2005-2011 Mitsubishi Triton Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

00-1

GROUP 00

GENERAL

CONTENTS

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00

GENERAL <ELECTRICAL> . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00E

00-1

GROUP 00

GENERAL

CONTENTS

HOW TO USE THIS MANUAL . . . . . . 00-3

HOW TO USE TROUBLESHOOTING/

INSPECTION SERVICE POINTS. . . . 00-6

CONTENTS OF TROUBLESHOOTING . . . 00-6

DIAGNOSIS FUNCTION. . . . . . . . . . . . . . . 00-8

HOW TO USE THE INSPECTION PROCEDURES

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-9

CONNECTOR MEASUREMENT SERVICE POINTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-12

CONNECTOR INSPECTION SERVICE POINTS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-13

INSPECTION SERVICE POINTS FOR A BLOWN

FUSE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-14

HOW TO COPE WITH INTERMITTENT

MALFUNCTIONS . . . . . . . . . . . . . . . . . . . . 00-14

HOW TO TREAT PAST TROUBLE . . . . . . 00-15

VEHICLE IDENTIFICATION . . . . . . . 00-15

MODELS . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-15

VEHICLE IDENTIFICATION NUMBER (CHASSIS

NUMBER) . . . . . . . . . . . . . . . . . . . . . . . . . . 00-18

VEHICLE INFORMATION CODE PLATE. . 00-19

VEHICLE IDENTIFICATION NUMBER (VIN) PLATE

<VEHICLES FOR RHD> . . . . . . . . . . . . . . . 00-19

MANUFACTURER PLATE . . . . . . . . . . . . . 00-20

ENGINE MODEL STAMPING. . . . . . . . . . . 00-20

GENERAL DATA AND SPECIFICATIONS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-21

GENERAL DATA AND SPECIFICATIONS

<VEHICLES FOR EUROPE> . . . . . . . . . . . 00-21

GENERAL DATA AND SPECIFICATIONS

<VEHICLES FOR RUSSIA (EASTERN EUROPE

COUNTRIES)> . . . . . . . . . . . . . . . . . . . . . . 00-32

GENERAL DATA AND SPECIFICATIONS

<VEHICLES FOR MOROCCO> . . . . . . . . . 00-35

PRECAUTIONS BEFORE SERVICE . 00-36

SERVICING COMMON RAIL ENGINE . . . . 00-36

CAUTIONS FOR AIR CONDITIONER STARITING

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-36

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-37

SERVICING ELECTRICAL SYSTEM . . . . . 00-37

IN ORDER TO PREVENT VEHICLES FROM FIRE

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-37

MULTI USE TESTER (M.U.T.-III) SUB ASSEMBLY

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-38

HOW TO PERFORM CHASSIS NUMBER (Chassis

No.) WRITING . . . . . . . . . . . . . . . . . . . . . . . 00-38

PRE-INSPECTION CONDITION . . . . . . . . . 00-42

ENGINE OILS . . . . . . . . . . . . . . . . . . . . . . . 00-42

WHAT THE COMMON RAIL ENGINE LEARNS

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-43

INJECTOR IDENTIFICATION CODE REGISTRATION

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 00-43

SMALL INJECTION QUANTITY LEARNING

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 00-45

SUPPLY PUMP CORRECTION LEARNING

PROCEDURE . . . . . . . . . . . . . . . . . . . . . . . 00-45

INITIALISATION PROCEDURE FOR LEARNING

VALUE IN DIESEL PARTICULATE FILTER (DPF)

SYSTEM <Euro5> . . . . . . . . . . . . . . . . . . . . 00-46

BATTERY CURRENT SENSOR CALIBRATION

<Euro5> . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-46

HOW TO USE THE THROTTLE CONTROLLER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-47

APPLICATION OF ANTI-CORROSION AGENTS AND

UNDERCOATS . . . . . . . . . . . . . . . . . . . . . . 00-47

VEHICLE WASHING . . . . . . . . . . . . . . . . . . 00-48

PRECAUTIONS FOR INSTALLATION OF ON-

VEHICLE RADIO TRANSMISSION EQUIPMENT

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-48

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-48

00-2

SRS SERVICE PRECAUTIONS . . . . 00-50 SUPPORT LOCATIONS FOR LIFTING AND

JACKING . . . . . . . . . . . . . . . . . . . . . . 00-54

HOW TO USE THIS MANUAL

GENERAL

00-3

HOW TO USE THIS MANUAL

M1001000103302

SCOPE OF MAINTENANCE, REPAIR AND

SERVICING EXPLANATIONS

This manual provides explanations, etc. concerning

procedures for the inspection, maintenance, repair

and servicing of the subject model. Note, however,

that for engine and transmission-related component

parts, this manual covers only on-vehicle inspec-

tions, adjustments, and the removal and installation

procedures for major components. For detailed infor-

mation concerning the inspection, checking, adjust-

ment, disassembly and reassembly of the engine,

transmission and major components after they have

been removed from the vehicle, please refer to sepa-

rate manuals covering the engine and the transmis-

sion.

