2017 Nissan Sentra (B17) Service & Repair Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

HAC-1

VENTILATION, HEATER & AIR CONDITIONER

C

D

E

F

G

H

J

K

L

M

SECTION HAC

A

B

HAC

N

O

P

CONTENTS

HEATER & AIR CONDITIONING CONTROL SYSTEM

AUTOMATIC AIR CONDITIONER

PRECAUTION .............................................. 5

PRECAUTIONS .................................................. 5

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .................................................................. 5

Precaution for Work ................................................. 5

Working with HFC-134a (R-134a) ............................ 5

Precaution for Service Equipment ............................ 6

PREPARATION ........................................... 8

PREPARATION .................................................. 8

Special Service Tool ................................................ 8

Commercial Service Tool ......................................... 8

SYSTEM DESCRIPTION ............................. 9

COMPONENT PARTS ....................................... 9

Component Part Location ........................................ 9

Component Description .......................................... 10

SYSTEM ............................................................12

System Diagram ..................................................... 12

System Description ................................................ 12

Air Flow Control ...................................................... 13

Air Inlet Control ...................................................... 14

Air Outlet Control .................................................... 15

Compressor Control ............................................... 15

Door Control ........................................................... 15

Temperature Control .............................................. 20

Fail-safe ................................................................. 20

OPERATION ......................................................21

Switch Name and Function .................................... 21

DIAGNOSIS SYSTEM (A/C AUTO AMP.) ........24

Description ............................................................. 24

CONSULT Function (HVAC) .................................. 24

DIAGNOSIS SYSTEM (BCM) ........................... 28

COMMON ITEM ........................................................28

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) ....................................................28

