2001-2007 Suzuki Liana (Aerio) RH413, RH416 Workshop Service Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

IMPORTANT

WARNING/CAUTION/NOTE

Please read this manual and follow its instructions carefully. To emphasize special information, the words

WARNING, CAUTION and NOTE have special meanings. Pay special attention to the messages highlighted by

these signal words.

WARNING:

Indicates a potential hazard that could result in death or injury.

CAUTION:

Indicates a potential hazard that could result in vehicle damage.

NOTE:

Indicates special information to make maintenance easier or instructions clearer.

WARNING:

This service manual is intended for authorized Suzuki dealers and qualified service mechanics only.

Inexperienced mechanics or mechanics without the proper tools and equipment may not be able to

properly perform the services described in this manual.

Improper repair may result in injury to the mechanic and may render the vehicle unsafe for the driver

and passengers.

WARNING:

For vehicles equipped with a Supplemental Restraint (Air Bag) System:

• Service on and around the air bag system components or wiring must be performed only by an

authorized SUZUKI dealer. Refer to “Air Bag System Components and Wiring Location View” under

“General Description” in air bag system section in order to confirm whether you are performing ser-

vice on or near the air bag system components or wiring. Please observe all WARNINGS and “Ser-

vice Precautions” under “On-Vehicle Service” in air bag system section before performing service

on or around the air bag system components or wiring. Failure to follow WARNINGS could result in

unintentional activation of the system or could render the system inoperative. Either of these two

conditions may result in severe injury.

• If the air bag system and another vehicle system both need repair, Suzuki recommends that the air

bag system be repaired first, to help avoid unintended air bag system activation.

• Do not modify the steering wheel, instrument panel or any other air bag system component (on or

around air bag system components or wiring). Modifications can adversely affect air bag system

performance and lead to injury.

• If the vehicle will be exposed to temperatures over 93°C (200°F) (for example, during a paint baking

process), remove the air bag system components (air bag (inflator) modules, SDM and/or seat belt

with pretensioner) beforehand to avoid component damage or unintended activation.

FOREWORD

This manual contains procedures for diagnosis, maintenance, adjustments, minor service operations, replace-

ment of components (Service) and for disassembly and assembly of major components (Unit Repair-Overhaul).

Applicable model: RH413/RH416

The contents are classified into sections each of which is given a section number as indicated in the Table of

Contents on following page. And on the first page of each individual section is an index of that section.

This manual should be kept in a handy place for ready reference of the service work.

Strict observance of the so specified items will enable one to obtain the full performance of the vehicle.

When replacing parts or servicing by disassembling, it is recommended to use SUZUKI genuine parts, tools and

service materials (lubricant, sealants, etc.) as specified in each description.

All information, illustrations and specifications contained in this literature are based on the latest product infor-

mation available at the time of publication approval. And used as the main subject of description is the vehicle of

standard specifications among others.

Therefore, note that illustrations may differ from the vehicle being actually serviced.

The right is reserved to make changes at any time without notice.

Related Manual

© COPYRIGHT SUZUKI MOTOR CORPORATION 2001

Manual Name Manual No.

RH413/RH416 Wiring Diagram Manual 99512-54G20-015

TABLE OF CONTENTS

GENERAL INFORMATION TRANSAXLE, CLUTCH AND

DIFFERENTIAL General Information 0A 0A

Maintenance and Lubrication 0B Manual Transaxle 7A1 0B 7A1

HEATING AND AIR CONDITIONING Automatic Transaxle (4 A/T) 7B1 7B1

Heater and Ventilation 1A Clutch 7C1 1A 7C1

Air Conditioning (Optional) 1B Transfer 7D 1B 7D

STEERING, SUSPENSION, WHEELS

AND TIRES

3

Rear Differential 7F 7F

ELECTRICAL SYSTEM 3

DRIVE SHAFT AND PROPELLER SHAFT Body Electrical System 8 8

Front Drive Shaft 4A Wiring Diagram 8A 4A 8A

Propeller Shafts 4B Immobilizer Control System (if equipped) 8G 4B 8G

Rear Drive Shaft 4C BODY SERVICE 9 4C 9

BRAKE SYSTEM RESTRAINT SYSTEM

Brakes 5 Restraint System 10 5 10

Antilock Brake System (ABS) 5B Air Bag System 10B 5B 10B

ENGINE

Engine General Information and

6

6

Diagnosis (M13/M16 Engines) 6A1

Engine Mechanical

6A1

6B

(M13 and M16 Engines) 6C

Engine Cooling 6B 6E1

Engine Fuel 6C 6F1

Engine and Emission Control System

6E1

6G

(M13/M16 Engines) 6H

Ignition System

6F1

6K

(Electronic Ignition System)

Cranking System 6G

Charging System 6H

Exhaust System 6K

NOTE:

The screen toned Section 8A is in Wiring Diagram Manual mentioned in FOREWORD of this manual.

