VW VOLKSWAGEN BEETLE 1300 Workshop Service Repair Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

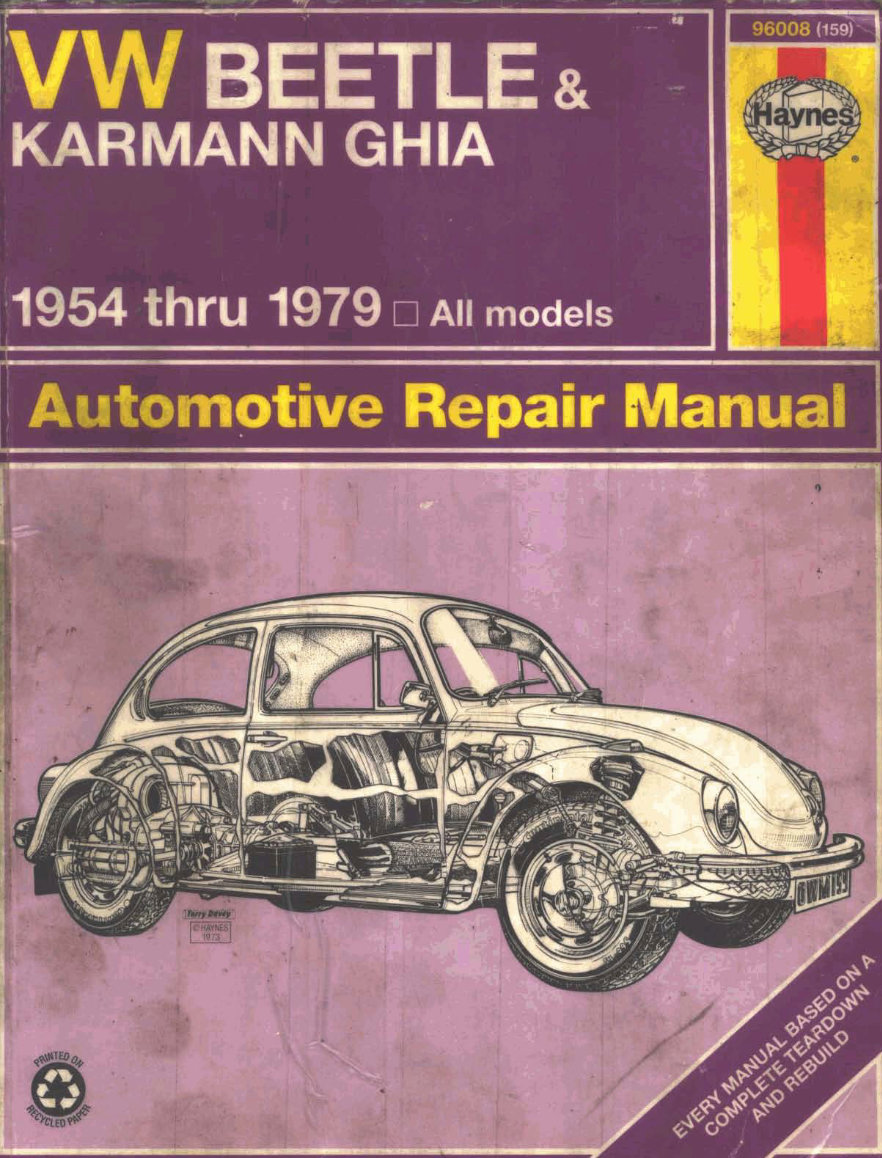

Beetle &

Automotive

Repair

Manua

by Ken Freund,

Mike Stubblefield,

and John H Haynes

Mernbr of the Guild of Mobnng Wrrters

Models covered:

All VW Beetles and Karmann Ghias

Does not include diesel engrne information

Haynes Publishing Group

Sparkford Nr Yeovil

Somerset BA22 7JJ England

Haynes North America, Inc

861 Lawrence Drive

Newbury Park

California 91320 USA

About this manual

Its purpose

The purpose of this manual is to help

you get the best value from your vahicle. It

can do so in several ways. It can help you

decide what work must be done, even if you

choose to have it done by a dealer service

department or a repair shop; it provides Infor-

mation and procedures for routine mainte-

nance and servicing; and it offers diagnostic

and repalr procedures to follow when trouble

occurs.

We hope you use the manual to tackle

the work yourself. For many simpler jobs,

doing it yourself may be quicker than arrang-

Ing an appointment to get the vehicle Into a

shop and making the trips to leave it and pick

It up. More Importantly, a lot of money can be!

saved by avoiding the expense the shop

must pass on to you to cover rts labor and

overhead costs. An added benefit is the

sense of satisfaction and accomplishment

that you feel after doing the job yourself.

Using the manual

The manual Is divided into Chapters.

Each Chapter Is dMded Into numbered Sec-

tions, which are headed in bold type between

horizontal lines. Each Sect~on consists of

consecutrvely numbered paragraphs.

At the b%glnnmg of each numbered Sec-

tion you will be referred to any illustrations

which apply to the procedures in that Sec-

tion. The reference numbers used In illustra-

tlon captlons pinpoint the pertinent Section

and the Step within that Sectfon. That is,

Illustretton 3.2 means the illustration refers to

Section 3 and Shp (or paragraph) 2 within

that Section.

Procedures. once described in the text,

are not normally repeated. When it's neces-

sary to refer to anothw Chaptw, the m c e

will be given as Chapter and Section numbr.

