2004-2007 Mitsubishi Endeavor Service & Repair Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

MITSUBISHI

Endeavor

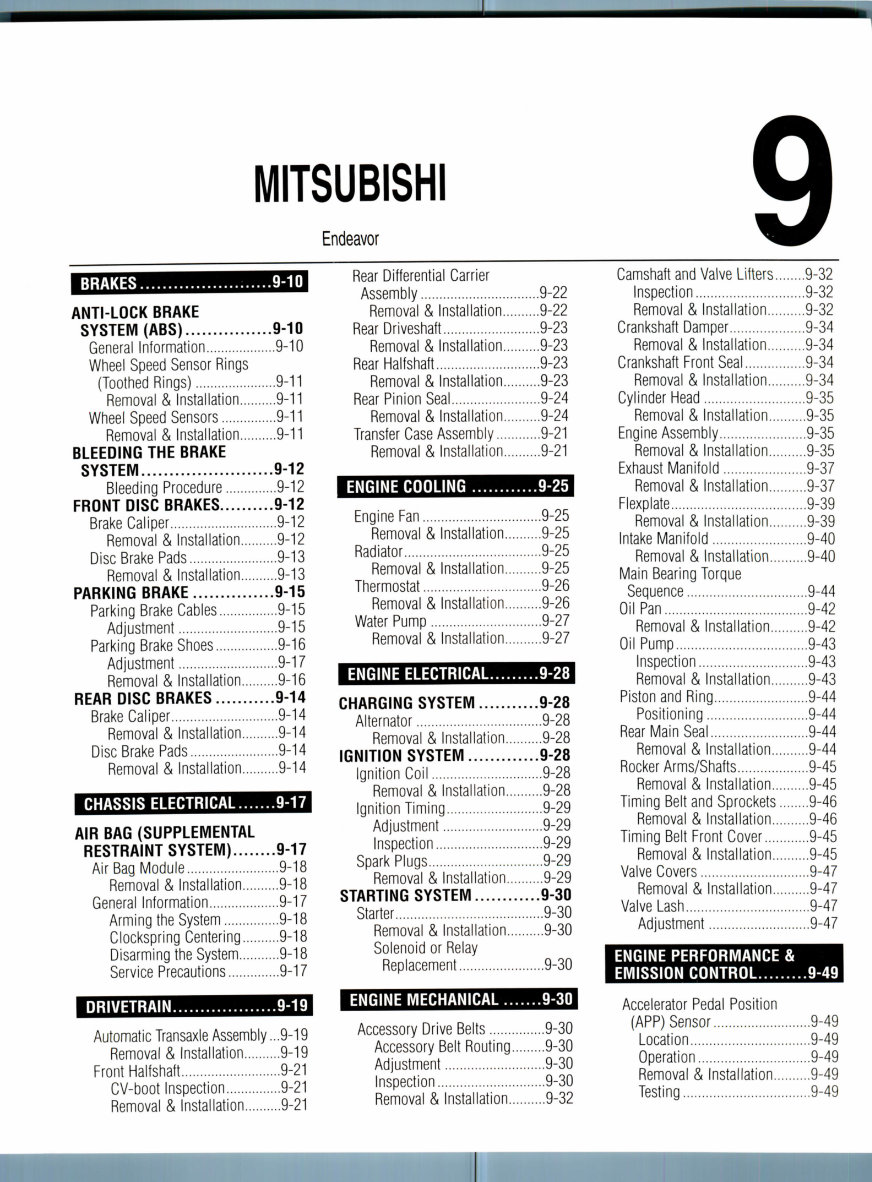

BRAKES 9-10

ANTI-LOCK BRAKE

SYSTEM (ABS) 9-10

General Information 9-10

Wheel Speed Sensor Rings

(Toothed Rings) 9-11

Removal & Installation 9-11

Wheel Speed Sensors 9-11

Removal & Installation 9-11

BLEEDING THE BRAKE

SYSTEM 9-12

Bleeding Procedure 9-12

FRONT DISC BRAKES 9-12

Brake Caliper 9-12

Removal & Installation 9-12

Disc Brake Pads 9-13

Removal & Installation 9-13

PARKING BRAKE 9-15

Parking Brake Cables 9-15

Adjustment 9-15

Parking Brake Shoes 9-16

Adjustment 9-17

Removal & Installation 9-16

REAR DISC BRAKES 9-14

Brake Caliper 9-14

Removal & Installation 9-14

Disc Brake Pads 9-14

Removal & Installation 9-14

CHASSIS ELECTRICAL 9-17

AIR BAG (SUPPLEMENTAL

RESTRAINT SYSTEM) 9-17

Air Bag Module 9-18

Removal & Installation 9-18

General Information 9-17

Arming the System 9-18

Clockspring Centering 9-18

Disarming the System 9-18

Service Precautions 9-17

DRIVETRAIN.

