2005 Scion xA Service & Repair Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

INTRODUCTION – REPAIR INSTRUCTION

IN–21

IN

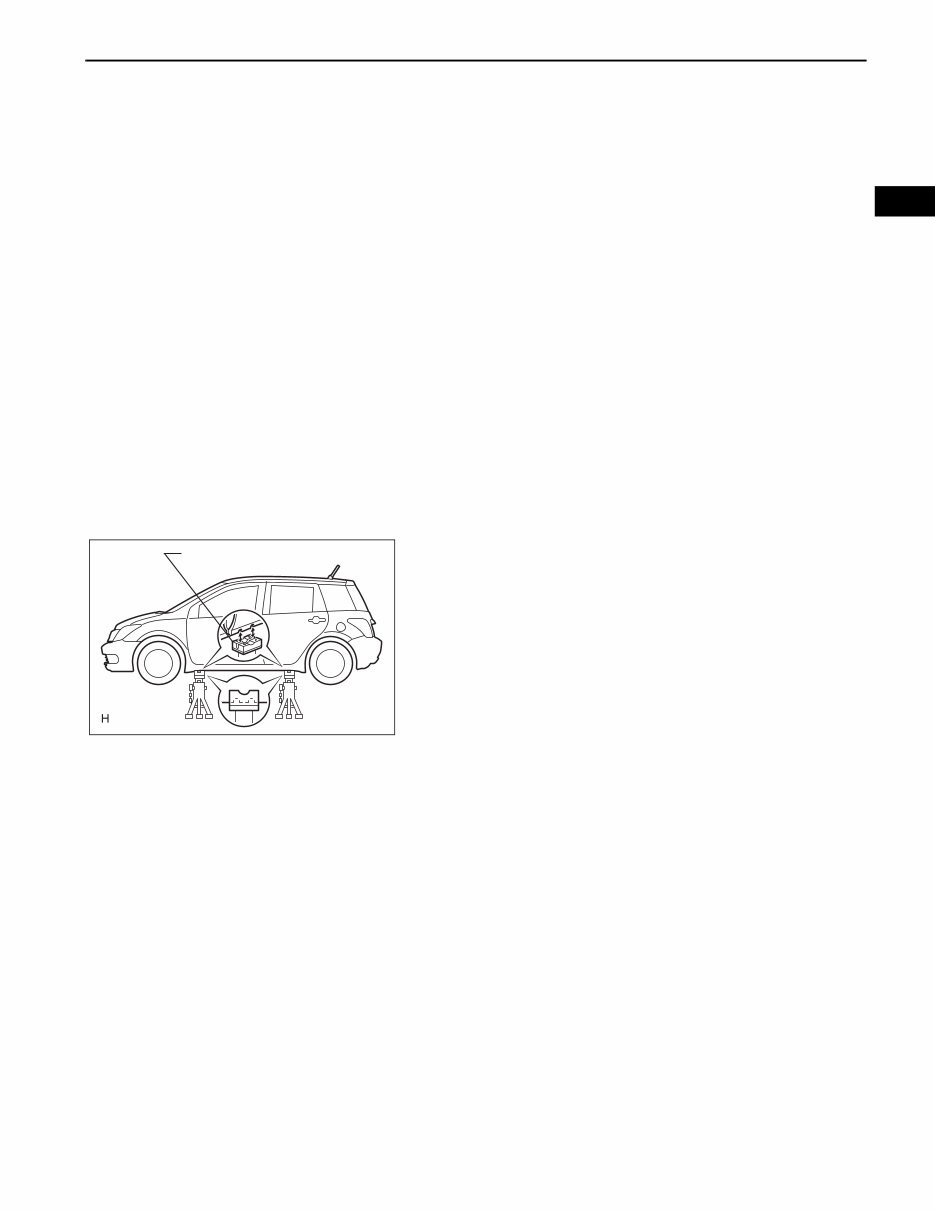

VEHICLE LIFT AND SUPPORT

LOCATIONS

1. NOTICE ABOUT VEHICLE CONDITION WHEN

JACKING UP VEHICLE

(a) The vehicle must be unloaded before jacking up /

lifting up the vehicle. Never jack up / lift up a heavily

loaded vehicle.

(b) When removing heavy parts such as the engine and

transmission, the center of gravity of the vehicle

may shift. To stabilize the vehicle, place a balance

weight in a location where it will not roll or shift, or

use a mission jack to hold the jacking support.

2. NOTICE FOR USING 4 POST LIFT

(a) Follow the safety procedures outlined in the lift

instruction manual.

(b) Use precautionary measures to prevent the free

wheel beam from damaging tires or wheels.

(c) Use wheel chocks to secure the vehicle.

3. NOTICE FOR USING JACK AND SAFETY STAND

(a) Work on a level surface. Use wheel chocks at all

times.

(b) Use safety stands with rubber attachments as

shown in the illustration.

(c) Set the jack and safety stands to the specified

locations of the vehicle accurately.

(d) When jacking up the vehicle, first release the

parking brake and move the shift lever to N.

(e) When jacking up the entire vehicle:

• When jacking up the front wheels first, make sure

wheel chocks are behind the rear wheels.

• When jacking up the rear wheels first, make sure

wheel chocks are in front of the front wheels.

(f) When jacking up only the front or rear wheels of the

vehicle:

• Before jacking up the front wheels, place wheel

chocks on both sides of the rear wheels.

• Before jacking up the rear wheels, place wheel

chocks on both sides of the front wheels.

(g) When lowering a vehicle that only has its front or

rear wheels jacked up:

• Before lowering the front wheels, make sure

wheel chocks are in front of the rear wheels.

• Before lowering the rear wheels, make sure

wheel chocks are behind the front wheels.

Rubber Attachment

D100678E01

IN–22

INTRODUCTION – REPAIR INSTRUCTION

IN

(h) It is extremely dangerous to perform any work on a

vehicle raised on a jack alone, even for work that

can be finished quickly. Safety stands must be used

to support it.

