1997-2002 Mitsubishi Mirage Service Repair manual

Have a question?Ask Us

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

00-1

GENERAL

CONTENTS 001 09000904

GENERAL <BODY AND CHASSIS> . . .. . . ... . . . ... ...... .. .. . . .. 00

GENERAL <ELECTRICAL> . . . . . . . . . . . . . . . ... . .. . . . .. . . . . . . . .. . . OOE

00-2

GENERAL

<BODY AND

CHASSIS>

CONTENTS M)109001172

GENERAL DATA AND SPECIFICATIONS .. 24 Engine Coolant ............................. 44

HOW TO USE THIS MANUAL ............ 3

Definition of Terms .......................... 3

Explanation of Manual Contents .............. 4

Model Indications ........................... 3

Maintenance. Repair and

Servicing Explanations ....................... 3

Tightening Torque Indication .................. 3

HOW TO USE TROUBLESHOOTING/

INSPECTION SERVICE POINTS ........... 6

Connector Inspection Service Points .......... 10

Connector Measurement Service Points ........ 9

Special Tool Note ........................... 3

Engine Oil .................................. 39

Engine Oil Filter ............................ 40

Evaporative Emission Control System ......... 33

Exhaust System ............................ 51

Fuel Hoses ................................. 32

Fuel System ................................ 32

Ignition Cables .............................. 33

Manual Transaxle ........................... 41

Rear Drum Brake Linings and

Rear Wheel Cylinders ....................... 45

SRS Air Bag System ........................ 47

Timing Belt ................................. 34

Spark Plugs ................................ 33

How to Cope with Intermittent Malfunctions ... 11

How to Use the Inspection Procedures ....... 8

PRECAUTIONS BEFORE SERVICE ....... 19

Inspection Service Points for a Blown Fuse ... 12

RECOMMENDED LUBRICANT AND

Troubleshooting Contents .................... 6 LUBRICANT CAPACITY TABLE ........... 28

LUBRICATION AND MAINTENANCE ...... 27 SCHEDULED MAINTENANCE TABLE ..... 31

MAINTENANCE SERVICE ................. 32 TOWING AND HOISTING ................. 21

MAIN SEALANT AND ADHESIVE TABLE .. 52 TIGHTENING TORQUE ................... 26

Air Cleaner Element ......................... 32

Automatic Transaxle ......................... 41

Ball Joint and Steering Linkage Seals ........ 46

Brake Hoses ............................... 46

Disc Brake Pads ............................ 45

Distributor Cap and Rotor .................... 34

Drive Belt .................................. 35

Drive Shaft Boots ........................... 46

VEHICLE IDENTIFICATION ............... 13

Engine Model Stamping ..................... 16

Theft Protection ............................. 16

Vehicle Identification Code Chart Plate ........ 13

Vehicle Identification Number List ............. 14

Vehicle Identification Number Location ........ 13

Vehicle Information Code Plate ............... 15

Vehicle Safety Certification Label ............. 15

GENERAL - How to Use This Manual 00-3

MAINTENANCE, REPAIR AND

SERVlC I NG EXPLAN AT1 0 N S

This manual providesexplanations,etc. concerning

procedures for the inspection, maintenance,repair

and servicing of the subject model. Unless other-

wise specified, each service procedure covers all

models. Procedures covering specific models are

identified by the modelcodes, or similar designation

(engine type, transaxle type, etc.). A description

of these designations is covered in this manual

under “VE H I C LE I DENT I F I CAT I 0 N ” .

ON-VEHICLE SERVICE

“On-vehicle Service” are proceduresfor performing

inspections and adjustments of particularly impor-

tant locations with regard to the construction and

for maintenance and servicing, but other inspections

(for looseness, play, cracking, damage, etc. ) must

also be performed.

SERVICE PROCEDURES

The service steps are arranged in numericalorder.

Attention must to be paid in performing vehicle

serviceare describedin detail in SERVICE POINTS.

DEFINITION OF TERMS

STANDARD VALUE

Indicatesthe value usedas the standardfor judging

the quality of a part or assembly on inspection

or the value to which the part or assembly is cor-

rected and adjusted. It is given by tolerance.