Cross references glven without use of the

word "Chapter" apply to Sections andror para-

graphs in the same Chapter. For example,

"see Section 8" means in the same Chapter.

References to the left or r~ght side of the

vehjcle assume you are sitting In the driver's

seat, facing forward.

Even though we have prepared this

manual with extreme care. neither the pub-

lisher nor the author can accept responsibility

for any errors In, ox omiss~ons from, the ~nfor-

mation glven.

NOTE

A Nata provides information necessary to properly complete a procedure or information which w~ll

make the procedure easier to understand.

CAUTION

A Cautfon provides a special procedure or special steps which must be taken while complet~ng the

procedure where the Cautlon is found. Not heeding a Caution can result in damage to the assembly

being worked on.

WARNING

A Warning provides a special pwedure or special steps which must be taken while completing the

procedure where the Warning 1s found. Not heeding a Warning can result in personal injury.

Acknowledgements

We are grateful for the help and cooperation of Volkswagen of Amer~ca, Inc., for asslstance with technical information,

certain illustrations and vehicle photos.

0 Haynes North America, Ine. 1991,1998

Wtfh mlsslon from J.H. Haynes & Co. ttd.

A book in the Haynes Automotivh Repair Manual Series

P~*inted In the U.S.A.

All rights resewed. No part af this book may be reproduced or transmitted In any form or by any means, electronic or

rnechanrcal, including photocopying, recording or by any information storage or retrieval system, without permission In writ-

ing from the mpyright holder.

Library of Congress Catalog Card Number 81 -70148

Whlle every attempt rs made to ensure that the Informd~on In this manual is correct, no liability can be accepted by the

authors or publishers for loss, damage or injury caused by any errors m, or omissions from, the information given.

98-320

Contents

Introductory pages

About thls manual

lntrod~ct~on 10 the VW Beetle and Karmann Ghia

Vehicle identification numbers

Buying parts

Maintenance techniques, tools and worklng facilities

Jacking and towing

Booster battery (lump) starting

Automottve chemicals and lubricants

Conversion factors

Safety first?

