1996 Mercury Cougar Service & Repair Manual Software

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

E - THEORY/OPERATION - 4.6L

1996 ENGINE PERFORMANCE Ford Motor Co. - Theory & Operation - EEC-V

INTRODUCTION

This article covers basic description and operation of engine performance-related systems and components.

Read this article before diagnosing vehicles or systems with which you are not completely familiar.

COMPUTERIZED ENGINE CONTROLS

CONTROLS

Powertrain Control Module (PCM)

PCM monitors engine operating conditions by input received from engine sensors. Control of output actuators

determines fuel mixture and idle speed. PCM is located behind right kick panel.

The engine control system consists of the PCM, relays, modules, sensors, switches and actuators. The PCM

sends out electrical reference signals to engine sensors and then analyzes the return signals. The engine sensors

supply the PCM with specific information, in the form of electrical signals, to determine engine operating

conditions.

In the event of a sensor or actuator failure, the PCM initiates an alternative strategy called Failure Mode Effects

Management (FMEM) to allow the vehicle to maintain driveability. In the event of PCM failure, Hardware

Limited Operation Strategy (HLOS) will be activated. HLOS is a system of alternate circuitry that provides

minimal engine operation if the PCM fails. During HLOS, all self-test function will stop and system will be

controlled by electronic hardware.

Malfunction Indicator Light (MIL) will remain on whenever FMEM or HLOS is in operation. FMEM and

HLOS substitute a fixed signal and continue to monitor system failure. If signal(s) return to within operating

limits, PCM will resume normal operation.

Constant Control Relay Module (CCRM)

CCRM interfaces with the PCM to control cooling fan, A/C clutch and fuel pump operation. The CCRM also

incorporates electronic engine control power relay to supply power to the EEC-V system.

Fuel Pump Driver Module (FPDM)

FPDM interfaces with the PCM to control fuel pump operation. By controlling fuel pump operation, noise and

the amount of hot fuel returned to the fuel tank is minimized. If FPDM or system fail self-test, DTC P1230,

P1233, P1234, P1235 P1236, P1237 or P1238 may be set in PCM memory.

NOTE: Components are grouped into 2 categories. The first category covers INPUT

DEVICES, which control or produce voltage signals monitored by the control

unit. The second category covers OUTPUT SIGNALS , covering components

controlled by the PCM.

1996 Ford Thunderbird LX

E - THEORY/OPERATION - 4.6L 1996 ENGINE PERFORMANCE Ford Motor Co. - Theory & Operation - EEC-V

1996 Ford Thunderbird LX

E - THEORY/OPERATION - 4.6L 1996 ENGINE PERFORMANCE Ford Motor Co. - Theory & Operation - EEC-V

INPUT DEVICES

Vehicles are equipped with different combinations of input devices. Not all devices are used on all models. To

determine the input device used on a specific model, see wiring diagram in the WIRING DIAGRAMS article.

The available input signals include the following:

Brake On/Off (BOO) Switch

BOO switch is wired to brakelight circuit. It signals the PCM when the brake is applied. The BOO input is used

to adjust engine idle when A/C is in use and to control torque converter clutch lock/unlock strategy.

Camshaft Position (CMP) Sensor

EEC-V uses 2 types of CMP sensors. A variable reluctance sensor is used.

CMP sensor is used to determine the position of the camshaft and to identify when piston No. 1 is at TDC of

compression stroke. CMP sensor provides cylinder identification information during engine start-up for PCM to

initiate correct firing order. Cylinder identification information signal is sent from CMP sensor to PCM through

CID circuit.

Clutch Pedal Position (CPP) Switch

CPP switch is mounted near clutch pedal. CPP indicates clutch pedal position by means of an on/off switch

signal. This signal is used by PCM to determine clutch pedal position and on some models, gear shift selector

position.

Coolant Temperature Sensor

See ENGINE COOLANT TEMPERATURE (ECT) SENSOR (Below).