LIMIT

Shows the standard for judging the quality of a

part or assemblyon inspectionand meansthe maxi-

mum or minimum value within which the part or

HOW TO USE THIS MANUAL 001 0001 0234

assembly must be kept functionally or in strength.

It is a value established outside the range of stan-

dard value.

REFERENCE VALUE

Indicates the adjustment value prior to starting the

work (presentedin order to facilitate assembly and

adjustment procedures, and so they can be com-

pleted in a shorter time).

CAUTION

Indicates the presentation of information particularly

vital to the worker duringthe performance of mainte-

nance and servicing procedures in order to avoid

the possibility of injury to the worker, or damage

to component parts, or a reduction of component

or vehicle function or performance, etc.

TIGHTENING TORQUE INDICATION

The tightening torque shown in this manual is a

basic value with a tolerance of -c 10% except the

following cases when the upper and lower limits

of tightening torque are given.

(1) The tolerance of the basic value is within f

10%.

(2) Special bolts or the like are in use.

(3) Special tightening methods are used.

SPECIAL TOOL NOTE

Only MMC special tool part numbers are called

out in the repair sections of this manual. Please

refer to the special tool cross referencechart, which

is located in the service manual at the beginning

of each group, for a cross referencefrom the MMC

special tool number to the special tool number that

is available in your market.

M 0 D EL INDlCATlONS

The following abbreviations are used in this manual for classification of model types.

M/T : Indicates the manual transaxle, or models equipped with the manual transaxle.

Indicates the automatic transaxle, or models equipped with the automatic transaxle.

