine has recently been running.

Fume or gas intoxication

l Exhaust fumes are

poisonous; they often

contain carbon

monoxide, which is

Burning

l Beware of burns from the exhaust system

and from any part of the engine. Brake discs

and drums can also be extremely hot

immediately after use.

rapidly fatal if inhaled.

Never run the

engine in a

confined space

such as a garage

with the doors shut.

l Fuel vapour is also

Crushing

poisonous, as are the vapours from some

cleaning solvents and paint thinners.

l When working under or near

a raised vehicle,

Poisonous or irritant substances

l Avoid skin contact with battery acid and

with any fuel, fluid or lubricant, especially

antifreeze, brake hydraulic fluid and Diesel

fuel. Don’t syphon them by mouth. If such a

substance is swallowed or gets into the eyes,

seek medical advice.

venture

under a car which

is only supported by a jack.

l Take care if loosening or tightening high-

torque nuts when the vehicle is on stands.

Initial loosening and final tightening should

be done with the wheels on the ground.

l Prolonged contact with used engine oil can

cause skin cancer. Wear gloves or use a

barrier cream if necessary. Change out of oil-

soaked clothes and do not keep oily rags in

your pocket.

l Air conditioning refrigerant forms a

poisonous gas if exposed to a naked flame

(including a cigarette). It can also cause skin

burns on contact.

Fire Asbestos

l Fuel is highly flammable; fuel vapour is

explosive.

l Don’t let fuel spill onto a hot engine.

l Do not smoke or allow naked lights

(including pilot lights) anywhere near a

vehicle being worked on. Also beware of

creating sparks

(electrically or by use of tools).

. Fuel vapour is heavier than air, so don’t

work on the fuel system with the vehicle over

an inspection pit.

l Another cause of fire is an electrical

overload or short-circuit. Take care when

repairing or modifying the vehicle wiring.

l Keep a fire extinguisher handy, of a type

suitable for use on fuel and electrical fires.

l Asbestos dust can cause cancer if inhaled

or swallowed. Asbestos may be found in

gaskets and in brake and clutch linings.

When dealing with such components it is

safest to assume that they contain asbestos.

Electric shock

l Ignition HT

voltage can be

dangerous,

especially to

people with heart

problems or a

pacemaker. Don’t

work on or near the

ignition system with

the engine running or

the ignition switched on.

Special hazards

Hydrofluoric acid

l This extremely corrosive acid is formed

when certain types of synthetic rubber, found

in some O-rings, oil seals, fuel hoses etc, are

exposed to temperatures above 400°C. The

rubber changes into a charred or sticky

substance containing the acid. Once formed,

the acid remains dangerous for years. If it

gets onto the skin, it may be necessary to

amputate the limb concerned.

l When dealing with a vehicle which has

suffered a fire, or with components salvaged

from such a vehicle, wear protective gloves

and discard them after use.

The battery

l Batteries contain sulphuric acid, which

attacks clothing, eyes and skin. Take care

when topping-up or carrying the battery.

l The hydrogen gas given off by the battery

is highly explosive. Never cause a spark or

allow a naked light nearby. Be careful when

connecting and disconnecting battery

chargers or jump leads.

Air bags

l Air bags can cause injury if they go off

accidentally. Take care when removing the

steering wheel and/or facia. Special storage

instructions may apply.

Diesel injection equipment

l Diesel injection pumps supply fuel at very

high pressure. Take care when working on

the fuel injectors and fuel pipes.

A

!

Warning: Never expose the hands,

face or any other part of the body

to injector spray; the fuel can

penetrate the skin with potential/y fatal

results.

0.6 Roadside repairs

The following pages are intended to help in dealing with

common roadside emergencies and breakdowns. You will find

more detailed fault finding information at the back of the

manual, and repair information in the main chapters.