Troubleshooting

Chapter i

Tune-up and rnuttne maintenance

Chapter 2

Engrne 2-1

Chapter 3

Cooling and heating systems 3-1

Chapter 4

Fuel and exhaust systems

Chapter 5

Engine electr~cal systems

Chapter 6

Em~ssions control systems 161

Chapter 7 Part A

Manual transaxle 74-1

Chapter 7 Part El

Automatic Stick Shift

Chapter 8

Clutch and drivellne

Chapter 9

Brakes

Chapter i Q

Suspension and steering systems 10-1 lo

Chapter 11

Body 11-1

Chapter f 2

Chassis electrical system and wlrlng diagrams

Wiring diagrams 12-1 8

Index rNB1 lFAD

! - -- A 2

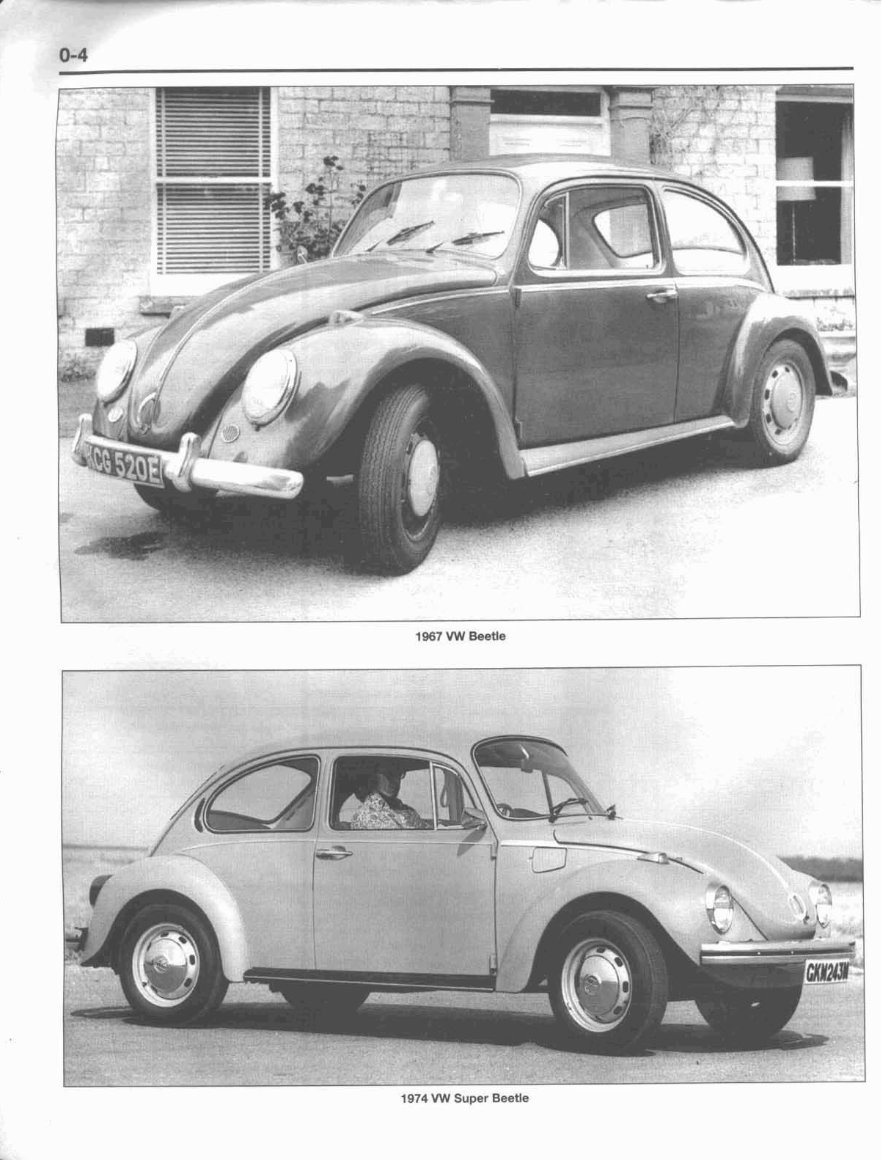

1974 VW Super Beetle

Introduction to the

Volkswagen Beetle and Karmann Ghia

)e rear susl

?ssed mer

The vehicles covered by thrs manual are axle-tyg penslon, in which the axles wlth the steering gearbox mounted to the

very sim~lar tn design. Although the Kamann are strt nbers of the suspension. front axle beam. Later models were equipped

Ghia may appear to be a completely different Later models use dtiveaxles, which are used with a rack-and-pinion style steering gear.

vehicle, it shares the same basic platform only for the transmission of power to the rear The rear suspension on a$ models is of

and components. wheels. a torsion bar des~gn, although there are sig-

The horizontally opposed, four-cyl~nder Independent suspenston, featuring tor- nlficant differences between models with

engine used in these models is equipped with sion bars, trailing arms, and telescopic shock swing axles and modeis with driveaxles (see

either a carburetor or electronic fuel ~nlection. absorbers in used on the front wheels of most Chapter 8 for more details). Telescopic shock

All models util~ze a breaker points-type igni- models. Beginning with the 1971 Super Bee- absorbers are also used at the rear.

tion system.

tle, some models were equipped w12h a All models are equipped wtth drum brakes on

The engine drtves the rear wheels MacPherson strut-type front suspension (all all four wheels, w~th the exception of later

through a 4-speed manual or 3-speed 1975 and later models were equrpped wlth model Karmann Gbias, which were equipped

semi-automatic transaxle vla independent this type of front suspension). Most models with disc brakes on the front wheels.

axles. Early models employ a swlng use a worm-and-roller type steering gear,

Vehicle identification numbers

Mod~ficat~ons are a continuing and compiled on a numerical basis, the Endrvidual

Chassis jdenfjfjation number

unpublicrzed process In vehicle manufactur- veh~cla numbers are necessary to correctly

ing. Since spare parts manuals and lists are identify the component requ~red.