-_____

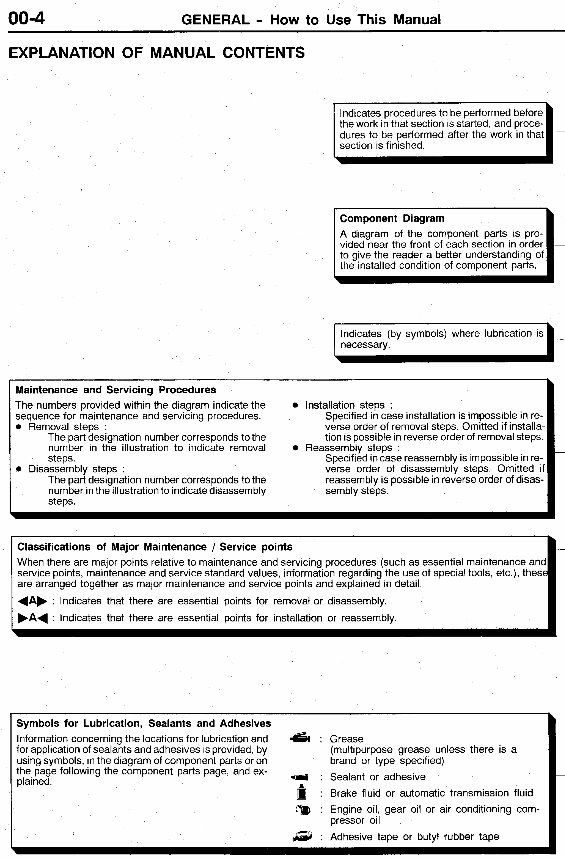

00-4 GENERAL - How to Use This Manual

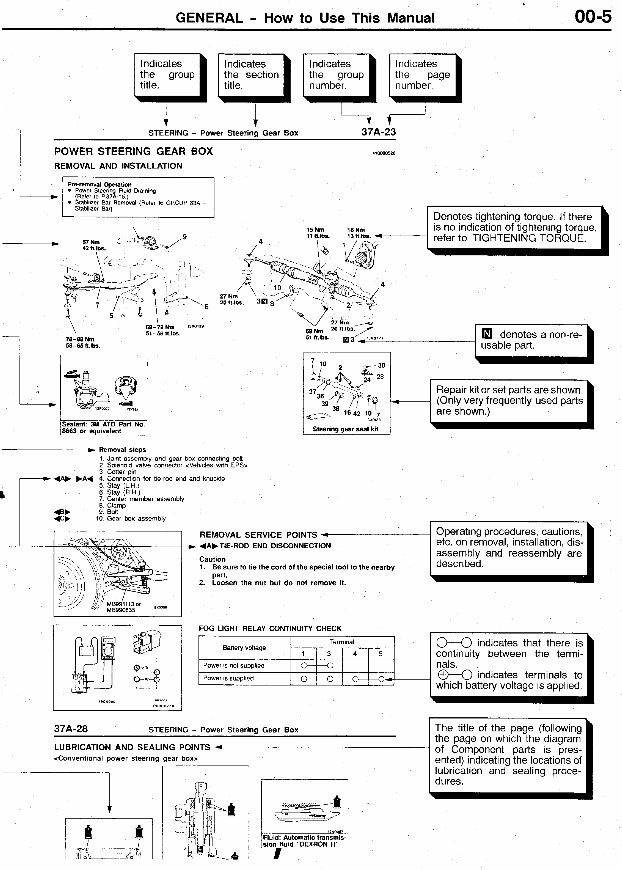

EXPLANATION OF MANUAL CONTENTS

Maintenance and Servicing Procedures

The numbers provided within the diagram indicate the

sequence for maintenance and servicing procedures.

0 Removal steps .

The part designation number corresponds to the

number in the illustration to indicate removal 0

steps

The part designation number corresponds to the

number in the illustration to indicate disassembly

steps.

0

0 Disassembly steps :

the work in that section is started, and proce-

section is finished.

A diagram of the component parts is pro-

to give the reader a better understanding of

the installed condition of component parts.

necessary.

I

Installation steps :

Specified in case installation is impossible in re-

verse order of removal steps Omitted if installa-

tion is possible in reverse order of removal steps

Specified in case reassembly is impossible in re-

verse order of disassembly steps Omitted if

reassembly is possible in reverse order of disas-

sembly steps

Reassembly steps

Classifications of Major Maintenance / Service points

When there are major points relative to maintenance and servicing procedures (such as essential maintenance and

service points, maintenance and service standard values, information regarding the use of special tools, etc ), these

are arranged together as major maintenance and service points and explained in detail

4Ab ' Indicates that there are essential points for removal or disassembly.

FA4 : Indicates that there are essential points for installation or reassembly.

-

Symbols for Lubrication, Sealants and Adhesives

Information concerningthe locations for lubrication and 6 : Grease

for application of sealants and adhesives is provided, by

using symbols, in the diagram of component parts or on

the page following the component parts page, and ex-

plained.

(multipurpose grease unless there is a

brand or type specified)

: Sealant or adhesive

: Brake fluid or automatic transmission fluid

pressor oil

:a : Engine oil, gear oil or air conditioning com-

a : Adhesive tape or butyl rubber tape

GENERAL - How to Use This Manual

Terminal

1 3 4 5

Battery voltage

Power is not supplied *4

Power is supplied 0 - 0 -+

__

00-5

0-0 indicates that there is

continuity between the termi-

nals.

0-0 indicates terminals to

which battery voltage is applied

FI

the group the section the group

STEERING - Power Steering Gear Box 37A-23

POWER STEERING GEAR BOX

REMOVAL AND INSTALLATION

15h 18Nm

.

D Removal sleps

1 Joint assembly and gear box connecting bolt

2 Solenoid valve wnnector <Vehicles with EPS>

3 Cotter p ~ n

4 Connection tor tie-rod end and knuckle

5 Stay (LH)

6 Slay (R H )

7 Center member assemblv

Repair kit or set parts are shown.

(Only very frequently used parts

I are shown.)

00-6 GENERAL - How to Use Troubleshooting/lnspection Service Points

HOW TO USE TROUBLESHOOTING/INSPECTlON SERVICE POINTS

00100020121

Troubleshootingof electronic control systems for which the scan tool can be used follows the basic outline

described below. Furthermore, even in systems for which the scan tool cannot be used, part of these

systems still follow this outline.

TROUBLESHOOTING CONTENTS

1.

2.

3.

4.

5.