Automatic Transaxle Assembly...9-19

Removal & Installation 9-19

Front Halfshaft 9-21

CV-boot Inspection 9-21

Removal & Installation 9-21

Rear Differential Carrier

Assembly 9-22

Removal & Installation 9-22

Rear Driveshaft 9-23

Removal & Installation 9-23

Rear Halfshaft 9-23

Removal & Installation 9-23

Rear Pinion Seal 9-24

Removal & Installation 9-24

Transfer Case Assembly 9-21

Removal & Installation 9-21

ENGINE COOLING 9-25

Engine Fan 9-25

Removal & Installation 9-25

Radiator 9-25

Removal & Installation 9-25

Thermostat 9-26

Removal & Installation 9-26

Water Pump 9-27

Removal & Installation 9-27

ENGINE ELECTRICAL 9-28

CHARGING SYSTEM 9-28

Alternator 9-28

Removal & Installation 9-28

IGNITION SYSTEM 9-28

Ignition Coil 9-28

Removal & Installation 9-28

Ignition Timing 9-29

Adjustment 9-29

Inspection 9-29

SparkPlugs 9-29

Removal & Installation 9-29

STARTING SYSTEM 9-30

Starter 9-30

Removal & Installation 9-30

Solenoid or Relay

Replacement 9-30

ENGINE MECHANICAL 9-30

Accessory Drive Belts 9-30

Accessory Belt Routing 9-30

Adjustment 9-30

Inspection 9-30

Removal & Installation 9-32

Camshaft and Valve Lifters 9-32

Inspection 9-32

Removal & Installation 9-32

Crankshaft Damper 9-34

Removal & Installation 9-34

Crankshaft Front Seal 9-34

Removal & Installation 9-34

Cylinder Head 9-35

Removal & Installation 9-35

Engine Assembly 9-35

Removal & Installation 9-35

Exhaust Manifold 9-37

Removal & Installation 9-37

Flexplate 9-39

Removal & Installation 9-39

Intake Manifold 9-40

Removal & Installation 9-40

Main Bearing Torque

Sequence 9-44

Oil Pan 9-42

Removal & Installation 9-42

Oil Pump 9-43

Inspection 9-43

Removal & Installation 9-43

Piston and Ring 9-44

Positioning 9-44

Rear Main Seal 9-44

Removal & Installation 9-44

Rocker Arms/Shafts 9-45

Removal & Installation 9-45

Timing Belt and Sprockets 9-46

Removal & Installation 9-46

Timing Belt Front Cover 9-45

Removal & Installation 9-45

Valve Covers 9-47

Removal & Installation 9-47

Valve Lash 9-47

Adjustment 9-47

ENGINE PERFORMANCE &

EMISSION CONTROL 9-49

Accelerator Pedal Position

(APP) Sensor 9-49

Location 9-49

Operation 9-49

Removal & Installation 9-49

Testing 9-49

QO MITSUBISHI

ENDEAVOR

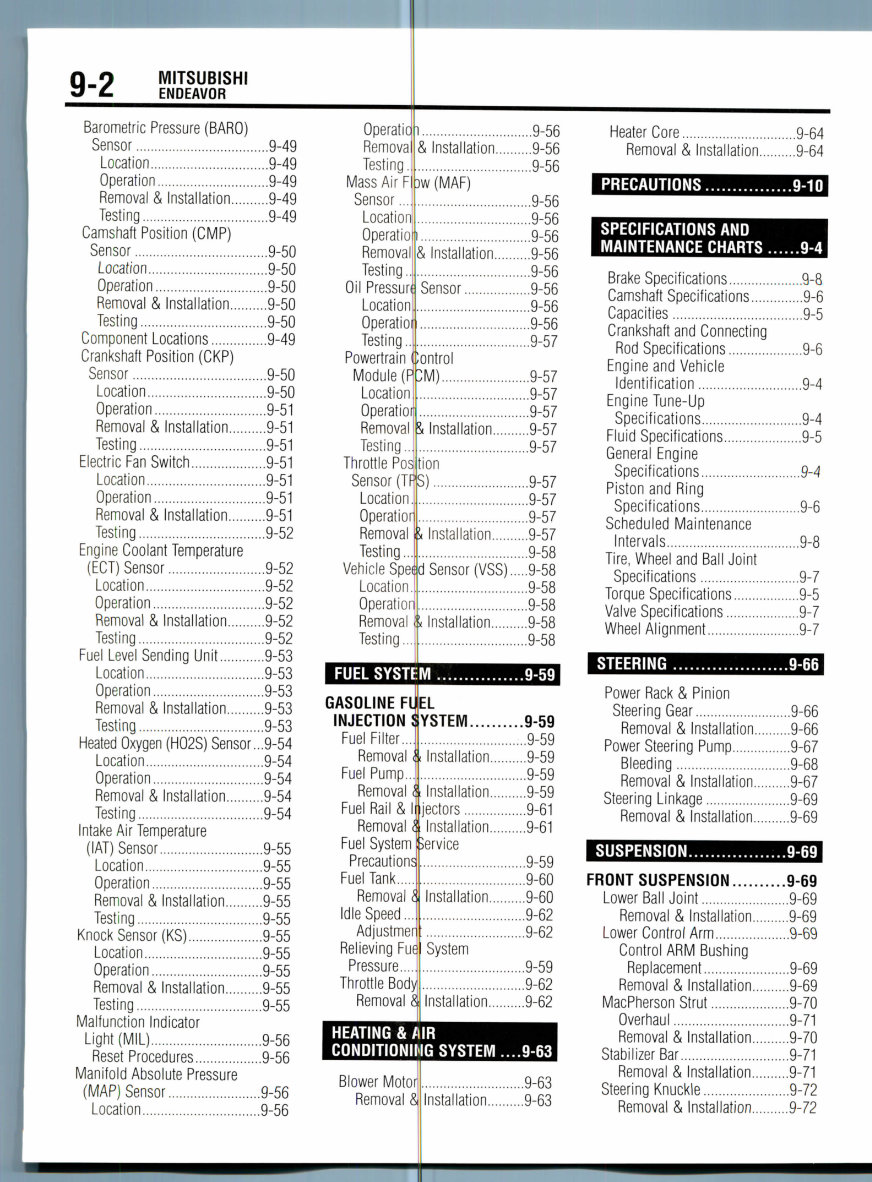

Barometric Pressure (BARO)

Sensor 9-49

Location 9-49

Operation 9-49

Removal & Installation 9-49

Testing 9-49

Camshaft Position (CMP)

Sensor 9-50

LocafJon 9-50

Operation 9-50

Removal & Installation 9-50

Testing 9-50

Component Locations 9-49

Crankshaft Position (CKP)

Sensor 9-50

Location 9-50

Operation 9-51

Removal & Installation 9-51

Testing 9-51

Electric Fan Switch 9-51

Location 9-51

Operation 9-51

Removal & Installation 9-51

Testing 9-52

Engine Coolant Temperature

(ECT) Sensor 9-52

Location 9-52

Operation 9-52

Removal & Installation 9-52

Testing 9-52

Fuel Level Sending Unit 9-53

Location 9-53

Operation 9-53

Removal & Installation 9-53

Testing 9-53

Heated Oxygen (H02S) Sensor...9-54

Location 9-54

Operation 9-54

Removal & Installation 9-54

Testing 9-54

Intake Air Temperature

(IAT) Sensor 9-55

Location 9-55

Operation 9-55

Removal & Installation 9-55

Testing 9-55

Knock Sensor (KS) 9-55

Location 9-55

Operation 9-55

Removal & Installation 9-55

Testing 9-55

Malfunction Indicator

Light (MIL) 9-56

Reset Procedures 9-56

Manifold Absolute Pressure

(MAP) Sensor 9-56

Location... ....9-56

Operatio

Remova

Testing.

Mass Air F

Sensor...

Location

Operatio

Removal

Testing.

Oil Pressur

Location

Operatio

Testing.

Powertrain

Module (P

Location

Operatio

Removal

Testing.

Throttle Po

Sensor(Tf

Location

Operatior

Removal

Testing..

Vehicle Spe

Location

Operation

Removal

Testing..

9-56

& Installation 9-56

9.55

w(MAF)

9-56

9-56

9-56

& Installation 9-56

9-56

Sensor 9-56

9-56

9-56

9-57

ontrol

}M) 9-57

9-57

9-57

i Installation 9-57

9-57

ion

)) 9-57

9-57

9-57

i Installation 9-57

9-58

d Sensor (VSS) 9-58

9-58

9-58

Installation 9-58

....9-58

FUEL SYSTEM 9-59

GASOLINE FL

INJECTION i

Fuel Filter...

Removal

Fuel Pump..

Removal

Fuel Rail & I

Removal

Fuel System

Precaution:

Fuel Tank....

Removal

Idle Speed..

Adjustmer

Relieving Fu

Pressure...

