1999-2006 Mitsubishi Pajero NM Service & Repair Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

DIESEL FUEL

<4D5-STEP III>

Click on the applicable bookmark to selected the required model year.

13E-1

DIESEL FUEL

<4D5-STEP III>

CONTENTS

GENERAL 2 .................................

Outline of Change 2 ............................

GENERAL INFORMATION 2 ...................

SERVICE SPECIFICATIONS 4 .................

SEALANT 4 ..................................

SPECIAL TOOLS 5 ...........................

TROUBLESHOOTING 6 .......................

ON-VEHICLE SERVICE 55 ....................

Injection Nozzle Check and Adjustment 55 .........

Injection Timing Check and Adjustment 55 .........

Idle Speed Check and Adjustment 55 .............

Accelerator Pedal Position Sensor (APS)

Adjustment 56 .................................

Control Relay Continuity Check 57 ................

Accelerator Pedal Position Sensor (APS)

Check 57 ......................................

Idle Switch Check 58 ............................

Boost Air Temperature Sensor (Intake Air

Temperature Sensor) Check 58 ..................

Engine Coolant Temperature Sensor Check 59 .....

Evacuation of Water from Fuel Filter 59 ............

Fuel Filter Cartridge Replacement 60 ..............

Evacuation of Air from Fuel Line 60 ...............

EGR Valve Position Sensor Check 60 .............

Fuel Injection Pump Check 61 ....................

Throttle Solenoid Valve Check 62 .................

Throttle Actuator Check 63 ......................

Variable Geometry Solenoid Valve Check 63 .......

EGR Control Solenoid Valve Check 63 ............

FUEL INJECTION NOZZLE 64 .................

FUEL INJECTION PUMP 64 ...................

CRANKSHAFT POSITION SENSOR 66 .........

ENGINE-ECU 66 .............................

DIESEL FUEL <4D5-step III>- General/General Information 13E-2

GENERAL

OUTLINE OF CHANGE

An electronically-controlled injection pump has been added in order to comply with Regulation STEP

III. Due to this, the following service procedures have been added.

GENERAL INFORMATION

The electronically-controlled fuel injection system consists of sensors which detect the condition of the

diesel engine, an engine-ECU which controls the system based on signals from these sensors, and actuators

which operate according to control commands from the engine-ECU.

The engine-ECU carries out operations such as fuel injection rate control, fuel injection timing control

and idle up control. In addition, the engine-ECU is equipped with several self-diagnosis functions which

make troubleshooting easier in the event that a problem develops.

FUEL INJECTION RATE CONTROL

The fuel injection completion timing is controlled by means of a solenoid-type spill valve to ensure that

the optimum amount of fuel is supplied to the engine in accordance with gradual changes in the engine

running condition.

Before fuel injection starts, the solenoid-type spill valve is on (energized), so that the valve is closed.

As the plunger turns and rises, fuel is sent out under pressure, and when the fuel flow rate reaches

the target value for fuel injection, the solenoid-type spill valve turns off. When the solenoid-type spill

valve turns off, the fuel under high pressure inside the plunger is leaked out into the pump chamber

and fuel injection is completed.

FUEL INJECTION TIMING CONTROL

The position of the injection pump timer piston is controlled so that fuel injection is carried out at the

optimum timing in accordance with the engine running condition.

The timer piston position is determined by duty control of the timing control solenoid valve which is located

in the line between the high-pressure chamber and the low-pressure chamber of the timer piston.

The fuel injection timing is advanced by increasing the control duty of the timing control solenoid valve.

IDLE SPEED CONTROL

Controlling the fuel injection rate in accordance with the engine running condition maintains the idle speed

at the optimum condition.

SELF-DIAGNOSIS FUNCTION

D When an abnormality is detected in any of the sensors or actuators, the engine warning lamp illuminates

to warn the driver.

D When an abnormality is detected in any of the sensors or actuators, a diagnosis code number

corresponding to the problem which occurred is output.

D The RAM data relating to the sensors and actuators which is stored in the engine-ECU can be read

using the MUT-II. In addition, the actuators can be force-driven under certain conditions.

OTHER CONTROL FUNCTIONS

1. Power Supply Control

When the ignition switch is turned to ON, the relay turns on and power is supplied to components

such as the timing control solenoid valve.

2. Intake Air Throttle Control

When the engine-ECU detects an abnormality in any of the sensors or actuators, the throttle valve

is half opened to restrict the amount of intake air in order to prevent the vehicle from running away.

3. A/C Relay Control

Turns the compressor clutch of the A/C ON and OFF

4. Condenser Fan Motor Relay Control

Controls the condenser fan motor relay based on the A/C switch, engine coolant temperature and

vehicle speed input signals.

5. Glow Control

Refer to GROUP 16.

6. EGR Control

Refer to GROUP 17.