AIR CONDITIONER ..................................................29

AIR CONDITIONER : CONSULT Function (BCM -

AIR CONDITIONER) ..............................................29

DIAGNOSIS SYSTEM (IPDM E/R) ................... 30

Diagnosis Description .............................................30

CONSULT Function (IPDM E/R) ............................31

ECU DIAGNOSIS INFORMATION ............. 34

A/C AUTO AMP. ............................................... 34

Reference Value .....................................................34

DTC Inspection Priority Chart ..............................38

DTC Index ..............................................................38

ECM, IPDM E/R, BCM ....................................... 40

List of ECU Reference ............................................40

WIRING DIAGRAM ..................................... 41

AUTOMATIC AIR CONDITIONING SYSTEM ... 41

Wiring Diagram .......................................................41

BASIC INSPECTION .................................. 51

DIAGNOSIS AND REPAIR WORKFLOW ........ 51

Work Flow ...............................................................51

OPERATION INSPECTION .............................. 53

Work Procedure ......................................................53

SYSTEM SETTING ........................................... 55

Temperature Setting Trimmer ................................55

Inlet Port Memory Function (FRE) ..........................55

Inlet Port Memory Function (REC) .........................56

Target Evaporator Temp Upper Limit .....................56

Revision: December 2014 2015 Sentra NAM

HAC-2

DOOR MOTOR STARTING POSITION RE-

SET ................................................................... 57

Description ............................................................. 57

Work Procedure ..................................................... 57

DTC/CIRCUIT DIAGNOSIS ........................ 58

U1000 CAN COMM CIRCUIT ........................... 58

Description ............................................................. 58

DTC Logic .............................................................. 58

Diagnosis Procedure ............................................. 58

U1010 CONTROL UNIT (CAN) ........................ 59

Description ............................................................. 59

DTC Logic .............................................................. 59

Diagnosis Procedure ............................................. 59

B2578, B2579 IN-VEHICLE SENSOR .............. 60

DTC Logic .............................................................. 60

Diagnosis Procedure ............................................. 60

Component Inspection ........................................... 61

B257B, B257C AMBIENT SENSOR ................ 63

DTC Logic .............................................................. 63

Diagnosis Procedure ............................................. 63

Component Inspection ........................................... 64

B2581, B2582 INTAKE SENSOR ..................... 66

DTC Logic .............................................................. 66

Diagnosis Procedure ............................................. 66

Component Inspection ........................................... 67

B2630, B2631 SUNLOAD SENSOR ................ 69

DTC Logic .............................................................. 69

Diagnosis Procedure ............................................. 69

Component Inspection ........................................... 70

B27A2, B27A3, B27A4, B27A5 AIR MIX

DOOR MOTOR (DRIVER SIDE) ....................... 72

DTC Logic .............................................................. 72

Diagnosis Procedure ............................................. 72

Component Inspection ........................................... 73

B27AA, B27AB, B27AC, B27AD AIR MIX

DOOR MOTOR (PASSENGER SIDE) .............. 74

DTC Logic .............................................................. 74

Diagnosis Procedure ............................................. 74

Component Inspection ........................................... 75

B27A6, B27A7, B27A8, B27A9 MODE DOOR

MOTOR ............................................................. 77

DTC Logic .............................................................. 77

Diagnosis Procedure ............................................. 77

Component Inspection ........................................... 78

B27A0, B27A1 INTAKE DOOR MOTOR ......... 79

DTC Logic .............................................................. 79

Diagnosis Procedure ............................................. 79

Component Inspection (PBR) ................................ 81

Component Inspection (Motor) .............................. 82

POWER SUPPLY AND GROUND CIRCUIT .... 83

A/C AUTO AMP. ....................................................... 83

A/C AUTO AMP. : Diagnosis Procedure ................ 83

A/C SWITCH ASSEMBLY ........................................ 83

A/C SWITCH ASSEMBLY : Component Function

Check ..................................................................... 83

A/C SWITCH ASSEMBLY : Diagnosis Procedure ... 84

A/C SWITCH ASSEMBLY SIGNAL CIRCUIT ... 85

Diagnosis Procedure .............................................. 85

A/C ON SIGNAL ............................................... 86

Component Function Check .................................. 86

Diagnosis Procedure .............................................. 86

BLOWER FAN ON SIGNAL ............................. 88

Component Function Check .................................. 88

Diagnosis Procedure .............................................. 88

BLOWER MOTOR ............................................ 90

Diagnosis Procedure .............................................. 90

Component Inspection (Blower Motor) .................. 92

Component Inspection (Blower Motor Relay) ........ 93

MAGNET CLUTCH ........................................... 94

Component Function Check .................................. 94

Diagnosis Procedure .............................................. 94

ECV (ELECTRICAL CONTROL VALVE) ......... 95

Diagnosis Procedure .............................................. 95

Component Inspection ........................................... 96

SYMPTOM DIAGNOSIS ............................ 97

HEATER AND AIR CONDITIONING SYSTEM

CONTROL SYMPTOMS ................................... 97

Diagnosis Chart By Symptom ................................ 97

INSUFFICIENT COOLING ................................ 99

Description ............................................................. 99

Diagnosis Procedure .............................................. 99

INSUFFICIENT HEATING ............................... 101

Description ........................................................... 101

Diagnosis Procedure ............................................ 101

COMPRESSOR DOES NOT OPERATE ......... 102

Description ........................................................... 102

Diagnosis Procedure ............................................ 102

REMOVAL AND INSTALLATION ............. 104

A/C SWITCH ASSEMBLY ............................... 104

Removal and Installation ...................................... 104

A/C AUTO AMP. .............................................. 105

Exploded View ..................................................... 105

Removal and Installation ...................................... 105

AMBIENT SENSOR ......................................... 106

Removal and Installation ...................................... 106

Revision: December 2014 2015 Sentra NAM

HAC-3

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

IN-VEHICLE SENSOR .................................... 107

Removal and Installation ...................................... 107

SUNLOAD SENSOR ....................................... 108

Removal and Installation ...................................... 108

INTAKE SENSOR ........................................... 109

Removal and Installation ...................................... 109

REFRIGERANT PRESSURE SENSOR .......... 110

Removal and Installation ...................................... 110

DOOR MOTOR ................................................ 111

Exploded View ..................................................... 111

INTAKE DOOR MOTOR ......................................... 112

INTAKE DOOR MOTOR : Removal and Installa-

tion ....................................................................... 112

MODE DOOR MOTOR ........................................... 112

MODE DOOR MOTOR : Removal and Installation .. 112

AIR MIX DOOR MOTOR ........................................ 112

AIR MIX DOOR MOTOR : Removal and Installa-

tion - Air Mix Door Motor RH ................................ 112

AIR MIX DOOR MOTOR : Removal and Installa-

tion - Air Mix Door Motor LH ................................. 112

POWER TRANSISTOR ................................... 113

Removal and Installation ...................................... 113

MANUAL AIR CONDITIONER

PRECAUTION ........................................... 114

PRECAUTIONS ............................................... 114

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" .............................................................. 114

Precaution for Work ............................................. 114

Working with HFC-134a (R-134a) ........................ 114

Precaution for Service Equipment ........................ 115

PREPARATION ........................................ 117

PREPARATION ............................................... 117

Special Service Tool ............................................ 117

Commercial Service Tool ..................................... 117

SYSTEM DESCRIPTION .......................... 118

COMPONENT PARTS .................................... 118

Component Part Location .................................... 118

Component Description ........................................ 119

SYSTEM .......................................................... 121

System Diagram ................................................... 121

System Description .............................................. 121

Air Flow Control .................................................... 122

Air Inlet Control .................................................... 122

Air Outlet Control .................................................. 122

Compressor Control ............................................. 122

Door Control ......................................................... 123

Temperature Control ............................................ 126

OPERATION ................................................... 127

Switch Name and Function ................................... 127

DIAGNOSIS SYSTEM (BCM) (WITH INTELLI-

GENT KEY SYSTEM) ..................................... 129

COMMON ITEM ...................................................... 129

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) .................................................. 129

AIR CONDITIONER ................................................ 130

AIR CONDITIONER : CONSULT Function (BCM -

AIR CONDITIONER) ............................................ 130

DIAGNOSIS SYSTEM (BCM) (WITHOUT IN-

TELLIGENT KEY SYSTEM) ........................... 131

COMMON ITEM ...................................................... 131

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) .................................................. 131