Throttle Bod\l

EL

YSTEM 9-59

9-59

Installation 9-59

9-59

Installation 9-59

jectors 9-61

Installation 9-61

ervice

9-59

9-60

Installation 9-60

9-62

9-62

System

9-59

9-62

Installation 9-62

HEATING & />IR

CONDITIONING SYSTEM ....9-63

Blower Motor

Removal &

9-63

Installation 9-63

Heater Core 9-64

Removal & Installation 9-64

PRECAUTIONS 9-10

SPECIFICATIONS AND

MAINTENANCE CHARTS 9-4

Brake Specifications 9-8

Camshaft Specifications 9-6

Capacities 9-5

Crankshaft and Connecting

Rod Specifications 9-6

Engine and Vehicle

Identification 9-4

Engine Tune-Up

Specifications 9-4

Fluid Specifications 9-5

General Engine

Specifications 9-4

Piston and Ring

Specifications 9-6

Scheduled Maintenance

Intervals 9-8

Tire, Wheel and Ball Joint

Specifications 9-7

Torque Specifications 9-5

Valve Specifications 9-7

Wheel Alignment 9-7

STEERING 9-66

Power Rack & Pinion

Steering Gear 9-66

Removal & Installation 9-66

Power Steering Pump 9-67

Bleeding 9-68

Removal & Installation 9-67

Steering Linkage 9-69

Removal & Installation 9-69

SUSPENSION 9-69

FRONT SUSPENSION 9-69

Lower Ball Joint 9-69

Removal & Installation 9-69

Lower Control Arm 9-69

Control ARM Bushing

Replacement 9-69

Removal & Installation 9-69

MacPherson Strut 9-70

Overhaul 9-71

Removal & Installation 9-70

Stabilizer Bar 9-71

Removal & Installation 9-71

Steering Knuckle 9-72

Removal & Installation 9-72

MITSUBISHI

ENDEAVOR

9-3

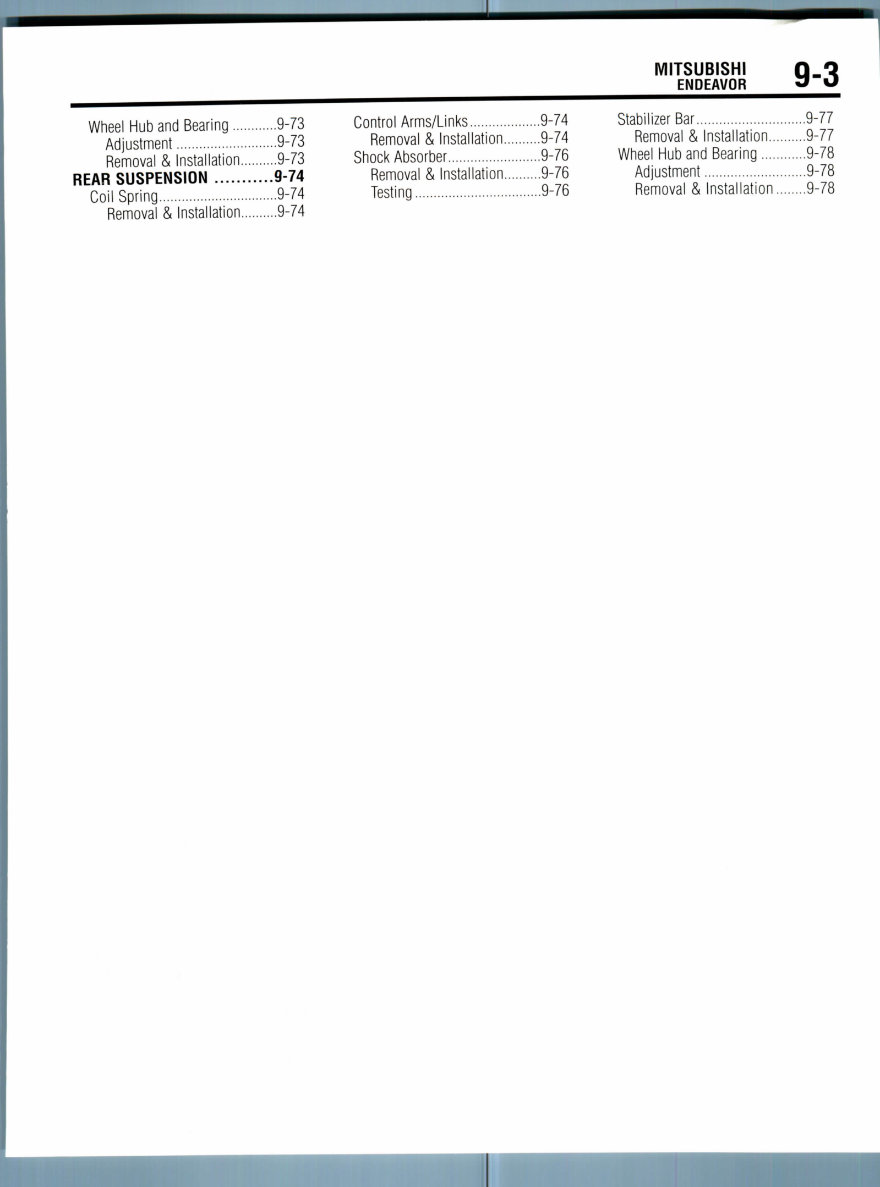

Wheel Hub and Bearing 9-73

Adjustment 9-73

Removal & Installation 9-73

REAR SUSPENSION 9-74

Coil Spring 9-74

Removal & Installation 9-74

Control Arms/Links 9-74

Removal & Installation 9-74

Shock Absorber 9-76

Removal & Installation 9-76

Testing 9-76

Stabilizer Bar 9-77

Removal & Installation 9-77

Wheel Hub and Bearing 9-78

Adjustment 9-78

Removal & Installation 9-78

9-4

MITSUBISHI

ENDEAVOR

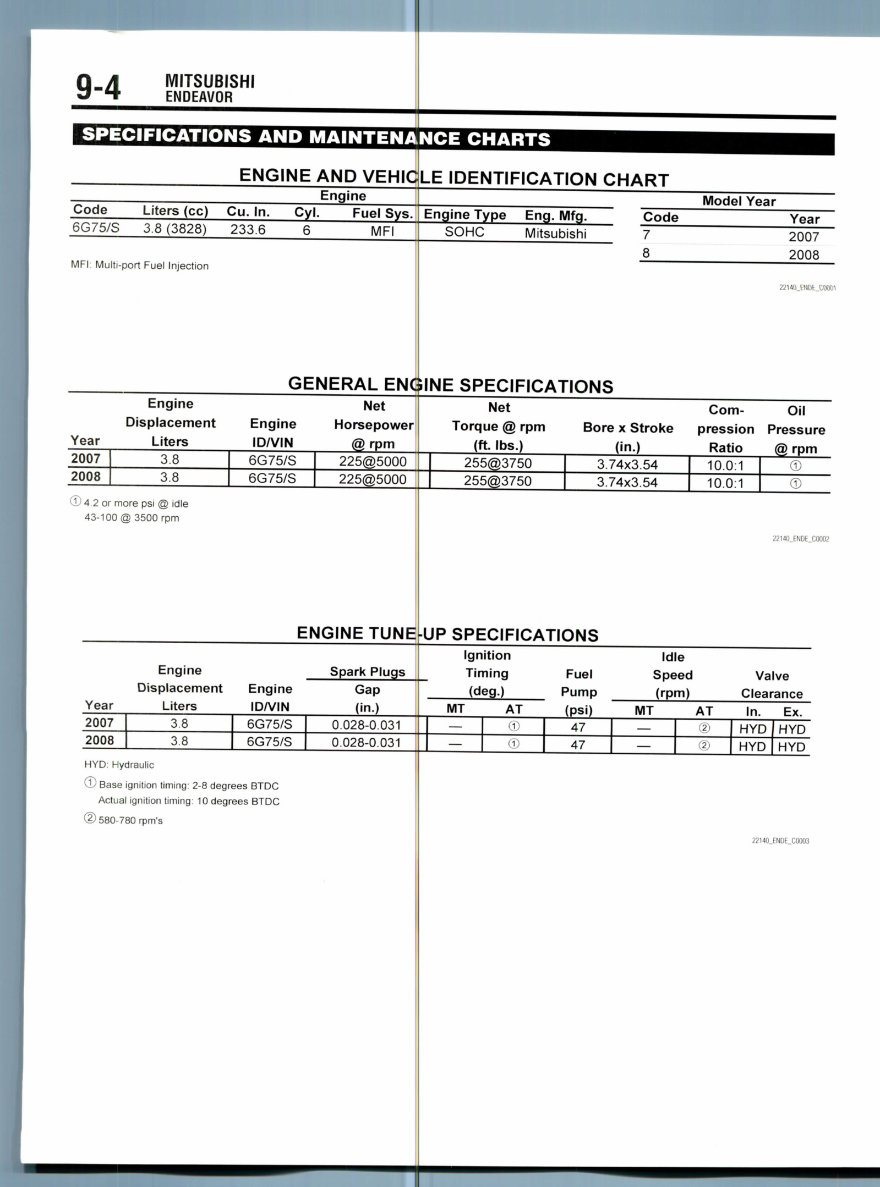

SPECIFICATIONS AND MAINTENANCE CHARTS

ENGINE AND VEHICLE IDENTIFICATION CHART

Engine Model Year

Code Liters (cc) Cu. In. Cyl. Fuel Sys. Engine Type Eng. Mfg. Code Year

3.8 (3828) 233.6 MFI

MFI Multi-port Fuel Injection

Mitsubishi 2007

2008

GENERAL ENCilNE SPECIFICATIONS

Engine Net

Displacement Engine Horsepower

Year Liters ID/VIN @ rpm

Net

Torque @ rpm

(ft. Ibs.)