DIESEL FUEL <4D5-step III>- General Information 13E-3

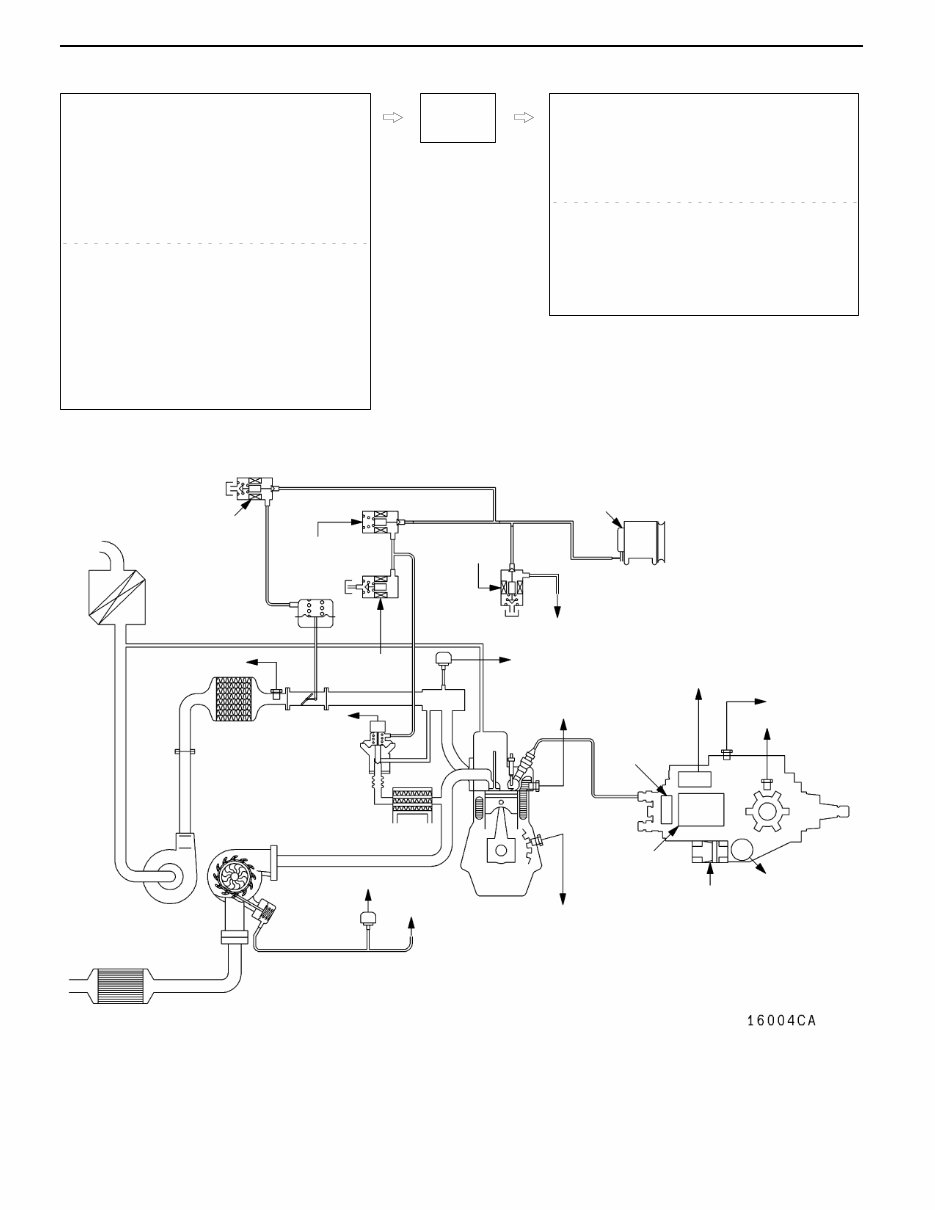

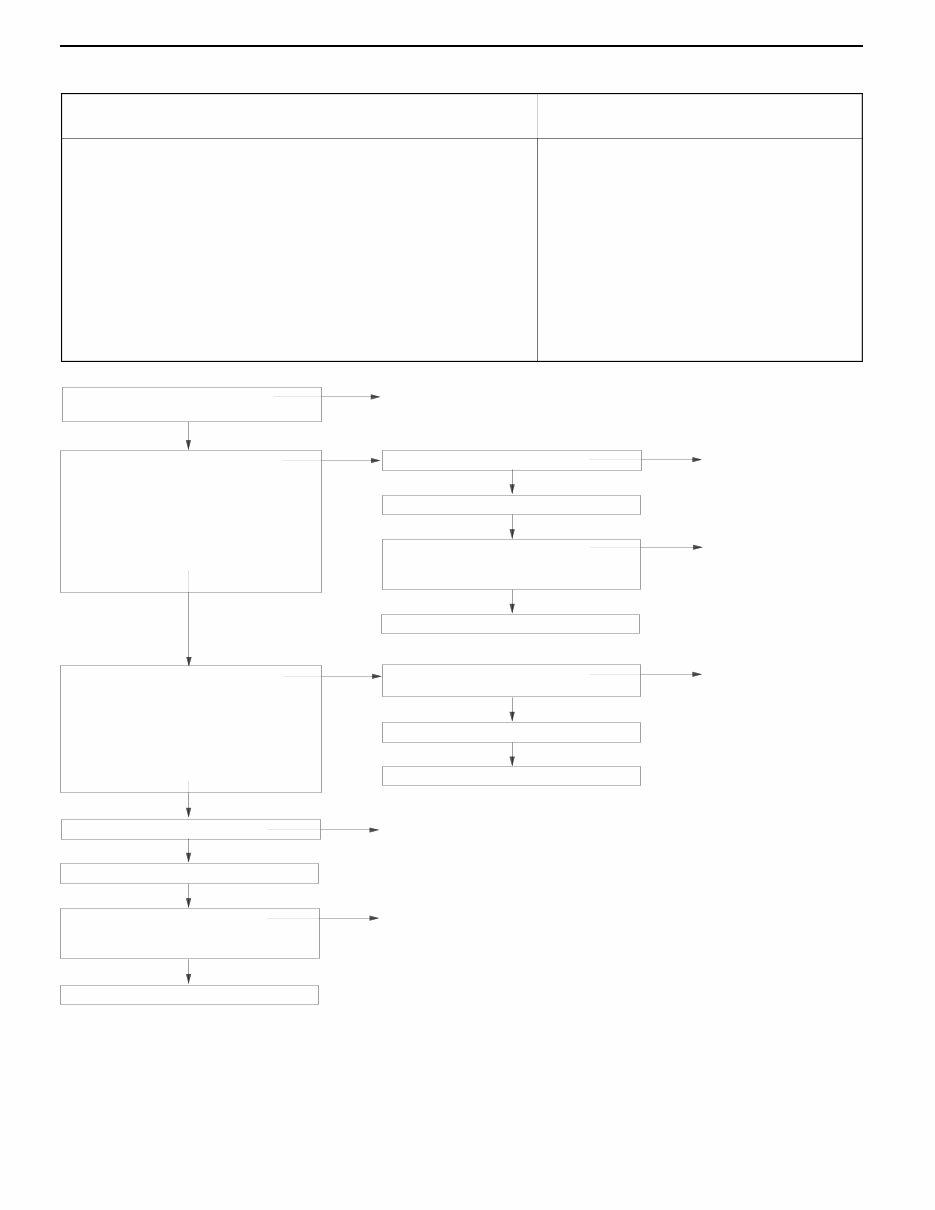

CONTROL SYSTEM DIAGRAM

L1. Pump speed sensor

L2. Crank angle sensor

L3. Engine coolant temperature sensor

L4. Boost pressure sensor

L5. Fuel temperature sensor

L6. Boost air temperature sensor

L7. Control sleeve position sensor

L8. Timer piston position sensor

L9. EGR valve position sensor

L10. Variable geometry control pressure sensor

D Accelerator pedal position sensor (main)

D Accelerator pedal position sensor (sub)

D Idle switch

D Power supply

D Ignition switch-IG

D Ignition switch-ST

D Vehicle speed sensor

D A/C switch

D A/C relay switch

D Injection volume adjusting ROM

D Barometric pressure sensor (ECU built-in)

l1. GE actuator (electronic governor)