Th~s very important Identification num-

ber is found in three different places: on the

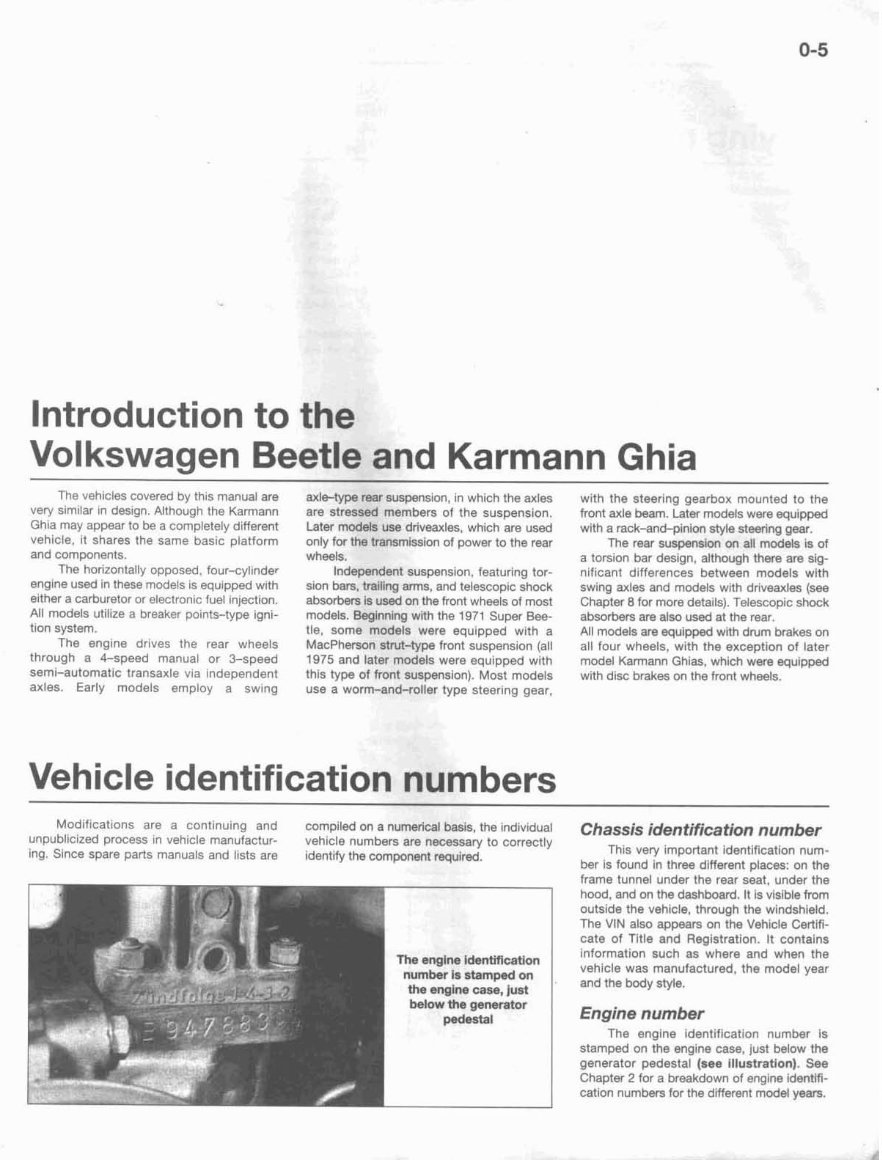

The engine idenWicatlon

number is stamped on

the engim case, just

below the generator

pedestal

frame tunnel under the rear seat, under the

hood. and on the dashboard. It IS visible from

outsida the vehicle, through the windshietd.

The VIM also appears on the Yehide Certifi-

cate of Title and Registration. It contains

information such as where and when the

vehicle was manufactured. the model year

and the body style.

Engine number

The engine identification number is

stamped on the engine case, just below the

generator pedestal (see illustration). See

Chaptw 2 for a breakdown of engine identifi-

cation numbers for the drlferent model years.

0-6

Buying parts

Replacement parts are available from

many sources, which generalry fall into one of

two categories - authorized dealer parts

departments and independent retail auto

parts stores. Our adv~ce concerning these

pans is as follows:

Retall auto parts stores: Good auto

parts stores will stock frequently needed

components which wear out relatively fast,

such as clutch components, exhaust sys-

tems, brake parts, tune-up parts, etc. these

stores often supply new or rscondit~oned

parts an an exchange basis, which can save

a considerable amount of money. Discount

auto parts stores are often very good places

to buy rnateriaTs and parts needed for general

vehicle maintenance such as 011, grease, fll-

ters, spark plugs, belts, touch-up paint,

bulbs, etc. They also usually sell tools and

general accessories, have conven~ent hours.

charge lower prtces and can often be found

not far from home.

Authorized dealer parts department:

This is the best source for parts which are

Maintenance techniques,

tools and working facilities

unique to the vehicle and not generally avail-

able elsewhere [such as major engine parts,

transm~ssron parts, trim pieces, etc.).

Warranty Infomatloon: If the veh~cle is

st111 covered under warranty, be sure that any

replacement parts purchased - regardless of

the source - do not lnvalldate the warranty!

To be sure of obtaining the correct

parts, have englne and chassis numbers

avatlable and, if possible, take the otd parts

along for positlve ~dentificat~on.

Maintenance techniques

There are a number of techniques

involved In maintenance and repair that will

be referred to throughout thls manual. Appli-

cation of these techniques will enable the

home mechanic to be more effictent, better

organized and capable of performing the var-

lous tasks properly, which will ensure that the

repair job is thorough and complete.

Fasteners

Fasteners are nuts, bolts, studs and

screws used to hold two or more parts

together. There are a few things to keep I ~ I

m~nd when working with fasteners. Almost all

of them use a locking device of some type,

either a lockwasher, locknut, locking tab or

thread adhesive. All threaded fasteners

should be clean and straight, wlth undam-

aged threads and undamaged corners on the

hex head where the wrench fits. Develop the

hablt of replacing all damaged nuts and bolts

w~th new ones. Special locknuts with nylon or

flber inserts can only be used once. If they

are removed, they lose thelr locktng abltity

and must be replaced with new ones.

Rusted nuts and bolts should be treated

this task, as well as other repair procedures, be replaced exactly as removed. Replace any

such as the repalr af threaded holes that damaged washers w~th new ones. Never use

have been strip@ out. a lockwasher on any soft metal surface (such

Flat washers and lockwashers, when as alurn~num), thin sheet metal or plastic.

