Porsche 928 Workshop Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Workshop Manual

srs

DR. ING. h. c. F. PORSCHE Aktiengesellschaft

928

Engine / Crankcase

10

a

TOLERANCES. AND WEAR LlMITS

Cooling System

Coolanr thermostat

Radiaror Cap

High pressure valve

LOW pressure valve

Oil Circuit

Oil consumprion

Oil pressure at 80’ C oil

temperarue and at 5000 rpm

Oil dipstick

Upper mark

Lower mark

Oil pump

Clearance

Valve Timing

Camshaft bore Inside dia.

Camshaft

Bucket rappet bore

Bucket tappet

Camshaft

Opening temperarure

Opening pressure

Opening pressure

ltr/lOOO km

Oil volume

Oil volume

Axial play

Radial play

Diamerer

Axial play

Inside dia.

Diameter

Runour

Cylinder Head and Valves

Bearing surface

Valve sear:

Intake

Exhausr

Make

Exhaust

Ourer correcrion angle

Inner correction angle

Valve guides:

Intake and exhaust

Valve stem:

lnrake

Exhaurt

Disrorrion

,Widrh

Width

seat angle

seat angle

lnside dia.

Diameter

Diameter

When Installed

(new)

81 - &so c

0.9 - 1.15 bar

0. 07 - 0.12 bar

5 bar

1. 5 1tr

6. 0 111

0.080 - 0.120

0.060 0.088

60. 5

+ 0.03

-0

60.5 - ‘. O3

- 0.045

0.10 - 0.18

38

+ 0.010

+ 0. 038

38 - 0.018

- 0.034

0.02

1.1

2. 0

450

4s”