GENERAL INFORMATION 0A-1

0A

6G

6H

6K

7A

7A1

7B1

7C1

7D

7E

7F

8A

8B

8C

8D

8E

9

10

10A

10B

SECTION 0A

GENERAL INFORMATION

CONTENTS

How To Use This Manual ................................0A-2

Precautions......................................................0A-3

Precaution for Vehicles Equipped with a

Supplemental Restraint (Air Bag) System..... 0A-3

Diagnosis................................................... 0A-3

Servicing and handling .............................. 0A-4

General Precautions ..................................... 0A-6

Precautions for Catalytic Converter............... 0A-9

Precaution for Installing Mobile

Communication Equipment ........................... 0A-9

Precaution for Vehicle Tie-Down Hooks...... 0A-10

Precaution in Servicing Full-Time 4WD

Vehicle ........................................................ 0A-10

Precautions for Electrical Circuit Service .... 0A-11

Electrical Circuit Inspection Procedure........ 0A-14

Open circuit check ................................... 0A-14

Short circuit check (wire harness to

ground) .................................................... 0A-16

Intermittent and Poor Connection ............... 0A-17

Identification Information............................. 0A-19

Vehicle Identification Number ..................... 0A-19

Engine Identification Number ...................... 0A-19

Transmission Identification Number............ 0A-19

Warning, Caution and Information Labels..0A-20

Vehicle Lifting Points ................................... 0A-21

Abbreviations and Symbols May Be Used

in This Manual ............................................... 0A-23

Fastener Information .................................... 0A-27

Metric Fasteners ......................................... 0A-27

Fastener Strength Identification .................. 0A-27

Standard Tightening Torque ....................... 0A-27

0A-2 GENERAL INFORMATION

How To Use This Manual

1) There is a “TABLE OF CONTENTS” on the third page of this manual, whereby you can easily find the sec-

tion that offers the information you need. Also, there is a CONTENTS on the first page of each section,

where the main items in that section are listed.

2) Each section of this manual has its own pagination. It is indicated at the top of each page along with the Sec-

tion name.

3) The special tool usage and torque specification are given as shown in the figure.

4) A number of abbreviations and symbols are used in the text.For their full explanations, refer to “ABBREVIA-

TIONS AND SYMBOLS MAY BE USED IN THIS MANUAL” in this section.

5) The SI, metric and foot-pound systems are used as units in this manual.

6) “DIAGNOSIS” are included in each section as necessary.

7) At the end of each section, there are descriptions of “SPECIAL TOOL”, “REQUIRED SERVICE MATERIAL”

and “TIGHTENING TORQUE SPECIFICATION” that should be used for the servicing work described in that

section.

GENERAL INFORMATION 0A-3

Precautions

Precaution for Vehicles Equipped with a Sup-

plemental Restraint (Air Bag) System

Diagnosis

• When troubleshooting air bag system, be sure to follow

“DIAGNOSIS” in Section 10B. Bypassing these procedures

may result in extended diagnostic time, incorrect diagnosis,

and incorrect parts replacement.

• Never use electrical test equipment other than that specified

in this manual.

WARNING:

