2003-2006 Mitsubishi Outlander 2.0L 4G63 Service & Repair Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

2008 ENGINE

Engine Overhaul (2.4L) - Outlander

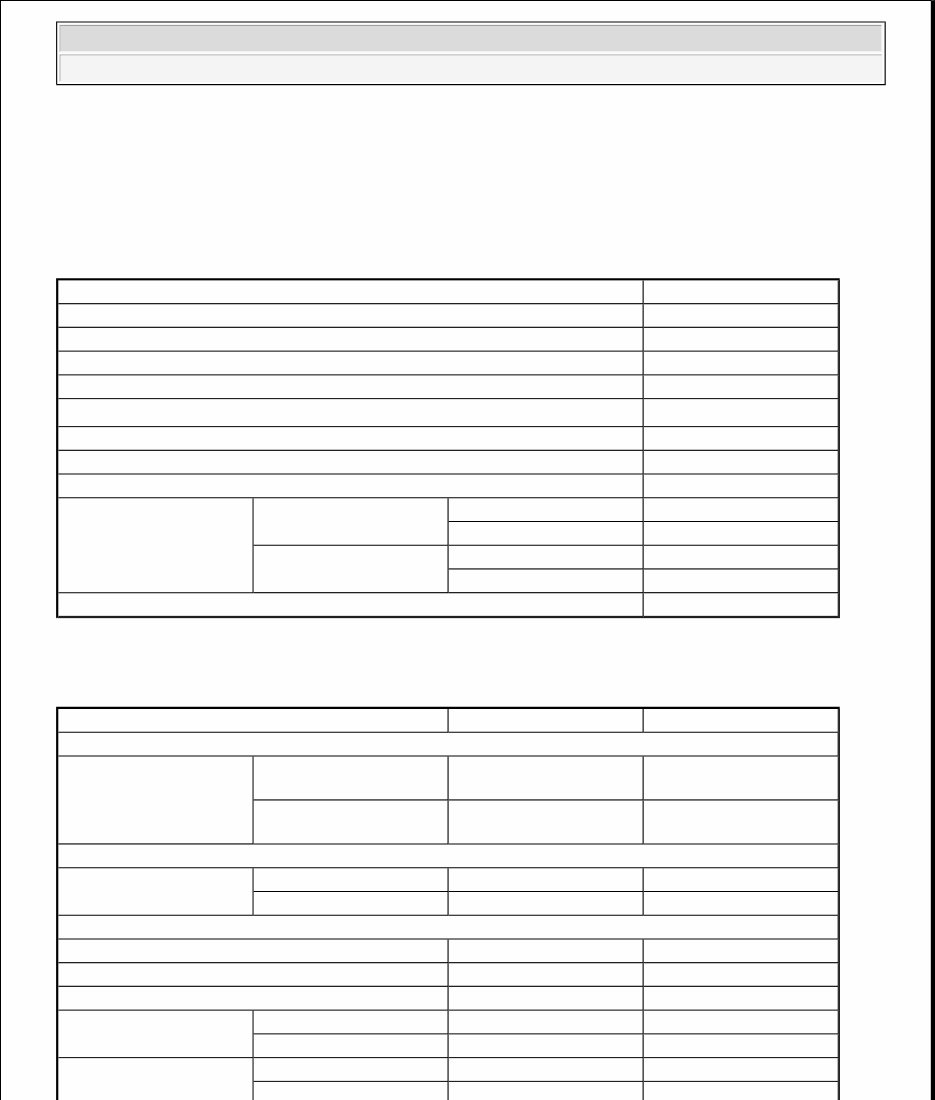

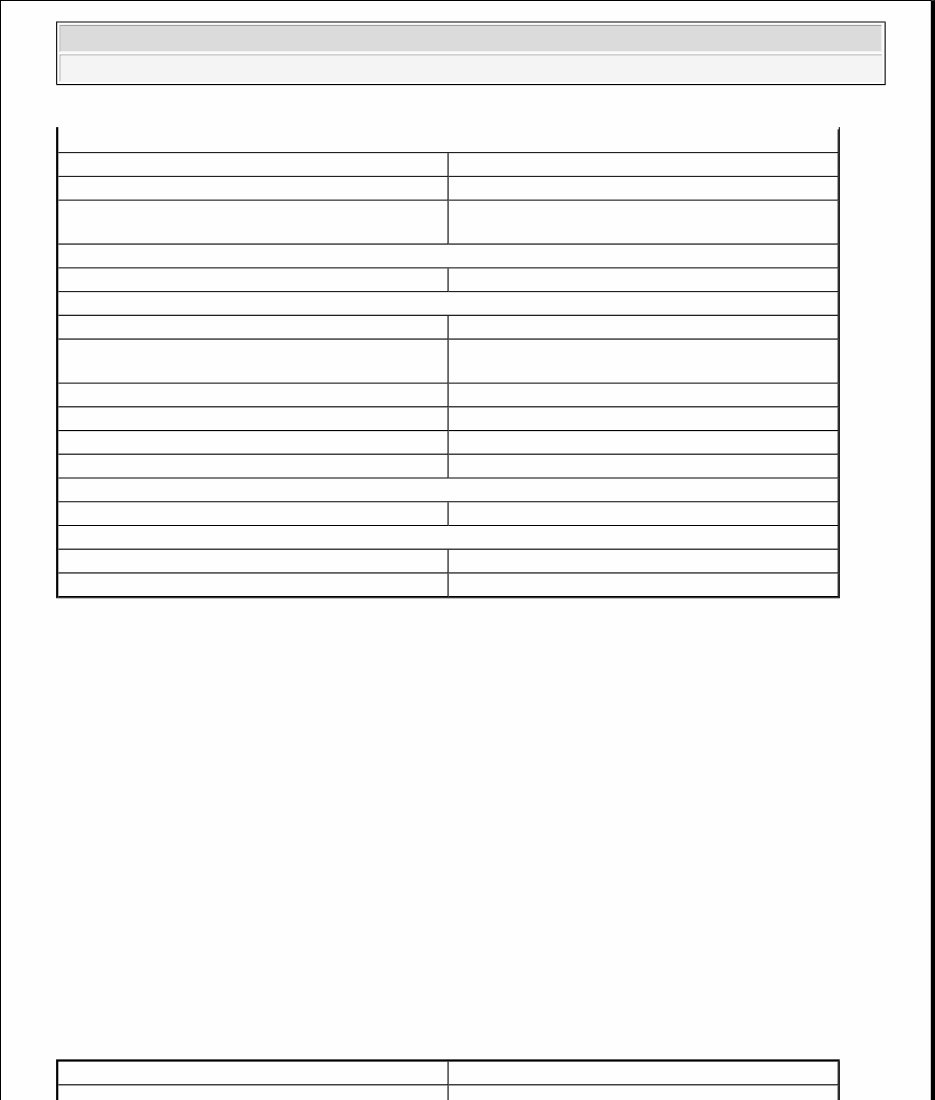

GENERAL SPECIFICATIONS

GENERAL SPECIFICATIONS

SERVICE SPECIFICATIONS

SERVICE SPECIFICATIONS

Item Specifications

Engine model 4B12

Type In-line OHV, DOHC

Number of cylinders 4

Combustion chamber Pentroof type

Total displacement cm

3

(cu in)

2,359 (144.0)

Cylinder bore mm 88

Piston stroke mm 97

Compression ratio 10.5

Valve timing Intake valve Open 0-40°

Close 64-24°

Exhaust valve Open 44-24°

Close 0-20°

Auto lash adjuster Non-equipped

Item Standard value Limit

Timing chain

Valve clearance mm (in) Intake 0.20 ± 0.03 (0.008 ±

0.001)

-

Exhaust 0.30 ± 0.03 (0.012 ±

0.001)

-

Camshaft

Cam height of camshaft

mm (in)