l2. Timing control valve

l3. EGR control solenoid valve No. 1

l4. EGR control solenoid valve No. 2

l5. Throttle solenoid valve

l6. Fuel cut solenoid valve

l7. Variable geometry solenoid valve

D Control relay

D A/C relay

D Condenser fan relay

D Glow indicator lamp

D Glow plug relay

D Engine warning lamp

D Diagnosis output

Engine-

ECU

L8 Timer piston

position

sensor

L2 Crank angle

sensor

L9 EGR

valve position

sensor

L10 Variable geometry control

pressure sensor

L6 Boost air

temperature sensor

L4 Boost pressure

sensor

L3 Engine coolant

temperature sensor

L7 Control

sleeve

position

sensor

l7

Variable geometry

solenoid valve

l3

EGR control

solenoid valve No. 1

l1 GE actuator

l5 Throttle solenoid valve

l6 Fuel cut

solenoid

valve

Vacuum pump

Alternator

To variable

geometry actuator

l2 Timing control

valve

Catalytic converter

Variable

geometry

actuator

Variable geometry

turbocharger

Throttle

actuator

EGR valve

To variable geome-

try solenoid valve

L1 Pump speed

sensor

L5 Fuel

temperature

sensor

l4 EGR control

solenoid

valve No. 2

DIESEL FUEL <4D5-step III>- Service Specifications/Sealant 13E-4

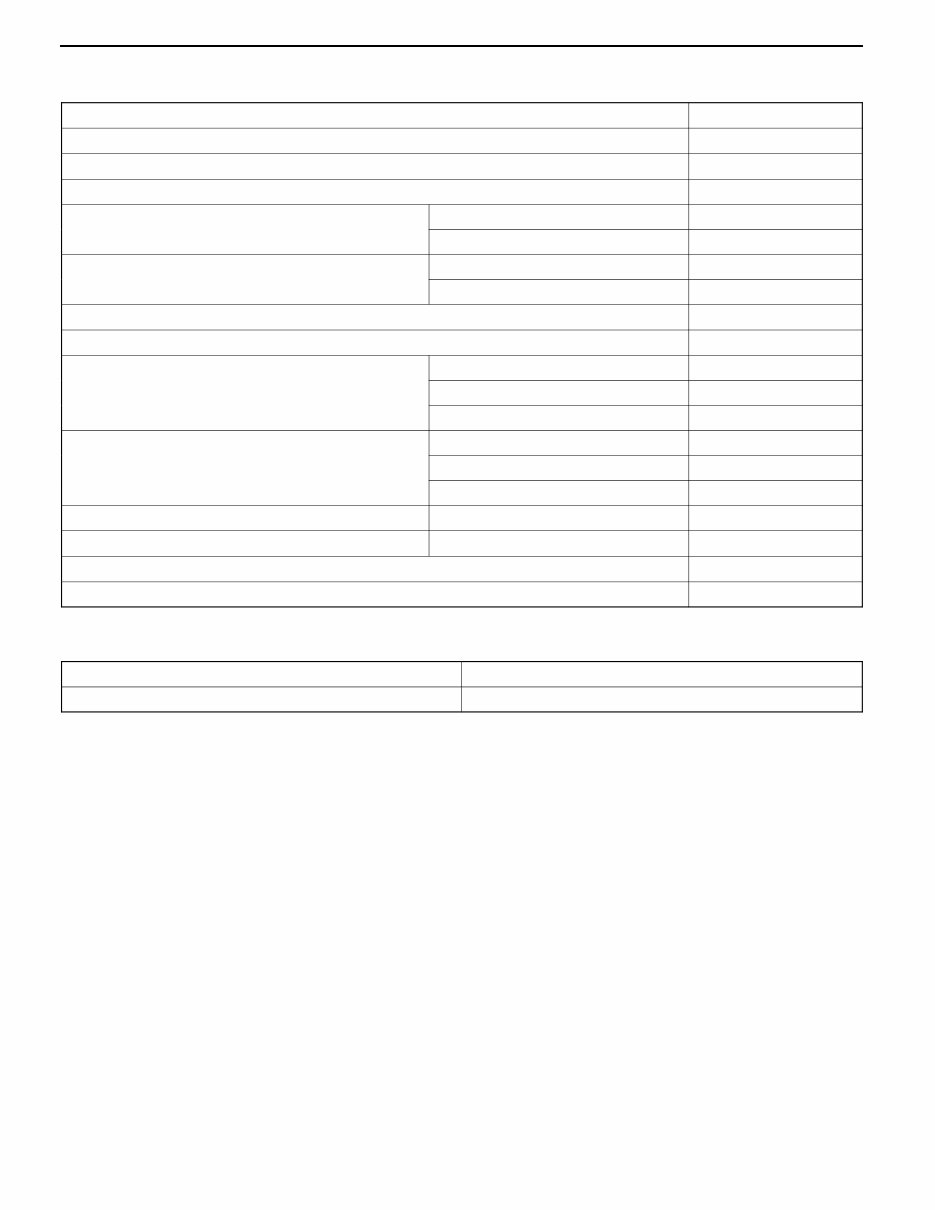

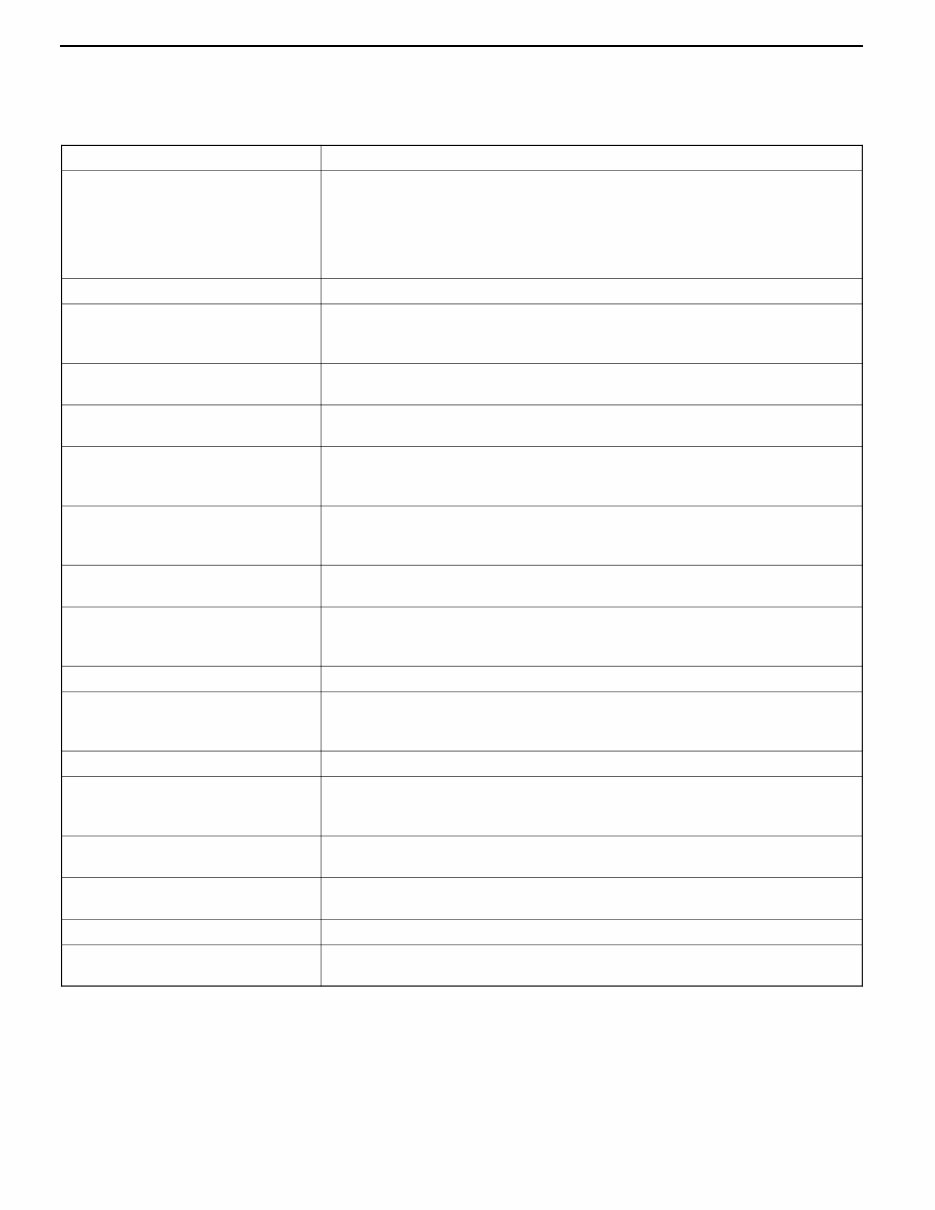

SERVICE SPECIFICATIONS

Item Standard value

Fuel injection initial pressure kPa 14,710 - 15,490

Accelerator pedal position sensor reference voltage V 0.985 - 1.085

Accelerator pedal position sensor resistance kΩ 3.5 - 6.5

Boost air temperature sensor (Intake air temperature

) it kΩ

When the temperature is 20_C 2.3 - 3.0

sensor) resistance kΩ

When the temperature is 80_C 0.30 - 0.42

Engine coolant temperature sensor resistance kΩ When the temperature is 20_C 2.1 - 2.7