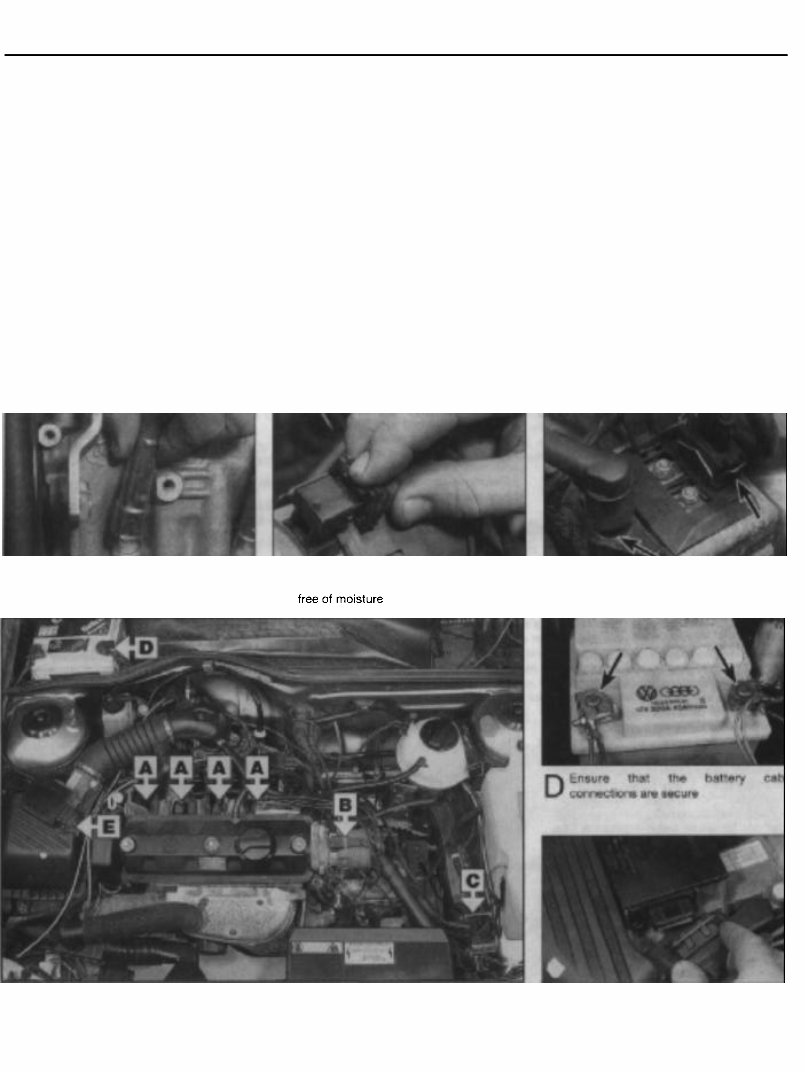

If your car won’t start If your car won’t start

and the starter motor even though the starter

doesn’t turn motor turns as normal

0 Open the bonnet and make sure that the battery terminals 0 Is there fuel in the tank?

are clean and tight. 0 Is there moisture on electrical components under the

0 Switch on the headlights and try to start the engine. If the bonnet? Switch off the ignition, then wipe off any obvious

headlights go very dim when you’re trying to start, the dampness with a dry cloth. Spray a water-repellent aerosol

battery is probably flat. Get out of trouble by jump starting product (WD-40 or equivalent) on ignition and fuel system

(see next page) using a friend’s car. electrical connectors like those shown in the photos.

Pay special attention to the ignition coil wiring connector

and H-T leads.

A

Check that the spark plug HT leads are

B

Check that the distributor hall sender

securely connected by pushing them connector is firmly pushed home and

down onto the plug tops

C

At the ignition coil, check that the LT and

HT cable connections are secure and

free of moisture

With the ignition switched off, check that electrical connections are secure and spray

them with a water dispersant spray, such as WD40, if you suspect that moisture may be

causing a problem.