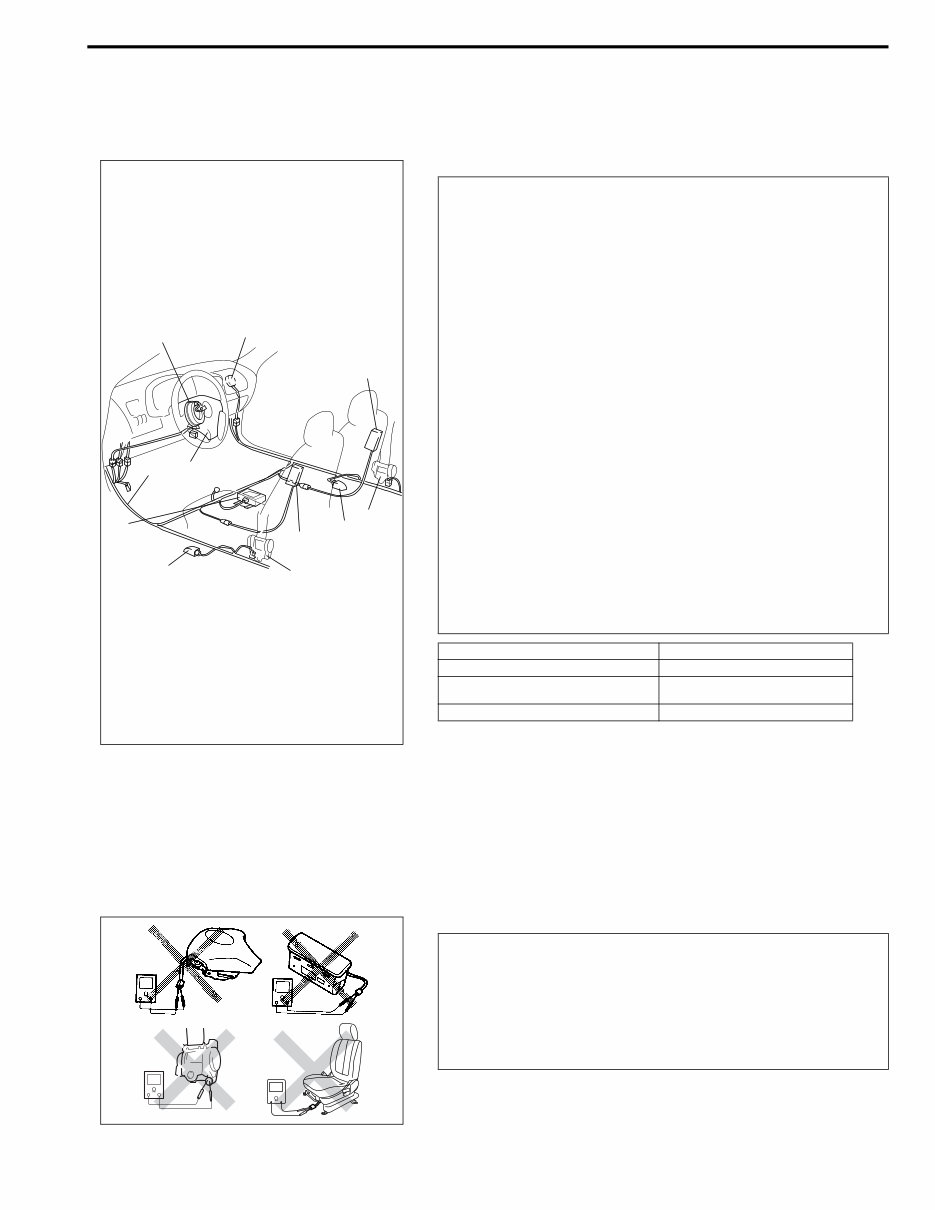

• The configuration of air bag system parts are as shown

in the figure. When it is necessary to service (remove,

reinstall and inspect) these parts, be sure to follow

procedures described in Section 10B. Failure to follow

proper procedures could result in possible air bag sys-

tem activation, personal injury, damage to parts or air

bag system being unable to activate when necessary.

• If the air bag system and another vehicle system both

need repair, SUZUKI recommends that the air bag sys-

tem be repaired first, to help avoid unintended air bag

system activation.

• Do not modify the steering wheel, dashboard, or any

other air bag system components. Modifications can

adversely affect air bag system performance and lead

to injury.

• If the vehicle will be exposed to temperatures over

93°C (200°F) (for example, during a paint baking pro-

cess), remove the air bag system components before-

hand to avoid component damage or unintended air

bag system activation.

1. Air bag wire harness (in floor harness) 5. Contact coil

2. Passenger air bag (inflator) module 6. Driver air bag (inflator) module

3. SDM 7. Side air bag (inflator) module

(if equipped)

4. Seat belt pretensioner 8. Side sensor (if equipped)

7

4

4

8

7

8

6

2

5

1

3

WARNING:

Never attempt to measure the resistance of the air bag

(inflator) modules (driver, passenger and side) and seat

belt pretensioners (driver and passenger). It is very dan-

gerous as the electric current from the tester may deploy

the air bag or activate the pretensioner.