When the temperature is 80_C 0.26 - 0.36

Fuel cut solenoid valve resistance Ω 6.8 - 9.2

Timing control valve resistance Ω 10.8 - 11.2

Timer piston position sensor resistance Ω Connector terminals No. 1 - No. 2 160 - 168

Connector terminals No. 1 - No. 3 80 - 84

Connector terminals No. 2 - No. 3 80 - 84

Control sleeve position sensor resistance Ω Connector terminals No. 4 - No. 12 11.2 - 12.4

Connector terminals No. 4 - No. 8 5.6 - 6.2

Connector terminals No. 8 - No. 12 5.6 - 6.2

GE actuator (electronic governor) resistance Ω Connector terminals No. 6 - No. 10 0.64 - 0.72

Fuel temperature sensor resistance kΩ Connector terminals No. 7 - No. 11 1.4 - 2.6

Pump speed sensor resistance kΩ 1.36 - 1.84

Throttle solenoid valve resistance Ω 36 - 44

SEALANT

Item Specified sealant

Engine coolant temperature sensor 3M Nut Locking Part No. 4171 or equivalent

DIESEL FUEL <4D5-step III>- Special Tools 13E-5

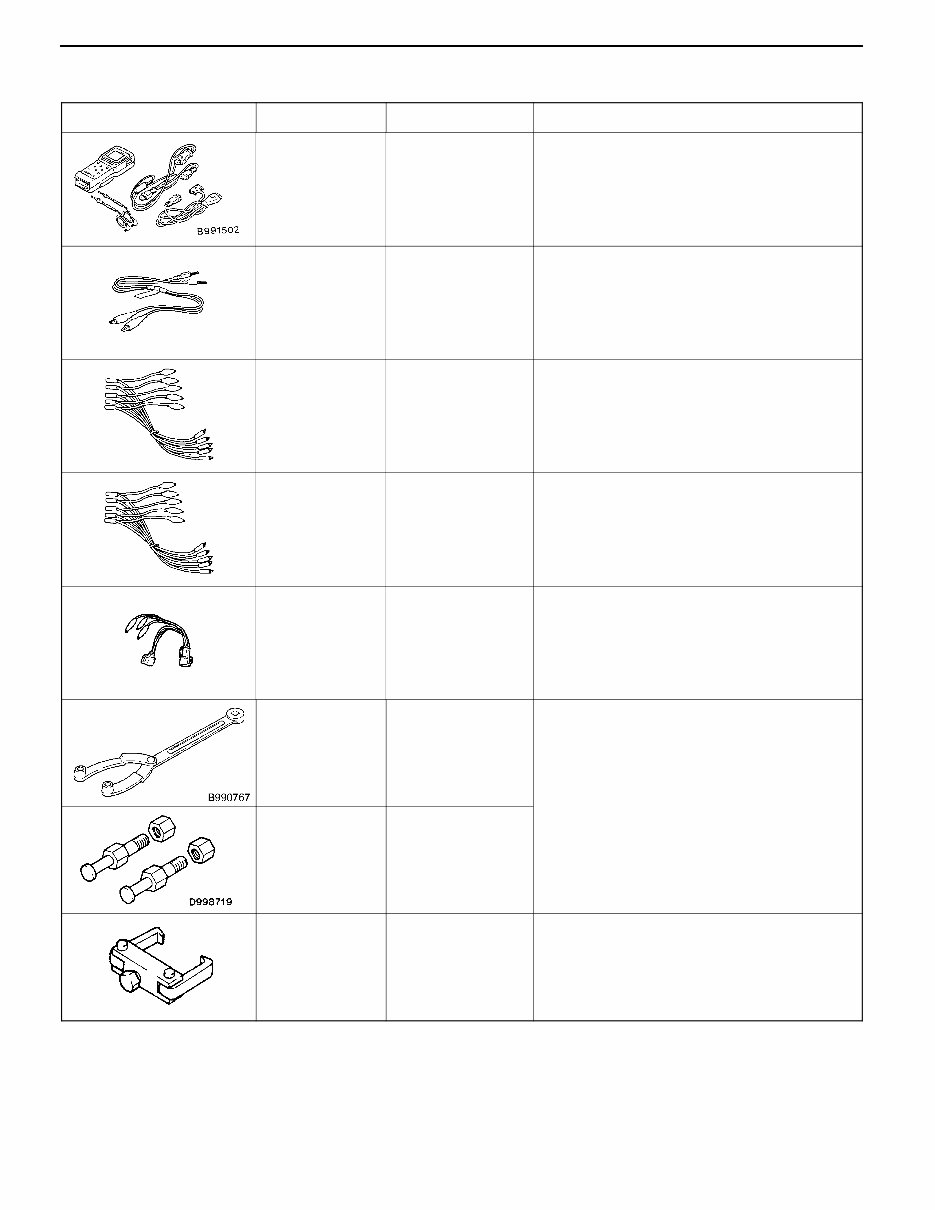

SPECIAL TOOLS

Tools Number Name Application

MB991502 MUT-II sub

assembly

Electronically controlled fuel injection system

check

MB991529 Diagnosis code

check harness

Diagnosis code reading

MB991348 Test harness set D Boost pressure sensor check

D Variable geometry control pressure sensor

check

MB991658 Test harness set D APS adjustment

D Inspection using an analyzer

MD998478 Test harness

(3-pin, square)

D Crank angle sensor check

D Inspection using an analyzer

MB990767 End yoke holder Holding the fuel injection pump sprocket

MD998719 Crankshaft pulley

holder pin

MD998388 Injection pump

sprocket puller

Fuel injection pump sprocket removal

DIESEL FUEL <4D5-step III>- Troubleshooting 13E-6

TROUBLESHOOTING

STANDARD FLOW OF DIAGNOSTIC

TROUBLESHOOTING

Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points.