ON-VEHICLE SERVICE

"On-vehicle Service" is procedures for performing

inspections and adjustments of particularly important

locations with regard to the construction and for

maintenance and servicing, but other inspection (for

looseness, play, cracking, damage, etc.) must also

be performed.

INSPECTION

Under this title are presented inspection and check-

ing procedures to be performed by using special

tools and measuring instruments and by feeling, but,

for actual maintenance and servicing procedures,

visual inspections should always be performed as

well.

DEFINITION OF TERMS

STANDARD VALUE

Indicates the value used as the standard for judging

the quality of a part or assembly on inspection or the

value to which the part or assembly is corrected and

adjusted. It is given by tolerance.

LIMIT

Shows the standard for judging the quality of a part

or assembly on inspection and means the maximum

or minimum value within which the part or assembly

must be kept functionally or in strength. It is a value

established outside the range of standard value.

REFERENCE VALUE

Indicates the adjustment value prior to starting the

work (presented in order to facilitate assembly and

adjustment procedures, and so they can be com-

pleted in a shorter time).

DANGER, WARNING, AND CAUTION

DANGER, WARNING, and CAUTION call special

attention to a necessary action or to an action that

must be avoided. The differences among DANGER,

WARNING, and CAUTION are as follows:

• If a DANGER is not followed, the result is severe

bodily harm or even death.

• If a WARNING is not followed, the result could be

bodily injury.

• If a CAUTION is not followed, the result could be

damage to the vehicle, vehicle components or

service equipment.

INDICATION OF TIGHTENING TORQUE

Tightening torques (units: N⋅m) are set to take into

account the central value and the allowable toler-

ance. The central value is the target value, and the

allowable tolerance provides the checking range for

tightening torques. If bolts and nuts are not provided

with tightening torques.

MODEL INDICATIONS

The following abbreviations are used in this manual

for identification of model types.

2500:Indicates an engine with the 2,477mL <4D56>

diesel engine.

2WD:Indicates the 2-wheel drive vehicles.

4WD:Indicates the 4-wheel drive vehicles.

A/C:Indicates the air conditioner.

A/T:Indicates the automatic transmission.

DOHC: Indicates an engine with the double over-

head camshaft.

M/T:Indicates the manual transmission.