300

600

9 + 0.015

8.97 0.012

8.95 - 0.012

Wear Limit

ca. 1. 5

max. 0.08

Printed inGerma”y - II. 1916 Tolerances and Wear Limits 10 - 01

10

Engine / Crankcase 928

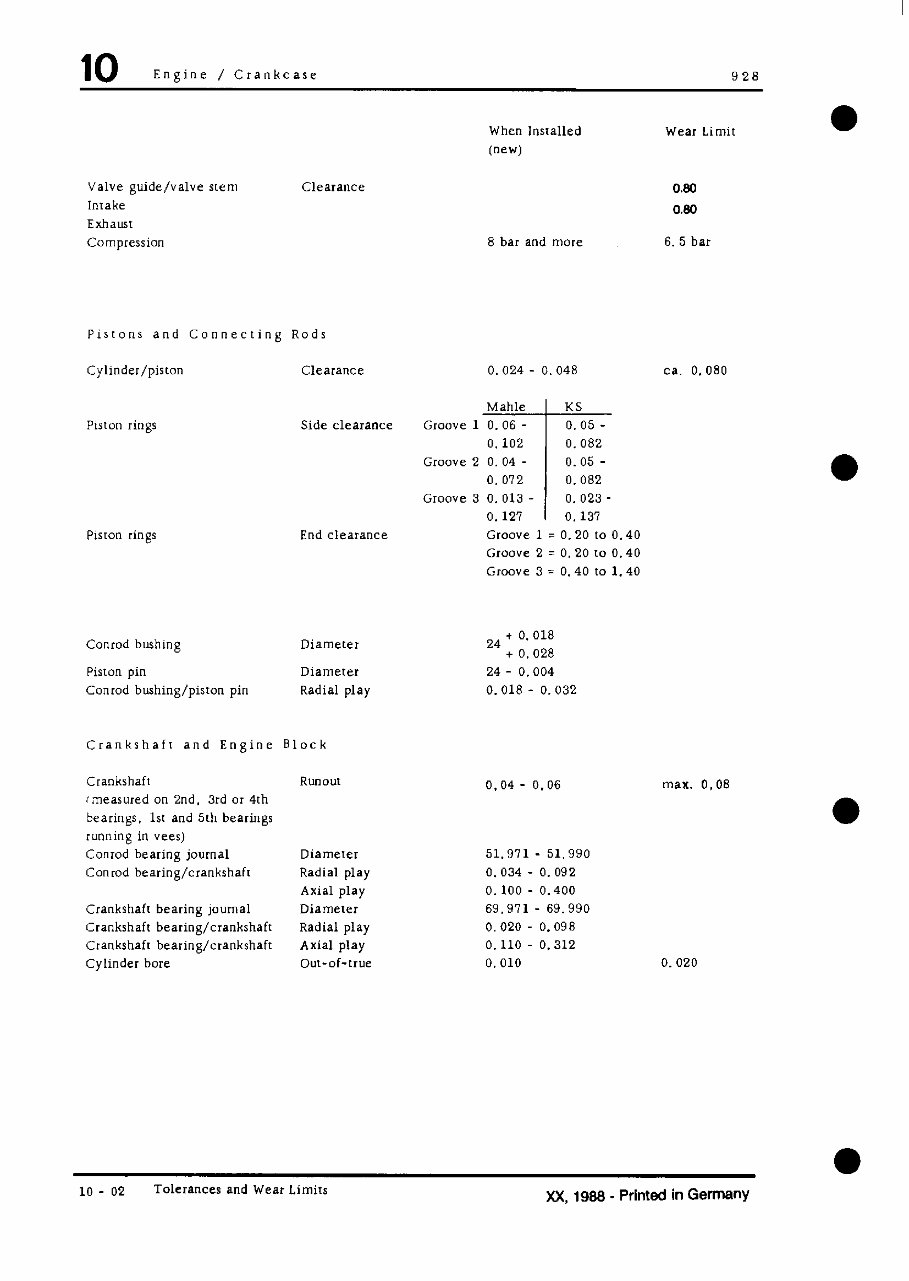

Valve guide/valve srem

lnrake

Exhaust

Compression

Clearance

When lnsralled

mew

Wear Limit

l

0.80

0.80

8 bar and more 6. 5 bar

Pistons and Connecting Rods

Cylinder/piston Clearance 0.024 - 0.048 ca. 0.080

Pisron rings

Pirron rings

Side clearance

Groove 2 0.04 -

Groove 3 0.013 -

End clearance Groove 1 = 0.20 to 0.40

Groove 2 = 0.20 co 0.40

Groo”e 3 = 0.40 to 1.40

Conrod bushing Diameter

Pisron pin Diameter

Conrod bushing/piston pin Radial play

Crankshafr and Engine Block

Crankshafr Runour

0.04 - 0.06

max. 0.08

/measured on 2nd. 3rd or 4th

bearings. 1st and 5th bearings

iunnmg in vees)