Crankshaft Position (CKP) Sensor

CKP sensor is a Hall Effect magnetic switch. The Hall Effect switch is activated by vanes on the crankshaft

damper and pulley assembly. The Profile Ignition Pick-Up (PIP) is a crankshaft position signal that is sent to the

PCM. The PIP signal generated by the Hall Effect sensor provides base timing and RPM information to the

PCM.

Cylinder Head Temperature (CHT) Sensor

CHT sensor is the input signal used for the cooling system failsafe strategy. CHT sensor signals PCM to

activate failsafe strategy if cylinder head temperature exceeds pre-programmed conditions. If CHT sensor or

system fail self-test, DTC P1288, P1289, P1290 or P1299 may set in PCM memory.

Data Link Connector (DLC)

The 16-pin Data Link Connector (DLC) is used to perform the Quick Test diagnostic procedure. When scan tool

connected to DLC, fault code output function can be activated.

Differential Pressure Feedback EGR (DPFE) Sensor

1996 Ford Thunderbird LX

E - THEORY/OPERATION - 4.6L 1996 ENGINE PERFORMANCE Ford Motor Co. - Theory & Operation - EEC-V

See EGR SYSTEM under EMISSION SYSTEMS.

Electronic Vacuum Regulator (EVR) Solenoid

See EGR SYSTEM under EMISSION SYSTEMS.

Engine Coolant Temperature (ECT) Sensor

ECT sensor is a thermistor device which changes resistance proportionate to temperature changes. ECT sensor

inputs coolant temperature to the PCM. ECT sensor is threaded into heater outlet fitting or coolant passage.

Engine RPM/Vehicle Speed Limiter System

The engine RPM/vehicle speed limiter system is integrated into PCM. The purpose of this system is to prevent

damage to the powertrain in overspeed conditions.

Whenever engine RPM or vehicle speed is detected, PCM will disable some or all of the fuel injectors. This will

cause engine to run rough and DTC P1270 will set in PCM memory. When overspeed condition has been

discontinued, normal engine operating conditions will be restored.

Fan Monitor (FANM)

FANM circuit is spliced into the Power-To-Low Speed Fan circuit. PCM monitors FANM circuit for diagnostic

purposes. When cooling fan(s) is off, FANM circuit voltage is pulled low by path to ground through cooling

fan.

With FANM circuit voltage low, PCM can verify FANM circuit and Power-To-Low Speed Fan circuit are

complete from FANM splice through cooling fan to ground. This also confirms that circuits are not shorted to

power.

When fan is on, voltage is supplied from CCRM to the appropriate Power-To-Fan and FANM circuit. With

cooling fan on and FANM circuit high, PCM can verify fan control relay contacts in the CCRM are closed and

that battery voltage is being supplied to the CCRM for the LFC and HFC relays. See CCRM circuit schematic

in CIRCUIT TEST X in the TESTS W/CODES article for more information.

Fuel Pump Monitor (FPM)

FPM circuit is spliced into the Power-To-Pump circuit and used by the PCM for diagnostic purposes. The PCM

sources a low current voltage down the FPM circuit.

With the fuel pump off, voltage is pulled low by the path to ground through the fuel pump. With the fuel pump

off and the FPM circuit low, the PCM can verify that FPM and, circuit and Power-To-Pump circuit are

complete from the FPM splice through the fuel pump to ground.

With the fuel pump on, voltage is supplied from the CCRM to the Power-To-Pump and FPM circuits. With the

fuel pump on and FPM circuit high, PCM can verify that Power-To-Pump circuit from CCRM to FPM splice is

complete. It can also verify that fuel pump relay contacts are closed and battery voltage is supplied to CCRM

for the relay. See CCRM circuit schematic in CIRCUIT TEST X in the TESTS W/CODES article for more

1996 Ford Thunderbird LX

E - THEORY/OPERATION - 4.6L 1996 ENGINE PERFORMANCE Ford Motor Co. - Theory & Operation - EEC-V

information.