AIR CONDITIONER ................................................ 132

AIR CONDITIONER : CONSULT Function (BCM -

AIR CONDITIONER) ............................................ 132

DIAGNOSIS SYSTEM (IPDM E/R) (WITH IN-

TELLIGENT KEY SYSTEM) ........................... 133

Diagnosis Description ........................................... 133

CONSULT Function (IPDM E/R) .......................... 134

DIAGNOSIS SYSTEM (IPDM E/R) (WITHOUT

INTELLIGENT KEY SYSTEM) ........................ 137

Diagnosis Description ........................................... 137

CONSULT Function (IPDM E/R) .......................... 138

ECU DIAGNOSIS INFORMATION ........... 141

A/C AUTO AMP. ............................................. 141

Reference Value ................................................... 141

ECM, IPDM E/R, BCM ..................................... 144

List of ECU Reference .......................................... 144

WIRING DIAGRAM ................................... 145

MANUAL AIR CONDITIONING SYSTEM ....... 145

Wiring Diagram ..................................................... 145

MANUAL HEATER SYSTEM .......................... 152

Wiring Diagram ..................................................... 152

BASIC INSPECTION ................................ 156

DIAGNOSIS AND REPAIR WORKFLOW ...... 156

Work Flow ............................................................. 156

OPERATION INSPECTION ............................ 157

Work Procedure .................................................... 157

DTC/CIRCUIT DIAGNOSIS ...................... 159

Revision: December 2014 2015 Sentra NAM

HAC-4

POWER SUPPLY AND GROUND CIRCUIT .. 159

A/C AUTO AMP. ..................................................... 159

A/C AUTO AMP. : Diagnosis Procedure .............. 159

A/C SWITCH ASSEMBLY ...................................... 159

A/C SWITCH ASSEMBLY : Component Function

Check ................................................................... 159

A/C SWITCH ASSEMBLY : Diagnosis Procedure .. 160

MODE DOOR MOTOR ................................... 161

Diagnosis Procedure ............................................ 161

Component Inspection .......................................... 162

AIR MIX DOOR MOTOR ................................. 163

Diagnosis Procedure ............................................ 163

Component Inspection .......................................... 164

INTAKE DOOR MOTOR ................................. 165

Diagnosis Procedure ............................................ 165

Component Inspection (Motor) ............................. 166

A/C SWITCH ASSEMBLY SIGNAL CIRCUIT . 167

Diagnosis Procedure ............................................ 167

A/C ON SIGNAL ............................................. 168

Component Function Check ................................. 168

Diagnosis Procedure ............................................ 168

INTAKE SENSOR ........................................... 170

Diagnosis Procedure ............................................ 170

Component Inspection .......................................... 171

BLOWER FAN ON SIGNAL ........................... 172

Component Function Check ................................. 172

Diagnosis Procedure ............................................ 172

BLOWER MOTOR .......................................... 174

Diagnosis Procedure ............................................ 174

Component Inspection (Blower Motor) ................. 176

Component Inspection (Blower Motor Relay) ....... 177

MAGNET CLUTCH ......................................... 178

Component Function Check ................................. 178

Diagnosis Procedure ............................................ 178

ECV (ELECTRICAL CONTROL VALVE) ....... 179

Diagnosis Procedure ............................................ 179

Component Inspection .......................................... 180

SYMPTOM DIAGNOSIS ........................... 181

HEATER AND AIR CONDITIONING SYSTEM

CONTROL SYMPTOMS .................................. 181

Symptom Table .................................................... 181

INSUFFICIENT COOLING ............................... 182

Component Function Check ................................ 182

INSUFFICIENT HEATING ............................... 184

Component Function Check ................................ 184

COMPRESSOR DOES NOT OPERATE ......... 186

Description ........................................................... 186

Diagnosis Procedure ............................................ 186

REMOVAL AND INSTALLATION ............. 188

A/C ASSEMBLY SWITCH ............................... 188

Removal and Installation ...................................... 188

A/C AUTO AMP. .............................................. 189

Exploded View ..................................................... 189

Removal and Installation ...................................... 189

INTAKE SENSOR ............................................ 190

Removal and Installation ...................................... 190

REFRIGERANT PRESSURE SENSOR .......... 191

Removal and Installation ...................................... 191

DOOR MOTOR ................................................ 192

Exploded View ..................................................... 192

INTAKE DOOR MOTOR ........................................ 193

INTAKE DOOR MOTOR : Removal and Installa-

tion ....................................................................... 193

MODE DOOR MOTOR ........................................... 193

MODE DOOR MOTOR : Removal and Installation . 193

AIR MIX DOOR MOTOR ........................................ 193

AIR MIX DOOR MOTOR : Removal and Installa-

tion ....................................................................... 193

BLOWER MOTOR RESISTOR ....................... 194

Removal and Installation ...................................... 194

Revision: December 2014 2015 Sentra NAM

PRECAUTIONS

HAC-5

< PRECAUTION >

[AUTOMATIC AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000011538352

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor(s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for Work INFOID:0000000011538353

• When removing or disassembling each component, be careful not to damage or deform it. If a component

may be subject to interference, be sure to protect it with a shop cloth.

• When removing (disengaging) components with a screwdriver or similar tool, be sure to wrap the component

with a shop cloth or vinyl tape to protect it.

• Protect the removed parts with a shop cloth and prevent them from being dropped.

• Replace a deformed or damaged clip.

• If a part is specified as a non-reusable part, always replace it with a new one.

• Be sure to tighten bolts and nuts securely to the specified torque.

• After installation is complete, be sure to check that each part works properly.

• Follow the steps below to clean components:

- Water soluble dirt:

• Dip a soft cloth into lukewarm water, wring the water out of the cloth and wipe the dirty area.

• Then rub with a soft, dry cloth.

- Oily dirt:

• Dip a soft cloth into lukewarm water with mild detergent (concentration: within 2 to 3%) and wipe the dirty

area.

• Then dip a cloth into fresh water, wring the water out of the cloth and wipe the detergent off.