Bore x Stroke

(in.)

Com-

pression

Ratio

Oil

Pressure

~ rpm

2007

2008

3.8

3.8

6G75/S

6G75/S

225@5000

225@5000

255@3750

255@3750

3.74x3.54

3.74x3.54

10.0:1

10.0:1

©

©

© 4.2 or more psi @ idle

43-100 @ 3500 rpm

22140JNDE_C0002

ENGINE TUNE4JP SPECIFICATIONS

Year

2007

2008

Engine

Displacement

Liters

3.8

3.8

Engine

IDA/IN

6G75/S

6G75/S

Spark Plugs

Gap

(in.)

0.028-0.031

0.028-0.031

Ignition

Timing

(deg.)

MT AT

—

®

ii :

Fuel

Pump

(psi)

47

47

Idle

Speed

(rpm)

MT AT

—

—

:2i

2

Valve

Clearance

In.

HYD

HYD

Ex.

HYD

HYD

HYD: Hydraulic

JJ Base ignition timing: 2-8 degrees BTDC

Actual ignition timing: 10 degrees BTDC

@ 580-780 rpm's

22140.ENDE C0003

MITSUBISHI

ENDEAVOR

9-5

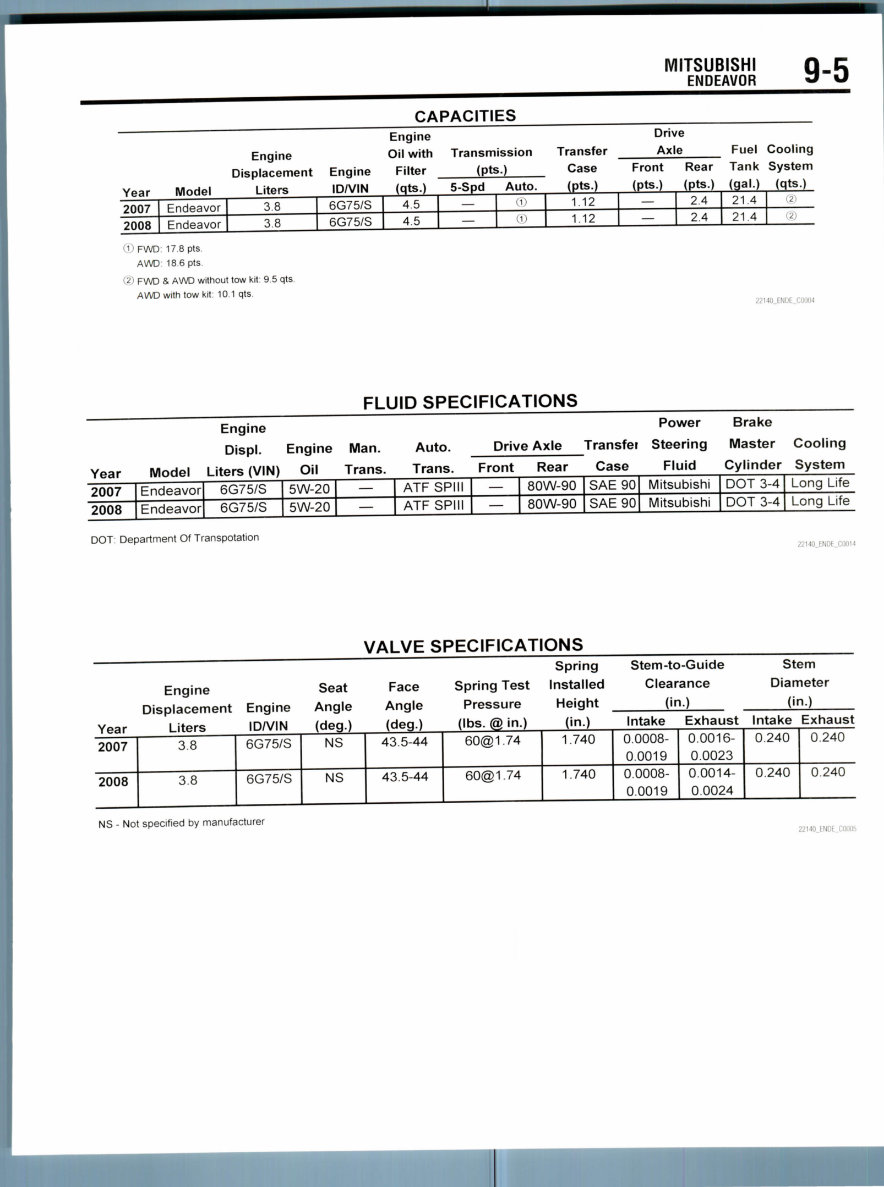

CAPACITIES

Engine

Displacement

Year Model Liters

2007 Endeavor 3.8

2008 Endeavor 3.8

Engine

IDA/IN

6G75/S

6G75/S

Engine

Oil with

Filter

(qts.)

4.5

4.5

Transmission Transfer

(pts.) Case

5-Spd

—

—

Auto. (pts.)

•1) 1.12

® 1.12

Drive

Axle

Front Rear

(pts.) (pts.)

— 2.4

— 2.4

Fuel

Tank

(gai.)

21 4

21.4

Cooling

System

(qts.)

2

2

'1 ' FWD: 17.8 pts.

AWD 18.6 pts.

(2) FWD & AWD without tow kit: 95 qts

AWD with tow kit: 10.1 qts.

1 : '.

FLUID SPECIFICATIONS

Engine

Displ. Engine Man. Auto.

Year Model Liters (VIN) Oil Trans. Trans.

2007

2008

Endeavor

Endeavor

6G75/S

6G75/S

5W-20

5W-20

—

—

ATF SPIN

ATF SPIN

Drive Axle

Front Rear

—

—

80W-90

80W-90

Power Brake

Transfei Steering Master Cooling

Case Fluid Cylinder System

SAE90

SAE90

Mitsubishi

Mitsubishi

DOT 3-4

DOT 3-4

Long Life

Long Life

• •. •.

VALVE SPECIFICATIONS

Spring

Engine Seat Face Spring Test Installed

Displacement Engine Angle Angle Pressure Height

Year Liters IDA/IN (deg.) (deg.) (Ibs. @ in.) (in.)

2007

2008

3.8

3.8

6G75/S

6G75/S

NS

NS

43.5-44

43.5-44

60@1.74

60@1.74

1.740

1.740

Stem-to-Guide Stem

Clearance Diameter

(in.) (in.)