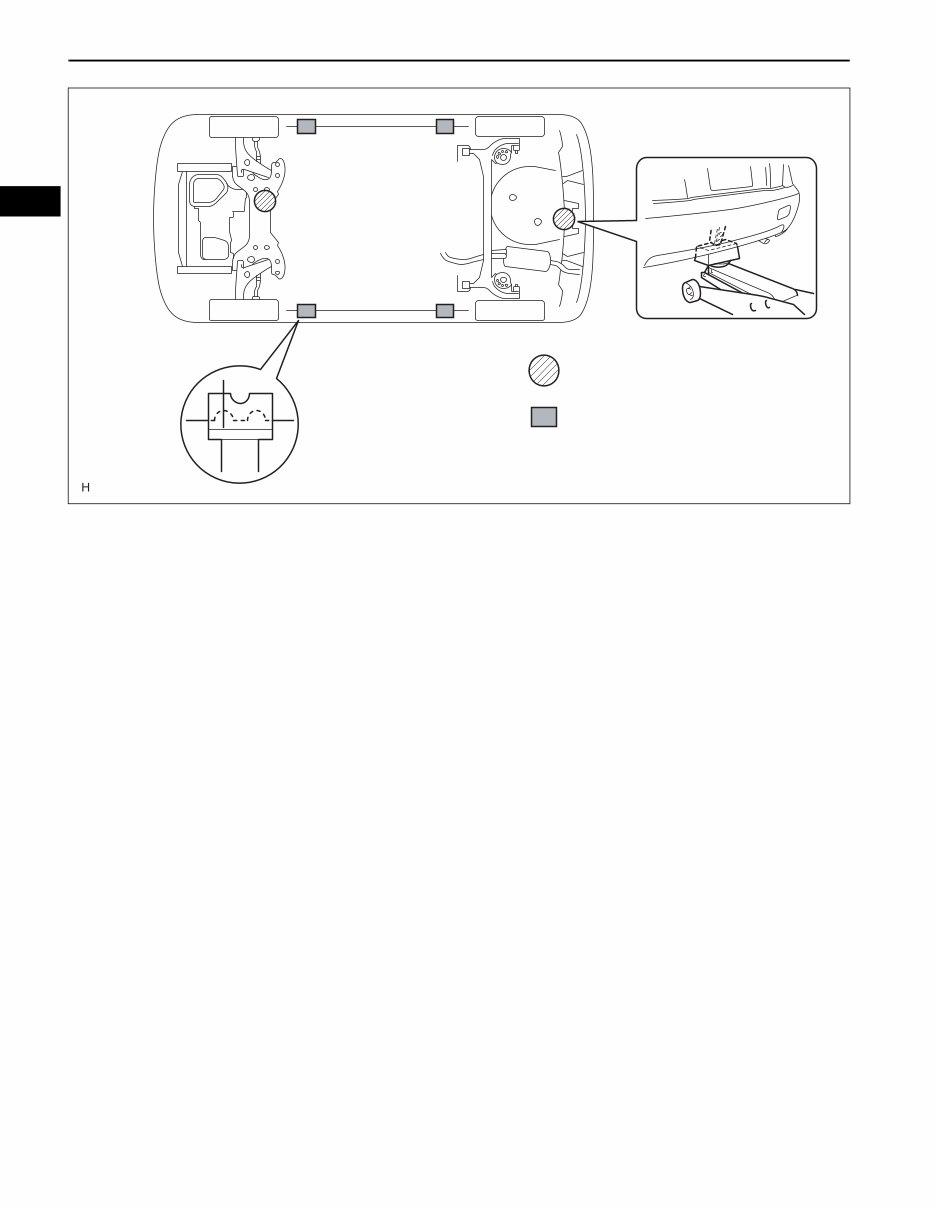

4. NOTICE FOR USING SWING ARM TYPE LIFT

(a) Follow safety procedures outlined in its instruction

manual.

(b) Use a swing arm equipped with a rubber

attachment, as shown in the illustration.

(c) When using the lift, make sure that the vehicle is

stabilized so that it will not tilt while work is being

performed. Stabilize the vehicle by adjusting the lift

arm's length and vehicle's position.