removed from an assembly, should always

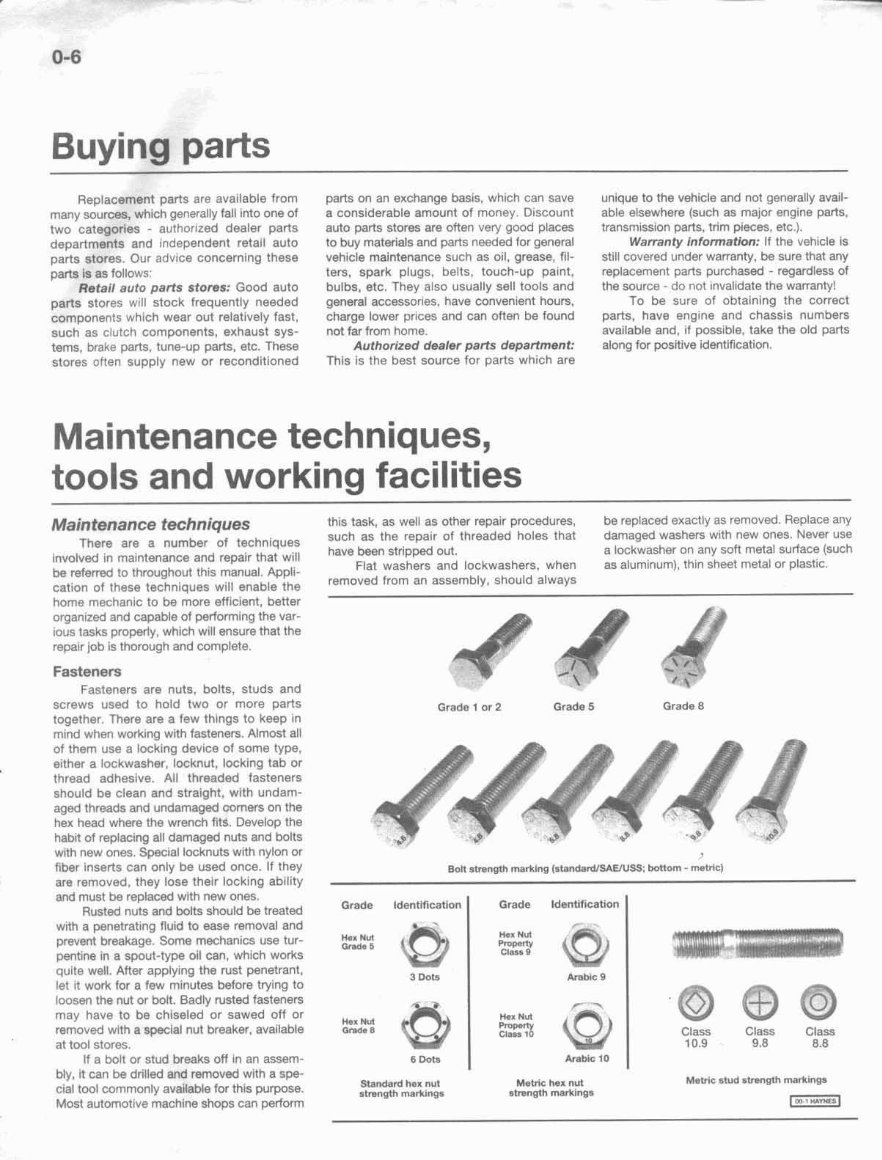

Grade 1 or 2 Grade 5 Grade 8

Grade ldenttfication I Grade Identification

I

with a penetrating flutd to ease removal and

prevent breakage. Some mechanics use tur-

FA",%

pent~ne in a spout-type oil can, which works

$2

quits well. After apply~ng the rust penetrant.

3 Dots

let it work for a few minutes before trying to

loosen the nut or blt. Badly rusted fasteners

may have to be chiseled or sawed off or

+fij

removed with a special nut breaker, available Grede B

at tool stores.

II a bolt or stud breaks off In an assem- 6 aot~

bly, it can be drilled and removed with a spe-

cial tool commonly available for this purpose.

andard hex nut

strength marklngn

Most autornot~ve machine shops can perform

2s Class 9 GI

Anhlc 9

Metfie hex nut

atrength markings

Class Class Class

10.9 9.8 8.8

Metric stud strength markings

Maintenance techniques, tools and working facilities

Fastener sires

For a number of reasons, automobile

manufacturers are making wider and wider

use of metric fasteners. Therefore, it is impor-

tant to be able to tell the difference 'between

standard (sometimes called U.S. or SAE) and

metric hardware, slnce they cannot be Inter-

changed.

kll bolts, whether standard or metric, are

sired accord~ng to diameter, thread pitch and

length. For example. a standard 112 - 13 x 1

bott Is 1/2 inch In diameter, has 13 threads per

inch and is 1 inch long. An MI2 - 1.75 x 25

metric bolt is 12 mm in dtameter, has a thread

pitch of 1.75 mm (the distance between

threads) and is 25 rnm long. Thatwo bolts are

nearly identical, and easily contused, but they

are not interchangeable.

In addition to the differences in diame-

ter, thread p~tch and length, metric and stan-

dard bolts can also be distinguished by

examining the bolt heads. To beg~n with, the

d~stance across the fiats on a standard bolt

head is measured In inches, whlle the same

d~mension on a metric belt 1s wed in millime-

ters [the same is true for nuts). As a result. a

standard wrench should not be used an a

metrtc bolt and a metric wrench should not

be used on a standard bolt. Also, most stan-

dard bolts have slashes radiating out from

the center of the head to denote the grade or

strength of the h l t , which is an indication of

the amount of torque that can be apphed to

It. The greater the number of slashes, the

greater the strength of the bolt. Grades D

through 5 are commonly used on autorno-

biles. Metric bolts have a property class

(grade) number, rather than a slash, molded

into their heads to indtcate bolt strength. In

this case. the higher the number,the stronger

the bolt. Property class numbers 8.8, 9.B and

1O.g are commonly used on automobiles.

Strength markings can also be used to

distinguish standard hex nuts from metric

hex nuts. Many standard nuts have dots

stamped into one side, whlle rnetnc nuts are

mark& with a number. The greater the nurn-

ber of dots. or the higher the number, the

greater the strength of the nut.

Metric studs are also marked on their

ends accordlng to property class (grade).

Larger studs are numbered (the same as

metric bolts), while smaller studs carry a geo-

metric code to denote grade.

It should be noted that many fasteners,

especially Grades 0 through 2, have no dis-

tinguishing marks on them. When such is the

case, the only way to determine whether tl is

standard or metric Is to measure the thread

p~tch or compare it to a known fastener of the

Same size.

Standard fasteners are often referred to

as SAE, as opposed to metric. However, it

should be noted that SAE technically refers to

a non-metric fine thread fastener only.