6.

7.

8.

9.

STANDARD FLOW OF DIAGNOSTIC TROUBLESHOOTING

The main procedures for diagnostic troubleshooting are shown.

SYSTEM OPERATION AND SYMPTOM VERIFICATION TESTS

If verification of the trouble symptoms is difficult, procedures for checking operation and verifying

trouble symptoms are shown.

DIAGNOSTIC FUNCTION

The following diagnostic functions are shown.

0

0

0 Input inspection service points

INSPECTION CHART FOR DIAGNOSTIC TROUBLE CODES

INSPECTION PROCEDURE FOR DIAGNOSTIC TROUBLE CODES

Indicates the inspection procedures corresponding to each diagnostic trouble code. (Refer to the

next page on how to read the inspection procedures.)

INSPECTION CHART FOR TROUBLE SYMPTOMS

If there are trouble symptoms, even though the results of inspection using the scan tool show that

all diagnostic trouble codes are normal, inspection proceduresfor each trouble symptom will be found

by means of this chart.

INSPECTION PROCEDURE FOR DIAGNOSTIC SYMPTOM

Indicatesthe inspection procedurescorresponding to each trouble symptoms classified in the Inspection

Chart for Trouble Symptoms. (Refer to the next page on how to read the inspection procedures.)

SERVICE DATA REFERENCE TABLE

Inspectionitems and normaljudgementvalues have been providedin this chart as referenceinformation.

CHECK AT ECU TERMINALS

Terminal numbers for the ECU connectors, inspection items and standard values have been provided

in this chart as reference information.

Terminal Voltage Checks

Method of reading diagnostic trouble codes

Method of erasing diagnostic trouble codes

Connect a needle-nosed wire probe or paper clip to a voltmeter probe.

Insert the needle-nosed wire probe into each of the ECU connector terminals from the wire side,

and measure the voltage while referring to the check chart.

NOTE

1. Measure voltage with the ECU connectors connected.

2. You may find it convenient to pull out the ECU to make it easier to reach the connector

terminals.

3. Checks don’t have to be carried out in the order given in the chart.

Caution

Short-circuiting the positive (+) probe betweena connectorterminal and ground could damage

the vehicle wiring, the sensor, the ECU, or all three.

Use care to prevent this !

If voltage readings differ from Normal Condition values, check related sensors, actuators, and

wiring, then replace or repair.

GENERAL - How to Use Troubleshooting/lnspection Service Points 00-7

4. After repair or replacement, recheck with the voltmeter to confirm that the repair has corrected

the problem.

Terminal Resistance and Continuity Checks

1.

2.

3.

4.

5.

Turn the ignition switch to “OFF.

Disconnect the ECU connector.

Measure the resistance and check for continuity between the terminals of the ECU harness-side

connector while referring to the check chart.

NOTE

Checks don’t have to be carried out in the order given in the chart.

Caution

If resistance and continuity checks are performed on the wrong terminals, damage to the

vehicle wiring, sensors, ECU, and/or ohmmeter may occur.

Use care to prevent this!

If the ohmmeter shows any deviation from the Normal Condition value, check the corresponding

sensor, actuator and related electrical wiring, then repair or replace.

After repair or replacement, recheck with the ohmmeter to confirm that the repair has corrected

the problem.

’

10. INSPECTION PROCEDURES USING AN OSCILLOSCOPE

When there are inspection procedures using an oscilloscope, these are listed here.