HOW TO USE THIS MANUAL

GENERAL

00-4

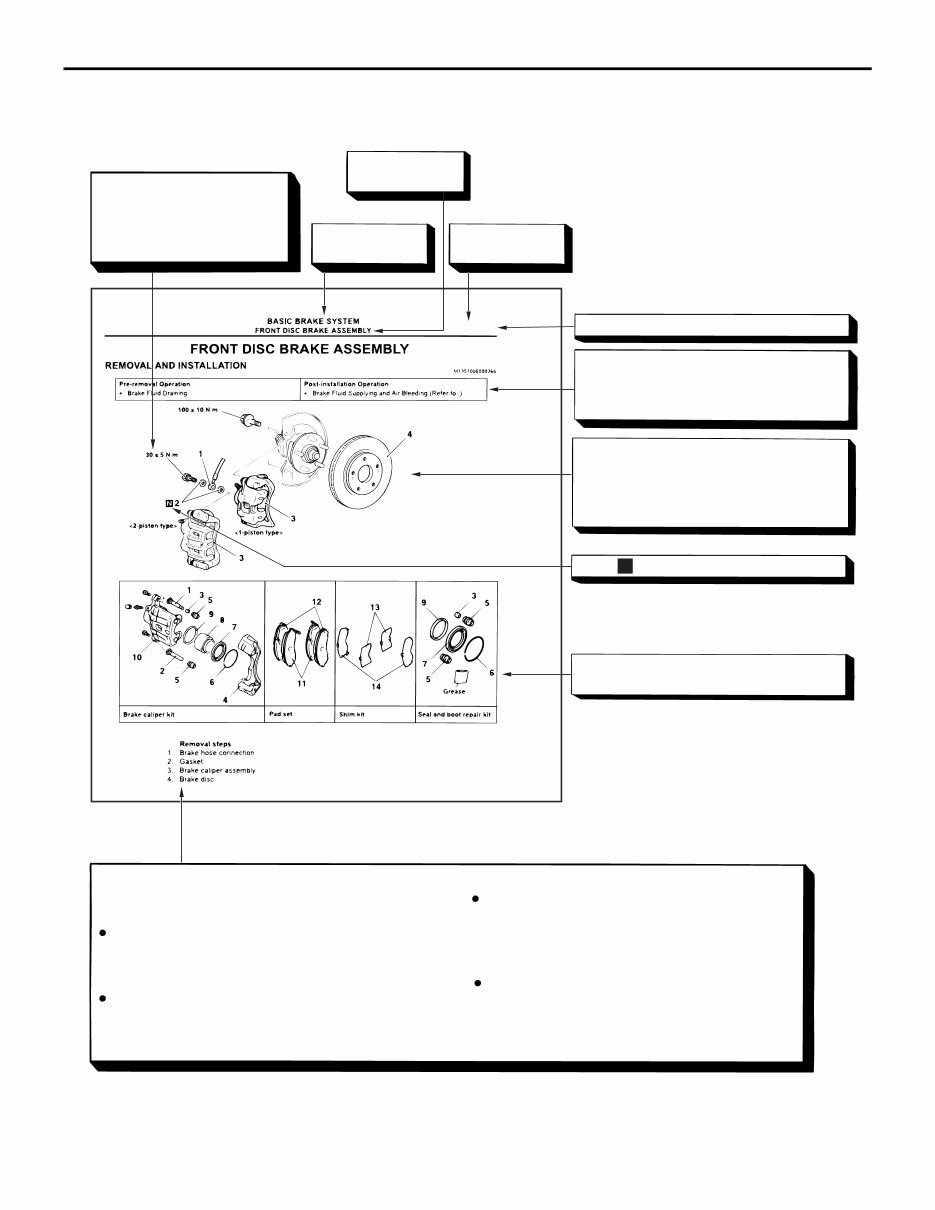

EXPLANATION OF MANUAL CONTENTS

AC311238

N

Denotes tightening torque.

For bolts and nuts which do

not have a tightening torque

listed, refer to the "Standard

Parts tightening-torque Table"

Indicates the

group title.

Indicates the

section title.

Indicates the

group number.

Indicates the page number.

Indicates procedures to be performed be-

fore the work in that section is started, and

procedures to be performed after the work

in that section is finished.

Component diagram

A diagram of the component parts is pro-

vided near the front of each section in order

to give the reader a better understanding of

the installed condition of component parts.

Mark denotes nonreusable part.

Repair kit or parts sets are shown.

(Only very frequently used parts are shown.)

Removal steps :

The part designation number corresponds to

the number in the illustration to indicate remov-

al steps.

Disassembly steps :

The part designation number corresponds to

the number in the illustration to indicate disas-

sembly steps.

Installation steps :

Specified in case installation is impossible in

reverse order of removal steps. Omitted if

installation is possible in reverse order of re-

moval steps.

Reassembly steps :

Specified in case installation is impossible in

reverse order of removal steps. Omitted if

reassembly is possible in reverse order of dis-

assembly steps.

Maintenance and servicing procedures

The numbers provided within the diagram indicate the

sequence for maintenance and servicing procedures.