0A-4 GENERAL INFORMATION

Servicing and handling

WARNING:

Many of service procedures require disconnection of

“AIR BAG” fuse and all air bag (inflator) module(s) from

initiator circuit to avoid an accidental deployment.

Driver, Passenger and Side Air Bag (Inflator) Modules

• For handling and storage of a live air bag (inflator)

module, select a place where the ambient temperature

below 65°C (150°F), without high humidity and away

from electric noise.

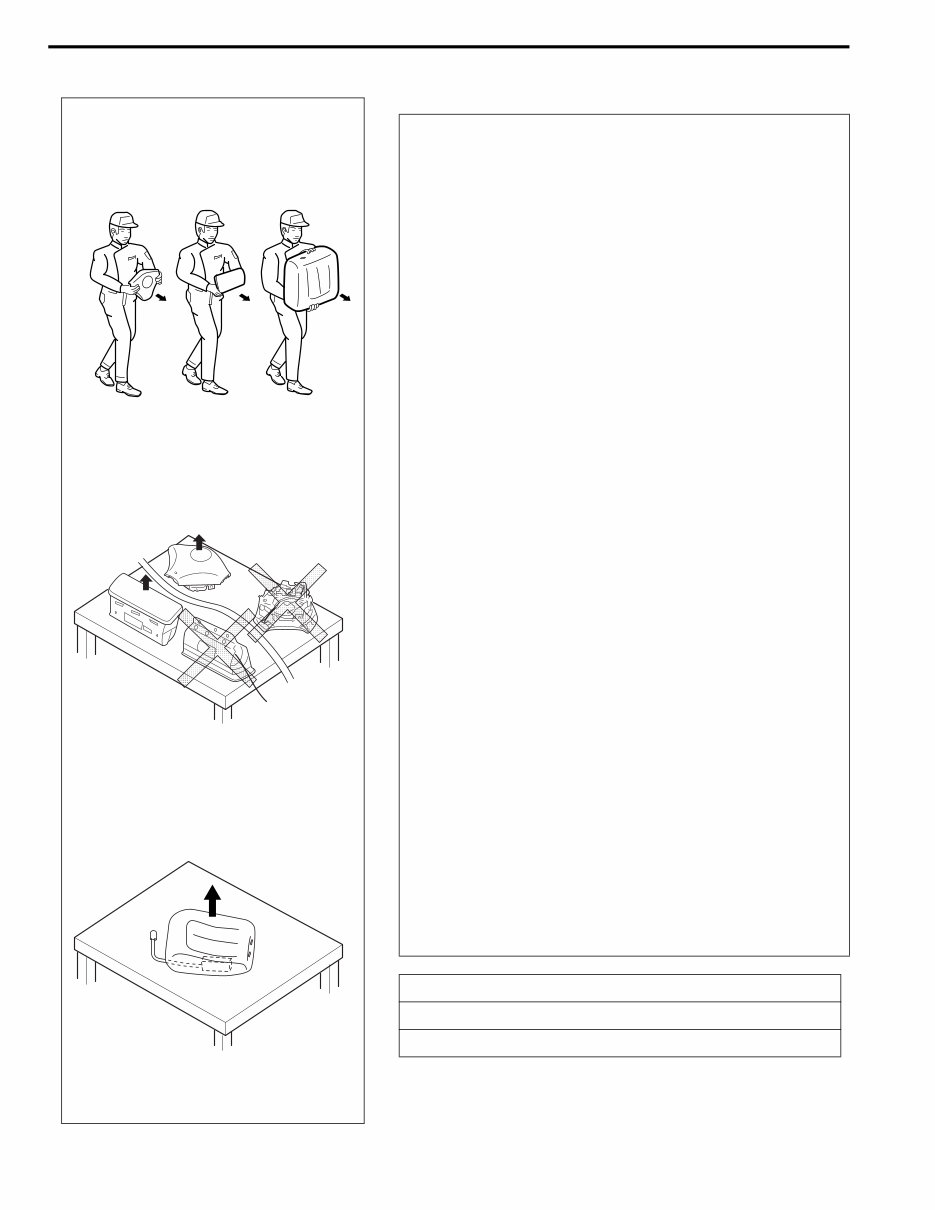

• When carrying a live air bag (inflator) module, make

sure the bag opening is pointed away from you. In case

of an accidental deployment, the bag will then deploy

with minimal chance of injury. Never carry the air bag

(inflator) module by the wires or connector on the

underside of the module. When placing a live air bag

(inflator) module on a bench or other surface, always

face the bag up, away from the surface. The front seat

back with the live air bag (inflator) module must be

placed with its frontal seat cover facing up. It is also

prohibited to place anything on top of the trim cover

and stack air bag (inflator) modules. This is necessary

so that a free space is provided to allow the air bag to

expand in the unlikely event of accidental deployment.