Intake 44.1 (1.736) 43.6 (1.717)

Exhaust 45.0 (1.772) 44.5 (1.752)

Cylinder head and valves

Distortion of cylinder head bottom mm (in) Within 0.05 (0.002) 0.02 (0.0008)

Grinding limit of cylinder head bottom mm (in) - 0.2 (0.008)

Overall height of cylinder head mm (in) 128.5 (5.06) -

Overall length of valve

mm (in)

Intake 113.18 (4.456) 112.68 (4.436)

Exhaust 105.89 (4.169) 105.39 (4.149)

Valve margin mm (in) Intake 1.022 (0.0402) 0.522 (0.0206)

2008 Mitsubishi Outlander XLS

2008 ENGINE Engine Overhaul (2.4L) - Outlander

2008 Mitsubishi Outlander XLS

2008 ENGINE Engine Overhaul (2.4L) - Outlander

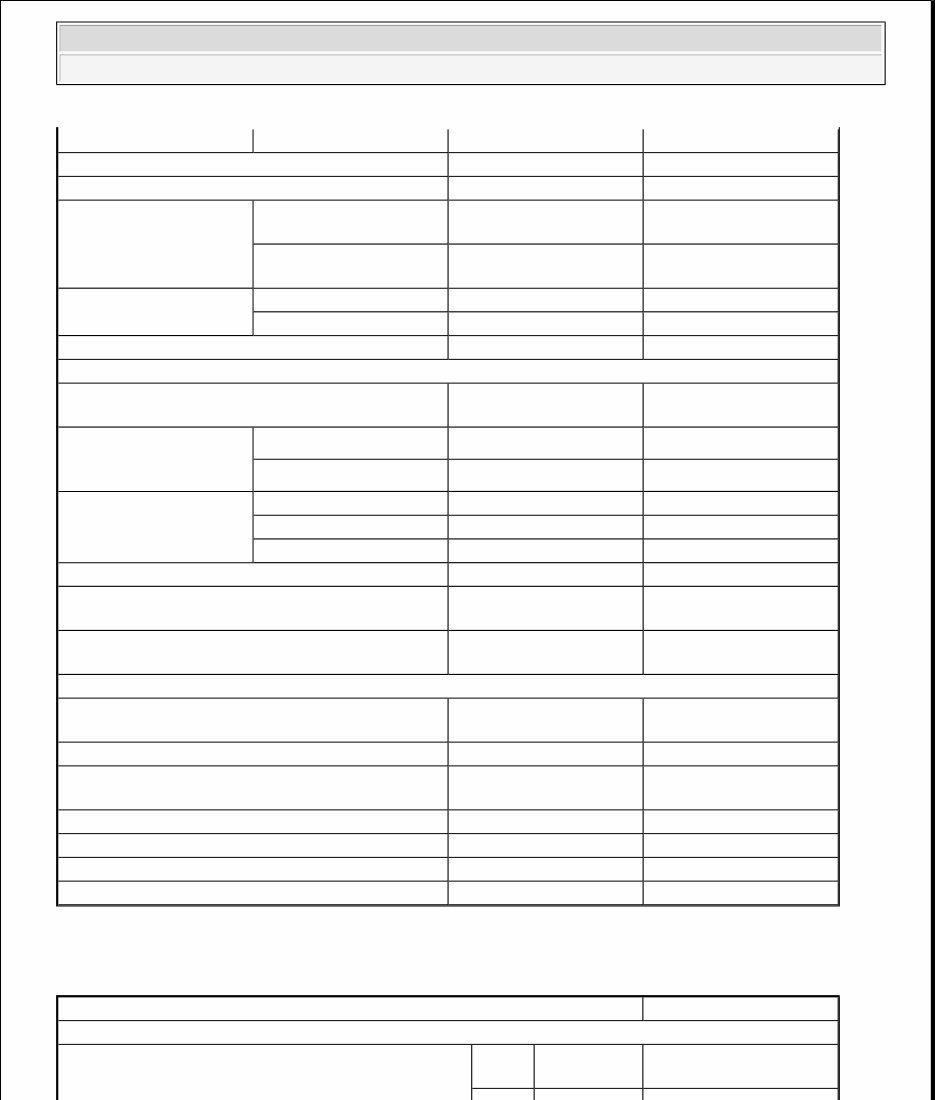

REWORK DIMENSIONS

REWORK DIMENSIONS

Exhaust 1.094 (0.0431) 0.594 (0.0234)

Free height of valve spring mm (in) 47.44 (1.867) -

Squareness of valve spring 2° or less 4°

Clearance between valve

guide and valve stem mm

(in)