00-8 GENERAL - How to Use Troubleshooting/lnspection Service Points

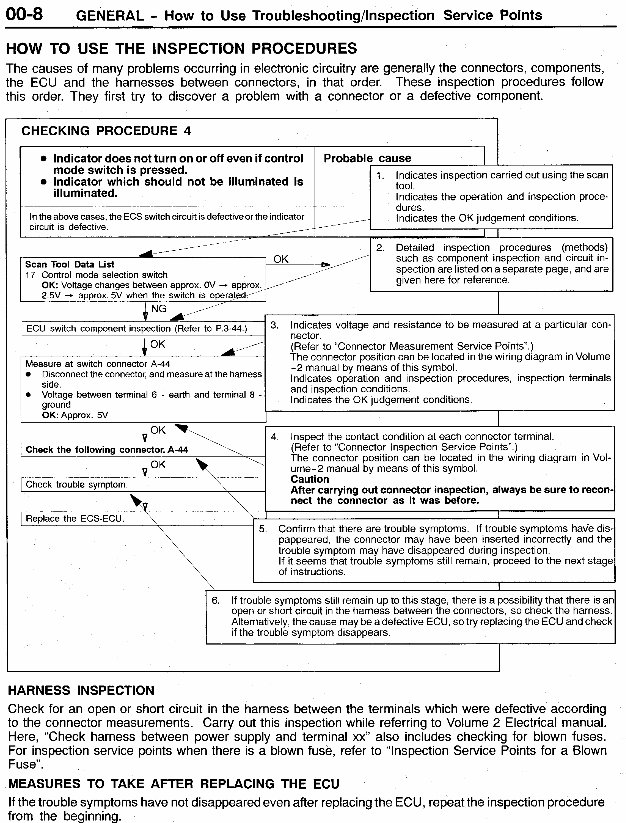

1 E~U switch component (Refer to p3-44 )

/

Measure at switch connector A-44

Disconnect the connector, and at the harness

side

0 Voltage between terminal 6 - earth and terminal 8 -

ground

0K:Approx 5V

4 OK

HOW TO USE THE INSPECTION PROCEDURES

3. Indicates voltage and resistance to be measured at a particular con-

nector.

(Refer to “Connector Measurement Service Points”.)

The connector position can be located in the wiring diagram in Volume

-2 manual by means of this symbol

Indicates operation and inspection procedures, inspection terminals

~ ~ ~ ~ ~ ~ ~ $ ~ ~ ~ ~ conditions

The causes of many problems occurring in electronic circuitry are generally the connectors, components,

the ECU and the harnesses between connectors, in that order. These inspection procedures follow

this order. They first try to discover a problem with a connector or a defective component.

CHECKING PROCEDURE 4

i°K \

4 OK

Check the following connector. A-44

-..,

~

I Check trouble symptom

I I

4 Inspect the contact condition at each connector terminal.

(Refer to “Connector Inspection Service Points”.)

The connector position can be located in the wiring diagram in Vol-

ume-2 manual by means of this symbol

Caution

After carrying out connector inspection, always be sure to recon-

nect the connector as it was before.

witch is pressed.

hich should not be illuminated is

tes the operation and inspection proce-

it is defective

1 Replace the ECS-ECU. \

\

I I

5. Confirm that there are trouble symptoms. If trouble symptoms have dis.

pappeared, the connector may have been inserted incorrectly and the

trouble symptom may have disappeared during inspection.

If it seems that trouble symptoms still remain, proceed to the next stage

of instructions.

I

6. If trouble symptoms still remain up to this stage, there is a possibility that there is ar

open or short circuit in the harness between the connectors, so check the harness.

Alternatively, the cause may be a defective ECU, so try replacingthe ECU and check

if the trouble symptom disappears.

HARNESS INSPECTION

Check for an open or short circuit in the harness between the terminals which were defective according

to the connector measurements. Carry out this inspection while referring to Volume 2 Electrical manual.

Here, “Check harness between power supply and terminal xx” also includes checking for blown fuses.

For inspection service points when there is a blown fuse, refer to “Inspection Service Points for a Blown

Fuse I’ .

MEASURES TO TAKE AFTER REPLACING THE ECU

If the trouble symptoms have not disappeared even after replacing the ECU, repeatthe inspection procedure

from the beginning.