AE

>>A<<

>>B<<

35A-19

AC509265

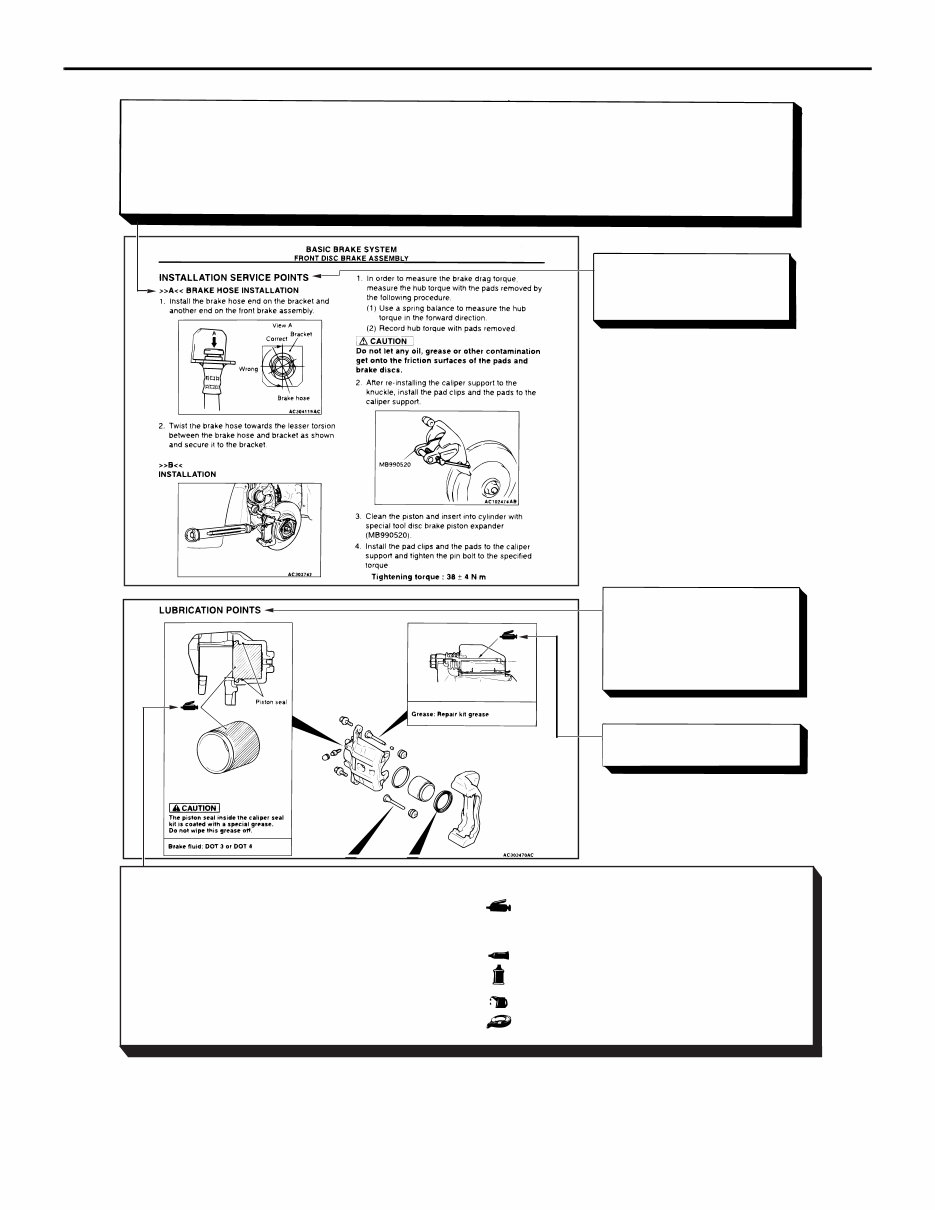

Classifications of major maintenance / service points

When there are major points relative to maintenance and servicing procedures (such as essential maintenance

and service points, maintenance and service standard values, information regarding the use of special tools, etc.).

These are arranged together as major maintenance and service points and explained in detail.

<<A>> : Indicates that there are essential points for removal or disassembly.

>>A<< : Indicates that there are essential points for installation or reassembly.

Operating procedures,

cautions, etc. on removal,

installation, disassembly and

reassembly are described

The title of the page

(following the page on which

the diagram of component

parts is presented) indicating

the locations of lubrication and

sealing procedures.

Indicates (by symbols) where

lubrication is necessary.

AF

BRAKE CALIPER ASSEMBLY

35A-21

Symbols for lubrication, sealants and adhesives

Symbols are used to show the locations for lubrication

and for application of sealants and adhesives.

These symbols are included in the diagram of compo-

nent parts or on the page following the component

parts page. The symbols do not always have accomp-

anying text to support that symbol.

: Grease

(Multi-purpose grease unless there is a brand

or type specified)

: Sealant or adhesive

: Automatic transmission fluid, brake fluid, power

steering fluid or air conditioning compressor oil

: Engine oil or gear oil

: Adhesive tape or butyl rubber tape

HOW TO USE THIS MANUAL

GENERAL

00-5

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE POINTS

GENERAL

00-6

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE

POINTS

CONTENTS OF TROUBLESHOOTING

M1001013300794

CAUTION

During diagnosis, a diagnosis code associated

with other system may be set when the ignition

switch is turned on with connector(s) discon-

nected. On completion, confirm all systems for

diagnosis code(s). If diagnosis code(s) are set,

erase them all.

WARNING

Since the radiator fan rotates during CAN

bus line diagnostics, make sure that no one

is servicing the engine compartment before

diagnosing the CAN bus line. Since the CAN

communication stops when diagnosing the

CAN bus line, the ETACS-ECU detects the

time-out of the engine-ECU, and activates

the radiator fan to prevent overheating as

fail-safe.

Troubleshooting of electronic control systems for

which the M.U.T.-III can be used follows the basic

outline described below. Even in systems for which

the M.U.T.-III cannot be used, some of these sys-

tems still follow this outline.