Intake 0.020-0.047 (0.0008-

0.0019)

0.10 (0.0039)

Exhaust 0.030-0.054 (0.0012-

0.0021)

0.11 (0.0043)

Valve seat contact width

mm (in)

Intake 1.16-1.46 (0.046-0.058) -

Exhaust 1.35-1.65 (0.053-0.065) -

Press fit the valve guide mm (in) 14.6-15.2 (0.57-0.60) -

Piston and connecting rod

Piston pin press-fit load N (lbf) 7,500-17,500 (1.686-

3.934)

-

Clearance between piston

ring and ring groove mm

(in)

Number 1 0.03-0.07 (0.001-0.003) 0.1 (0.004)

Number 2 0.03-0.07 (0.001-0.003) 0.1 (0.004)

Piston ring end gap mm

(in)

Number 1 0.15-0.25 (0.006-0.011) 0.8 (0.03)

Number 2 0.25-0.40 (0.010-0.016) 0.8 (0.03)

Oil 0.10-0.35 (0.004-0.014) 1.0 (0.04)

Clearance of connecting rod big end thrust mm (in) 0.10-0.25 (0.004-0.010) 0.4 (0.016)

Difference of outside diameter of connecting rod

bolt mm (in)

- 0.1 (0.04)

Connecting rod bearing oil clearance mm (in) 0.018-0.045 (0.0007-

0.0018)

0.1 (0.04)

Crankshaft and cylinder block

Underhead length of crankshaft bearing cap bolt

mm (in)

75.5-76.5 (2.972-3.012) -

Crankshaft end play mm (in) 0.05-0.25 (0.002-0.010) 0.4 (0.016)

Crankshaft journal oil clearance mm (in) 0.012-0.030 (0.0005-

0.0012)

0.08 (0.0031)

Distortion of cylinder block top surface mm (in) - 0.05 (0.0020)

Grinding limit of cylinder block top surface mm (in) - 0.2 (0.008)

Cylinder block cylinder bore mm (in) 88 (3.46) -

Cylindricity of cylinder block mm (in) 0.0076 (0.0003) -

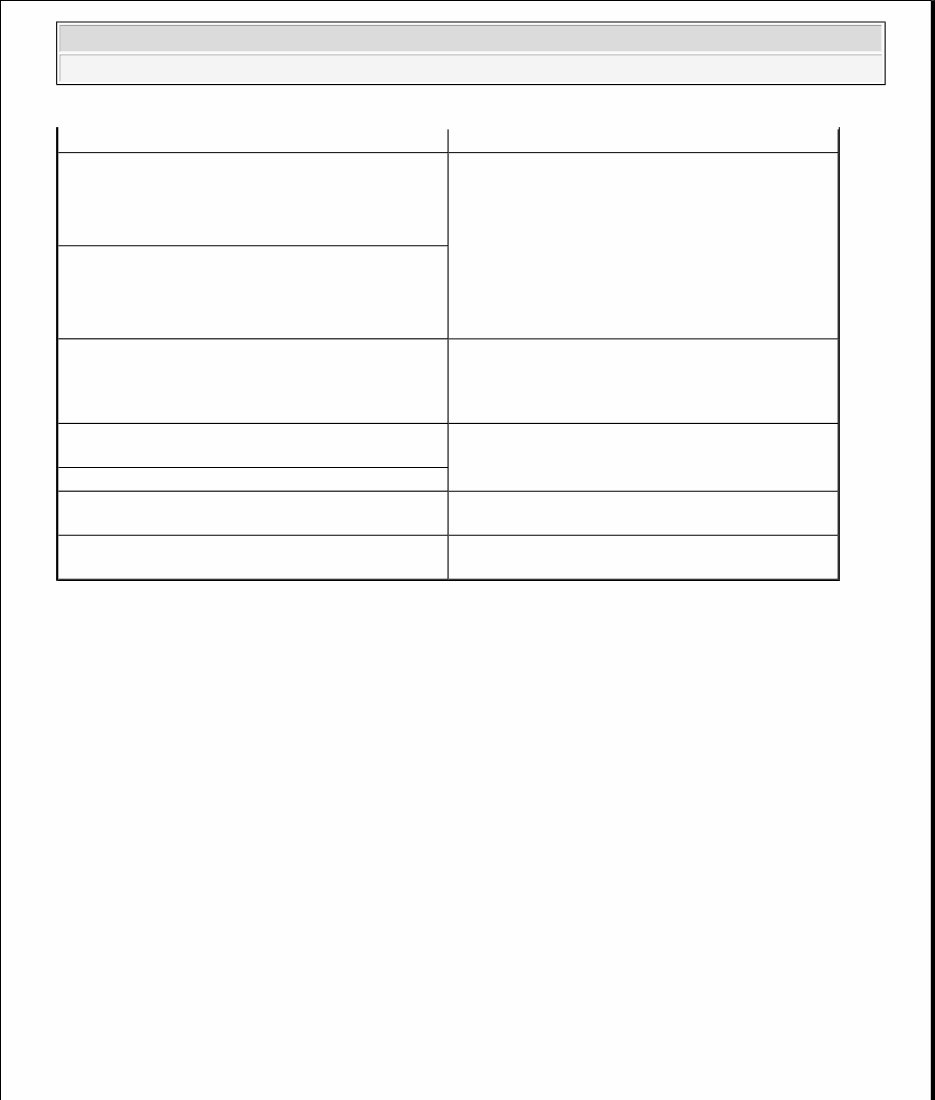

Item Standard value

Cylinder head and valve

Cylinder head oversize valve seat bore diameter mm

Intake

0.30 Over

size

36.22-36.24 (1.426-

1.427)

2008 Mitsubishi Outlander XLS

2008 ENGINE Engine Overhaul (2.4L) - Outlander

TORQUE SPECIFICATIONS

TORQUE SPECIFICATIONS

(in)

Exhaust

0.30 Over

size

30.22-30.24 (1.190-

1.191)

Cylinder head oversize valve guide bore diameter mm (in)

0.25 Over

size

11.23-11.25 (0.442-

0.443)