• Then rub with a soft, dry cloth.

- Do not use organic solvent such as thinner, benzene, alcohol or gasoline.

- For genuine leather seats, use a genuine leather seat cleaner.

Working with HFC-134a (R-134a) INFOID:0000000011538354

WARNING:

• CFC-12 (R-12) refrigerant and HFC-134a (R-134a) refrigerant are not compatible. If the refrigerants

are mixed compressor failure is likely to occur. Refer to HA-25, "Inspection" . To determine the purity

of HFC-134a (R-134a) in the vehicle and recovery tank, use Refrigerant Recovery/Recycling Recharg-

ing equipment and Refrigerant Identifier.

Revision: December 2014 2015 Sentra NAM

HAC-6

< PRECAUTION >

[AUTOMATIC AIR CONDITIONER]

PRECAUTIONS

• Use only specified oil for the HFC-134a (R-134a) A/C system and HFC-134a (R-134a) components. If

oil other than that specified is used, compressor failure is likely to occur.

• The specified HFC-134a (R-134a) oil rapidly absorbs moisture from the atmosphere. The following

handling precautions must be observed:

- When removing refrigerant components from a vehicle, immediately cap (seal) the component to

minimize the entry of moisture from the atmosphere.

- When installing refrigerant components to a vehicle, do not remove the caps (unseal) until just

before connecting the components. Connect all refrigerant loop components as quickly as possible

to minimize the entry of moisture into system.

- Only use the specified oil from a sealed container. Immediately reseal containers of oil. Without

proper sealing, oil will become moisture saturated and should not be used.

- Avoid breathing A/C refrigerant and oil vapor or mist. Exposure may irritate eyes, nose and throat.

Remove HFC-134a (R-134a) from the A/C system using certified service equipment meeting require-

ments of SAE J2210 [HFC-134a (R-134a) recycling equipment], or J2209 [HFC-134a (R-134a) recy-

cling equipment], If accidental system discharge occurs, ventilate work area before resuming

service. Additional health and safety information may be obtained from refrigerant and oil manufac-

turers.

- Do not allow A/C oil to come in contact with styrofoam parts. Damage may result.

CONTAMINATED REFRIGERANT

If a refrigerant other than pure HFC-134a (R-134a) is identified in a vehicle, your options are:

• Explain to the customer that environmental regulations prohibit the release of contaminated refrigerant into

the atmosphere.

• Explain that recovery of the contaminated refrigerant could damage your service equipment and refrigerant

supply.

• Suggest the customer return the vehicle to the location of previous service where the contamination may

have occurred.

• If you choose to perform the repair, recover the refrigerant using only dedicated equipment and contain-

ers. Do not recover contaminated refrigerant into your existing service equipment. If your facility does

not have dedicated recovery equipment, you may contact a local refrigerant product retailer for available ser-

vice. This refrigerant must be disposed of in accordance with all federal and local regulations. In addition,

replacement of all refrigerant system components on the vehicle is recommended.

• If the vehicle is within the warranty period, the air conditioner warranty is void. Please contact NISSAN Cus-

tomer Affairs for further assistance.