Conrod bearing journal

Conrod bearing/crankshaft

Crankshafr bearing journal

Crankshaft bearing/crankshaft

Crankshaft bearing/crankshaft

Cylinder bore

Diamerer 51.971 - 51.990

Radial play 0.034 - 0.092

Axial play 0.100 - 0.400

Diameter 69.971 - 69.990

Radial play 0.020 - 0.098

Axial play 0.110 0.312

our-of-rrue 0.010 0.020

24 + 0.018

+ 0.028

24 - 0.004

0.018 - 0.032

l

10 - 02

Tolerances and Wear Limirs

xx, 1988 - Printed in Germany

928 Engine/Crankcase

10

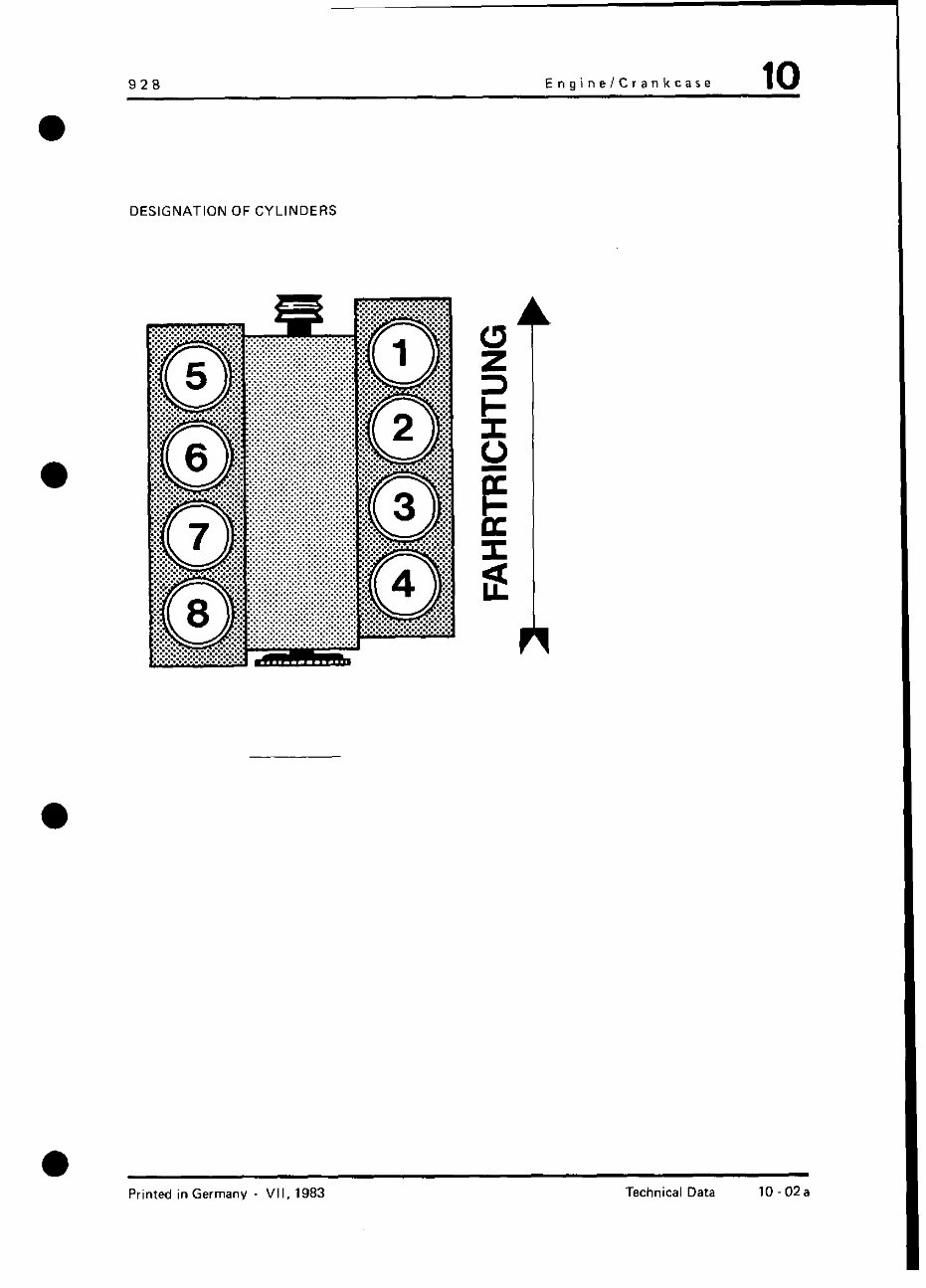

DESIGNATION OF CYLINDERS

l

Printed in Germany - VII, 1983 Technical Data lo-02a

928 Engine/Crankcase

10

l

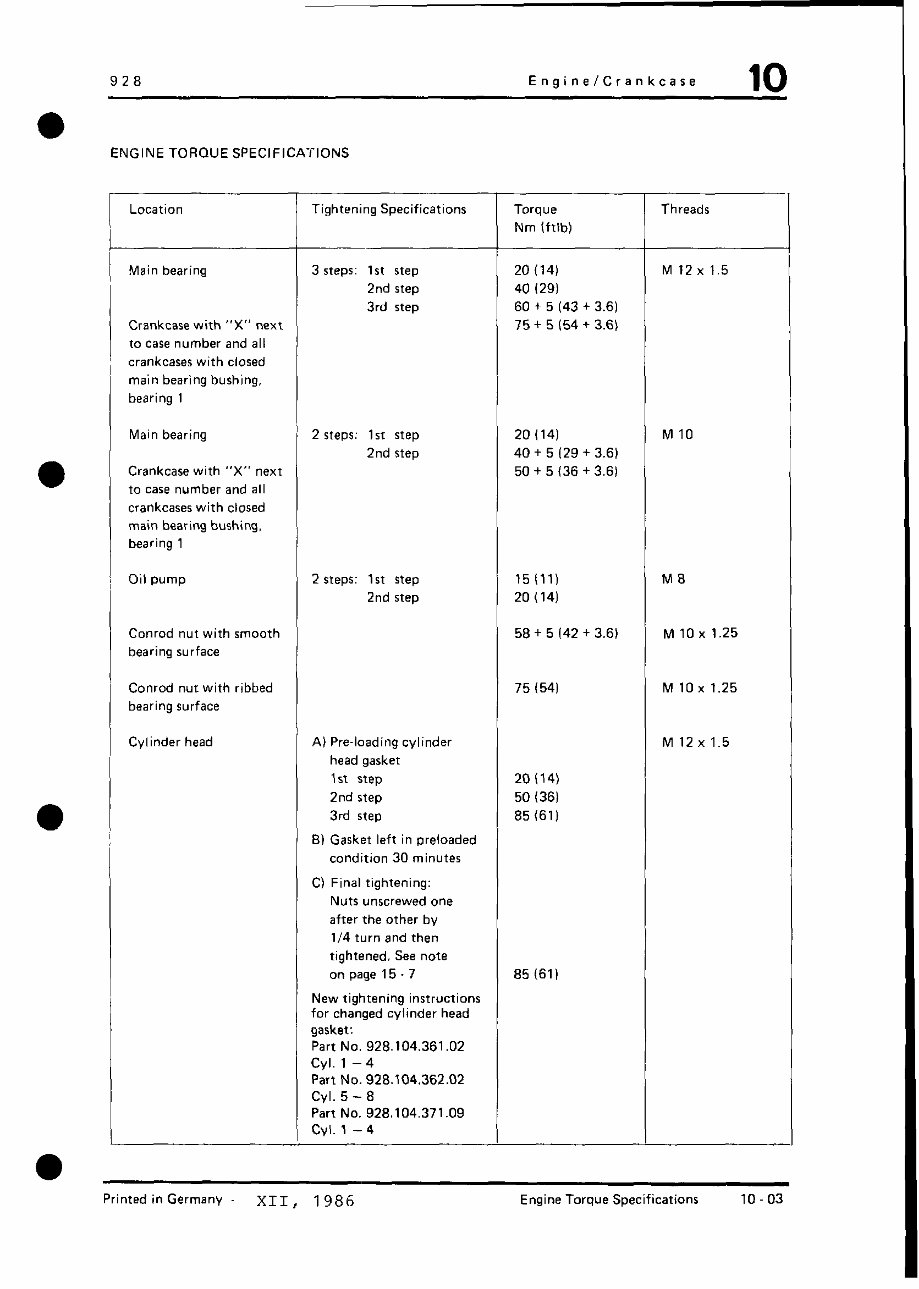

ENGINE TORQUE SPECIFICATIONS

Location

Main bearing

Crankcase with “X” next

to case number and all

crankcases with closed

main bearing bushing,

bearing 1

Main bearing

Crankcase with “X” next

to case number and all

crankcases with closed

main bearing bushing,

bearing 1

Oil pump

Conrad nut with smooth

bearing surface

Conrod nut with ribbed

bearing surface

Cylinder head

Tightening Specifications

3 steps: 1st step

2nd step

3rd step

2 step5: 1st step

2nd step

2 steps: 1st step

2nd step

A) Pre-loading cylinder

head gasket

1st Step

2nd step

3rd step

6) Gasket left in preloaded

condition 30 minutes

C) Final tightening:

Nuts unscrewed one

after the other by

l/4 turn and then

tightened, See note

onpage15.7

New tightening instructions

for changed cylinder head

gasket:

Part No. 928.104.361.02

Cyl. 1 - 4

Part No. 928.104.362.02

Cyl. 5 - 8

Part No. 928.104.371.09

Cyl. 1 - 4

Torque

Nm Iftlb)