NOTE

When replacing the engine-ECU, replace immobilizer-ECU

and ignition key as well at the same time.

DIAGNOSIS FUNCTION

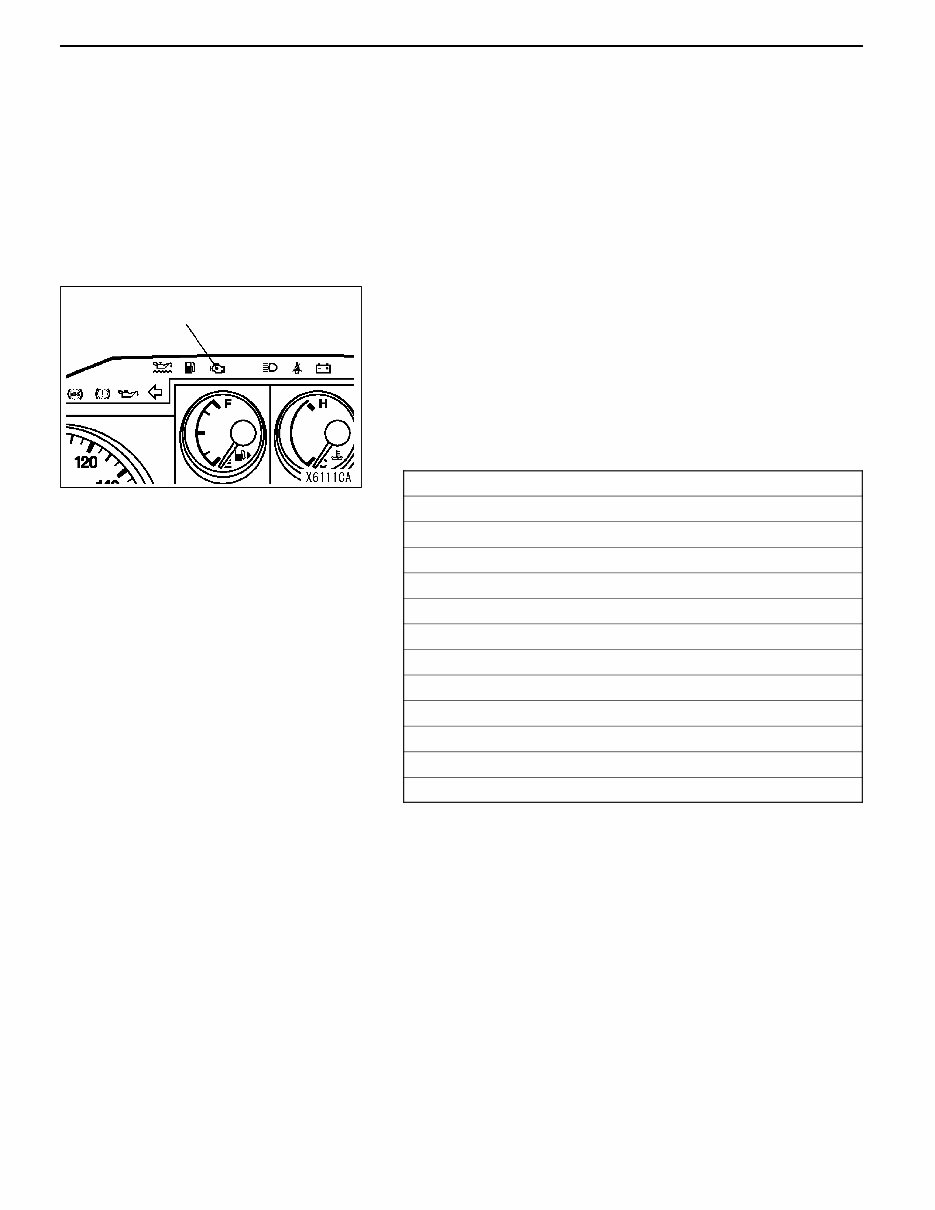

ENGINE WARNING LAMP (CHECK ENGINE LAMP)

Engine warning lamp is lit when any abnormality takes place

in the item related to electronically controlled fuel injection

system shown in the following table.

If the malfunction indicator lamp has been on and/or is lit

when the engine is in operation, check the diagnosis output.

Engine warning lamp check items

Accelerator pedal position sensor (main)

Accelerator pedal position sensor (sub)

Boost pressure sensor (Boost sensor)

Crank angle sensor

Control sleeve position sensor

Timer piston position sensor

Throttle solenoid valve

GE actuator

Variable geometry control pressure sensor

Barometric pressure sensor

Timing control valve

Idle switch

Engine-ECU

METHOD OF ERASING AND ERASING DIAGNOSIS

CODES

Refer to GROUP 00 - How to Use Troubleshooting/Inspection

Service Points.

INSPECTION USING MUT -II DATA LIST AND

ACTUATOR TESTING

1. Carry out inspection by means of the data list and the

actuator test function.

If there is an abnormality, check and repair the chassis

harnesses and components.

2. After repairing, re-check using MUT-II and check that

the abnormal input and output have returned to normal

as a result of the repairs.

3. Erase the diagnosis code memory.

4. Remove the MUT-II.

5. Start the engine again and carry out a road test to confirm

that the problem has disappeared.