GENERAL - How to Use Troubleshooting/lnspection Service Points 00-9

ooooo2 \

Inspection harness

for connector pin

contact pressure

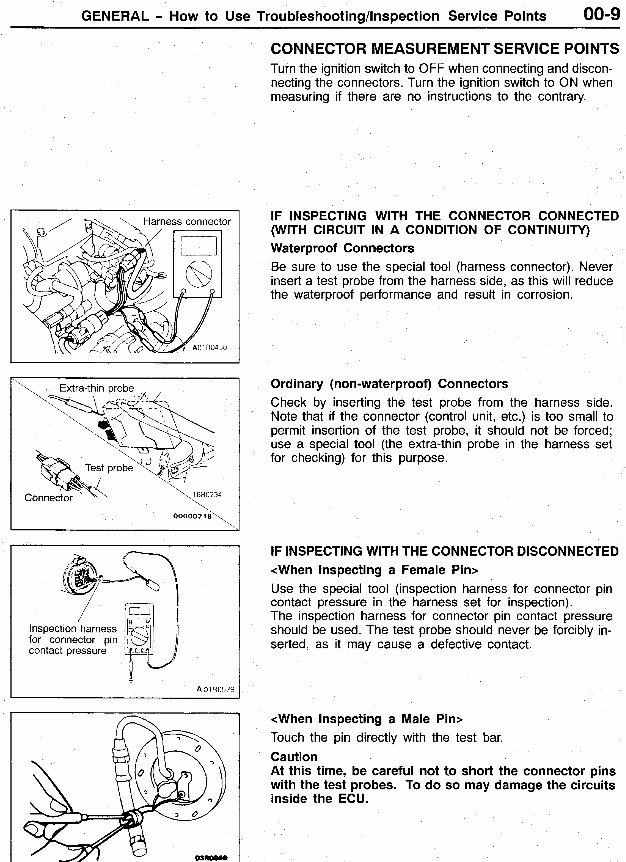

CONNECTOR MEASUREMENT SERVICE POINTS

Turn the ignition switch to OFF when connecting and discon-

necting the connectors. Turn the ignition switch to ON when

measuring if there are no instructions to the contrary.

IF INSPECTING WITH THE CONNECTOR CONNECTED

(WITH CIRCUIT IN A CONDITION OF CONTINUITY)

Waterproof Connectors

Be sure to use the special tool (harness connector). Never

insert a test probe from the harness side, as this will reduce

the waterproof performance and result in corrosion.

Ordinary (non-waterproof) Connectors

Check by inserting the test probe from the harness side.

Note that if the connector (control unit, etc.) is too small to

permit insertion of the test probe, it should not be forced;

use a special tool (the extra-thin probe in the harness set

for checking) for this purpose.

IF INSPECTING WITH THE CONNECTOR DISCONNECTED

<When Inspecting a Female Pin>

Use the special tool (inspection harness for connector pin

contact pressure in the harness set for inspection).

The inspection harness for connector pin contact pressure

should be used. The test probe should never be forcibly in-

serted, as it may cause a defective contact.

<When Inspecting a Male Pin>

Touch the pin directly with the test bar.

Caution

At this time, be careful not to short the connector pins

with the test probes. To do so may damage the circuits

inside the ECU.