: Jack position

: Support position, pantograph

jack position

D100679E01

INTRODUCTION – REPAIR INSTRUCTION

IN–23

IN

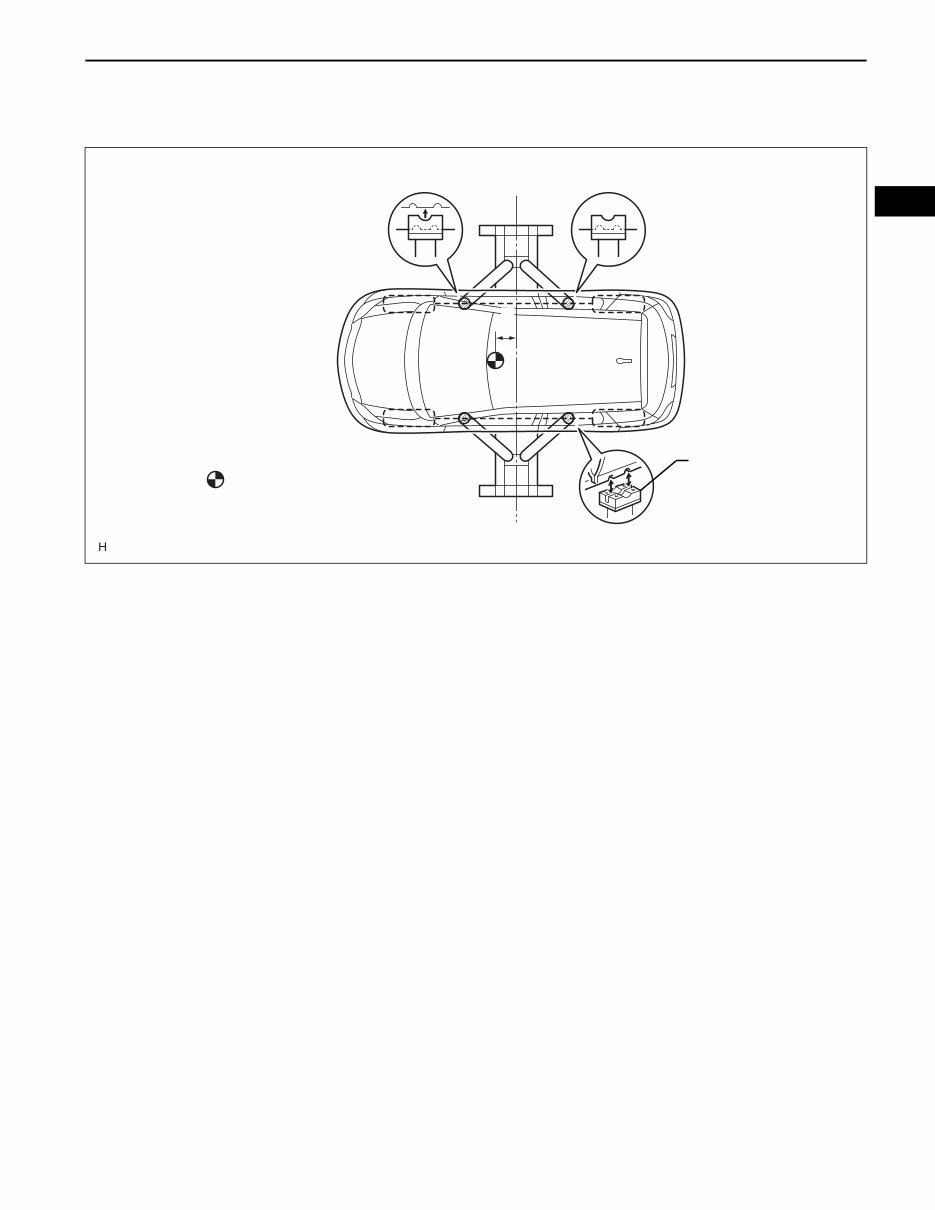

(d) When using the lift, its center should be as close to

the vehicle's center of gravity as possible (length of

"L" in the illustration should be as short as possible).

(e) Set the vehicle on the lift as level as possible. Then

match the groove of the cradle to the rigid rack

support location.

(f) Be sure to lock the swing arms before lifting and

during work (if equipped with arm locks).

(g) Lift the vehicle up off the ground. Stand at a safe

distance and shake the vehicle to check its stability.

5. NOTICE FOR USING PLATE TYPE LIFT

(a) Follow safety procedures outlined in its instruction

manual.

(b) Use plate lift attachments (rubber lifting blocks) on

top of the plate surface.

: Center of vehicle gravity

(unloaded condition)

Rubber Attachment

Center of Lift

L

D100680E01

IN–24

INTRODUCTION – REPAIR INSTRUCTION

IN

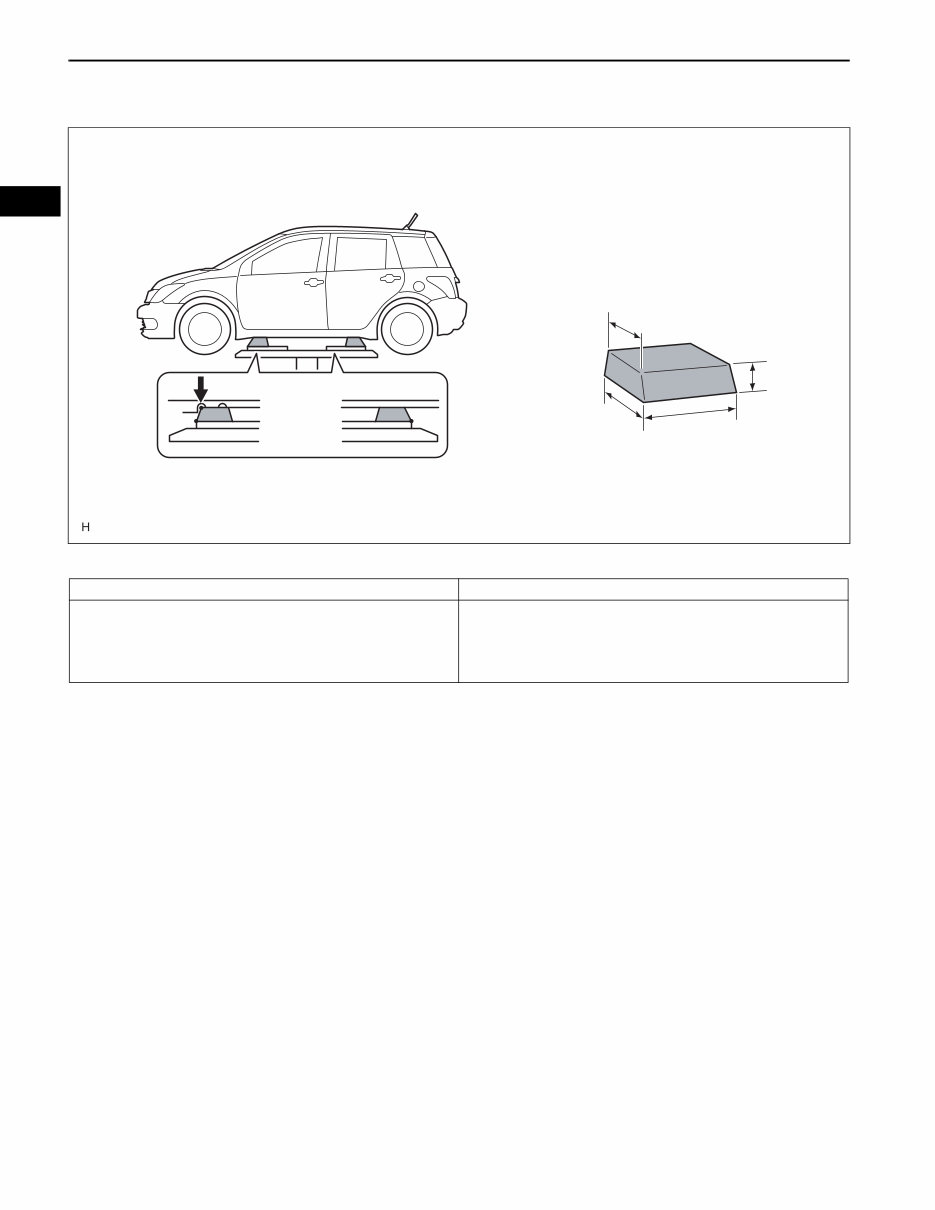

(c) Refer to the illustration below to determine how to

properly set the vehicle.