E

Check that the airflow meter harness

connector is secure and free of moisture

Roadside repairs 0.7

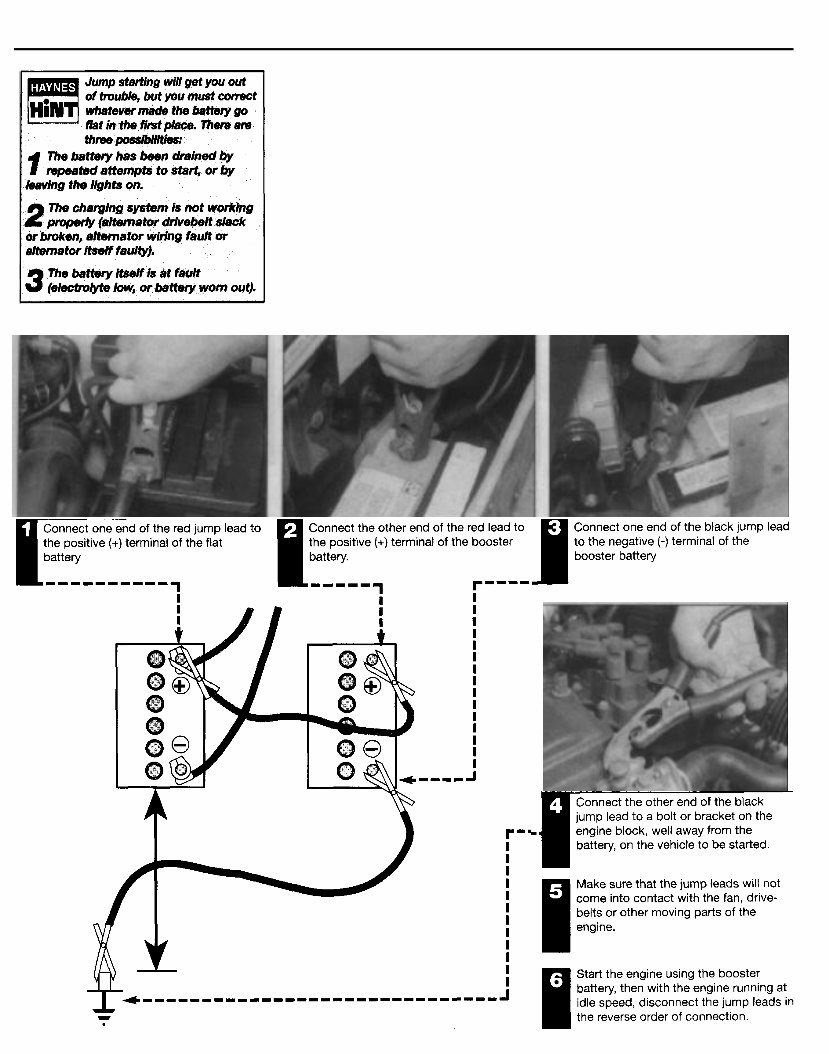

When jump-starting a car using a 3 Make sure that the booster battery is

booster battery, observe the following the same voltage as the discharged

precautions: one in the vehicle.

1 Before connecting the booster

battery, make sure that the ignition is

switched off.

4 If the battery is being jump-started

from the battery in another vehicle,

the two vehicles MUST NOT TOUCH

each other.

2 Ensure that all electrical equipment

(lights, heater, wipers, etc) is

switched off.

5/ Make sure that the transmission is in

neutral (or PARK, in the case of

automatic transmission).

Jump starting

0.8 Roadside repairs

Wheel changing

Some of the details shown here will vary

according to model. For instance, the location

of the spare wheel and jack is not the same

on all cars. However, the basic principles

apply to all vehicles.

Preparation

0 When a puncture occurs, stop as soon as

it is safe to do so.

0 Park on firm level ground, if possible,

and well out of the way of other traffic.

q Use hazard warning lights if necessary.

Changing the wheel

A

Warning: Do not change a wheel in a situation where you risk being hit by

!

other traffic. On busy roads, try to stop in a lay-by or a gateway.Be wary of

passing traffic while changing the wheel - it is easy to become distracted by

the job in hand.

0l If you have one, use a warning triangle to

alert other drivers of your presence.

0 Apply the handbrake and engage first or

reverse gear (or Park on models with

automatic transmission.

0 Chock the wheel diagonally opposite the

one being removed - a couple of large

stones will do for this.

0 If the ground is soft, use a flat piece of

wood to spread the load under the jack.