Engine warning lamp

(check engine lamp)

DIESEL FUEL <4D5-step III>- Troubleshooting 13E-7

FAIL-SAFE, BACKUP FUNCTIONS

When abnormalities in the major sensors are detected by diagnosis functions, pre-set control logic operates

to maintain a safe driving condition for the vehicle.

Diagnosis item Control features in malfunction

Accelerator pedal position sensor D Accelerator pedal released (idle switch ON)

Acceleration opening degree = 0 %

D Accelerator pedal applied (idle switch OFF)

Engine controlled at low speed

Acceleration opening degree = 30 % fixed

D Void EGR control

Idle switch Void idling speed control.

Engine speed sensor D Engine controlled at low speed

D Void EGR control

D Void variable geometry turbocharger control

Boost air temperature sensor D Maintain the intake air temperature at 50_C.

D Void EGR control

Vehicle speed sensor D Void idling speed control.

D Void EGR control

Engine coolant temperature sensor D Maintain the engine coolant temperature at 80_C (However, the system

assumes the coolant temperature as 0_C).

D Void EGR control

Control sleeve position sensor D Engine controlled at low speed

D Void EGR control

D Void variable geometry turbocharger control

Timer piston position sensor D Injection timing stabilizing control

D Void EGR control

Barometric pressure sensor (ECU

built-in)

D Keep the barometric pressure at 101 kPa.

D Void EGR control

D Void variable geometry turbocharger control

Fuel temperature sensor Maintain the fuel temperature at 40_C.

Boost pressure sensor D Keep the boost pressure as barometric pressure (101 kPa).

D Void EGR control

D Void variable geometry turbocharger control

Injection volume adjusting ROM Void correction.