Coarse thread non-rnetrlc fasteners are

referred to as USS sizes.

Since fasteners of the same size (both

standard and metric) may have different

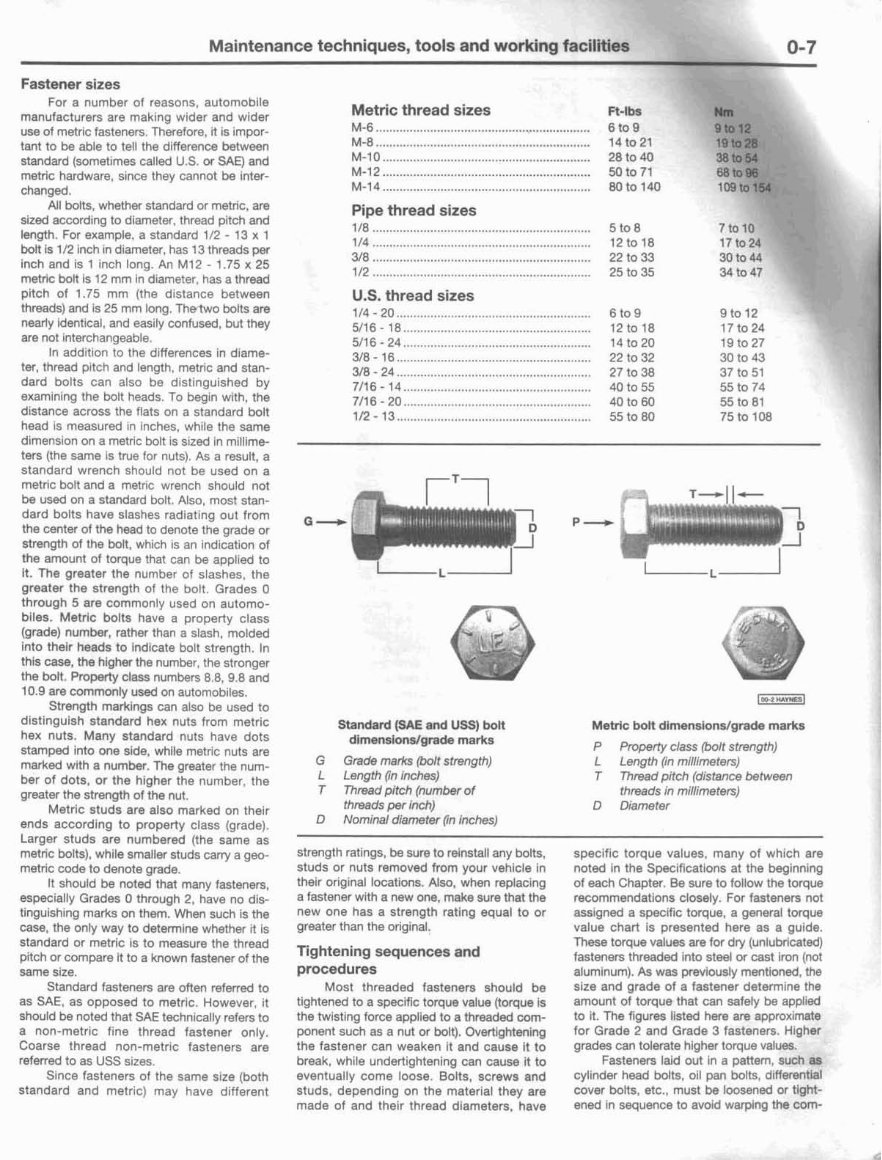

Metric thread sizes

M-6 ...................................... .. .....................

M-8 ...............................................................

M-10 .............................................................

Pipe thread sizes

U.S. thread sizes

1 /4 - 20 ........................................................

5/16 - 18 ...................................................

511 6 - 24 .......................................................

318 - 16 .........................................................

318 - 24 .........................................................

7/16 - 14 .......................................................

7/76 - 20 .....................................................

1rZ - 13 .........................................................

Standard (SAE and USS) bolt

dimens~onslgrade marks

G Grade marks (bolt strength)

L Length (in inches)

T Thread pitch (number of

thm~ds per Inch}

D Nomtnal diameter (in Inches)

Metric bolt dimensionstgrade marks

P Property class (bolt strength)

C Length (in rni//rmete~)

T Mad pitch (distance between

threads in miilimefers)

D Diameter

strength ratings, be sure to relnstalt any bolts,

studs or nuts removed from your vehicle in

their original locations. Also, when replacing

a fastener with a new one, make sure that the

new one has a strength rating equal to or

greater than the original.

Tightening sequences and

procedures

Most threaded fasteners should be

tightened to a specific torque value (torque is

the hvistrng force applied to a threaded com-

ponent such as a nut or bolt). Overtightening

the fastener can weaken it and cause it to

break, while undertightening can cause it to

eventually come loose. Bolts, screws and

studs, depending on the material they are

made of and their thread diameters, have

specific torque values, many of which are

noted In the Specifications at the beglnnlng

of each Chapter. Be sure to folilow the torque

recommendations closely. For fasteners not

assrgned a specrfic torque, a general torque

value chart is presented here as a guide.

These torque values are for dry (unlubricated)

fasteners threaded into steel or cast iron (not

aluminum). As was previously mentioned, the

s~zs and grade of a fastener determine the

amount of torque that can safely be applred

to rt. The figures listed here are approximate

for Grade 2 and Grade 3 fasteners. Higher

grades can tolerate higher torque values.