HINT:

(d) Use the lift to raise the vehicle up off the ground,

and shake it to make sure that it is stable.

Attachment

Attachment Dimensions

85 mm (3.35 in.)

100 mm (3.94 in.)

200 mm (7.87 in.)

70 mm

(2.76 in.)

B

A

C

D100687E01

Right and left set position Place the vehicle over the center of the lift.

Front and rear set position Place the attachments at the ends of the rubber plate surface, under

the vehicle lift pad (A and C in the illustration). Raise the plate slightly

and reposition the vehicle so the top of the attachment (B in the

illustration) is aligned with the front side notch in the vehicle rocker

flange.

INTRODUCTION – REPAIR INSTRUCTION

IN–25

IN

INITIALIZATION

1. RESET SLIDING ROOF DRIVE GEAR (MOTOR)

NOTICE:

The sliding roof drive gear (motor) must be reset

(pulse sensor's location must be set) when one of

the following occurs: 1) the battery cable has been

disconnected, 2) the drive gear connector is

connected/disconnected, or 3) the sliding roof is

replaced or installed/removed. If the drive gear is not

reset, the AUTO function will not operate.

(a) The sliding roof AUTO operation and the jam

protection function may not operate normally if the

battery cable is disconnected/reconnected, or the

battery is replaced or recharged. Initialize the sliding

roof system using the method below.

(1) Turn the ignition switch ON.

(2) Fully open the sliding roof.

(3) Press and hold the sliding roof motor switch on

the SLIDE/OPEN side for 2 seconds or more.

The sliding roof control ECU built into the drive

gear will memorize the position of the sliding

roof. Initialization is now complete.

HINT:

If the battery cable is disconnected, the sliding

roof control ECU may not detect the position of

the roof glass. If the sliding roof AUTO operation

is still disabled even after the drive gear has

been initialized, the Hall IC may be

malfunctioning. The Hall IC is built into the drive

gear and detects the roof glass position. If the

result is not as specified, replace the drive gear

assembly (sliding roof control ECU).

System Name

Sliding Roof System

IN–34

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN

ELECTRONIC CIRCUIT INSPECTION

PROCEDURE

1. BASIC INSPECTION

(a) WHEN MEASURING RESISTANCE OF

ELECTRONIC PARTS

(1) Unless otherwise stated, all resistance

measurements should be made at an ambient

temperature of 20°C (68°F). Resistance

measurements may be inaccurate if measured

at high temperatures, i.e. immediately after the

vehicle has been running. Measurements should

be made after the engine has cooled down.

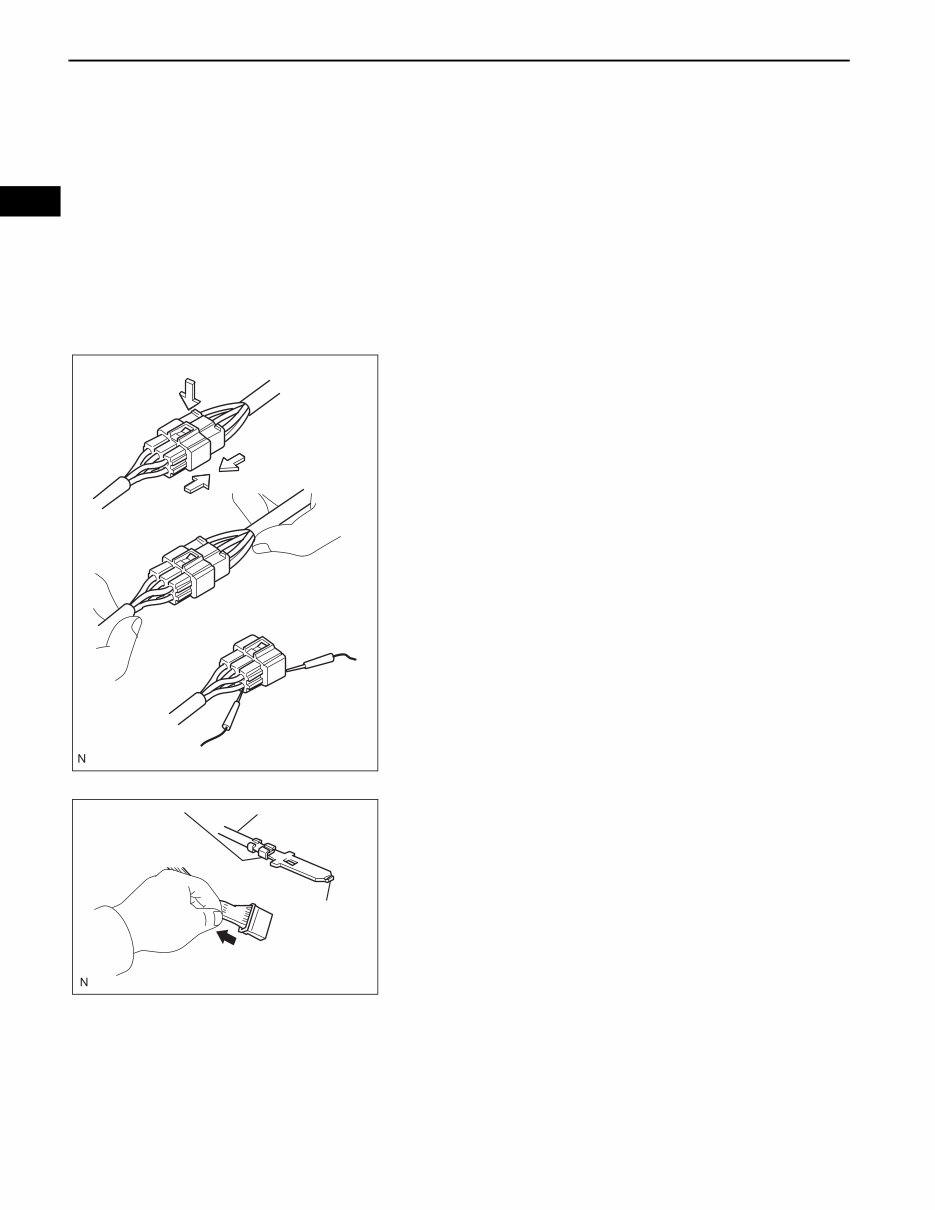

(b) HANDLING CONNECTORS

(1) When disconnecting a connector, first squeeze

the mating halves tightly together to release the

lock, and then press the lock claw and separate

the connector.