20 (141

40 (29)

60 + 5 (43 + 3.6)

75 + 5 (54 + 3.6)

20 (14)

40 + 5 (29 + 3.61

50 + 5 136 + 3.61

15 111)

20 (14)

58 + 5 (42 + 3.61

75 (541

20 (14)

50 (361

85 161)

85 (611

Threads

M 12 x 1.5

M 10

M8

M 10 x 1.25

M 10 x 1.25

M 12x 1.5

Printed in Germany

XII, 1986

Engine Torque Specifications 10-03

10

Engine, Crankcase

928

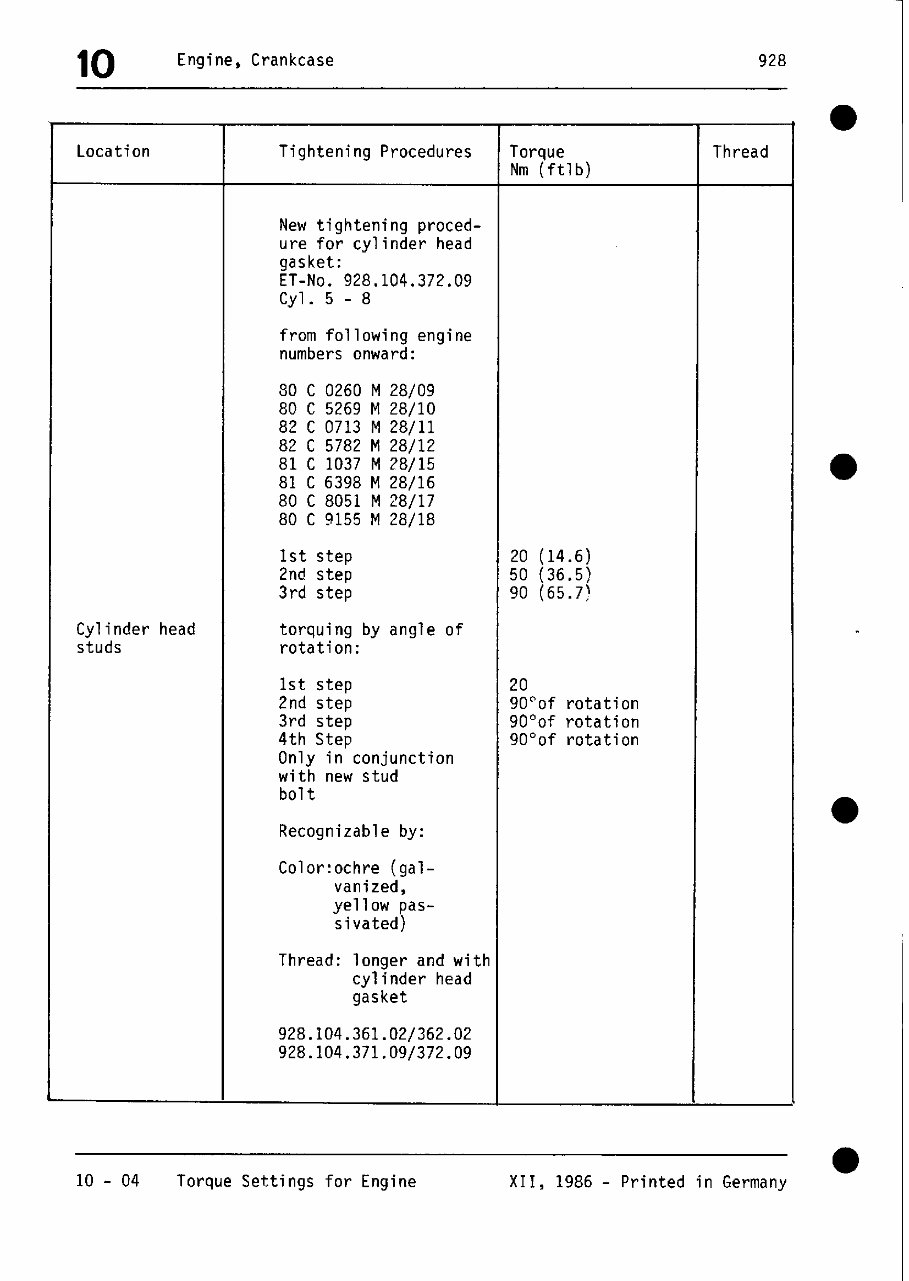

Location Location

I

Cs$;;;der head

!

Tightening Procedures

I

New tightening proced-

ure for cylinder head

sasket:

CT-NO. 928.104.372.09

Cyl. 5 - 8

from following engine

numbers onward:

80 C 0260 M 28/09 I

80 C 5269 M 28;lO

82 C 0713 M 28/11

82 C 5782 M 28/12

81 C 1037 M 28/15

81 C 6398 M 28/16

80 C 8051 M 28/17

80 C 9155 M 28/18

1st step 20 (14.6)

2nd step 50 (36.5)

3rd step 90 (65.7)

torquing by angle of

rotation:

1st step

2nd step

3rd step

4th Step

Only in conjunction

with new stud

bolt

20

90"of rotation

90"of rotation

90"of rotation

Recognizable by:

I

Color:ochre (gal-

vanized,

yellow pas-

sivated)