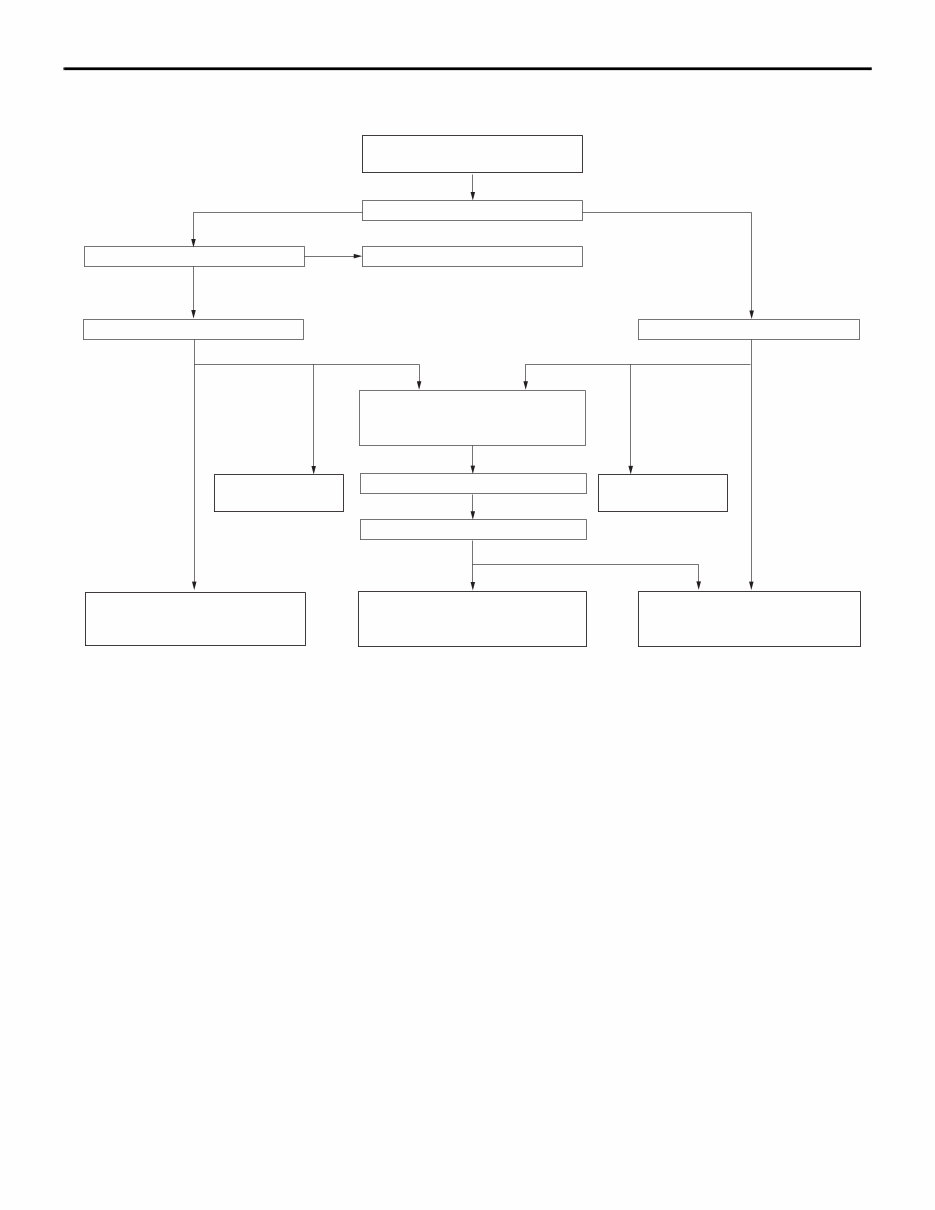

1. STANDARD FLOW OF DIAGNOSIS TROUBLESHOOTING

Troubleshooting sections are based on the diagnostic flow as below. If the diagnostic flow is different from

that given below, or if additional explanation is required, the details of such differences or additions will also

be listed.

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE POINTS

GENERAL

00-7

Diagnosis method

AC501888

Gathering information

from the customer.

Check trouble symptom.

Reoccurs

Does not reoccur

CAN bus diagnosis chart* CAN bus diagnosis*

Read the diagnosis code. Read the diagnosis code.

After taking note of the

malfunction code, erase the

diagnosis code memory.

Recheck trouble symptom.

Read the diagnosis codes.

How to treat past

trouble*

Refer to the INSPECTION CHART

FOR DIAGNOSIS CODES

(Refer to applicable group).