Fasteners laid out in a pattern, such as

cylinder head bolts, oil pan bolts. differentla1

cover bolts, etc.. must be loosend or tight-

ened in sequence to avoid warping the com-

0-8 Maintenance techniques, tools and working facilities

Micrometer set Dial indicator set

ponent. This sequence will normally be

shown In the appropriate Chapter. If a spe-

crflc pattern is not given, the following proce-

dures can be used to prevent warplng.

Initially, the bolts or nuts should be

assembled finger-tlght only. Next, they

should be trghtened one full turn each, in a

crlss-cross or d~agonal pattern. After each

one has been tightened one full turn, return to

the first one and tighten them all one-half

turn, following the same pattern. Finally,

tighten each of them one-quarter turn at a

time unt~l each fastener has been tightened to

the proper torque. To loosen and remove the

fasteners, the procedure would be reversed.

Component disassembly

Component d~sassembly should be

done with care and purpose to help ensure

that the parts go back together properly.

Always keep track of the sequence in which

parts are removed. Make note of special

characteristics or marks on parts that can be

installed more than one way, such as a

grooved thrust washer on a shaft. tt is a good

idea to fay the disassembled parts out on a

clean surface in the order that they were

removed. It may also be helpful to make

sketches or take instant photos of compo-

nents before removal,

When removing fasteners from a com-

ponent, keep track nf therr locations. Some-

times threadlng a bolt back in a part, or

putting the washers and nut back on a stud.

can prevent mlx-ups later. If nuts and bolts

cannot be returned to thelr original locat~ons,

they should be kept in a compartmented box

or a series of small boxes. A cupcake or muf-

fin tln is Ideal for this purpose, slnce each

cavity can hold the bolts and nuts from a par-

ticular area (4.e. oil pan bolts, valve cover

bolts, engine mount bolts, etc.). A pan of this

type rs especially helpful when working on

assemblies with very srnali parts, such as the

carburetor, alternator, valve train or interlor

dash and trim pieces. The cavltles can be

marked with paint or tape to Identify the con-

tents.

Whenever wir~ng looms, harnesses or

connectors are separated, ~t is a good idea to

identify the two halves with numbered pieces

of masking tape so they can be easily recon-

nected.

Gasket sealing surfaces

Throughout any vsh~cle, gaskets are

used to seal the rnat~ng surfaces between

two parts and keep lubricants, flu~ds, vacuum

or pressure contained tn an assembly.

Many t~mes these gaskets are coated

w~th a llquid or paste-type gasket sealing

compound before assembly. Age, heat and

pressure can sometimes cause the two parts

to st~ck together so tightly that they are very

dlfflcult to separate. Often, the assembly can

be loosened by striking it with a soft-face

hammer near the mating surfaces. A regular

hammer can be used if a block of wood IS

placed ktween the hammer and the part. Do

not hammer on cast parts or parts that could

be easily damaged. W~th any particularly

stubborn part, always recheck to make sure

that every fastener has been removed.

Avoid using a screwdriver or bar to pry

apart an assembly, as they can easily mar the

gasket sealing surfaces of the parts, whlch

must remaln smooth. If prying is absolutely

necsssavy, use an old broom handle, but

keep In mlnd that extra clean up will be nec-

essary if the w w d splinters.

After the parts are separated, the old

gasket must be carefully scraped off and the

gasket sulfaces cleaned. Stubborn gasket

material can be soaked with rust penetrant or

treated with a special chemical to soften ~t so

it can be eastly scraped off. A scraper can be

fashioned from a piece of copper tubing by

flattening and sharpening one end. copper is

recommended because it is usuallv softer

than the surfaces to be scraped: which

reduces the chance of gnuglng the part.

Some gaskets can be removed with a wire

brush,. but regardless of the method used,

the matlng surfaces must be left clean and

smooth. If for some reason the gasket sur-

face is gouged, then a gasket sealer thick

enough to fill scratches will have to be used

during reassembly of the components. For

most applicatinns, a non-drying (or semi-dry-

ing) gasket sealer should be used.

Hose removaF tips

Warning: If the veh~cle rs equipped with air

conditioning, do not drsconnect any of the

AIC hoses w~thoui first hanng the system

depressurired by a dealer serwtce department

or a servrce statton.

Hose removal precautt~ns closely paral-

lel gasket removal precautions. Avord

scratching or gouglng the surface that the

hose mates against or the connect~on may

leak. Thls is espec~ally true for radiator hoses.

Because of varlous chemlcal reactions, the

rubber in hoses can bond ~tself to the metal

splgot that the hose fits over. To remove a

hose, first loosen the hose clamps that

secure it to the spigot. Then. with slipjoint

pliers, grab the hose at the clamp and rotate

~taround the spigot. Work ~t back and forth

unt~l rt is completely free, then pull It off. Sill-

cone or other lubr~cants w~ll ease removal if

they can be applied between the hose and

the outside of the spigot. Apply the same

lubr~cant to the inside of the hose and the

outside of the splgol to srrnpllfy lnstallatlon.

As a last resort (and if the hose is to be

replaced with a new one anyway). the rubber

can be slit with a knlfe and the hose peeled

from the spigot. If this must be done, be

careful that the metal connection IS not dam-

aged.