Thread: longer and with

cylinder head

gasket

928.104.361.02/362.02

928.104.371.09/372.09

Torque

Nm (ftlb)

Thread

a

10 - 04 Torque Settings for Engine XII, 1986 - Printed in Germany

Engine/Crankcase

10

a

i

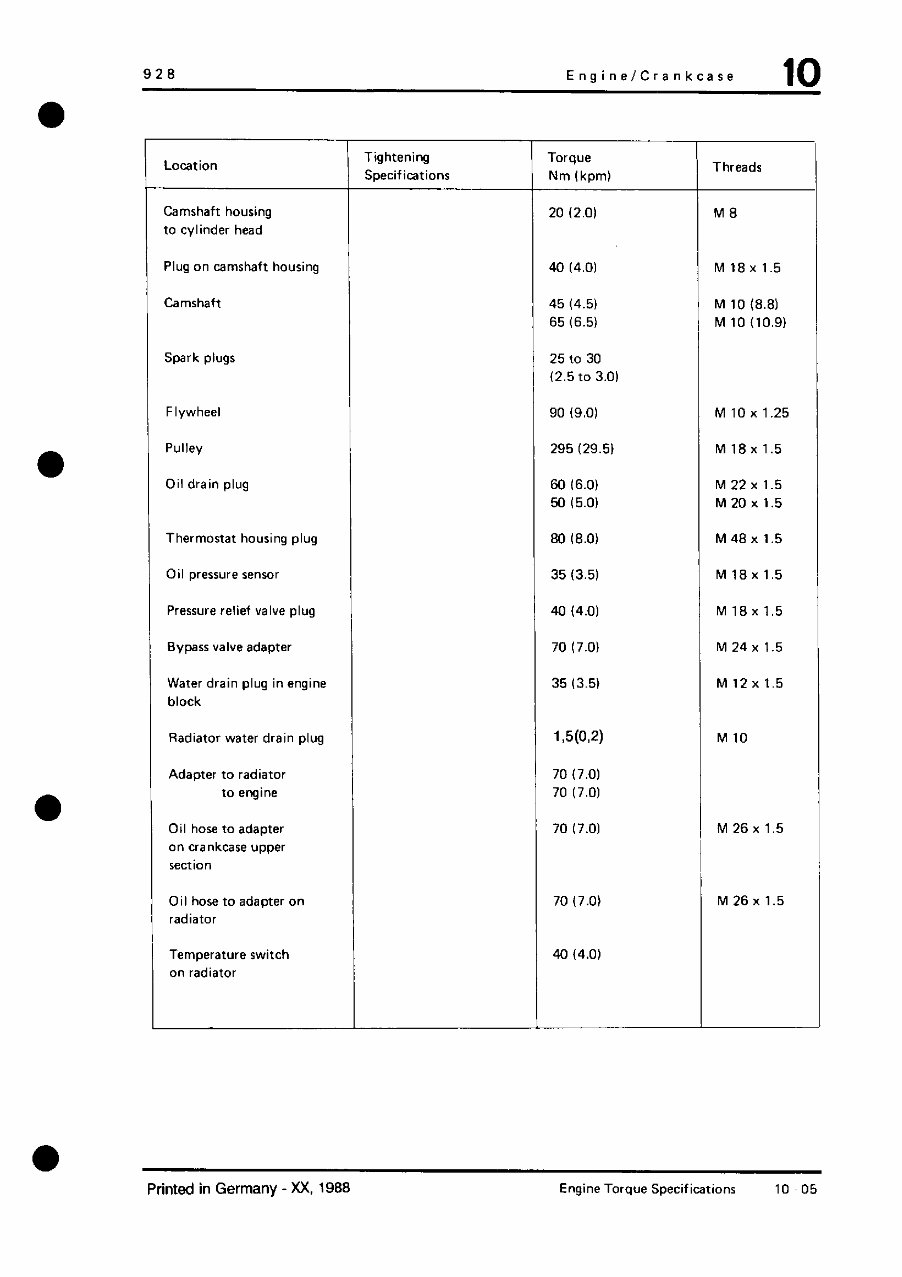

xcation

Camshaft housing

:o cylinder head

Tightening

Specifications

Torque

Nm (kpm)

20 (2.01

Threads

Ma

‘lug on camshaft housing

3amshaft

Spark plugs

40 (4.0) M 18x 1.5

45 (4.51 M 10 (8.8)

65 (6.51 M 10 (10.9)

25 to 30

(2.5 to 3.0)

Flywheel

PlJlk?y

Oil drain plug

Thermostat housing plug

Oil pressure sensor

Pressure relief valve plug

Bypass valve adapter

Water drain plug in engine

block

90 (9.01 M 10x 1.25

295 (29.5) M18x1.5

60 (6.0) M22x1.5

50 (5.0) MZOx1.5

80 (8.0) M48x1.5

35 (3.5) M 18x 1.5

40 (4.0) M 18x 1.5

70 (7.0) M 24 x 1.5

35 (3.51 MlZx1.5

Radiator water drain plug

Adapter to radiator

to engine

Oil bore to adapter

on crankcase upper

section

1,5(0,2) M 10

70 (7.01

70 17.0)