Intake Exhaust Intake Exhaust

0.0008-

0.0019

0.0008-

0.0019

0.0016-

0.0023

0.0014-

0.0024

0.240

0.240

0.240

0.240

NS - Not specified by manufacturer

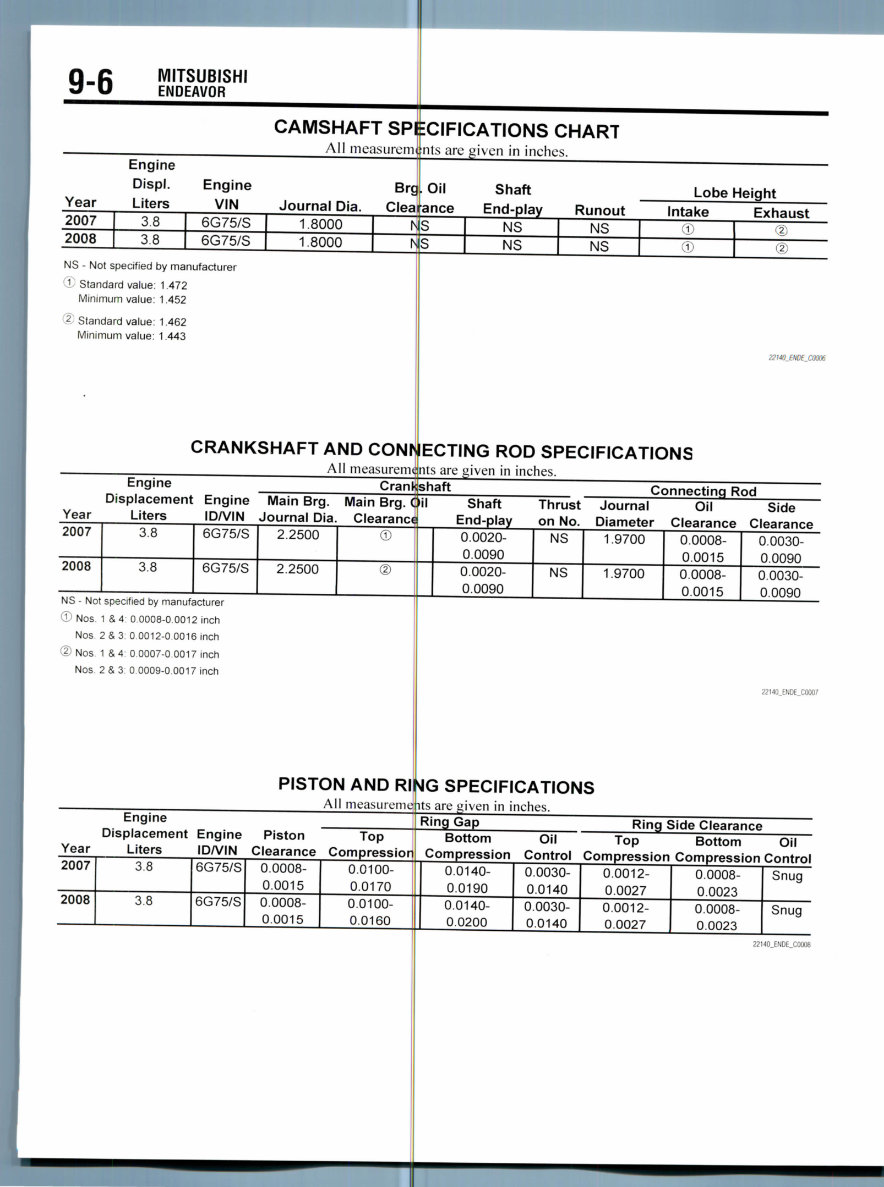

9-6

Year

2007

2008

MITSUBISHI

ENDEAVOR

Engine

Displ.

Liters

3.8

3.8

Engine

VIN

6G75/S

6G75/S

CAMSHAFT SPI

All measurerm

Journal Dia.

1.8000

1.8000

Brg

Clea

IN

IN

CIFICATIONS CHART

nts arc given in inches.

Oil

ance

S

S

Shaft

End-play

NS

NS

Lobe Height

Runout Intake Exhaust

NS (

NS C

j ''2;

") ''2;

NS - Not specified by manufacturer

1 Standard value: 1.472

Minimum value: 1.452

'2 Standard value: 1.462

Minimum value: 1.443

CRANKSHAFT AND CONK

All measurem

22140JNOE_C0006

ECTING ROD SPECIFICATIONS

nts are uiven in inches.

Engine

Displacement Engine

Year Liters IDA/IN

2007

2008

3.8

3.8

6G75/S

6G75/S

Crank

Main Brg. Main Brg. (

Journal Oia. Clearance

2.2500

2.2500

©

®

shaft Connecting Rod

il Shaft Thrust Journal Oil Side

End-play on No. Diameter Clearance Clearance

0.0020-

0.0090

0.0020-

0.0090

NS

NS

1.9700

1.9700

0.0008-

0.0015

0.0008-

0.0015

0.0030-

0.0090

0.0030-

0.0090

NS - Not specified by manufacturer

© Nos. 1 & 4 0.0008-0.0012 inch

Nos 2 & 3: 0.0012-0.0016 inch

© Nos. 1 & 4: 0.0007-0.0017 inch

Nos 2&3 00009-0 0017 inch

2214(LENDE_C0007

PISTON AND R

All measurem

>4G SPECIFICATIONS

Us are given in inches.

Engine

Displacement Engine Piston

Year Liters IDA/IN Clearance

2007

2008

3.8

3.8

6G75/S

6G75/S

0.0008-

0.0015

0.0008-

0.0015

Top

Compression

0.0100-

0.0170

0.0100-

0.0160

Ring Gap Ring Side Clearance

Bottom Oil Top Bottom Oil

Compression Control Compression Compression Control

0.0140-

0.0190

0.0140-

0.0200

0.0030-

0.0140

0.0030-

0.0140

0.0012-

0.0027

0.0012-

0.0027

0.0008-

0.0023

0.0008-

0.0023

Snug

Snug

22140_ENDE,C0008

MITSUBISHI

ENDEAVOR 9-7

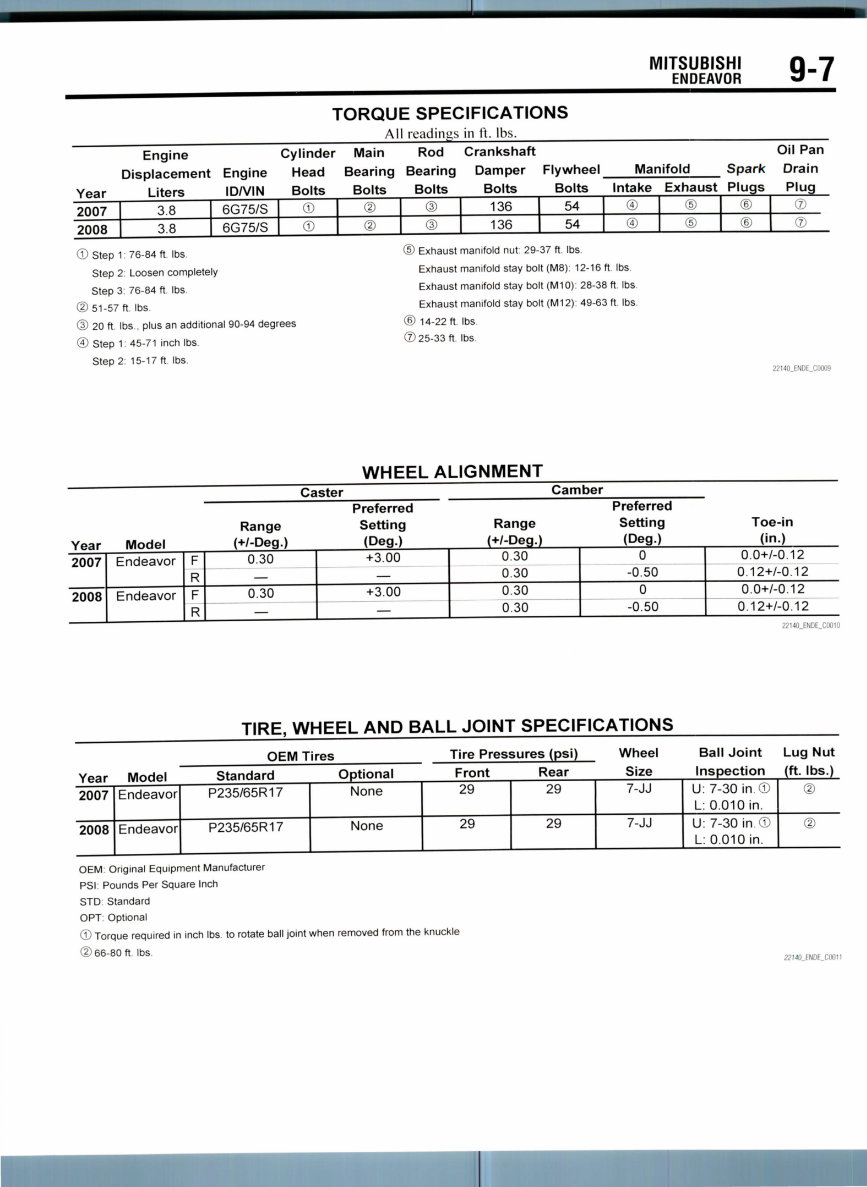

TORQUE SPECIFICATIONS

All readings in It. Ihs.