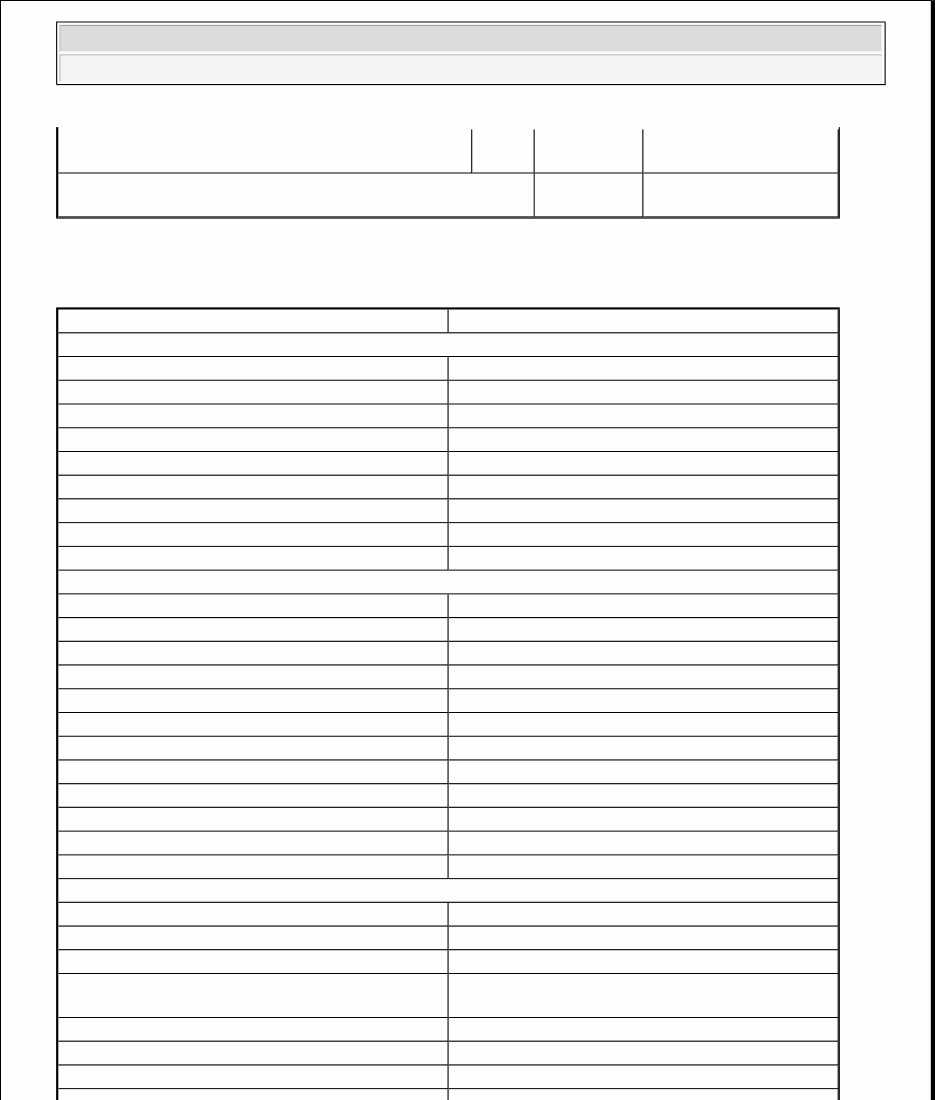

Item Specification

Generator and ignition system

Idler pulley bolt 48 ± 7 N.m (36 ± 4 ft-lb)

Auto tensioner bolt 22 ± 4 N.m (17 ± 2 ft-lb)

Crankshaft pulley center bolt 210 N.m (155 ft-lb)

Generator nut 44 ± 10 N.m (32 ± 7 ft-lb)

Generator bolt 44 ± 10 N.m (32 ± 7 ft-lb)

Ignition coil bolt 10 ± 2 N.m (89 ± 17 in-lb)

Spark plug 25 ± 5 N.m (19 ± 3 ft-lb)

Power steering pump bracket bolt (M8) 23 ± 2 N.m (17 ± 1 ft-lb)

Power steering pump bracket bolt (M10) 44 ± 8 N.m (33 ± 5 ft-lb)

Throttle body and EGR system

Vacuum pipe and hose bolt (M6) 11 ± 1 N.m (98 ± 8 in-lb)

Vacuum pipe and hose bolt (M8) 24 ± 3 N.m (18 ± 1 ft-lb)

Water pipe bolt 10 ± 2 N.m (89 ± 17 in-lb)

Throttle body bolt 9.5 ± 2.5 N.m (84 ± 22 in-lb)

Throttle body stay bolt 20 ± 2 N.m (15 ± 1 ft-lb)

EGR valve support bolt 20 ± 2 N.m (15 ± 1 ft-lb)

EGR pipe bolt 20 ± 2 N.m (15 ± 1 ft-lb)

EGR support stay A bolt 20 ± 2 N.m (15 ± 1 ft-lb)

EGR support stay B bolt 20 ± 2 N.m (15 ± 1 ft-lb)

EGR valve bolt 24 ± 3 N.m (18 ± 1 ft-lb)

Manifold absolute pressure (MAP) sensor screw 4.0 ± 1.0 N.m (36 ± 8 in-lb)

Solenoid valve screw 4.0 ± 1.0 N.m (36 ± 8 in-lb)

Intake manifold and fuel system

Oil dipstick guide bolt 10 ± 2 N.m (89 ± 17 in-lb)

Injector protector rear bolt 20 ± 2 N.m (15 ± 1 ft-lb)

Fuel rail bolt 20 ± 2 N.m (15 ± 1 ft-lb)

Intake manifold bolt and nut 3.5 ± 1.5 N.m (31 ± 13 in-lb) --> 20 ± 2 N.m (15 ± 1

ft-lb)

Intake manifold stay bolt 20 ± 2 N.m (15 ± 1 ft-lb)

Injector protector front bolt 20 ± 2 N.m (15 ± 1 ft-lb)

Generator bracket bolt 44 ± 8 N.m (33 ± 5 ft-lb)

2008 Mitsubishi Outlander XLS

2008 ENGINE Engine Overhaul (2.4L) - Outlander

Detonation sensor bolt 20 ± 2 N.m (15 ± 1 ft-lb)

Engine oil pressure switch 10 ± 2 N.m (89 ± 17 in-lb)