Precaution for Service Equipment INFOID:0000000011538355

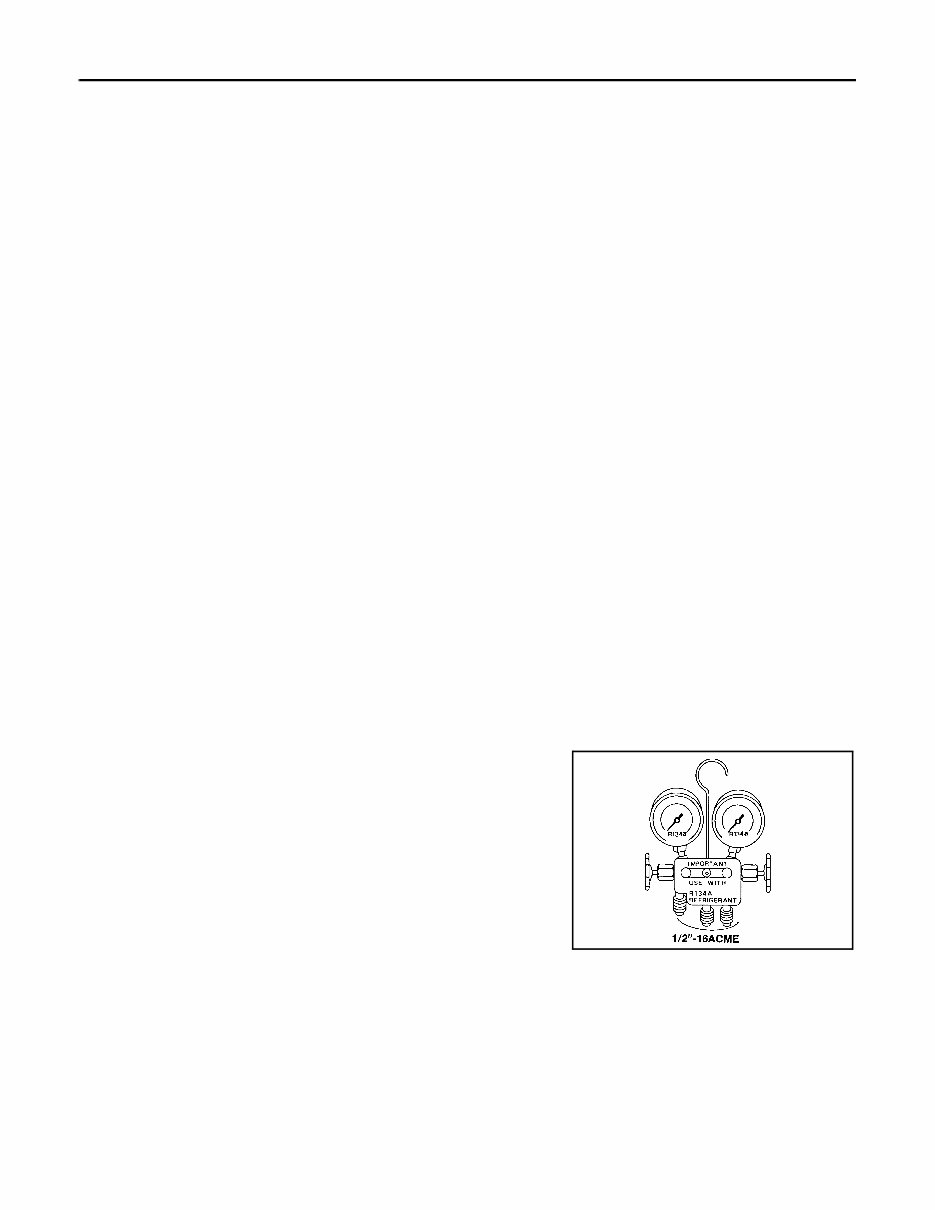

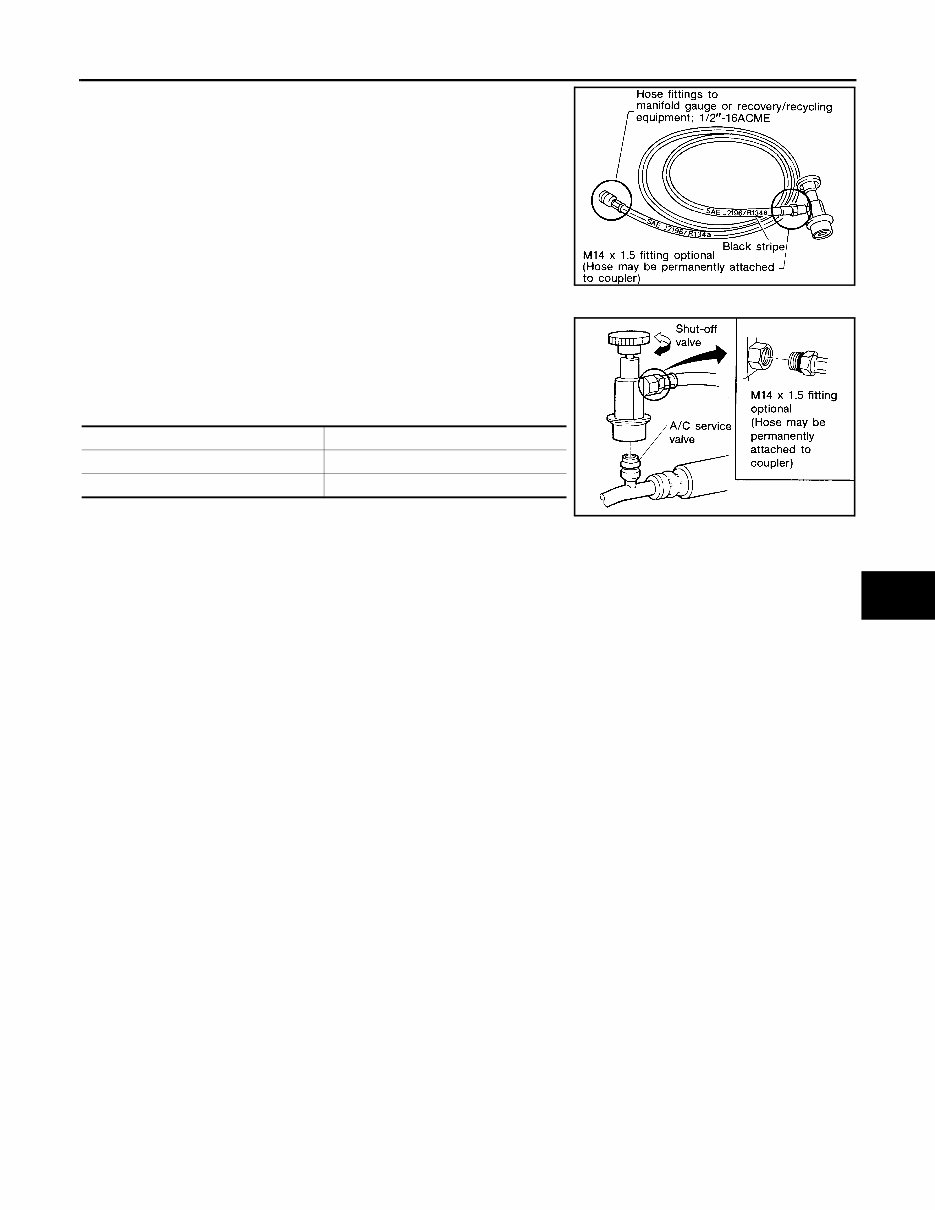

MANIFOLD GAUGE SET

Be certain that the gauge face indicates R-134a or 134a. Make sure

the gauge set has 1/2″-16 ACME threaded connections for service

hoses. Confirm the set has been used only with refrigerant HFC-

134a (R-134a) along with specified oil.