Year

2007

2008

Engine

Displacement Engine

Liters IDA/IN

3.8

3.8

6G75/S

6G75/S

Cylinder

Head

Bolts

©

©

Main

Bearing

Bolts

©

©

Rod

Bearing

Bolts

©

©

Crankshaft

Damper

Bolts

136

136

Flywheel Manifold

Bolts Intake Exhaust

54

54

0 ©

D (5J

Spark

Plugs

©

©

Oil Pan

Drain

Plug

©

©

© Step 1: 76-84 ft. Ibs.

Step 2: Loosen completely

Step 3: 76-84 ft. Ibs.

(D 51-57 ft. Ibs

© 20 ft. Ibs , plus an additional 90-94 degrees

© Step 1: 45-71 inch Ibs

Step 2: 15-17 ft. Ibs.

© Exhaust manifold nut: 29-37 ft. Ibs.

Exhaust manifold stay bolt (M8): 12-16 ft. Ibs.

Exhaust manifold stay bolt (M10): 28-38 ft. Ibs

Exhaust manifold stay bolt (M12): 49-63 ft. Ibs.

© 14-22 ft. Ibs.

©25-33 ft Ibs

22l4C_ENDE_C0009

WHEEL ALIGNMENT

Caster Camber

Preferred Preferred

Range Setting Range Setting Toe-in

Year Model (+/-Deg.) (Deg.) (+/-Deg.) (Deg.) (in.)

2007

2008

Endeavor

Endeavor

F

R

F

R

0.30

0.30

+3.00

+3.00

0.30

0.30

0.30

0.30

0

-0.50

0

-0.50

0.0+/-0.12

0.12+/-0.12

0.0+/-0.12

0.12+/-0.12

22140_ENOE_C0010

TIRE, WHEEL AND BALL JOINT SPECIFICATIONS

Year Model

2007

2008

Endeavor

Endeavor

OEM Tires Tire Pressures (psi)

Standard Optional Front Rear

P235/65R17

P235/65R17

None

None

29

29

29

29

Wheel Ball Joint Lug Nut

Size Inspection (ft. Ibs.)

7-JJ

7-JJ

U: 7-30 in ©

L: 0.010 in.

U: 7-30 in ©

L: 0.010 in.

@

©

OEM Original Equipment Manufacturer

PSI: Pounds Per Square Inch

STD: Standard

OPT: Optional

© Torque required in inch Ibs. to rotate ball joint when removed from the knuckle

©66-80 ft. Ibs.

22MO_ENDE_C0011

9-8

MITSUBISHI

ENDEAVOR

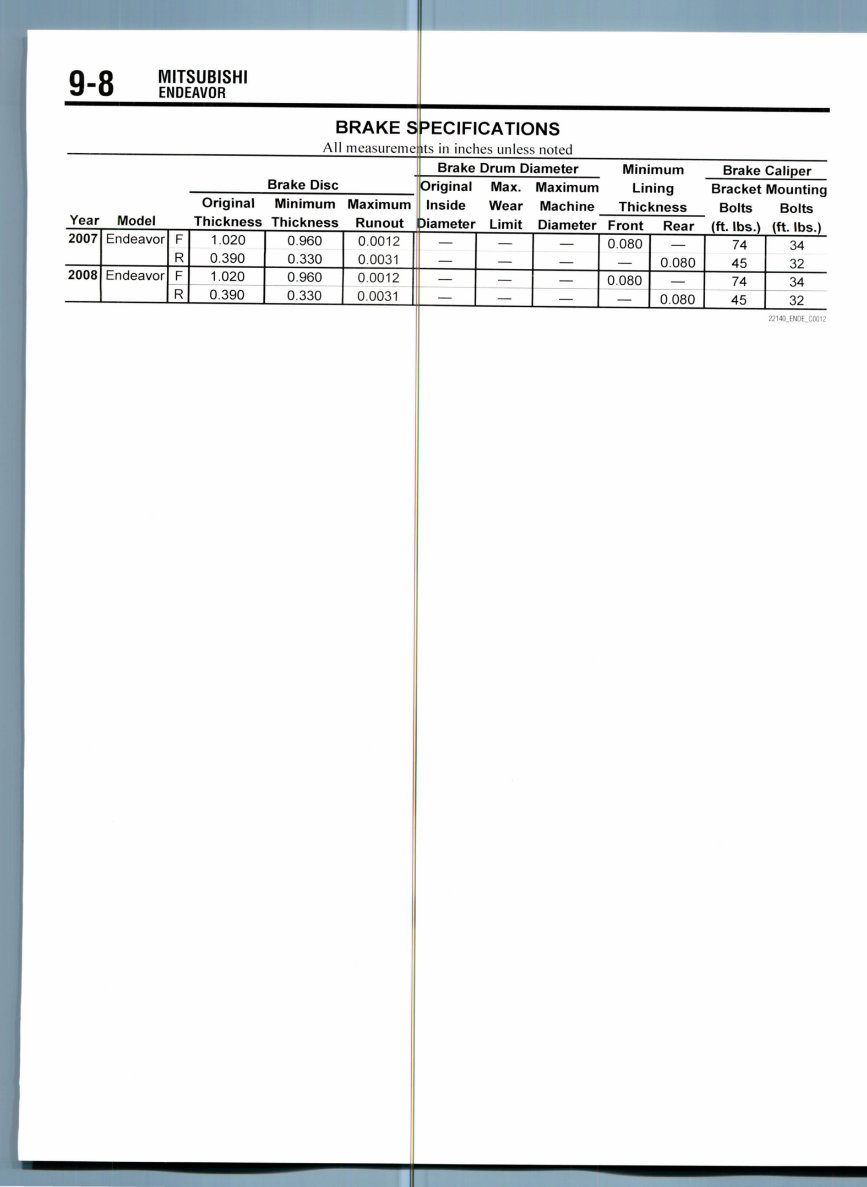

BRAKE S

All measureine

Year Model

2007

2008

Endeavor

Endeavor

F

R

F

R

Brake Disc

Original Minimum Maximum

Thickness Thickness Runout

1.020

0.390

1.020

0.390

0.960

0.330

0.960

0.330

0.0012

0.0031

0.0012

0.0031

=>ECIFICATIONS

its in inches unless noted

Brake Drum Diameter

f

riginal Max. Maximum

nside Wear Machine

ameter Limit Diameter

i

—

—

—

—

—

Minimum

Lining

Thickness

Front Rear

0.080

0.080

0.080

0.080

Brake Caliper

Bracket Mounting

Bolts Bolts

(ft. Ibs.) (ft. Ibs.)