Otherwise, personal injury may result.

• Never dispose of live (undeployed) air bag (inflator)

modules (driver, passenger and side). If disposal is

necessary, be sure to deploy them according to

deployment procedures described in Section 10B

before disposal.

• The air bag (inflator) module immediately after deploy-

ment is very hot. Wait for at least half an hour to cool it

off before proceeding the work.

• After an air bag (inflator) module has been deployed,

the surface of the air bag may contain a powdery resi-

due. This powder consists primarily of cornstarch

(used to lubricate the bag as it inflates) and by-prod-

ucts of the chemical reaction. As with many service

procedures, gloves and safety glasses should be

worn.

[A] : ALWAYS CARRY AIR BAG (INFLATOR) MODULE WITH TRIM COVER (AIR BAG

OPENING) AWAY FROM BODY.

[B] : ALWAYS PLACE AIR BAG (INFLATOR) MODULE ON WORKBENCH WITH TRIM

COVER (AIR BAG OPENING) UP, AWAY FROM LOOSE OBJECTS.

[C] : ALWAYS PLACE WITH ITS FRONTAL SEAT COVER FACING UP, AWAY FROM

LOOSE OBJECTS.

[A]

[B]

[C]

GENERAL INFORMATION 0A-5

• Even when the accident was light enough not to cause air bags to activate, be sure to inspect sys-

tem parts and other related parts according to instructions under “REPAIRS AND INSPECTIONS

REQUIRED AFTER AN ACCIDENT” in Section 10B.

• When servicing parts other than air bag system, if shocks may be applied to air bag system compo-

nent parts, remove those parts beforehand.

• When handling the air bag (inflator) modules (driver, passenger and side), seat belt pretensioners

(driver and passenger), side sensors or SDM, be careful not to drop it or apply an impact to it. If an

excessive impact was applied, never attempt disassembly or repair but replace it with a new one.

• When grease, cleaning agent, oil, water, etc. has got onto air bag (inflator) modules (driver, passen-

ger and side) or seat belt pretensioners (drive and passenger), wipe off immediately with a dry cloth.