(2) When disconnecting a connector, do not pull on

the harnesses. Grasp the connector directly and

separate it.

(3) Before connecting a connector, check that there

are no deformed, damaged, loose or missing

terminals.

(4) When connecting a connector, press firmly until

it locks with a "click" sound.

(5) If checking a connector with a TOYOTA

electrical tester, check the connector from the

backside (harness side) using a mini test lead.

NOTICE:

• As a waterproof connector cannot be

checked from the backside, check it by

connecting a sub-harness.

• Do not damage the terminals by moving

the inserted tester needle.

(c) CHECKING CONNECTORS

(1) Checking when a connector is connected:

Squeeze the connector together to confirm that

they are fully connected and locked.

(2) Checking when a connector is disconnected:

Check by pulling the wire harness lightly from

the backside of the connector. Look for

unlatched terminals, missing terminals, loose

crimps or broken conductor wires. Check

visually for corrosion, metallic or foreign matter

and water, and bent, rusted, overheated,

contaminated, or deformed terminals.

INCORRECT

INCORRECT

CORRECT

D100803E01

Core Wire

Terminal

Deformation

Pull Lightly

Looseness of

Crimping

D100734E01

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN–35

IN

(3) Checking the contact pressure of the terminal:

Prepare a spare male terminal. Insert it into a

female terminal, and check for ample tension

when inserting and after full engagement.

NOTICE:

When testing a gold-plated female terminal,

always use a gold-plated male terminal.

(d) REPAIR METHOD OF CONNECTOR TERMINAL

(1) If there is any foreign matter on the terminal,

clean the contact point using an air gun or cloth.

Never rub the contact point using sandpaper as

the plating may come off.

(2) If there is abnormal contact pressure, replace

the female terminal. If the male terminal is gold-

plated (gold color), use a gold-plated female

terminal; if it is silver-plated (silver color), use a

silver-plated female terminal.

(3) Damaged, deformed, or corroded terminals

should be replaced. If the terminal does not lock

into the housing, the housing may have to be

replaced.

(e) HANDLING OF WIRE HARNESS

(1) If removing a wire harness, check the wiring and

clamping before proceeding so that it can be

restored in the same way.

(2) Never twist, pull or slacken the wire harness

more than necessary.

(3) The wire harness should never come into

contact with a high temperature part, or rotating,

moving, vibrating or sharp-edged parts. Avoid

contact with panel edges, screw tips and other

sharp items.

(4) When installing parts, never pinch the wire

harness.

(5) Never cut or break the cover of the wire harness.

If it is cut or broken, replace it or repair it with

vinyl tape.