How to treat past

trouble*

Refer to the INSPECTION CHART

FOR TROUBLE SYMPTOMS

(Refer to applicable group).

INTERMITTENT MALFUNCTIONS*

Diagnosis code

displayed.

(Current trouble)*

Diagnosis code

displayed.

(Current trouble)*

No diagnosis

code.

No diagnosis

code.

Diagnosis code

displayed.

(Past trouble)*

Diagnosis code

displayed.

(Past trouble)*

No diagnosis code

or communication

with M.U.T.-III not

possible

Diagnosis code

displayed.

OK

NG

2 1

3

3 3

3

4

4

5

• *

1

: For how to diagnose CAN bus lines, refer to GROUP 54C .

• *

2

: For the CAN bus diagnosis chart, refer to GROUP 54C .

• *

3

: When the M.U.T.-III detects a diagnosis code, its display informs users whether a mechanical problem

currently exists or whether it existed before. The message for the former state identifies it as a "Active"

and the message for the latter identifies it as a "Stored".

• *

4

: For how to treat past trouble, refer to P.00-15.

• *

5

: For how to cope with intermittent malfunctions, refer to P.00-14.

2. SYSTEM OPERATION AND SYMPTOM

VERIFICATION TESTS

If verification of the symptom(s) is difficult, proce-

dures for checking operation and verifying symptoms

are shown.

3. DIAGNOSIS FUNCTION

Details specific to individual systems are described.

4. DIAGNOSIS CODE CHART

Diagnosis codes and diagnostic items are shown.

5. DIAGNOSIS CODE PROCEDURES

Indicates the inspection procedures corresponding to

each diagnosis code (Refer to How to Use Inspection

Procedures P.00-9).

6. TROUBLE SYMPTOM CHART

If there are trouble symptoms even though the

M.U.T.-III does not find any diagnosis codes, Inspec-

tion procedures for each trouble symptom will be

found by means of this chart.

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE POINTS

GENERAL

00-8

7. SYMPTOM PROCEDURES

Indicates the inspection procedures corresponding to

each symptoms classified in the Symptom Chart

(Refer to How to Use Inspection Procedures P.00-9).

8. SERVICE DATA REFERENCE TABLE

Inspection items and normal judgment values have

been provided in this chart as reference information.

9. ACTUATOR TEST TABLE

The Actuator Test item numbers, inspection items,

and judgment values have been provided in this

chart as reference information.

10. CHECK AT ECU TERMINALS

Terminal numbers for the ECU connectors, inspec-

tion items, and judgment values have been provided

in this chart as reference information.

11. INSPECTION PROCEDURE BY USING

AN OSCILLOSCOPE

When there are inspection procedures using an

oscilloscope, these are described here.

DIAGNOSIS FUNCTION

M1001013400865

The diagnosis function retrieves diagnosis code and

service data by M.U.T.-III and enables the perform-

ance of the actuator test.

• DIAGNOSIS CODE

• Service data sent

• Actuator test

• Diagnosis deletion using M.U.T.-III

• Freeze frame data

• Status indication by diagnosis code

• ECU information display

NOTE: If a diagnosis code is set, the "status indica-

tion by diagnosis code" informs users whether a

mechanical problem currently exists (current trouble)

or whether it existed before but normal operation has

been restored (past trouble).

HOW TO READ DIAGNOSIS CODE

CAUTION

Before connecting or disconnecting the M.U.T.-

III, turn the ignition switch to the "LOCK" (OFF)

position.