SERVICE HOSES

SHA533D

Revision: December 2014 2015 Sentra NAM

PRECAUTIONS

HAC-7

< PRECAUTION >

[AUTOMATIC AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

Be certain that the service hoses display the markings described

(colored hose with black stripe). All hoses must include positive shut-

off devices (either manual or automatic) near the end of the hoses

opposite the manifold gauge.

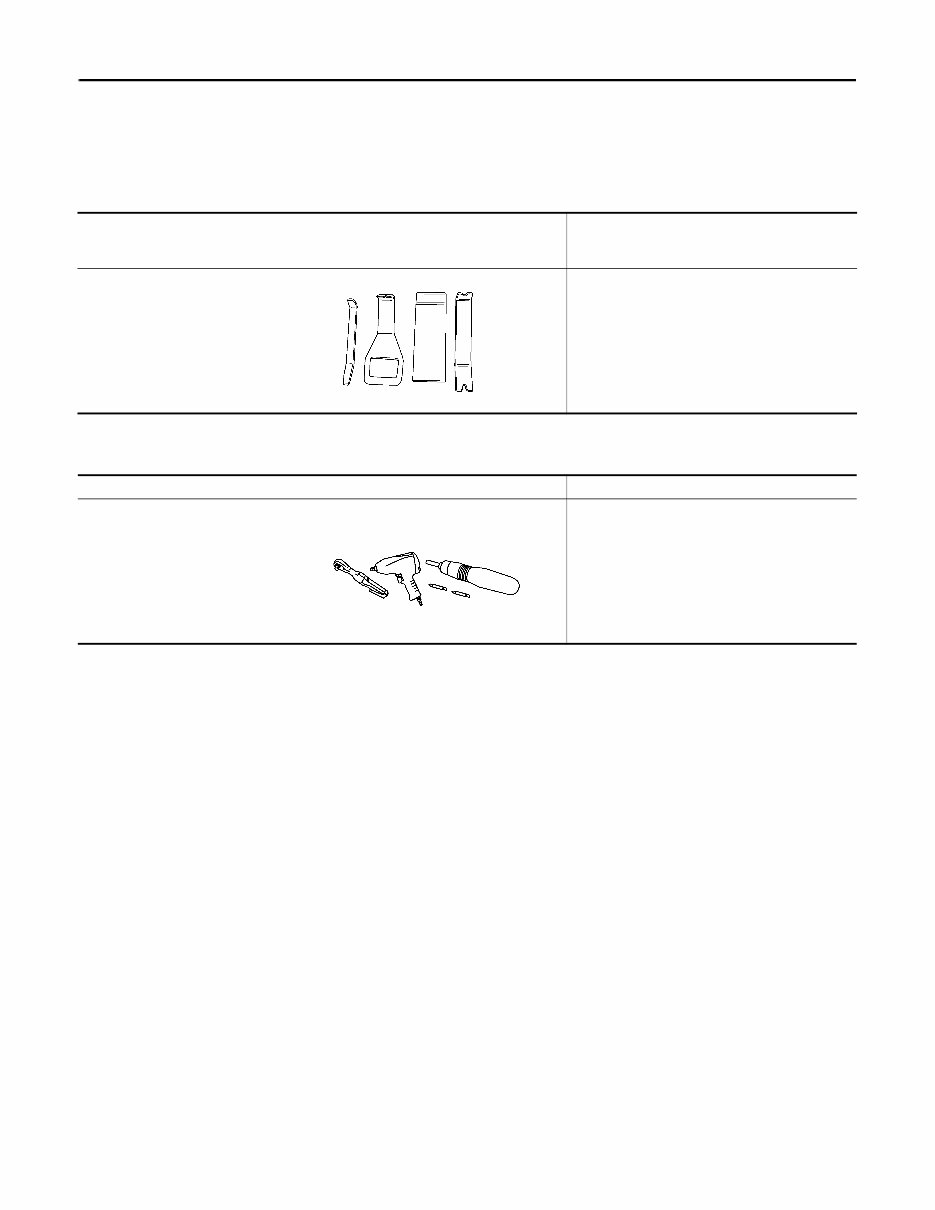

SERVICE COUPLERS

Do not attempt to connect HFC-134a (R-134a) service couplers to a

CFC-12 (R-12) A/C system. The HFC-134a (R-134a) couplers will

not properly connect to the CFC-12 (R-12) system. However, if an

improper connection is attempted, discharging and contamination

may occur.

RHA272D

Shut-off valve rotation A/C service valve

Clockwise Open

Counterclockwise Close

RHA273D

Revision: December 2014 2015 Sentra NAM

HAC-8

< PREPARATION >

[AUTOMATIC AIR CONDITIONER]

PREPARATION

PREPARATION

PREPARATION

Special Service Tool INFOID:0000000011538356

The actual shape of the tools may differ from those illustrated here.

Commercial Service Tool INFOID:0000000011538357

Tool number

(TechMate No.)