74

45

74

45

34

32

34

32

MITSUBISHI

ENDEAVOR 9-9

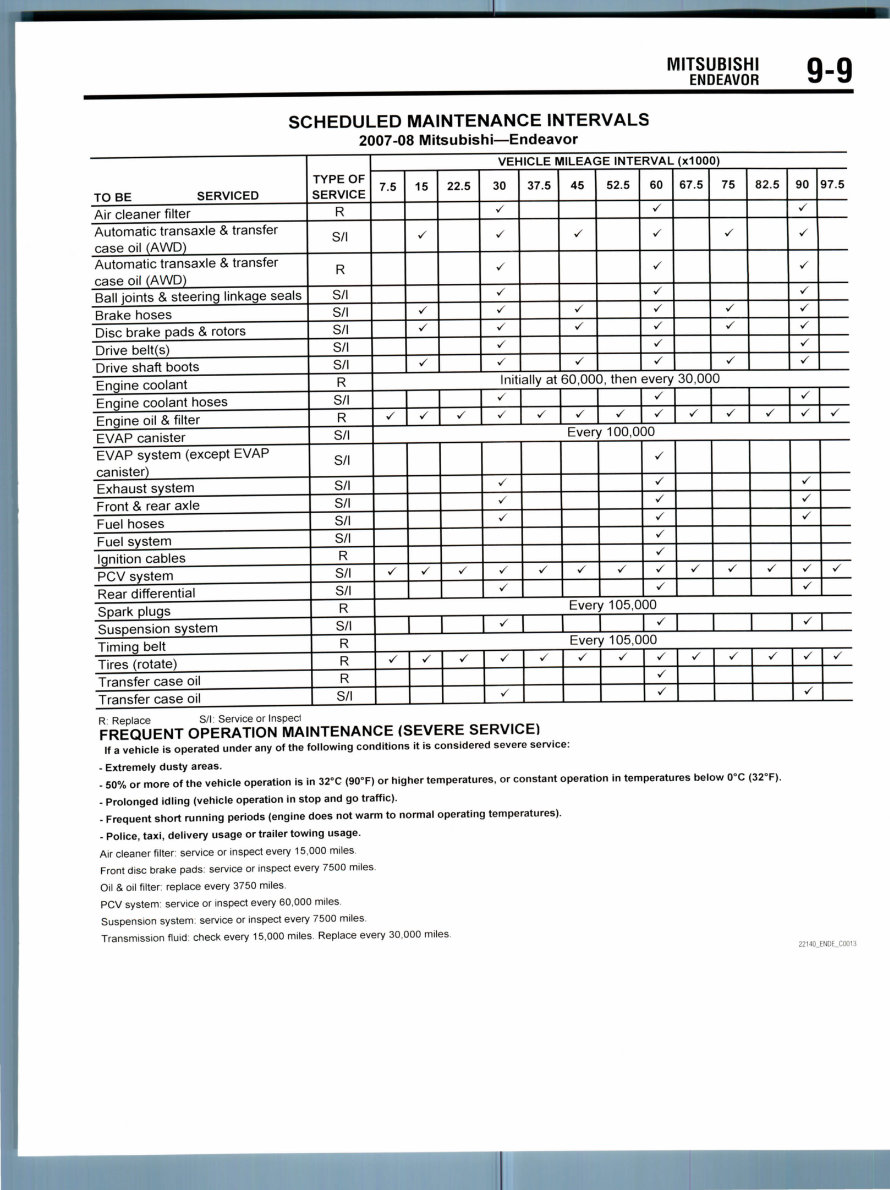

SCHEDULED MAINTENANCE INTERVALS

2007-08 Mitsubishi—Endeavor

TO BE SERVICED

Air cleaner filter

Automatic transaxle & transfer

case oil (AWD)

Automatic transaxle & transfer

case oil (AWD)

Ball joints & steering linkage seals

Brake hoses

Disc brake pads & rotors

Drive belt(s)

Drive shaft boots

Engine coolant

Engine coolant hoses

Engine oil & filter

EVAP canister

EVAP system (except EVAP

canister)

Exhaust system

Front & rear axle

Fuel hoses

Fuel system

Ignition cables

PCV system

Rear differential

Spark plugs

Suspension system

Timing belt

Tires (rotate)

Transfer case oil

Transfer case oil

TYPE OF

SERVICE

R

S/l

R

S/l

S/l

S/l

S/l

S/l

R

S/l

R

S/l

S/l

S/l

S/l

S/l

S/l

R

S/l

S/l

R

S/l

R

R

R

S/l

VEHICLE MILEAGE INTERVAL (xlOOO)

7.5 15

•/

</

S

S

22.5 30

•/

S

S

•/

S

S

V

•/

37.5 45

S

•/

S

•/

52.5 60

S

S

</

S

•/

S

S

S

67.5 75

S

•/

V

•/

82.5 90

•/

S

S

v

S

•/

•/

•S

97.5

Initially at 60,000, then every 30,000

s •/ •/

</

S S •/ S

•/

•/ •/ S V

V

S •/

Every 100,000

s •S v1

•

•/

•/

S

•/

•/ </ V

S

•/

S

S

•/

•/

•/

S

•/ V S

S

•/

V

S

•/

V

Every 105,000

V S S

Every 105,000

s -/ S </

S

•/ V V S

•/

V

S •/ V V

•/

S

R Replace S/l: Service or Inspecl

FREQUENT OPERATION MAINTENANCE (SEVERE SERVICE)

If a vehicle is operated under any of the following conditions it is considered severe service:

- Extremely dusty areas.

- 50% or more of the vehicle operation is in 32°C (90°F) or higher temperatures, or constant operation in temperatures below 0°C (32*

- Prolonged idling (vehicle operation in stop and go traffic).

- Frequent short running periods (engine does not warm to normal operating temperatures).

- Police, taxi, delivery usage or trailer towing usage.

Air cleaner filter: service or inspect every 15,000 miles

Front disc brake pads: service or inspect every 7500 miles

Oil & oil filter: replace every 3750 miles

PCV system: service or inspect every 60,000 miles

Suspension system: service or inspect every 7500 miles

Transmission fluid: check every 15,000 miles Replace every 30,000 miles

F).