GE actuator D Engine controlled at low speed

D Void EGR control

D Void variable geometry turbocharger control

Over boost D Void variable geometry turbocharger control

D Engine controlled at low fuel injection

Timing control valve D Injection timing stabilizing control

D Void EGR control

EGR valve position sensor Void EGR control

Variable geometry control pressure

sensor

D Void EGR control

D Void variable geometry turbocharger control

DIESEL FUEL <4D5-step III>- Troubleshooting 13E-8

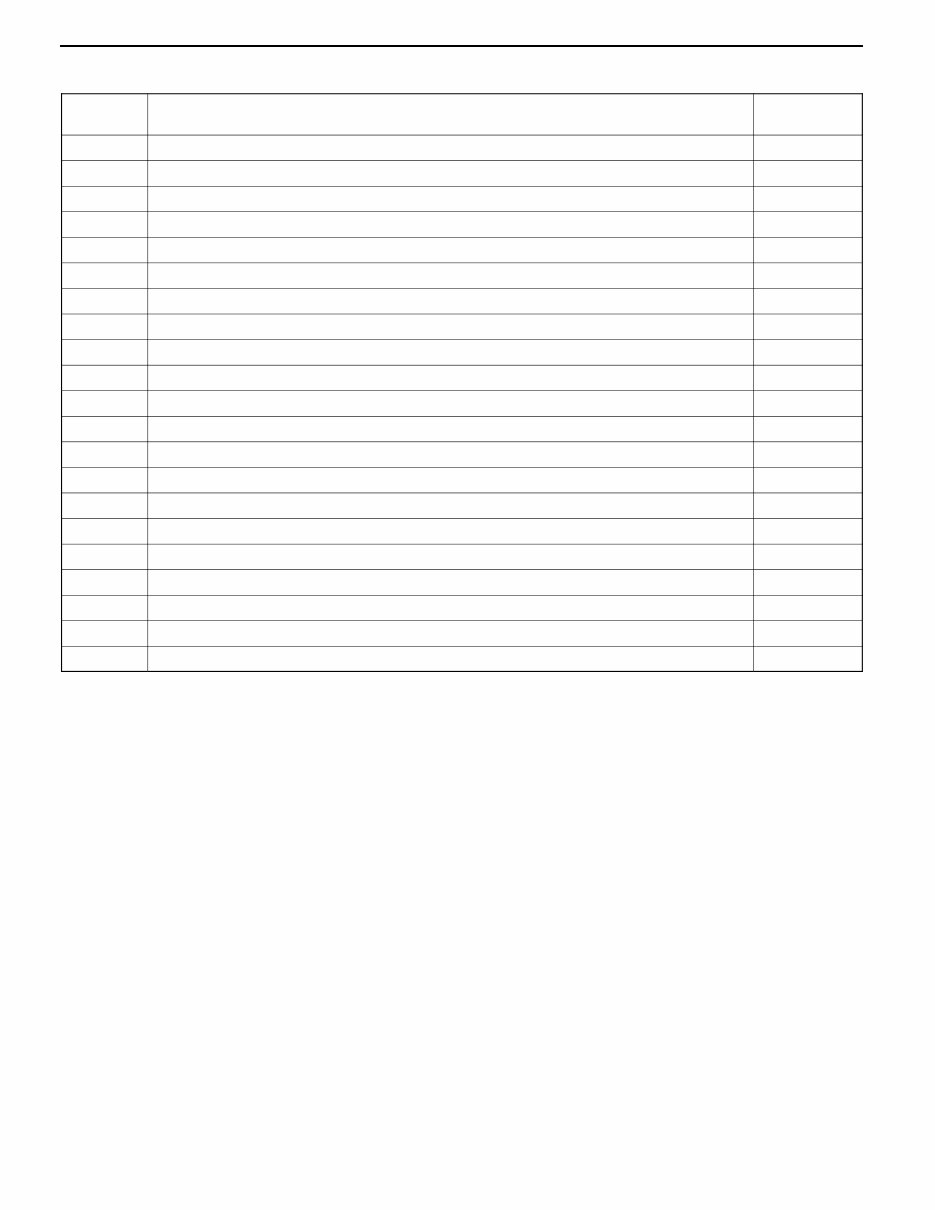

INSPECTION CHART FOR DIAGNOSIS CODES

Code No. Diagnosis item Reference

page

11 Accelerator pedal position sensor (main) system 13E-9

12* Boost pressure sensor system 13E-10

13 Barometric pressure sensor (ECU built-in) system 13E-11

14 Fuel temperature sensor system 13E-11

15 Engine coolant temperature sensor system 13E-12

16 Boost air temperature sensor system 13E-12

17 Vehicle speed sensor system 13E-13

18 Pump speed sensor system 13E-14

21 Crank angle sensor system 13E-15

23 Idle switch (accelerator pedal position sensor built-in) system 13E-16

25* Timer piston position sensor system 13E-17

26* Control sleeve position sensor system 13E-18

27 Accelerator pedal position sensor (sub) system 13E-19

41* Throttle solenoid valve system 13E-20

43 Timing control valve system 13E-21

46 Injection volume adjusting ROM system 13E-22

48* GE actuator (in the middle of control sleeve position sensor inoperative) system 13E-23

49* Over boost (variable geometry control pressure sensor system malfunction) 13E-24

51 EGR valve position sensor system 13E-25

52 Variable geometry control pressure sensor system 13E-26

54 Immobilizer system 13E-27

Caution

If the above-mentioned diagnosis code number with the asterisks can be displayed along with another

code number in parentheses simultaneously, check the other code number before replacing the

engine-ECU.

12 (41, 49), 26 (48), 25 (43), 41 (12, 49), 48 (26), 49 (12, 41)

DIESEL FUEL <4D5-step III>- Troubleshooting 13E-9

INSPECTION PROCEDURE FOR DIAGNOSIS CODE

Code No. 11 Accelerator pedal position sensor (main)

system

Probable cause

Range of Check

D Ignition switch: ON, accelerator pedal position sensor (sub) operative, except

for during engine cranking

Set Conditions

D Accelerator pedal position sensor output voltage is as below for 1 second:

Sub side: 0.2 V or more, less than 2.5 V

Main side: 4.5 V or more

or

Sub or main side: less than 0.2 V

Range of Check

D Ignition switch: ON, except for during engine cranking

Set Conditions

D The output voltage of accelerator pedal position sensor (main and sub) for

0.2 second is 0.2 V or higher, or lower than 4.5 V and the difference in

sensor output voltage between the main and sub is 1 V or higher, or idle