Tool name

Description

—

(J-46534)

Trim Tool Set

Removing trim components

AWJIA0483ZZ

Tool name Description

Power tool Loosening nuts, screws and bolts

PIIB1407E

Revision: December 2014 2015 Sentra NAM

COMPONENT PARTS

HAC-9

< SYSTEM DESCRIPTION >

[AUTOMATIC AIR CONDITIONER]

C

D

E

F

G

H

J

K

L

M

A

B

HAC

N

O

P

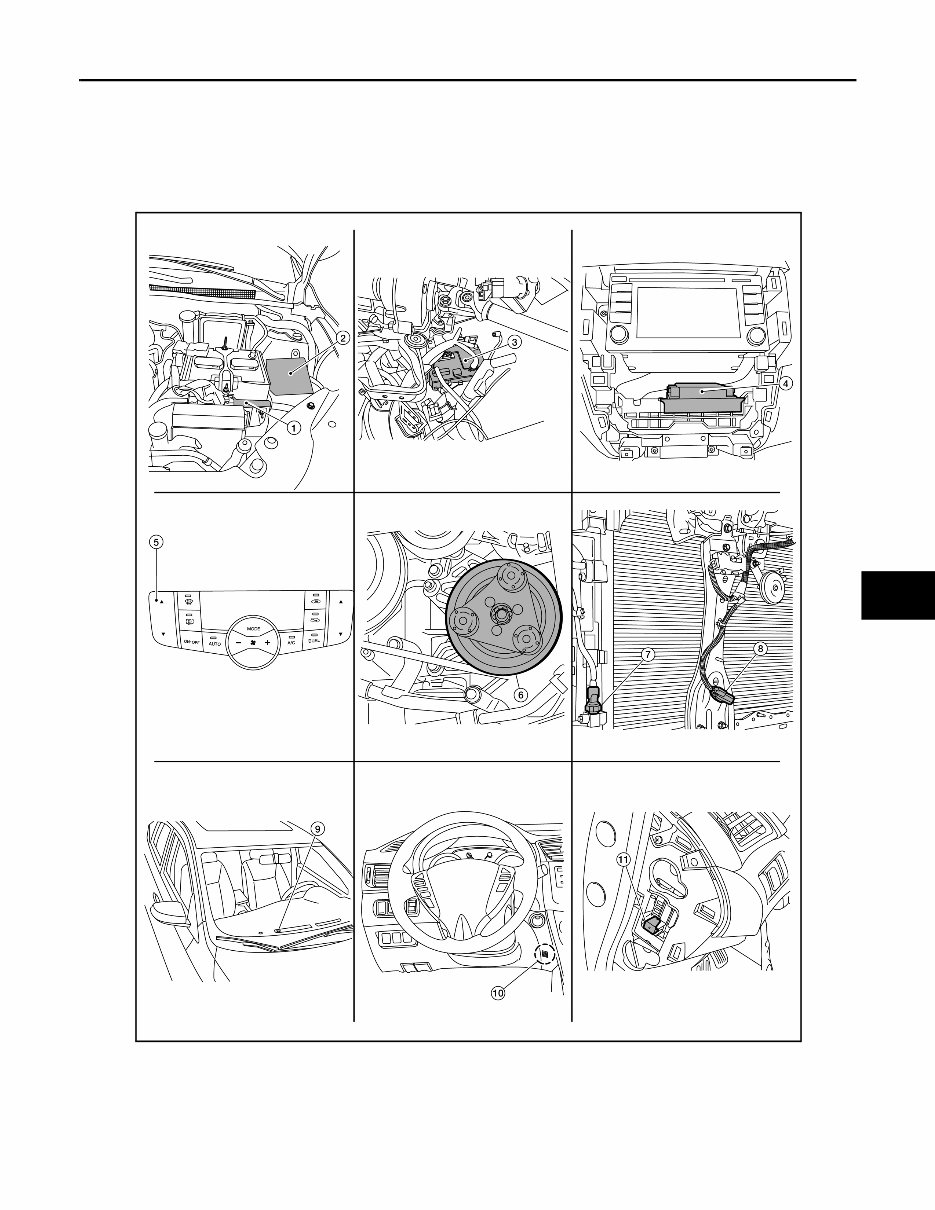

SYSTEM DESCRIPTION

COMPONENT PARTS

Component Part Location INFOID:0000000011538358

ALIIA0703ZZ

Revision: December 2014 2015 Sentra NAM

HAC-10

< SYSTEM DESCRIPTION >

[AUTOMATIC AIR CONDITIONER]