70 (7.0) M26x1.5

Oil hose to adapter on

radiator

Temperature switch

on radiator

70 (7.0) M26x1.5

40 (4.0)

l

Printed in Germany - XX. 1988 Engine Torque Specifications 10~05

10

Engine/Crankcase 928

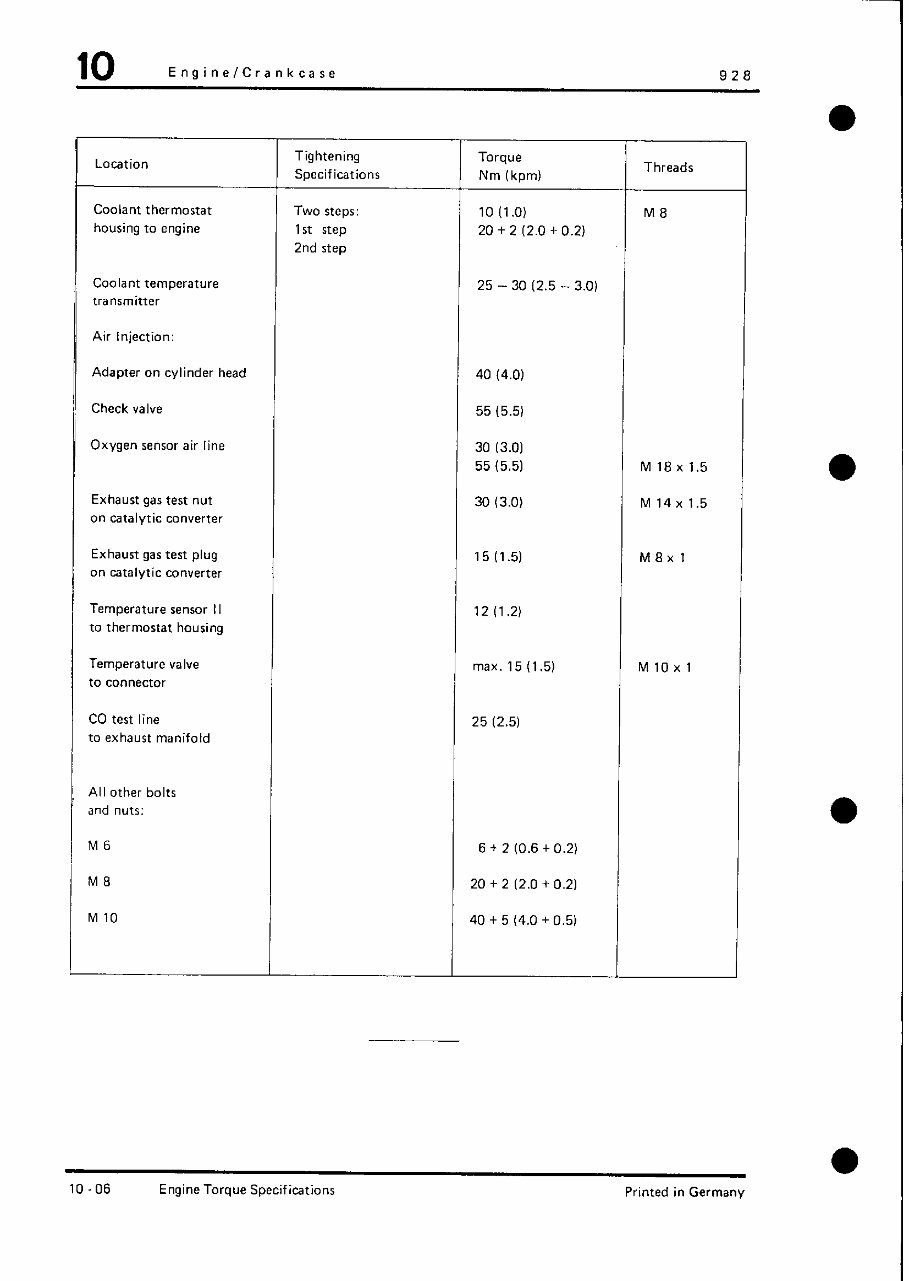

Location

Coolant thermostat

housing to engine

Tightening

Specifications

Two steps:

1st step

2nd step

Torque

Nm (kpml

10 (1.0)

20 + 2 (2.0 + 0.2)

Threads

M8

Coolant temperature

transmitter

25 - 30 (2.5 - 3.0)

Air Injection:

Adapter on cylinder head

Check valve

Oxygen sensor air line

Exhaust gas test nut

on catalytic converter

Exhaust gas test plug

on catalytic converter

Temperature sensor II

to thermostat housing

Temperature valve

to connector

CO test line

to exhaust manifold

40 (4.01

55 (5.51

30 13.01

55 (5.5) M 16x 1.5

30 (3.0) M 14x 1.5

15 (1.5) M8xl

12 (1.2)

max. 15 (1.5) MlOxl

25 12.5)

All other bolts

and nuts:

M6

6 + 2 (0.6 + 0.21

M8 20 + 2 12.0 + 0.2)