22HO_ENDE_C0013

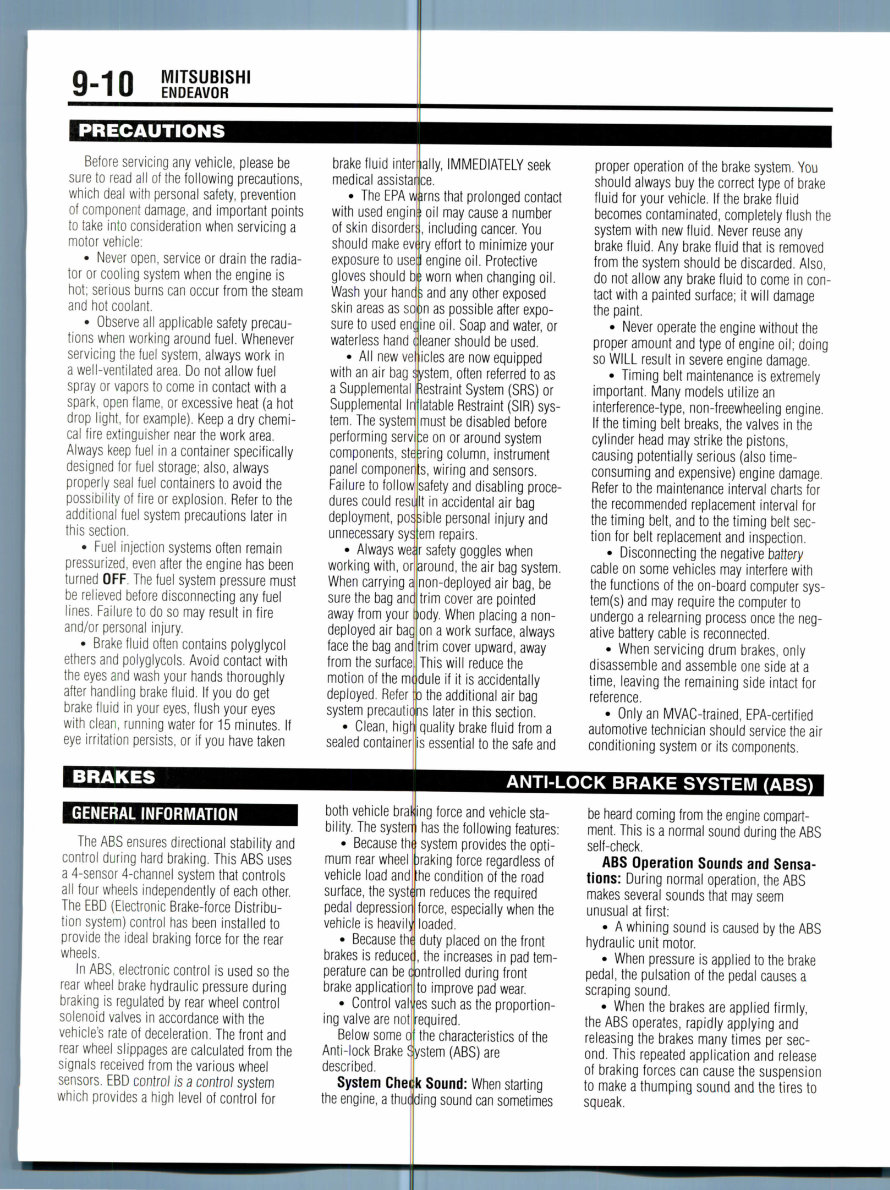

PRECAUTIONS

Before servicing any vehicle, please be

sure to read all ot the following precautions,

which deal with personal safety, prevention

of component damage, and important points

to take into consideration when servicing a

motor vehicle:

• Never open, service or drain the radia-

tor or cooling system when the engine is

hot; serious burns can occur from the steam

and hot coolant.

• Observe all applicable safety precau-

tions when working around fuel. Whenever

servicing the fuel system, always work in

a well-ventilated area. Do not allow fuel

spray or vapors to come in contact with a

spark, open flame, or excessive heat (a hot

drop light, for example). Keep a dry chemi-

cal fire extinguisher near the work area.

Always keep fuel in a container specifically

designed for fuel storage; also, always

properly seal fuel containers to avoid the

possibility of fire or explosion. Refer to the

additional fuel system precautions later in

this section.

• Fuel injection systems often remain

pressurized, even after the engine has been

turned OFF. The fuel system pressure must

be relieved before disconnecting any fuel

lines. Failure to do so may result in fire

and/or personal injury.

• Brake fluid often contains polyglycol

ethers and polyglycols. Avoid contact with

the eyes and wash your hands thoroughly

after handling brake fluid. If you do get

brake fluid in your eyes, flush your eyes

with clean, running water for 15 minutes. If

eye irritation persists, or if you have taken

BRAKES

GENERAL INFORMATION

The ABS ensures directional stability and

control during hard braking. This ABS uses

a 4-sensor 4-channel system that controls

all four wheels independently of each other.

The EBD (Electronic Brake-force Distribu-

tion system) control has been installed to

provide the ideal braking force for the rear

wheels.

In ABS. electronic control is used so the

rear wheel brake hydraulic pressure during

braking is regulated by rear wheel control

solenoid valves in accordance with the

vehicle's rate of deceleration. The front and

rear wheel slippages are calculated from the

signals received from the various wheel

sensors. EBD control is a confrol system

which provides a high level of control for

brake fluid

medical assistai)

• The EPA vJ

with used enginl

of skin disorder!

should make evj

exposure to use

gloves should b

Wash your hand

skin areas as sot

sure to used entj

waterless hand

• All new vej

with an air bag \ Supplemental

Supplemental In

tern. The system

performing servj

components, std

panel componen

Failure to follow

dures could

deployment, pos

unnecessary sys

• Always we;

working with,

When carrying

sure the bag anc

away from your

deployed air bac

face the bag and

from the surface

motion of the mi

deployed. Refer

system

• Clean, higf

sealed container

internally, IMMEDIATELY seek

o

precautions

rns that prolonged contact

oil may cause a number

including cancer. You

'y effort to minimize your

engine oil. Protective

worn when changing oil.

and any other exposed

n as possible after expo-

ne oil. Soap and water, or

(jjeaner should be used,

ides are now equipped

ystem, often referred to as

estraint System (SRS) or

atable Restraint (SIR) sys-

must be disabled before

e on or around system

ring column, instrument

s, wiring and sensors.

;afety and disabling proce-

l in accidental air bag

ible personal injury and

em repairs,

r safety goggles when

or| around, the air bag system.

a non-deployed air bag, be

trim cover are pointed

ody. When placing a non-

on a work surface, always

trim cover upward, away

This will reduce the

dule if it is accidentally

the additional air bag

later in this section,

quality brake fluid from a

is essential to the safe and

proper operation of the brake system. You

should always buy the correct type of brake

fluid for your vehicle. If the brake fluid

becomes contaminated, completely flush the

system with new fluid. Never reuse any

brake fluid. Any brake fluid that is removed

from the system should be discarded. Also,

do not allow any brake fluid to come in con-

tact with a painted surface; it will damage

the paint.

• Never operate the engine without the

proper amount and type of engine oil; doing

so WILL result in severe engine damage.

• Timing belt maintenance is extremely

important. Many models utilize an

interference-type, non-freewheeling engine.

If the timing belt breaks, the valves in the

cylinder head may strike the pistons,

causing potentially serious (also time-

consuming and expensive) engine damage.

Refer to the maintenance interval charts for

the recommended replacement interval for

the timing belt, and to the timing belt sec-

tion for belt replacement and inspection.

• Disconnecting the negative battery

cable on some vehicles may interfere with

the functions of the on-board computer sys-

tem^) and may require the computer to

undergo a relearning process once the neg-

ative battery cable is reconnected.

• When servicing drum brakes, only

disassemble and assemble one side at a

time, leaving the remaining side intact for

reference.

• Only an MVAC-trained, EPA-certified

automotive technician should service the air

conditioning system or its components.

ANTI-LOCK BRAKE SYSTEM(ABS)

bral ing both vehicle

bility. The systeq

• Becauseth

mum rear wheel

vehicle load and

surface, the system

pedal depressior

vehicle is heavily

• Becauseth

brakes is reduce!

perature can be

brake applicatior

• Control val1

ing valve are not

Below some c

Anti-lock Brake

described.

System Chedk

the engine, a thudding

force and vehicle sta-

has the following features:

system provides the opti-

)raking force regardless of

he condition of the road

reduces the required

force, especially when the

loaded.

duty placed on the front

, the increases in pad tem-

(fjontrolled during front

to improve pad wear,

es such as the proportion-

equired.

the characteristics of the

ystem (ABS) are

Sound: When starting

sound can sometimes

be heard coming from the engine compart-

ment. This is a normal sound during the ABS

self-check.

ABS Operation Sounds and Sensa-

tions: During normal operation, the ABS

makes several sounds that may seem

unusual at first:

• A whining sound is caused by the ABS

hydraulic unit motor.

• When pressure is applied to the brake

pedal, the pulsation of the pedal causes a

scraping sound.

• When the brakes are applied firmly,

the ABS operates, rapidly applying and

releasing the brakes many times per sec-

ond. This repeated application and release

of braking forces can cause the suspension

to make a thumping sound and the tires to

squeak.

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$32.99

Viewed 29 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$32.99

Mitsubishi Endeavor 2004-2007 Service Repair Manual is a comprehensive guide covering all aspects of car repair and maintenance. Whether you are a professional mechanic or a DIY enthusiast, this manual provides detailed instructions for servicing your vehicle.

The manual is available in PDF format, allowing for easy reading, zooming, and printout. It is compatible with both Windows and MAC systems, ensuring accessibility for a wide range of users.