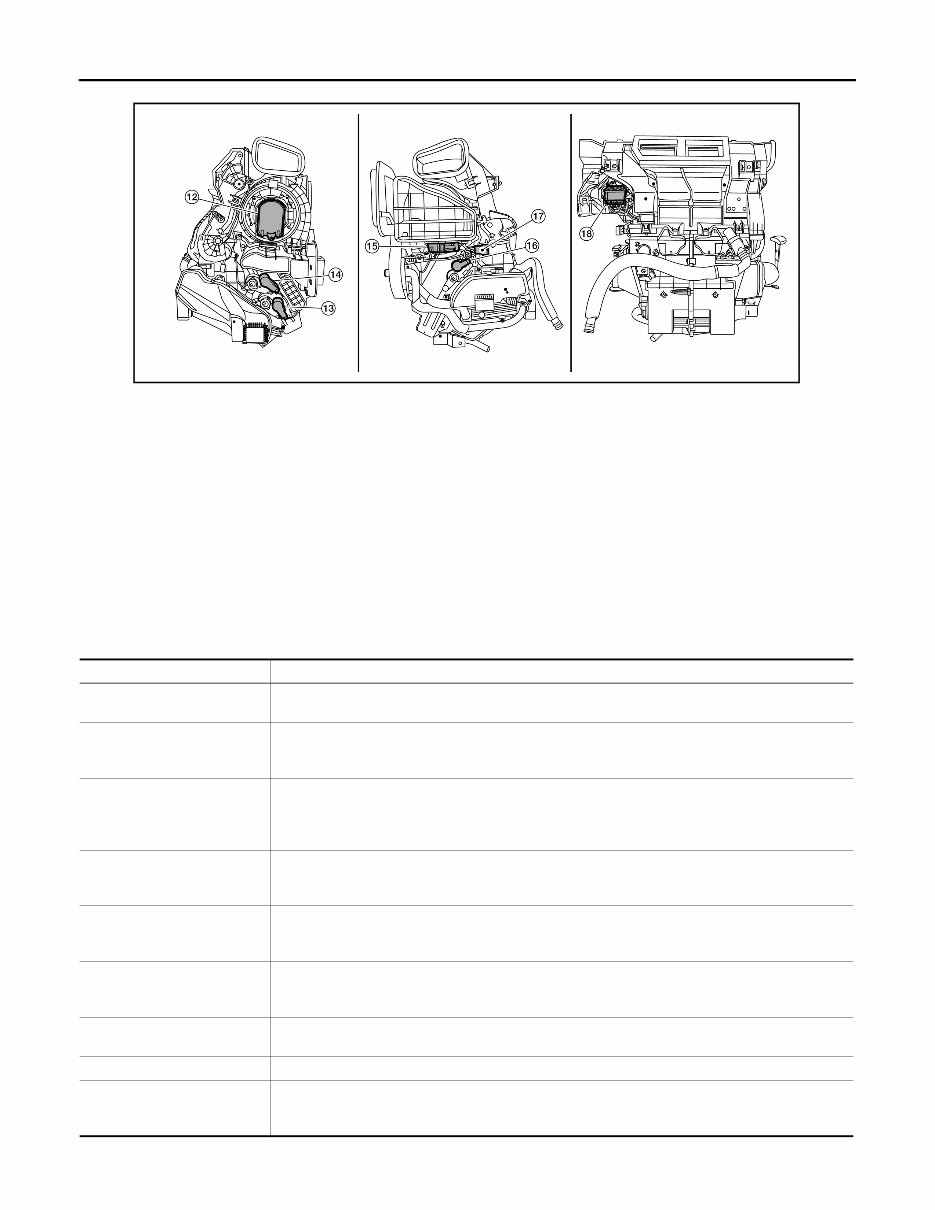

COMPONENT PARTS

Component Description INFOID:0000000011538359

1. ECM 2. IPDM E/R 3. BCM (view with instrument panel re-

moved)

4. A/C auto amp. (view with A/C switch

assembly removed)

5. A/C switch assembly 6. A/C Compressor

7. Refrigerant pressure sensor (view

with front bumper fascia removed)

8. Ambient sensor 9. Sunload sensor

10. In-vehicle sensor 11. Blower motor relay 12. Blower motor (view with front A/C

assembly removed from vehicle)

13. Air mix door motor RH 14. Mode door motor 15. Intake door motor

16. Air mix door motor LH 17. Intake sensor 18. Variable blower control

ALIIA0704ZZ

Component Description

A/C auto amp.

A/C auto amp. controls front automatic air conditioning system by inputting and calculating signals

from each sensor and each switch.

A/C Compressor

Vaporized refrigerant is drawn into the A/C compressor from the evaporator, where it is compressed

to a high pressure, high temperature vapor. The hot, compressed vapor is then discharged to the con-

denser.

A/C switch assembly

The A/C switch assembly controls the operation of the A/C and heating system based on inputs from

the temperature control knob, the mode switches, the blower control dial, the ambient temperature

sensor, the intake sensor, and inputs received from the ECM across the CAN. Diagnosis of the A/C

switch assembly can be performed using the CONSULT.

Air mix door motor LH

The air mix door controls the mix of hot or cold air that enters the ventilation system. It is controlled

by the A/C auto amp. based on the position of the temperature dial. The air mix door motor LH re-

ceives position commands from the A/C auto amp.

Air mix door motor RH

The air mix door controls the mix of hot or cold air that enters the ventilation system. It is controlled

by the A/C auto amp. based on the position of the temperature dial. The air mix door motor RH re-

ceives position commands from the A/C auto amp.

Ambient sensor

The ambient sensor measures the temperature of the air surrounding the vehicle. The sensor uses a

thermistor which is sensitive to the change in temperature. The electrical resistance of the thermistor

decreases as temperature increases.

BCM

The BCM receives the fan ON and A/C ON signals from the A/C auto amp. and sends a compressor

ON request to the ECM.

Blower motor The blower motor varies the speed at which the air flows through the ventilation system.

Blower motor relay

The blower motor relay controls the flow of current to fuse 20, 21 and 22 in the Fuse Block (J/B). The

relay is connected directly to ground, and is energized when the ignition switch is in the ON or START

position.

Revision: December 2014 2015 Sentra NAM

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

Viewed 16 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

This workshop manual contains maintenance and repair procedures for the 2017 Nissan Sentra B17. It also includes a wiring diagram.

Size: 359 MB

Format: .PDF