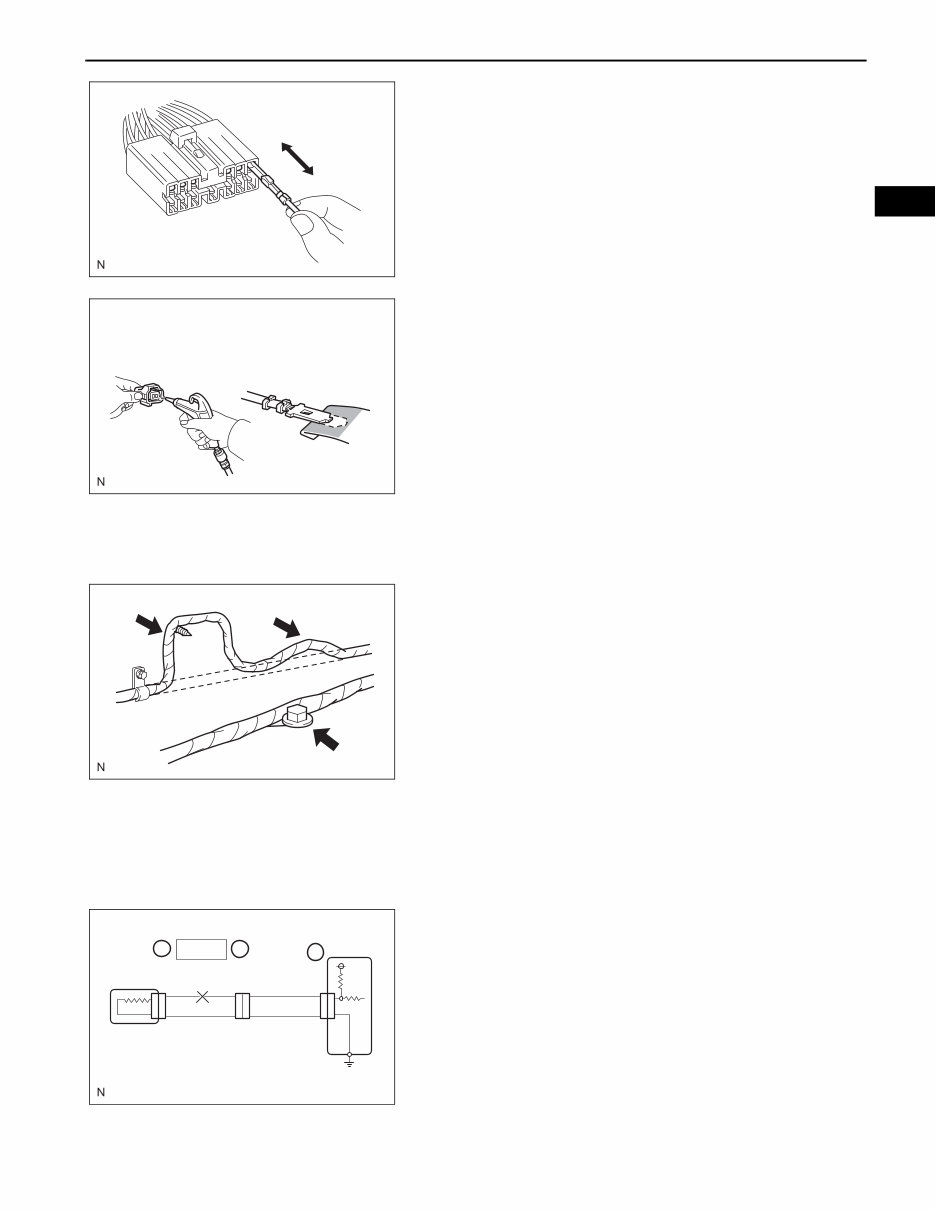

2. CHECK FOR OPEN CIRCUIT

(a) For an open circuit in the wire harness in Fig. 1,

check the resistance or voltage, as described below.

D100735

INCORRECT CORRECT

D100736E01

INCORRECT INCORRECT

INCORRECT

D100784E01

Fig. 1

OPEN C B

A

ECU

SENSOR

1

2

1

2

1

2

1

2

D100785E01

IN–36

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN

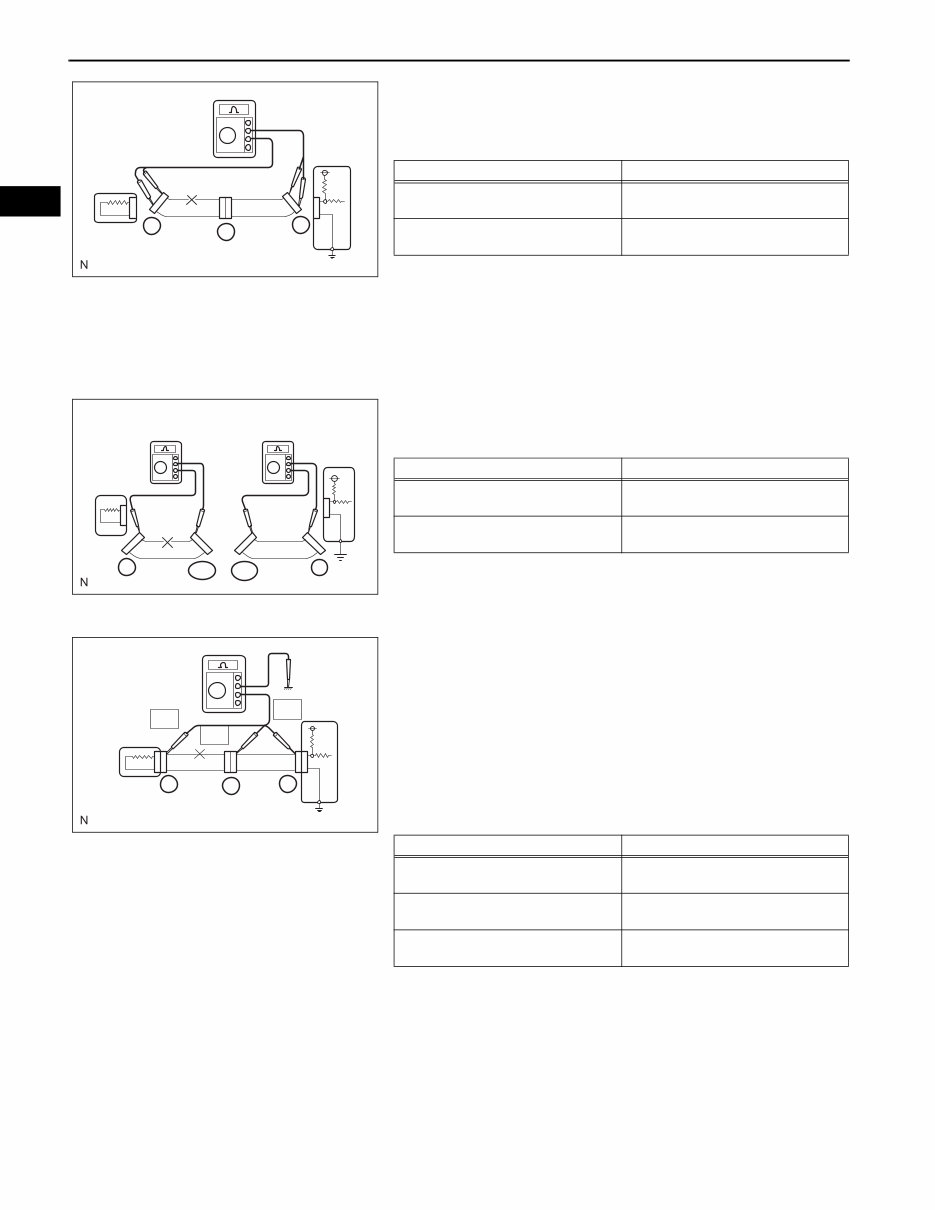

(b) Check the resistance.

(1) Disconnect connectors A and C, and measure

the resistance between them.

Standard resistance (Fig. 2)

HINT:

Measure the resistance while lightly shaking the

wire harness vertically and horizontally.

If the results match the examples above, an

open circuit exists between terminal 1 of

connector A and terminal 1 of connector C.

(2) Disconnect connector B and measure the

resistance between the connectors.

Standard resistance (Fig. 3)

If the results match the examples above, an

open circuit exists between terminal 1 of

connector B2 and terminal 1 of connector C.

(c) Check the voltage.

(1) In a circuit in which voltage is applied to the ECU

connector terminal, an open circuit can be

checked by conducting a voltage check.