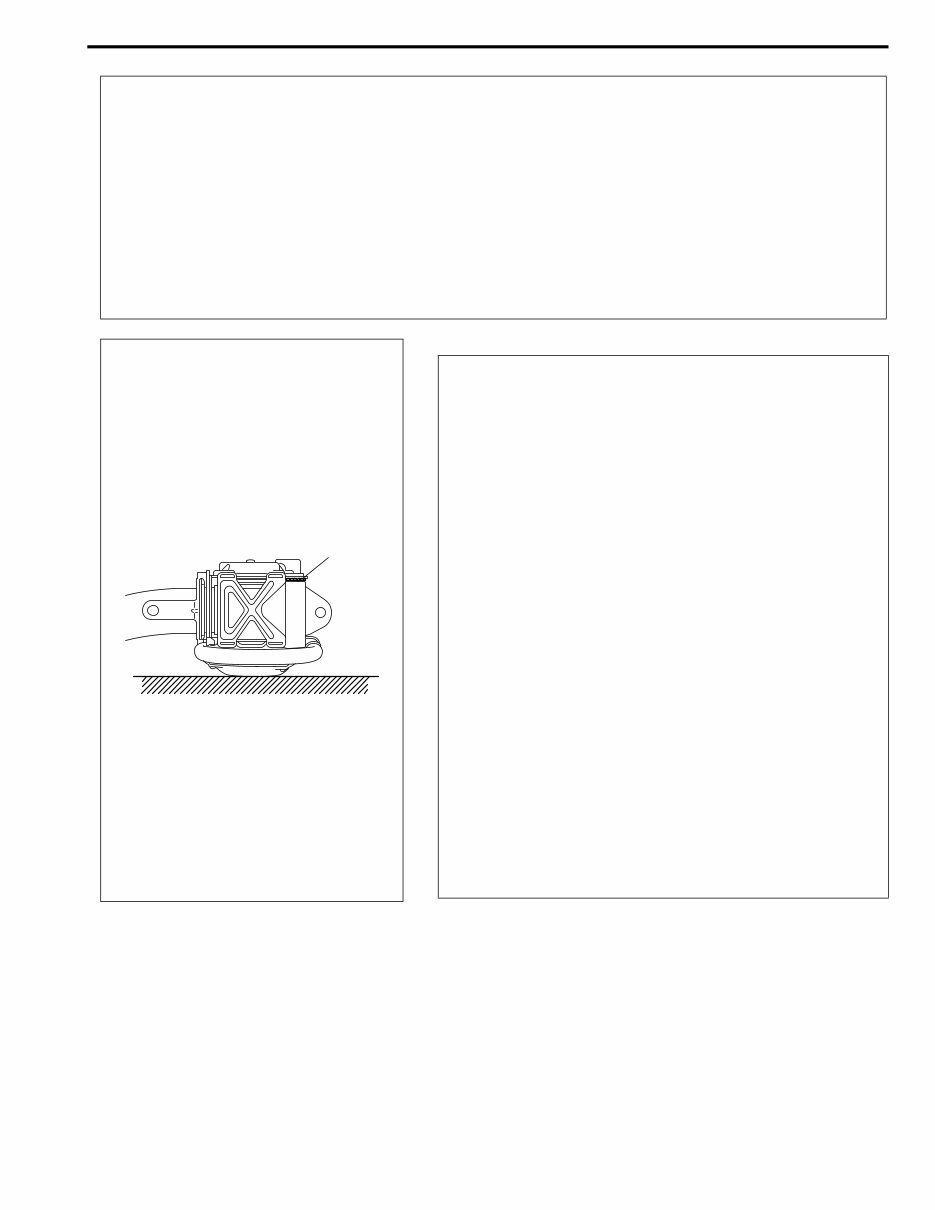

WARNING:

SDM

• For handling and storage of a SDM, select a place where the ambient temperature below 65°C

(150°F), without high humidity and away from electric noise.

• During service procedures, be very careful when handling a Sensing and Diagnostic Module (SDM).

Never strike or jar the SDM.

• Never power up the air bag system when the SDM is not rigidly attached to the vehicle. All SDM and

mounting bracket fasteners must be carefully torqued and the arrow must be pointing toward the

front of the vehicle to ensure proper operation of the air bag system.

The SDM could be activated when powered while not rigidly attached to the vehicle which could

cause deployment and result in personal injury.

WARNING:

Driver and Passenger Seat Belt Pretensioners

(If equipped)

• For handling and storage of a live seat belt preten-

sioner, select a place where the ambient temperature

below 65°C (150°F), without high humidity and away

from electric noise.

• Never carry seat belt pretensioner by wire or connec-

tor of pretensioner. When placing a live seat belt pre-

tensioner on the workbench or some place like that, be

sure not to lay it with its exhaust hole (1) provided side

facing down. It is also prohibited to put something on

its face with an exhaust hole or to put a seat belt pre-

tensioner on top of another. Otherwise, personal injury

may result.

• Never dispose of live (inactivated) seat belt pretension-

ers (drive and passenger). If disposal is necessary, be

sure to activate them according to activation proce-

dures described in Section 10B before disposal.

• The seat belt pretensioner immediately after activation

is very hot. Wait for at least half an hour to cool it off

before proceeding the work.

• With many service procedures, gloves and safety

glasses should be worn to prevent any possible irrita-

tion of the skin or eyes.

1

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

Viewed 72 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

- This workshop service manual for the 2001-2007 Suzuki Liana (Aerio) RH413, RH416 is a comprehensive resource for both professional mechanics and DIY enthusiasts.

- It contains detailed instructions, diagrams, illustrations, and wiring schematics for engine overhaul, rebuilding, brakes, sunroofs, timing belt replacement, and troubleshooting.

- The manual also covers topics such as computer diagnostic trouble tree charts, front end alignment procedures, suspension, transmission removal and installation, air conditioning, and more.

- Additionally, it includes factory maintenance schedules, torque specifications, wiring diagrams, hundreds of illustrations, vacuum diagrams, and other relevant information.

- With this manual, users can perform repairs, maintenance, rebuild, refurbish, or restore their vehicles confidently, saving significant costs on repair bills.

- It is a high-quality resource that covers a wide range of repair and maintenance procedures, making it an essential tool for anyone working on the specified vehicle models.

For the .OVA file manual, please note that it is not interactive and should be used as a reference guide for car repair procedures.