M 10 40 + 5 (4.0 + 0.51

10.06 EngineTorque Specifications Printed in Germany

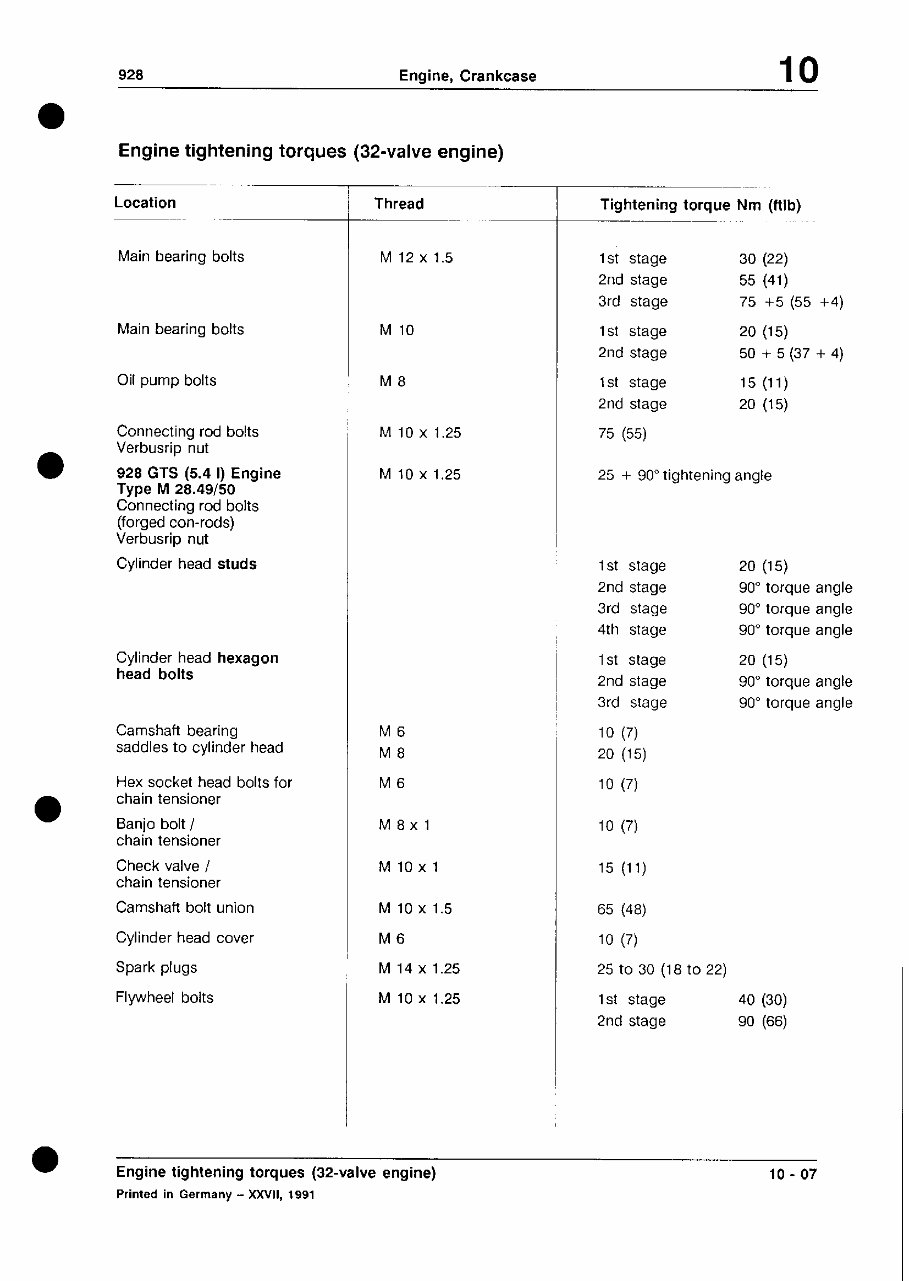

928 Engine, Crankcase 10

Engine tightening torques (32~valve engine)

Location

/-

Thread

I

Main bearing bolts

Main bearing bolts

Oil pump bolts

Connecting rod bolts

Verbusrip nut

928 GTS (5.4 I) Engine

Type M 28.49150

Connecting rod bolts

(forged con-rods)

Verbusrip nut

Cylinder head studs

Cylinder head hexagon

head bolts

Camshaft bearing

saddles to cylinder head

Hex socket head bolts for

chain tensioner

Banjo bolt /

chain tensioner

Check valve /

chain tensioner

Camshaft bolt union

Cylinder head cover

Spark plugs

Flywheel bolts

M 12 x 1.5

M 10

M8

M 10 x 1.25

M 10 x 1.25

M6

M8

M6

M8X1

MlOxl

M 10 x 1.5

M6

M 14 x 1.25

M 10 x 1.25

Tightening torque Nm (ftlb)

1st stage 30 (22)

2nd stage 55 (41)

3rd stage 75 +5 (55 c4)

1st stage 20 (15)

2nd stage 50 + 5 (37 + 4)

1st stage 15 (11)

2nd stage 20 (15)

75 (55)

25 + 90” tightening angle

a

Engine tightening torques (32~valve engine)

Printed in Germany - XXVII, 1991

1st stage

2nd stage

3rd stage

4th stage

1st stage

2nd stage

3rd stage

10 (7)

20 (15)

10 (7)

10 (7)

15 (11)

65 (48)

10 (7)

25 to 30 (18 to 22)

1st stage

2nd stage

20 (15)

90” torque angle

90” torque angle

90” torque angle

20 (15)

90” torque angle

90” torque angle

40 (30)

90 (66)