00-1 0 GENERAL - How to Use Troubleshooting/lnspection Service Points

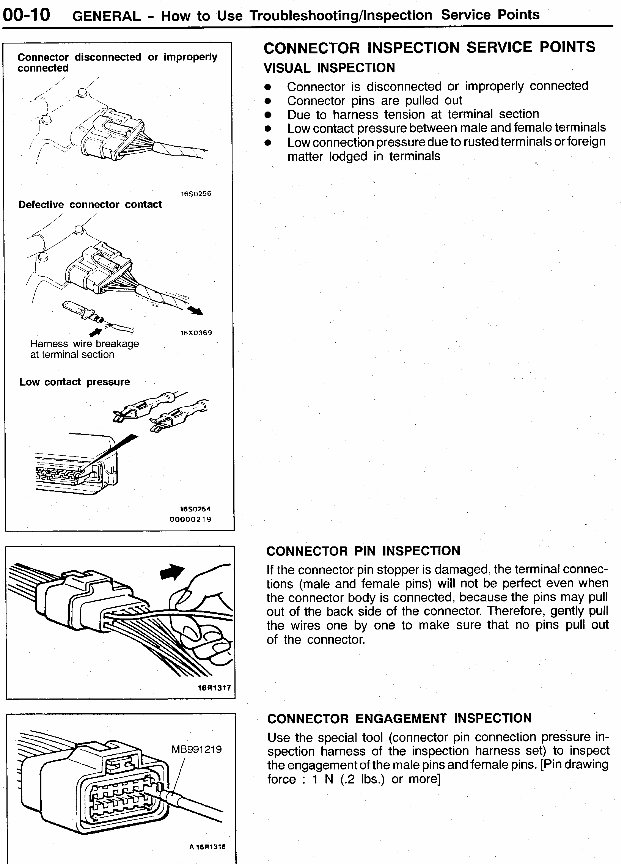

Connector disconnected or improperly

connected

16S0256

Defective connector contact

Harness wire breakage

at terminal section

Low contact pressure

1630254

000002 19

l6R1317

A 16U1318

CONNECTOR INSPECTION SERVICE POINTS

VISUAL INSPECTION

0

0

0

0

Connector is disconnected or improperly connected

Connector pins are pulled out

Due to harness tension at terminal section

Low contact pressure betweenmale and female terminals

Low connectionpressuredue to rustedterminalsor foreign

matter lodged in terminals

CONNECTOR PIN INSPECTION

If the connector pin stopper is damaged, the terminal connec-

tions (male and female pins) will not be perfect even when

the connector body is connected, because the pins may pull

out of the back side of the connector. Therefore, gently pull

the wires one by one to make sure that no pins pull out

of the connector.

CONNECTOR ENGAGEMENT INSPECTION

Use the special tool (connector pin connection pressure in-

spection harness of the inspection harness set) to inspect

the engagement of the male pins andfemale pins. [Pin drawing

force : 1 N (.2 Ibs.) or more]

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

Viewed 17 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$30.99

You are purchasing a comprehensive 1997-2002 Mitsubishi Mirage Factory Service Workshop Manual. This manual is utilized by professional technicians at Mitsubishi dealerships to service and repair vehicles. It encompasses a wide range of services and repairs, from basic oil changes to intricate transmission rebuilds, making it ideal for both professional mechanics and DIY enthusiasts.

The manual covers an extensive list of sections, including but not limited to:

- Antilock brakes

- Bumpers

- Doors

- Keyless Entry

- Lightning system

- Disk brakes

- Park Brake

- Hydraulic Brake

- Front suspension

- Rear Suspension

- Interior Trim

- Exterior trim

- HVAC

- Engine Cooling

- Engine Exhaust

- Engine Electrical

- Engines Power Steering

- Roof and Sunroof

- SIR

- Steering wheel

- Transmission

- Wheel drive shaft

- Washer and wiper

The manual is available in .PDF format and is compatible with Win95/98/ME/XP/Vista/7, Linux, and MAC operating systems. It is a valuable resource for anyone working on or maintaining a 1997-2002 Mitsubishi Mirage.

We're currently collecting product reviews for this item. In the meantime, here are some reviews from our past customers sharing their overall shopping experience.

4.5

Out of 5.0

Overall Rating

89%

of customers that buyfrom this merchant give

them a 4 or 5-Star rating.

Verified Buyer

September 24, 2025 by SEAN N. (Florida, US)

“Great Quality and price”

Verified Buyer

September 24, 2025 by phillip G. (US)

“good”

Verified Buyer

September 24, 2025 by Tammi G. (Florida, US)

“Hope this helps me ! Sounds good!”

Verified Buyer

September 24, 2025 by Bret G. (US)

“Good”

Verified Buyer

September 24, 2025 by Eric H. (Kentucky, US)

“Great and Quick Service”

Verified Buyer

September 24, 2025 by Eamonn M. (CO ROSCOMMON, IE)

“good layout hoping the manual has what I need to know”

Verified Buyer

September 24, 2025 by 仁和 木村 (???, JP)

“簡単です”

Verified Buyer

September 24, 2025 by Robert S. (Minnesota, US)

“Finding my manual and buying it was fast and easy.”

Verified Buyer

September 23, 2025 by Michel M. (Quebec, CA)

“Easy and fast find car model manual”

Verified Buyer

September 23, 2025 by Gilberto M. (US)

“N/a”