Exhaust manifold

Exhaust manifold upper cover bolt 14 ± 1 N.m (124 ± 8 in-lb)

Exhaust manifold lower cover bolt 14 ± 1 N.m (124 ± 8 in-lb)

Exhaust manifold nut 49 ± 5 N.m (36 ± 3 ft-lb)

Exhaust manifold bracket C bolt (M8) 20 ± 5 N.m (15 ± 3 ft-lb)

Exhaust manifold bracket A bolt (M10) 41 ± 10 N.m (30 ± 7 ft-lb)

Crankshaft position sensor bolt 11 ± 1 N.m (98 ± 8 in-lb)

Crankshaft position sensor cover bolt (M6) 11 ± 1 N.m (98 ± 8 in-lb)

Crankshaft position sensor cover bolt (M10) 49 ± 6 N.m (36 ± 4 ft-lb)

Water hose and pipe

Water inlet fitting bolt 24 ± 3 N.m (18 ± 1 ft-lb)

Water outlet fitting bolt 24 ± 3 N.m (18 ± 1 ft-lb)

Thermostat housing bolt 24 ± 3 N.m (18 ± 1 ft-lb)

Engine hanger bolt 24 ± 3 N.m (18 ± 1 ft-lb)

Engine coolant temperature sensor 30 ± 9 N.m (22 ± 6 ft-lb)

Water pump bolt 24 ± 3 N.m (18 ± 1 ft-lb)

Water pipe nut 24 ± 3 N.m (18 ± 1 ft-lb)

Camshaft position sensor bolt 11 ± 1 N.m (98 ± 8 in-lb)

Oil pan and timing chain case

Cylinder head cover bolt 3.0 ± 1.0 N.m (27 ± 8 in-lb) --> 5.5 ± 0.5 N.m (49 ±

8 in-lb)

Timing chain case bolt (M6) 10 ± 2 N.m (89 ± 17 in-lb)

Timing chain case bolt (M8 x 10) 13 ± 1 N.m (115 ± 8 in-lb)

Timing chain case bolt (M8 x 28) 24 ± 4 N.m (18 ± 1 ft-lb)

Oil pan bolt (M6) 10 ± 2 N.m (89 ± 17 in-lb)

Oil pan bolt (M8) 29 ± 2 N.m (21 ± 1 ft-lb)

Air compressor bracket bolt 23 ± 6 N.m (17 ± 4 ft-lb)

Oil drain plug 39 ± 5 N.m (29 ± 3 ft-lb)

Oil filter 14 ± 2 N.m (124 ± 17 in-lb)

Positive Crankcase Ventilation Valve 2.5 ± 0.4 N.m (22 ± 3 in-lb)

Engine support bracket bolt 45 ± 5 N.m (33 ± 3 ft-lb)

Timing chain

Chain upper guide bolt 10 ± 2 N.m (89 ± 17 in-lb)

Oil jet bolt 10 ± 2 N.m (89 ± 17 in-lb)

V.V.T. intake sprocket bolt 59 ± 5 N.m (44 ± 3 ft-lb)

V.V.T. exhaust sprocket bolt 59 ± 5 N.m (44 ± 3 ft-lb)

Timing chain tensioner bolt 10 ± 2 N.m (89 ± 17 in-lb)

Tensioner lever bolt 10 ± 2 N.m (89 ± 17 in-lb)

Timing chain guide bolt 10 ± 2 N.m (89 ± 17 in-lb)

2008 Mitsubishi Outlander XLS

2008 ENGINE Engine Overhaul (2.4L) - Outlander

NEW TIGHTENING METHOD BY USING PLASTIC REGION TIGHTENING BOLT

Plastic region tightening bolts are used in some parts of the engine. Install these bolts according to the method

described in the body of the manual because the tightening method of these bolts are different from the

conventional method. The service limit is determined for these bolts. Be sure to strictly follow the service limit

described in the body of the manual.

Parts to be used

1. Cylinder head bolt

2. Bearing cap bolt

3. Connecting rod cap bolt

Tightening method

After tightening to the specified tightening torque, further tighten 90° and 90°, or 180° (90° + 90°).

Follow the tightening method described in the body of the manual because the tightening method differs

from part to part.

SEALANTS

SEALANTS REFERENCE

Camshaft

Engine oil control valve (OCV) bolt 10 ± 2 N.m (89 ± 17 in-lb)

Camshaft bearing cap bolt (M6) 12 ± 1 N.m (107 ± 8 in-lb)

Front camshaft bearing cap bolt (M8) 17 ± 3 N.m (14 ± 2 ft-lb) --> 30 ± 2 N.m (22 ± 1 ft-

lb)

Cylinder head and valves

Cylinder head bolt 35 ± 2 N.m (26 ± 1 ft-lb) --> +180°

Balancer chain

Drive plate bolt 40 N.m (30 ft-lb) --> 130 N.m (95 ft-lb)

Balancer shaft module bolt 20 (15 ft-lb) --> 44 (32 ft-lb) --> 0 --> 20 (15 ft-lb) -

-> +135°

Balancer shaft chain tensioner bolt 10 ± 2 N.m (89 ± 17 in-lb)

Lever tensioner bolt 10 ± 2 N.m (89 ± 17 in-lb)

Balancer shaft chain guide bolt 10 ± 2 N.m (89 ± 17 in-lb)

Ladder frame bolt 26 ± 1 N.m (19 ± 1 ft-lb)

Piston and connecting rod

Connecting rod cap bolt 5.0 N.m (44 in-lb) --> 20 N.m (15 ft-lb) --> +90°

Crankshaft and cylinder block

Crankshaft sensing ring bolt 11 N.m (98 in-lb)

Bearing cap bolt 26.5 ± 2.0 N.m (20 ± 1 ft-lb) --> +45°

Points of application Specified sealant/adhesive

2008 Mitsubishi Outlander XLS

2008 ENGINE Engine Overhaul (2.4L) - Outlander

LIQUID GASKET (FIPG)

FIPG is used for some parts in the engine. It is necessary to pay attention to an application amount, application

procedure and applied surface condition for this gasket to fully achieve its purpose.