switch: ON, and sensor main output voltage is 1.875 V or higher.

D Accelerator pedal position sensor inoperative

D Accelerator pedal position sensor open circuit,

short circuit, or connector contact inoperative

D Engine-ECU inoperative

NG

OK

OK

Measure at D-135 accelerator pedal position

sensor connector

D Disconnect the connector and measure

at the harness side.

D Voltage between 2 and earth

(Ignition switch: ON)

OK: 4.5 - 5.5 V

D Continuity between 1 and earth

OK: Continuity

NG

Check the following connector: D-113

NG

Repair

OK

OK

Repair

NG

Accelerator pedal position sensor check

(Refer to P.13E-57.)

Replace

Check the trouble symptoms.

Replace the engine-ECU.

NG

Check the trouble symptoms.

NG

Replace the engine-ECU.

NG

Repair Check the following connectors:

D-113, D-135

OK

NG

NG

Check the following connector: D-113

NG

Repair

OK

Check the harness between the

engine-ECU and the accelerator pedal

position sensor connector.

OK

Measure at D-113 engine-ECU connector

D Connect the connector.

D Voltage between 84 and the earth

(Ignition switch: ON)

OK: 0.9 - 1.1 V

(Throttle lever idling position)

4.1 V or higher

(Throttle lever fully opened position)

Check the harness between the

engine-ECU and the accelerator pedal

position sensor connector.

NG

Repair

NG NG NG NG NG

Check the trouble symptoms.

OK

Replace the engine-ECU.

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

Viewed 96 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$33.99

This workshop repair manual is for the MITSUBISHI PAJERO NM from 1999 to 2006 and covers the following engines:

- 3.5L 6G74GDI V6 ENGINE

- 2.5L 4D56 TD ENGINE

- 3.2L 4M41 Di-D ENGINE

The transmission covered includes:

- 5 SPEED MANUAL V5MT1/V5M31

- 5 SPEED AUTOMATIC V5A51

The manual includes detailed information on the following:

- GENERAL INFORMATION

- ENGINE

- ENGINE LUBRICATION

- FUEL

- ENGINE COOLING

- INTAKE AND EXHAUST

- ENGINE ELECTRICAL

- EMISSION AND ENGINE CONTROL

- CLUTCH

- AUTOMATIC TRANSMISSION

- MANUAL TRANSMISSION

- PROPELLER SHAFT

- FRONT AXLE

- REAR AXLE

- WHEEL AND TYRE

- POWER PLANT MOUNT

- FRONT SUSPENSION

- REAR SUSPENSION

- SERVICE BRAKES

- PARKING BRAKES

- STEERING

- BODY

- EXTERIOR

- INTERIOR

- SRS

- HEATING AND VENTILATION

- AIR CONDITIONING

- CIRCUIT DIAGRAM

This comprehensive manual is available in .PDF format and features detailed exploded views. It is the same manual used by technicians for vehicle repairs. The manual includes complete step-by-step procedures with pictures and diagrams, and it is fully printable, allowing for the selection of specific pages or the entire manual. It is an illustrated manual suitable for repairs, maintenance, and servicing needs.