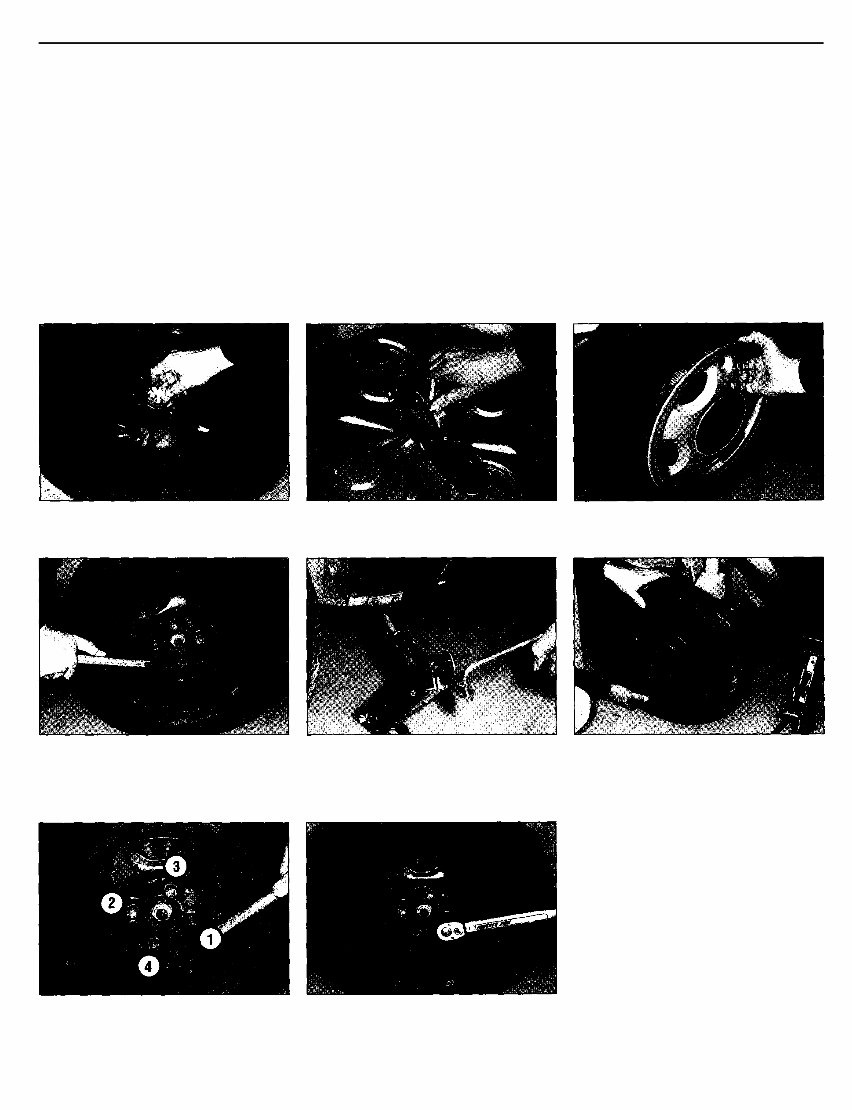

1

The spare wheel and tools are stored in

the luggage compartment. Unscrew the

wing nut and lift out the spare wheel

2

The jack is located beneath the spare

wheel. The wheel brace is on the right-

hand side of the luggage compartment

3

Remove the wheel trim . . .

4

. . . then slacken each wheel bolt by a

half turn 5

Locate the jack below the reinforced point

on the sill (don’t jack the vehicle at any

other point of the sill) and on firm ground

then turn the jack handle clockwise until the

wheel is raised clear of the ground

6

Unscrew the wheel bolts and remove the

wheel. Fit the spare wheel, and screw in

the bolts. Lightly tighten the bolts with

the brace, and lower the vehicle to the

ground.

7

Securely tighten the wheel bolts in the

sequence shown, Refit the wheel trim,

and stow the punctured wheel and tools.

8

The wheel bolts should be slackened and

retightened to the specified torque at the

earliest possible opportunity

Finally...

0 Remove the wheel chocks.

0 Stow the jack and tools in the correct

locations in the car.

0 Check the tyre pressure on the wheel just

fitted. If it is low, or if you don’t have a

pressure gauge with you, drive slowly to

the nearest garage and inflate the tyre to

the right pressure.

0 Have the damaged tyre or wheel repaired

as soon as possible.

Roadside repairs 0.9

Puddles on the garage floor or drive, or

obvious wetness under the bonnet or

underneath the car, suggest a leak that needs

investigating. It can sometimes be difficult to

decide where the leak is coming from,

especially if the engine bay is very dirty

already. Leaking oil or fluid can also be blown

rearwards by the passage of air under the car,

giving a false impression of where the

problem lies.