With each connector still connected, measure

the voltage between the body ground and these

terminals (in this order): 1) terminal 1 of

connector A, 2) terminal 1 of connector B, and 3)

terminal 1 of connector C.

Standard voltage (Fig. 4)

If the results match the examples above, an

open circuit exists in the wire harness between

terminal 1 of connector B and terminal 1 of

connector C.

Fig. 2

ECU

1

2

1

2

1

2

SENSOR

C

B

A

D100786E01

Tester Connection Specified Condition

Connector A terminal 1 - Connector

C terminal 1

10 kΩ or higher

Connector A terminal 2 - Connector

C terminal 2

Below 1 Ω

Fig. 3

SENSOR

ECU

C

1 1

2 2

1 1

2 2

B2 B1

A

D100787E01

Tester Connection Specified Condition

Connector A terminal 1 - Connector

B1 terminal 1

Below 1 Ω

Connector B2 terminal 1 - Connector

C terminal 1

10 kΩ or higher

Fig. 4

ECU

5 V

5 V

0 V

SENSOR

1

1

2 2 2 2

C A

B

D100788E01

Tester Connection Specified Condition

Connector A terminal 1 - Body

ground

5 V

Connector B terminal 1 - Body

ground

5 V

Connector C terminal 1 - Body

ground

Below 1 V

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN–37

IN

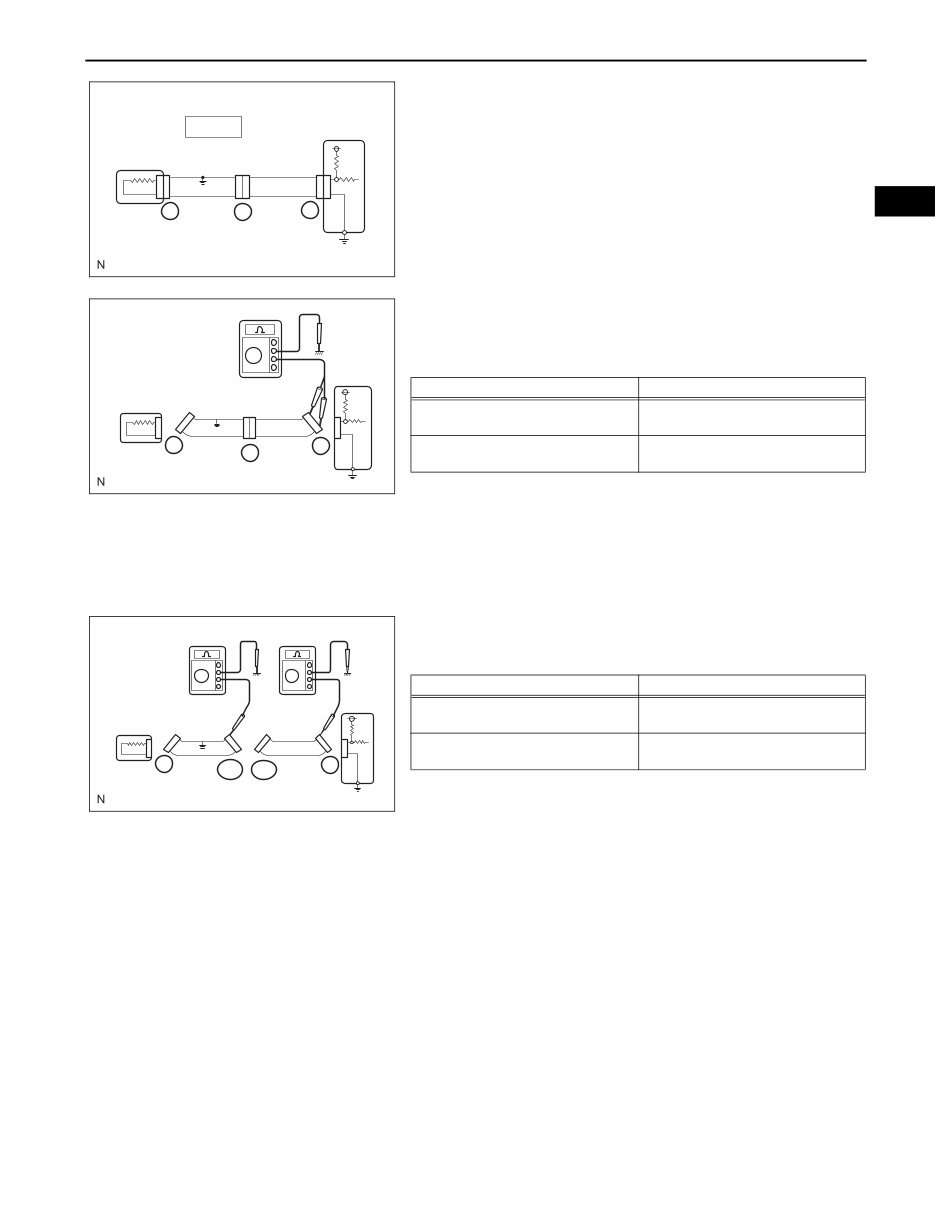

3. CHECK FOR SHORT CIRCUIT

(a) If the wire harness is ground shorted (Fig. 5), locate

the section by conducting a resistance check with

the body ground (below).

(b) Check the resistance with the body ground.

(1) Disconnect connectors A and C, and measure

the resistance.

Standard resistance (Fig. 6)

HINT:

Measure the resistance while lightly shaking the

wire harness vertically and horizontally.

If the results match the examples above, a short

circuit exists between terminal 1 of connector A

and terminal 1 of connector C.

(2) Disconnect connector B and measure the

resistance.

Standard resistance (Fig. 7)

If the results match the examples above, a short

circuit exists between terminal 1 of connector B2

and terminal 1 of connector C.