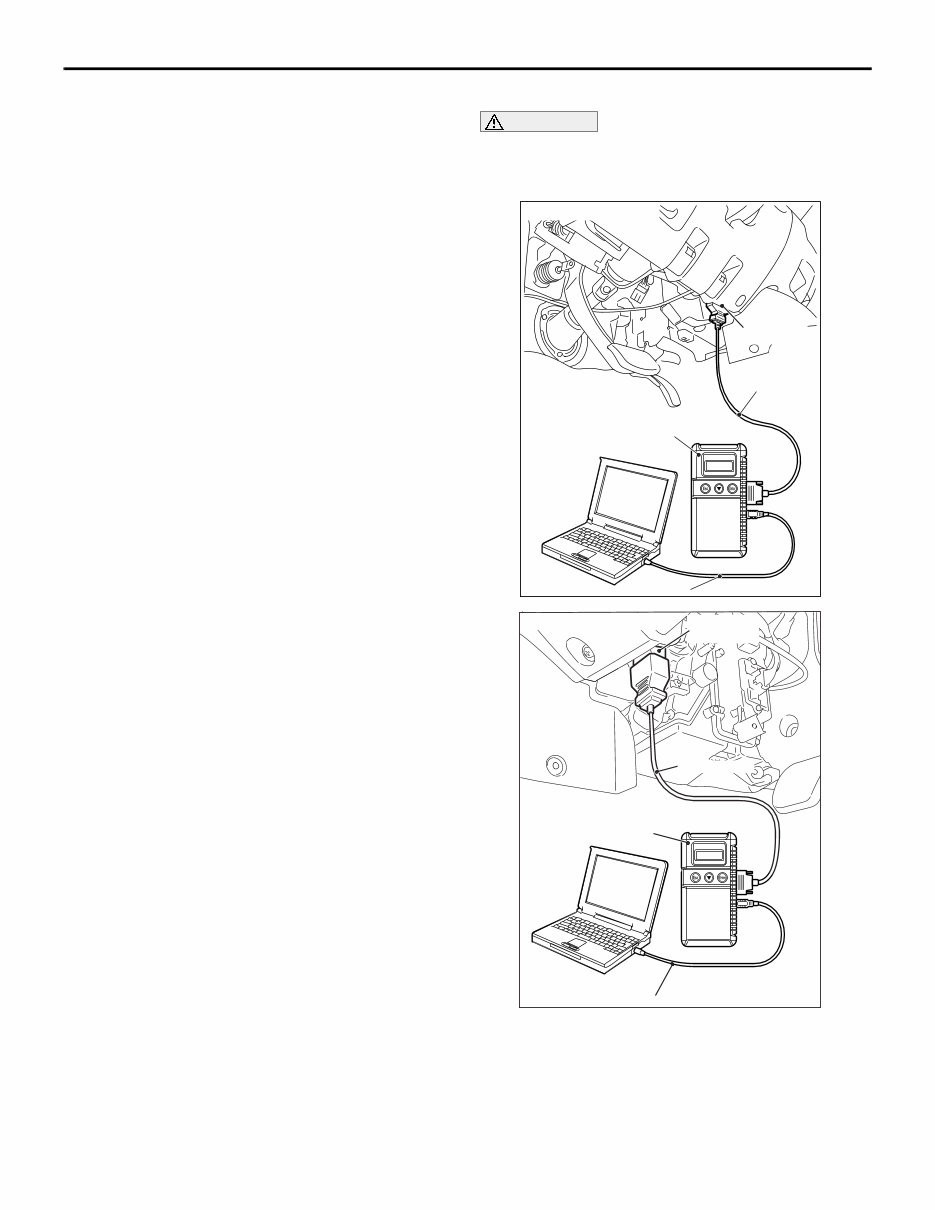

AC509179 AB

Diagnosis

connector

MB991827

MB991824

MB991910

<LH drive vehicles>

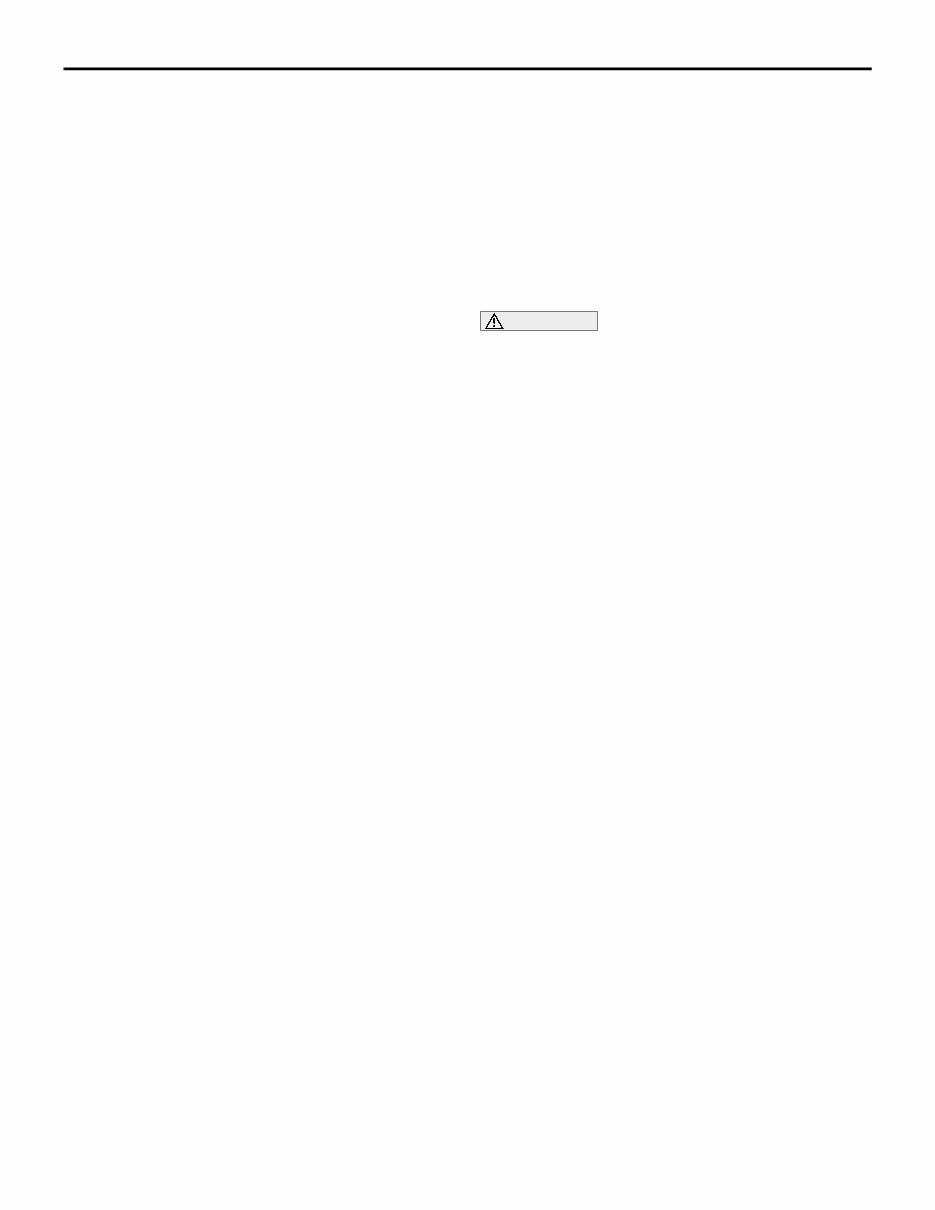

AC501413AC

Diagnosis

connector

MB991827

MB991824

MB991910

<RH drive vehicles>

Connect the M.U.T.-III to the 16-pin diagnosis con-

nector, and read the diagnosis code.

NOTE: For details on how to use the M.U.T.-III, refer

to the "M.U.T.-III operation manual."

1. Ensure that the ignition switch is at the "LOCK"

(OFF) position.

2. Start up the personal computer.

HOW TO USE TROUBLESHOOTING/INSPECTION SERVICE POINTS

GENERAL

00-9

3. Connect special tool M.U.T.-III USB cable

MB991827 to V.C.I. (MB991824) and the personal

computer.

4. Connect special tool M.U.T.-III main harness A

(MB991910) to the V.C.I.

5. Connect the M.U.T.-III main harness A to the

diagnosis connector of the vehicle.

6. Turn the V.C.I. power switch to the "ON" position.

NOTE: When the V.C.I. is energized, the V.C.I.

indicator lamp will be illuminated in a green col-

our.

7. Start the M.U.T.-III system on the personal

computer and turn the ignition switch to the "ON"

position.

8. Read the diagnosis code.

NOTE: When storing the diagnosis code as refer-

ence information, the freeze frame data obtains the

data when the diagnosis code is confirmed, and then

stores the ECU status of that time. By analysing

each data using M.U.T.-III, troubleshooting can be

carried out efficiently.

9. Disconnecting the M.U.T.-III is the reverse of the