If a hose clamp is brok8n or damaged,

do not reuse ~ t . Wire-type clamps usually

weaken wlth age, so ~t IS a good ldea to

replace them w~th screw-type clamps when-

ever a hose is removed

Tools

A selection of good tools is a basic

requirement for anyone who plans to main-

tain and repalr his or her own vehtcle. For the

owner who has few tools, the inrtjal invest-

ment might seem hrgh, but when compared

to the sr$raling costs of profess~onal auto

maintenance and repair. ~t 1s a wise one.

To help the owner decide which tools

are needed to perform the tasks detailed rn

this manual, the fallowing tool lists are

offered: Maintenance and minor repaw,

Repa!r/overhaul and Specral.

The newcomer to practical rnechan~cs

Maintenance techniques, tools and working facilities

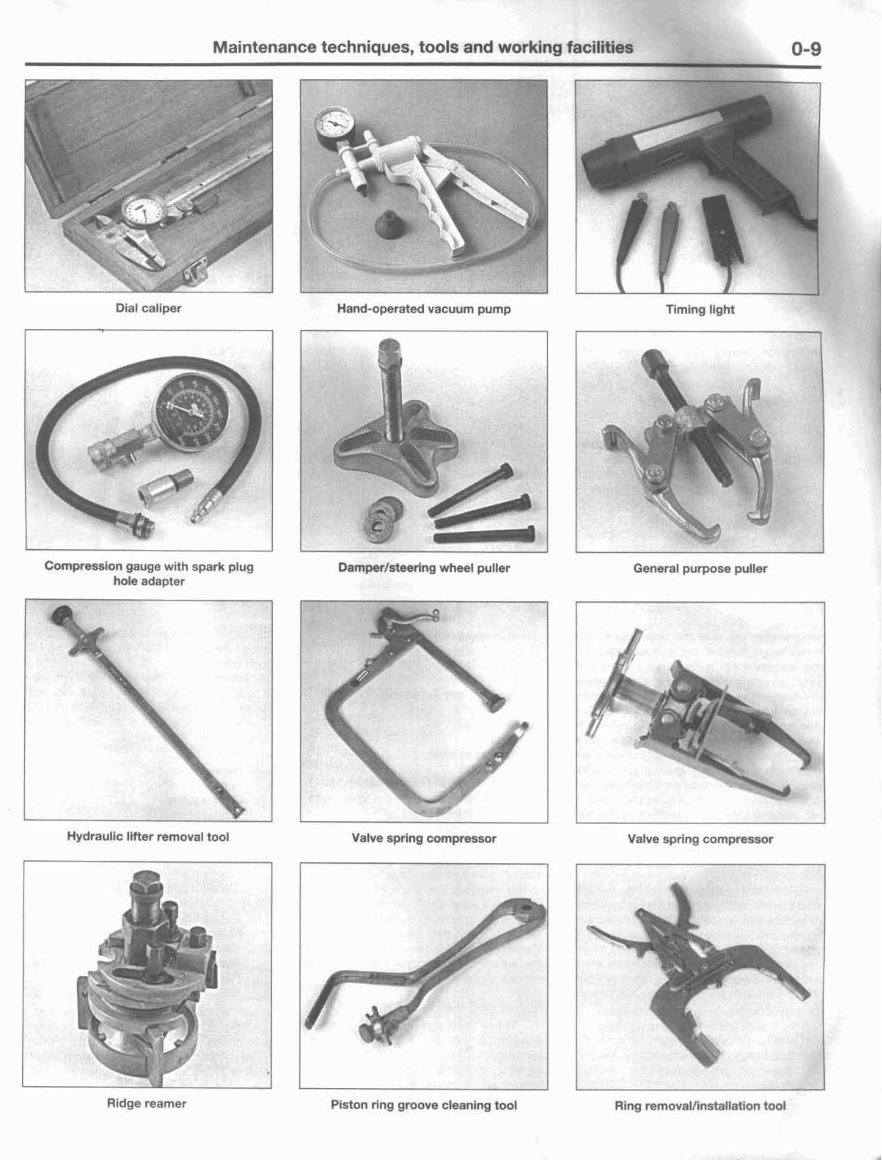

Dial caliper

Compression gauge with spark plug

hole adapter

Hand-operated vacuum pump Timtng light

3rlng wheel puller General purpose puller

Hydraulic Imer removal tool Valve sprlng compressor Valve spring cornpressor

Ridge reamer Piston ring groove cleaning took Ring removalfinstallatlon tool

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

Viewed 14 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$39.99

This workshop service repair manual is for the VW Volkswagen Beetle 1300 with a 1.3L 4-cylinder petrol aspirated engine. It includes detailed information on various aspects such as:

- General information

- Automatic transmission

- Body repair

- Brake system

- Chassis electrical

- Clutch system

- Cooling system

- Drivability & troubleshooting

- Emission control

- Engine electrical

- Engine mechanical

- Engine performance and tune-up

- Engine rebuilding

- Exhaust system

- Front disc brake

- Front drum brake

- Front suspension

- Fuel system

- Hydraulic brake

- Lubrication system

- Maintenance

- Manual transmission

- Parking brake

- Precaution

- Rear drum brake rear suspension

- Steering

- Valve system

- Wiring diagram

This comprehensive manual provides detailed exploded views and step-by-step procedures with illustrations and diagrams. It is the same manual used by technicians for vehicle repairs and covers maintenance, servicing, and more. The manual is fully printable, allowing easy access to specific pages or the entire manual.