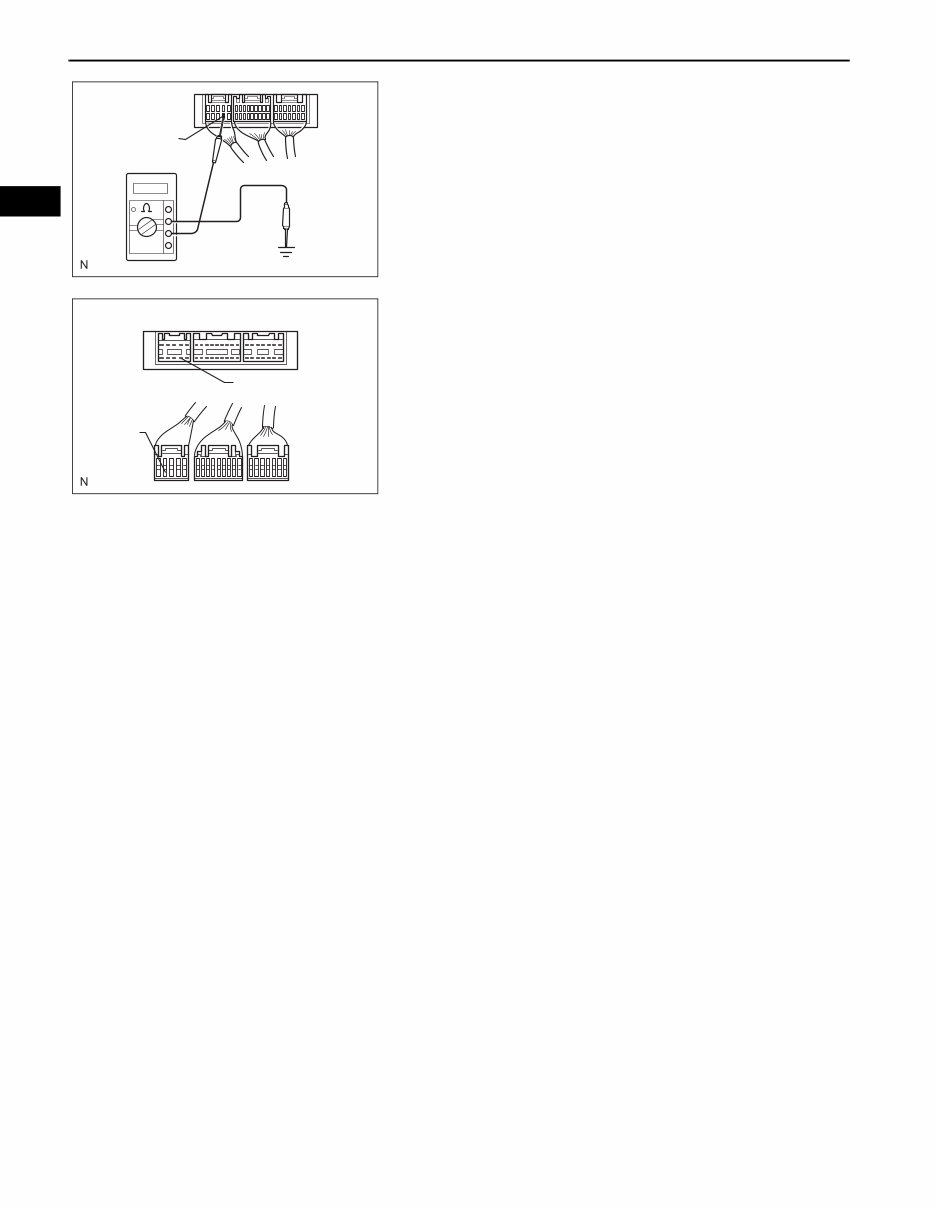

4. CHECK AND REPLACE ECU

NOTICE:

• The connector should not be disconnected from

the ECU. Perform the inspection from the

backside of the connector on the wire harness

side.

• When no measuring condition is specified,

perform the inspection with the engine stopped

and the ignition switch ON.

• Check that the connectors are fully seated. Check

for loose, corroded or broken wires.

Fig. 5

SHORT

ECU

C B

A

1

2

1

2

1

2

D100789E01

Fig. 6

SENSOR

ECU

C

B

A

1 1 1

2 2 2

D100790E01

Tester Connection Specified Condition

Connector A terminal 1 - Body

ground

Below 1 Ω

Connector A terminal 2 - Body

ground

10 kΩ or higher

Fig. 7

SENSOR

ECU

1 1

2 2

1 1

2 2

C A

B1 B2

D100800E01

Tester Connection Specified Condition

Connector A terminal 1 - Body

ground

10 kΩ or higher

Connector B2 terminal 1 - Body

ground

Below 1 Ω

IN–38

INTRODUCTION – HOW TO TROUBLESHOOT ECU CONTROLLED SYSTEMS

IN

(a) First, check the ECU ground circuit. If it is faulty,

repair it. If it is normal, the ECU could be faulty.

Temporarily replace the ECU with a normally

functioning one and check if the symptoms occur. If

the trouble symptoms disappear, replace the

original ECU.

(1) Measure the resistance between the ECU

ground terminal and body ground.

Standard resistance:

Below 1 Ω

(2) Disconnect the ECU connector. Check the

ground terminal on the ECU side and wire

harness side for bending, corrosion or foreign

matter. Lastly, check the contact pressure of the

female terminals.

Example:

Ground

D100801E01

ECU Side

Wire Harness Side

Ground

Ground

D100802E02

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

Viewed 27 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

- The 2005 Scion xA Service & Repair Manual is a comprehensive guide for fixing vehicle issues using a Do-It-Yourself approach.

- It includes troubleshooting and replacement procedures recommended by the manufacturer, along with step-by-step instructions, clear images, and exploded-view illustrations.

- Regular maintenance is essential for the durability of your vehicle, and this manual provides the manufacturer's recommended troubleshooting charts and replacement procedures.

- By using this manual, you can save on repairs, increase your vehicle’s reliability, and reduce the frequency of visits to the repair shop.

- It eliminates the need to search through numerous pages for specific information and offers the convenience of digital access, allowing you to carry, search, screenshot, and bookmark the content.

- Additionally, the manual is printable and compatible with various electronic devices, including PC & Mac computers, Android and Apple smartphones & tablets, etc. It requires Adobe Reader, which is available for free.