Sump oil

Engine oil may leak from the drain plug...

Antifreeze

Leaking antifreeze often leaves a crystalline

deposit like this.

When all else fails, you may find yourself

having to get a tow home - or of course you

may be helping somebody else. Long-distance

recovery should only be done by a garage or

breakdown service. For shorter distances, DIY

towing using another car is easy enough, but

observe the following points:

q Use a proper tow-rope - they are not

expensive. The vehicle being towed must

display an ‘ON TOW’ sign in its rear window.

q Always turn the ignition key to the ‘on’

position when the vehicle is being towed, so

that the steering lock is released, and that the

direction indicator and brake lights will work.

0 Only attach the tow-rope to the towing

eyes provided.

0 Before being towed, release the handbrake

and select neutral on the transmission.

0 Note that greater-than-usual pedal

A

Warning: Most automotive oils

!

and fluids are poisonous. Wash

them off skin, and change out of

contaminated clothing, without

delay.

. ..or from the base of the oil filter.

Brake fluid

A leak occurring at a wheel is almost

certainly brake fluid.

pressure will be required to operate the

brakes, since the vacuum servo unit is only

operational with the engine running.

0 On models with power steering, greater-

than-usual steering effort will also be required.

0 The driver of the car being towed must

keep the tow-rope taut at all times to avoid

snatching.

0 Make sure that both drivers know the route

before setting off.

q Only drive at moderate speeds and keep

the distance towed to a minimum. Drive

smoothly and allow plenty of time for slowing

down at junctions.

q The front towing eye is supplied as part 01

the tool kit stored in the luggage

compartment. To fit the eye, carefully prise

out the removable panel from the front

bumper. Securely screw the eye into position,

Identifying leaks

Gearbox oil

Gearbox oil can leak from the seals at the

inboard ends of the driveshafts.

Power steering fluid

Power steering fluid may leak from the pipe

connectors on the steering rack.

Towing

(noting that on some models it may have a

left-handed thread) and tighten using the

wheelbrace handle (see illustration).

The front towing eye is supplied as part of

the vehicle tool kit and must be screwed

into position

0.10 Weekly checks

Introduction

There are some very simple checks which

need only take a few minutes to carry out, but

which could save you a lot of inconvenience

and expense.

These “Weekly checks” require no great skill

or special tools, and the small amount of time

they take to perform could prove to be very

well spent, for example;

q Keeping an eye on tyre condition and

pressures, will not only help to stop them

wearing out prematurely, but could also save

your life.

0 Many breakdowns are caused by electrical

problems. Battery-related faults are particularly

common, and a quick check on a regular basis

will often prevent the majority of these.

Underbonnet check points

q If your car develops a brake fluid leak, the

first time you might know about it is when

your brakes don’t work properly. Checking

the level regularly will give advance warning of

this kind of problem.

0 If the oil or coolant levels run low, the cost

of repairing any engine damage will be far

greater than fixing the leak, for example.

1 1.3 litre model

A

Engine oil level dipstick

B

Engine oil filler cap

C

Coolant expansion tank

D

Brake fluid reservoir

E

Screen washer fluid reservoir

F

Battery

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

Viewed 44 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

Discover the 1990-1994 VW POLO Service Repair Manual, a comprehensive guide tailored to assist in maintaining, repairing, and troubleshooting your VW POLO from 1990 to 1994. Whether you're a professional mechanic or a DIY enthusiast, this manual is your ultimate resource for keeping your VW POLO in optimal condition.

Key Features:

- Step-by-step instructions for various repairs and maintenance tasks

- Clear and detailed diagrams, illustrations, and photographs

- Comprehensive information on engine, electrical systems, transmission, suspension, brakes, and more

- Troubleshooting guides for issue diagnosis and resolution

- Proven techniques and tips from expert VW mechanics

Models Covered:

- 1990 VW POLO

- 1991 VW POLO

- 1992 VW POLO

- 1993 VW POLO

- 1994 VW POLO

Acquire the 1990-1994 VW POLO Service Repair Manual today to ensure your VW POLO performs at its best for years to come. Whether you require a quick repair or a detailed overhaul, this manual has got you covered!