Too small amount causes leakage while too much amount squeezes out to block or narrow water and oil

passages. Therefore, it is absolutely essential to apply a correct amount of liquid sealant continuously without

break to eliminate leakage from joints. FIPG used for engine parts hardens reacting with moisture in the air, and

is usually used for metal flanges.

DISASSEMBLY

Parts assembled with FIPG can be easily disassembled without using a special method. In some cases, however,

it is necessary to lightly tap parts with a wooden hammer or similar tool to break sealant between mating

surfaces. Or lightly driving a smooth and thin gasket scraper in mating surfaces is useful, but full care must be

exercised not to damage mating surfaces. As special tool oil pan FIPG cutter (MD998727) is set, use this tool.

CLEANING OF GASKET SURFACE

Completely remove all deposits from the gasket surface with a gasket scraper or wire brush. Make sure that the

surface to which FIPG is applied is smooth. The gasket surface must be free from grease and foreign

substances. Be sure to remove old FIPG that has entered mounting holes and screw holes.

Drive plate bolt Three bond 1324 or exact equivalent

Ladder frame Three bond 1227D,

Three bond 1217G

(Mitsubishi Genuine Tool number and name

1000A923),

Three bond 1207F

(Mitsubishi Genuine Tool number and name

MD970389),

LOCTITE 5971, LOCTITE 5970,

LOCTITE 5900

Oil pan

Cylinder head cover (matching area of the cylinder

head and the timing chain case assembly)

Three bond 1227D,

Three bond 1217G

(Mitsubishi Genuine Tool number and name

1000A923),

Cylinder head gasket (matching area of the cylinder

block and the cylinder head)

Three bond 1217G

(Mitsubishi Genuine Tool number and name

1000A923),

Timing chain case

Engine coolant temperature sensor Three bond 1324N, LOCTITE 262 or exact

equivalent

Engine oil pressure switch Three bond 1212D, Three bond 1215 or exact

equivalent

NOTE: The number in square brackets shows the genuine part number.

2008 Mitsubishi Outlander XLS

2008 ENGINE Engine Overhaul (2.4L) - Outlander

APPLICATION PROCEDURE

Apply FIPG in a determined diameter and continuously without break. Completely enclose the periphery of

mounting holes. FIPG can be wiped off if it is not hardened. Install parts in place while FIPG is still wet. Take

care not to allow FIPG to adhere to other locations than necessary locations during installation. Do not pour oil

or water on applied locations or do not start the engine until sufficient time (approximately one hour) passes.

The application procedure of FIPG may differ depending on areas. Follow the procedure in the body of the

manual to apply FIPG.