connecting sequence, making sure that the

ignition switch is at the "LOCK" (OFF) position.

ERASING DIAGNOSIS CODE

CAUTION

Before connecting or disconnecting the M.U.T.-

III, turn the ignition switch to the "LOCK" (OFF)

position.

Connect the M.U.T.-III to the diagnosis connector,

and erase the diagnosis code. The procedure is the

same as "How to Read Diagnosis Code ."

HOW TO USE THE INSPECTION

PROCEDURES

M1001013500345

The causes of many of the problems occurring in electric circuitry are generally the connectors, components,

the ECU, the wiring harnesses between connectors, in that order. These inspection procedures follow this

order. They first try to discover a problem with a connector or a defective component.

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 95 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get instant access to the Complete Factory Service Repair Workshop Manual without any extra fees or expiry dates. This Professional Manual is suitable for both professional Mechanics and Technicians, as well as DIY enthusiasts. It covers all repairs, servicing, and troubleshooting procedures with detailed photos, diagrams, step-by-step instructions, and highly detailed exploded diagrams & pictures to ensure every job is completed correctly.

Print out a single page or the entire manual as per your choice. This Manual can be used on multiple computers without any limitations or trial periods, and it does not expire or require any renewal fees. It is fully compatible with all Windows & MAC Computers.