10 - 07

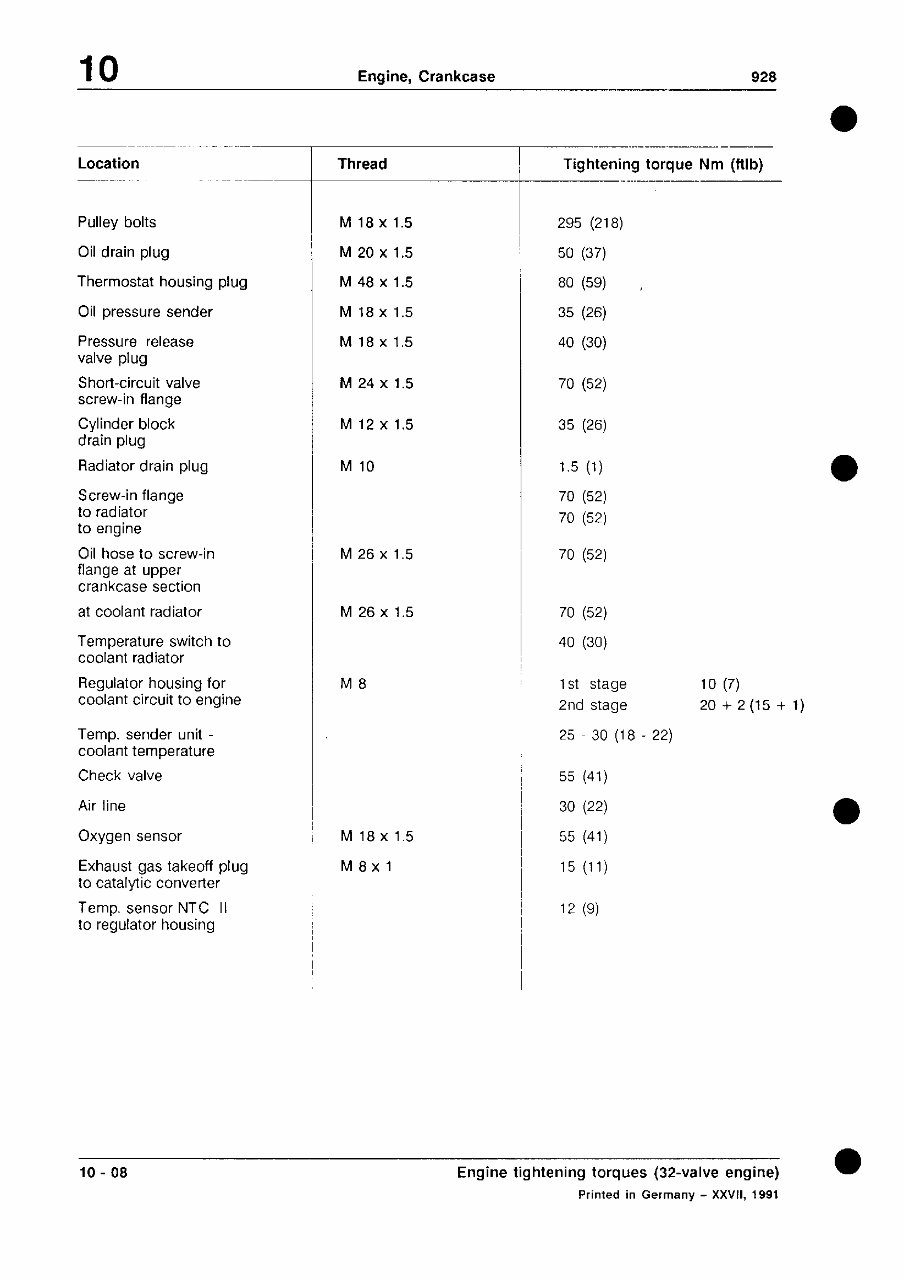

Engine, Crankcase 928

Location

Pulley bolts

Oil drain plug

Thermostat housing plug

Oil pressure sender

Pressure release

valve plug

Short-circuit valve

screw-in flange

Cylinder block

drain plug

Radiator drain plug

Screw-in flange

to radiator

to engine

Oil hose to screw-in

flange at upper

crankcase section

at coolant radiator

Temperature switch to

coolant radiator

Regulator housing for

coolant circuit to engine

Temp. sender unit

coolant temperature

Check valve

Air line

Oxygen sensor

Exhaust gas takeoff plug

to catalytic converter

Temp. sensor NTC II

to regulator housing

-1

M 20 x 1.5

M 48 x 1.5

M 18 x 1.5

M 18 x 1.5

M 24 x 1.5

M 12 x 1.5

M 10

M 26 x 1.5

M 26 x 1.5

M8

M 18x 1.5

M8x1

Tightening torque Nm (ftlb)

295 (218)

50 (37)

80 (59)

35 (26)

40 (30)

70 (52)

35 (26)

1.5 (1)

70 (52)

70 (52)

70 (52)

70 (52)

40 (30)

1st stage

10 (7)

2nd stage 20 + 2(15 + 1)

25 30 (18 22)

55 (41)

30 (22)

55 (41)

15 (11)

12 (9)

lo-08 Engine tightening torques (32~valve engine)

a

Printed in Germany - XXVII, 1991

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$24.99

Viewed 68 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$24.99

Porsche 928 Workshop Manual

Models / Engines:

- All 928 models from 1979 to 1993

Topics Included:

- General Information / Specification

- Engine

- Lubrication, Cooling, Fuelling System

- Clutch, Gearbox, Rear Axle

- Steering

- Front Suspension

- Rear Suspension, Shock Absorbers

- Brakes, Wheels and Tyres

- Instrument and Control

- Heating, Ventilation and AC

- Electric System

- Torque Settings

- Body

- Emission Controls

- Plus More