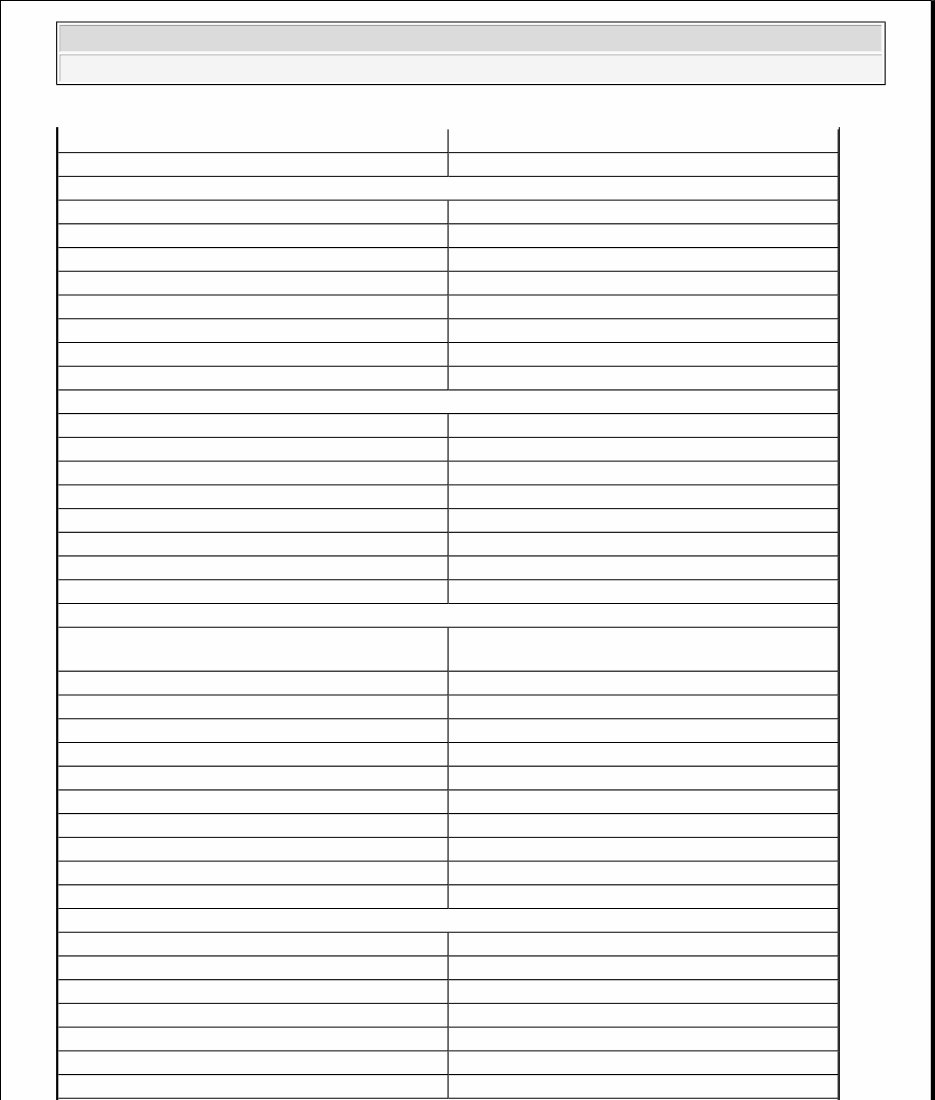

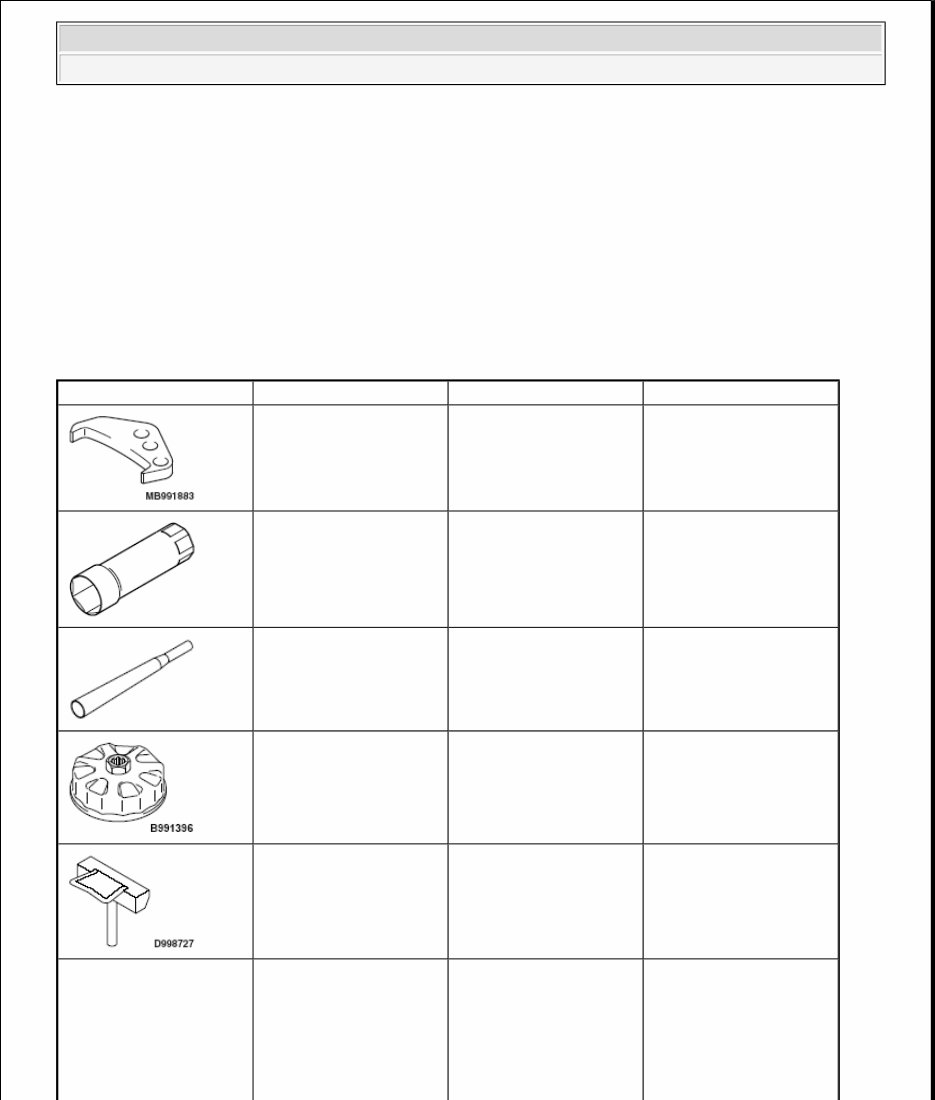

SPECIAL TOOLS

SPECIAL TOOLS DESCRIPTION

Tool Tool number and name Supersession Application

MB991883

Flywheel stopper

- Securing of drive plate

MB991398

Spark plug wrench

- Removal and installation

of spark plug

MB992106

O-ring installer

- Installation of O-ring on

injector injection nozzle

side

MB991396

Oil filter wrench

- Removal and installation

of oil filter

MD998727

Oil pan FIPG cutter

MD998727-01 Removal of oil pan

MB991448

Bushing remover and

installer base

MB991448-01 Press fit of front oil seal

2008 Mitsubishi Outlander XLS

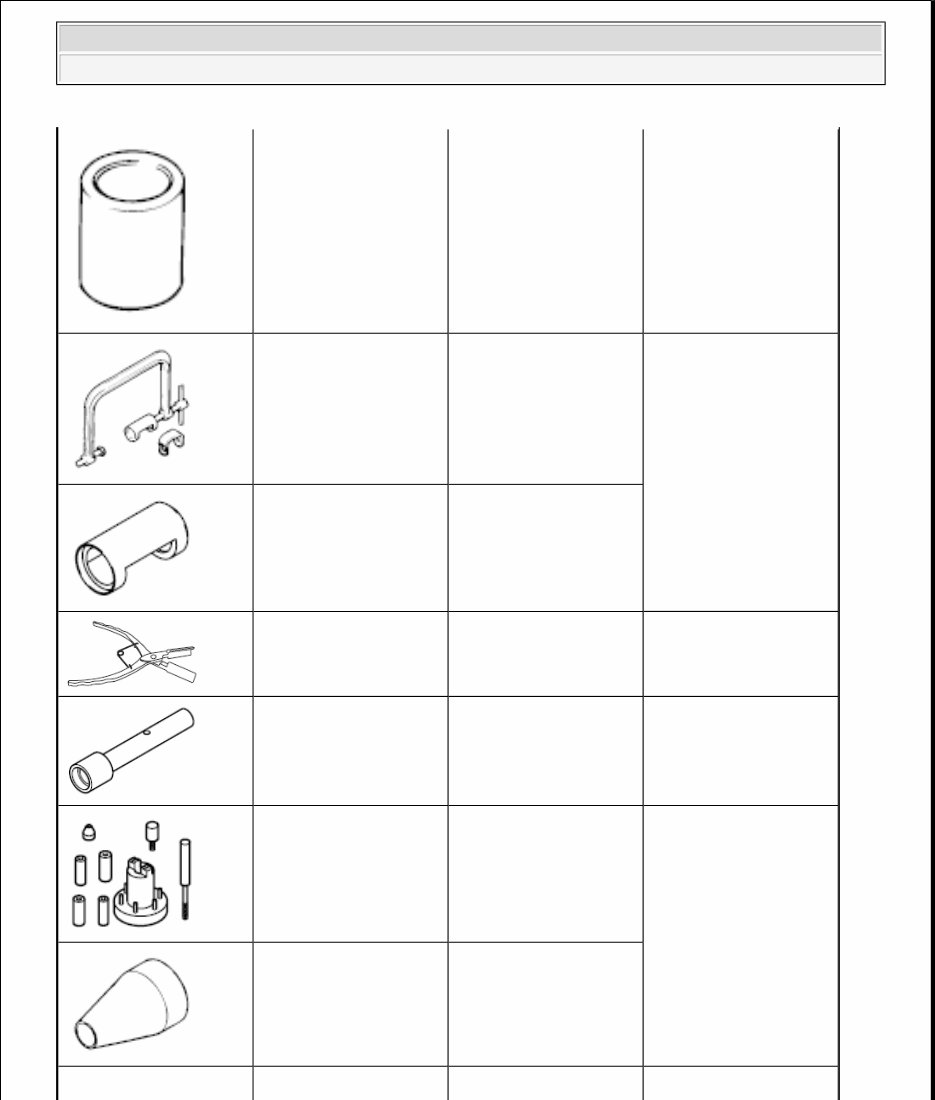

2008 ENGINE Engine Overhaul (2.4L) - Outlander

MD998735

Valve spring compressor

MD998735-01 Compression of valve

spring

MB992089

Retainer holder C

MB992089-01

MB992085

Valve stem seal pliers

- Extraction of valve stem

seal

MD998737

Valve stem seal installer

MD998737-01 Installation of valve stem

seal

MD998780

Piston pin setting tool

MIT216941 Extraction and press fit of

piston pin

MB991659

Guide D

-

MB991614 General service tool Installation of crankshaft

2008 Mitsubishi Outlander XLS

2008 ENGINE Engine Overhaul (2.4L) - Outlander

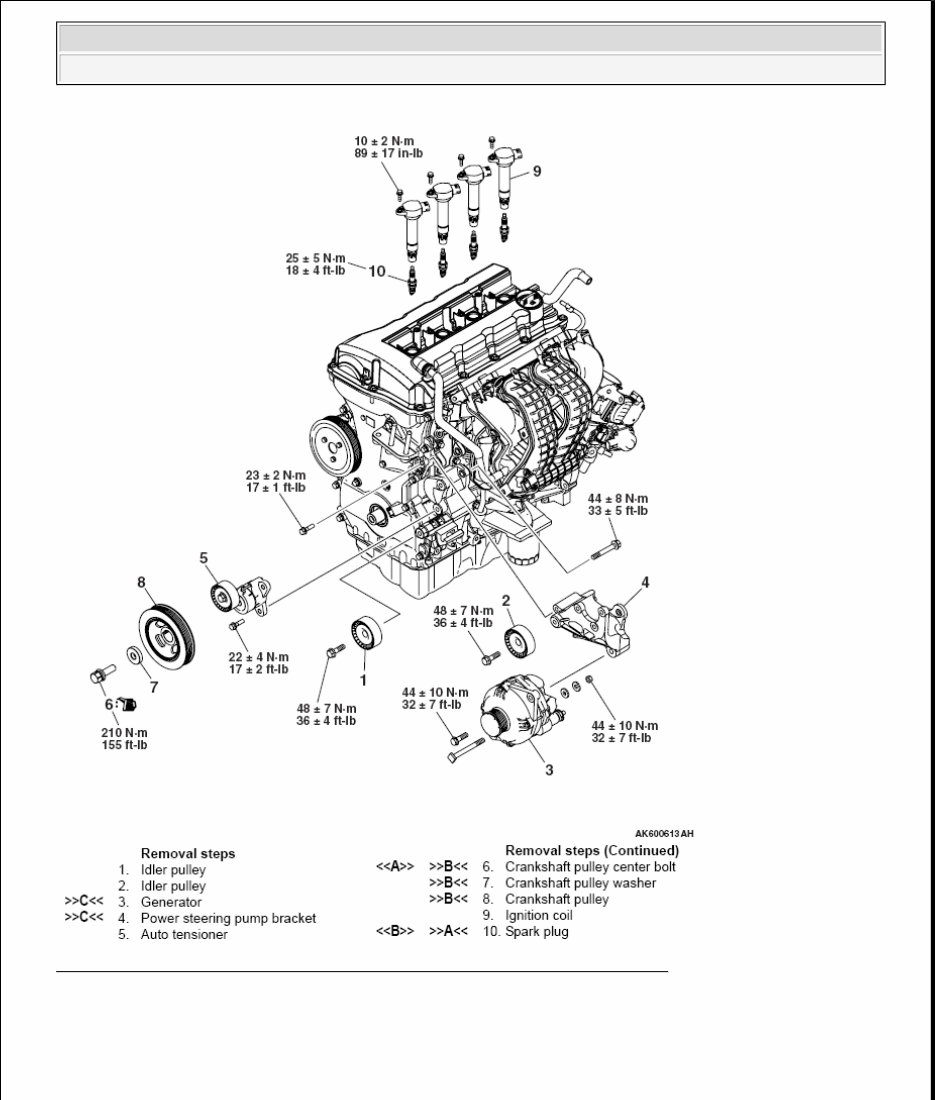

GENERATOR AND IGNITION SYSTEM

REMOVAL AND INSTALLATION

Angle gauge bearing cap bolt and

installation of balancer

shaft module bolt

MD998718

Rear oil seal installer

MD998718-01 Press fit of rear oil seal

2008 Mitsubishi Outlander XLS

2008 ENGINE Engine Overhaul (2.4L) - Outlander

Fig. 1: Identifying Generator And Ignition System With Torque Specifications

Courtesy of MITSUBISHI MOTOR SALES OF AMERICA.

Required Special Tool:

MB991883: Flywheel Stopper

MB991398: Spark plug wrench

2008 Mitsubishi Outlander XLS

2008 ENGINE Engine Overhaul (2.4L) - Outlander

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 71 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Get instant access to the Complete Factory Service Repair Workshop Manual without any extra fees or expiry dates. This Professional Manual is suitable for both professional Mechanics and DIY enthusiasts, covering all repairs, servicing, and troubleshooting procedures with step-by-step instructions, detailed photos, diagrams, and highly detailed exploded diagrams & pictures. You can print out a single page or the entire manual as per your choice. The Manual can be used on multiple computers without any limitations or trial periods and is compatible with all Windows & MAC Computers. There's no need to renew or pay any extra, as this Manual can be used for life.