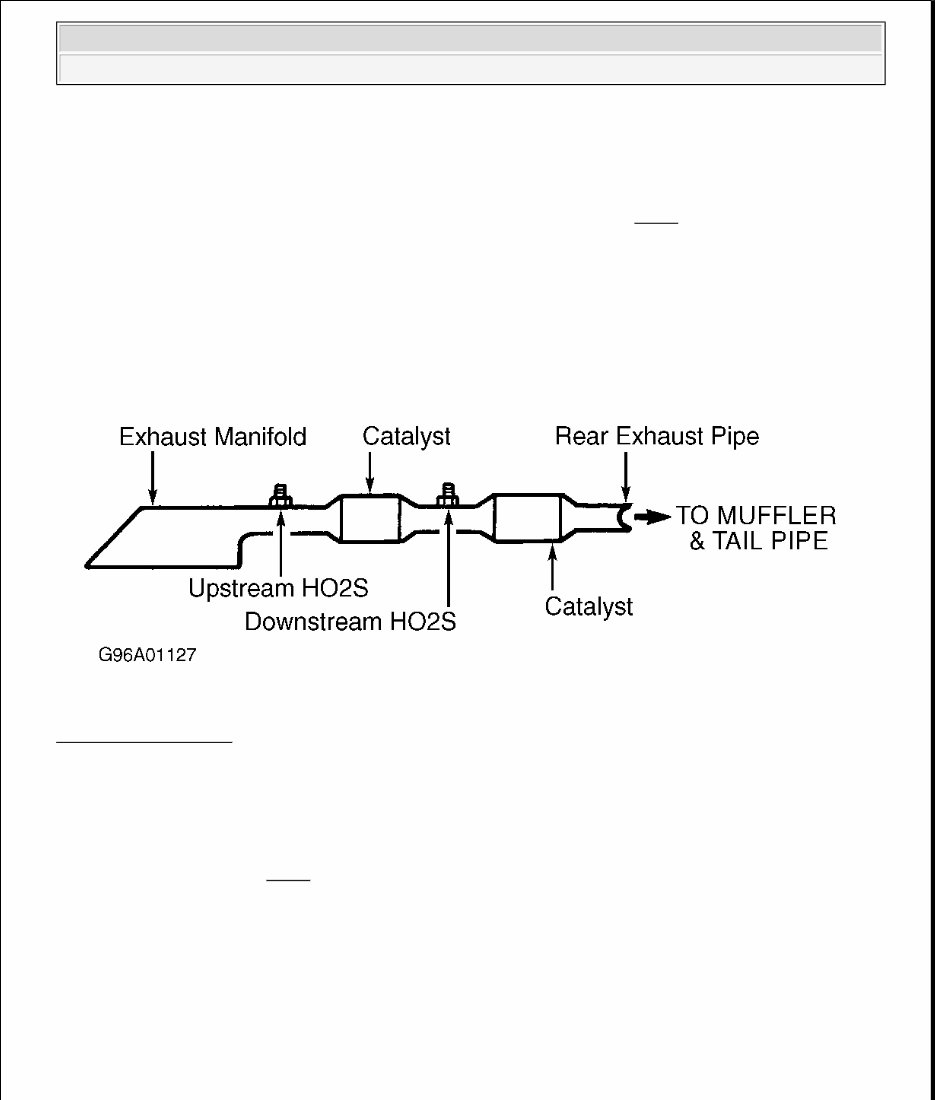

Heated Oxygen Sensor (HO2S)

The heated oxygen sensors are mounted in the exhaust manifold and pipe. See Fig. 1 . HO2S sensor uses a

built-in heating circuit. The heating circuit is used to bring the HO2S sensor up to operating temperature,

enabling faster conversion to closed-loop operation.

HO2S monitors oxygen content of exhaust gases. When HO2S is at operating temperature, a voltage signal is

produced, which varies according to oxygen content of exhaust gases. Signal is transmitted to the PCM and is

translated into a rich or lean mixture signal.

Fig. 1: Locating HO2S

Courtesy of FORD MOTOR CO.

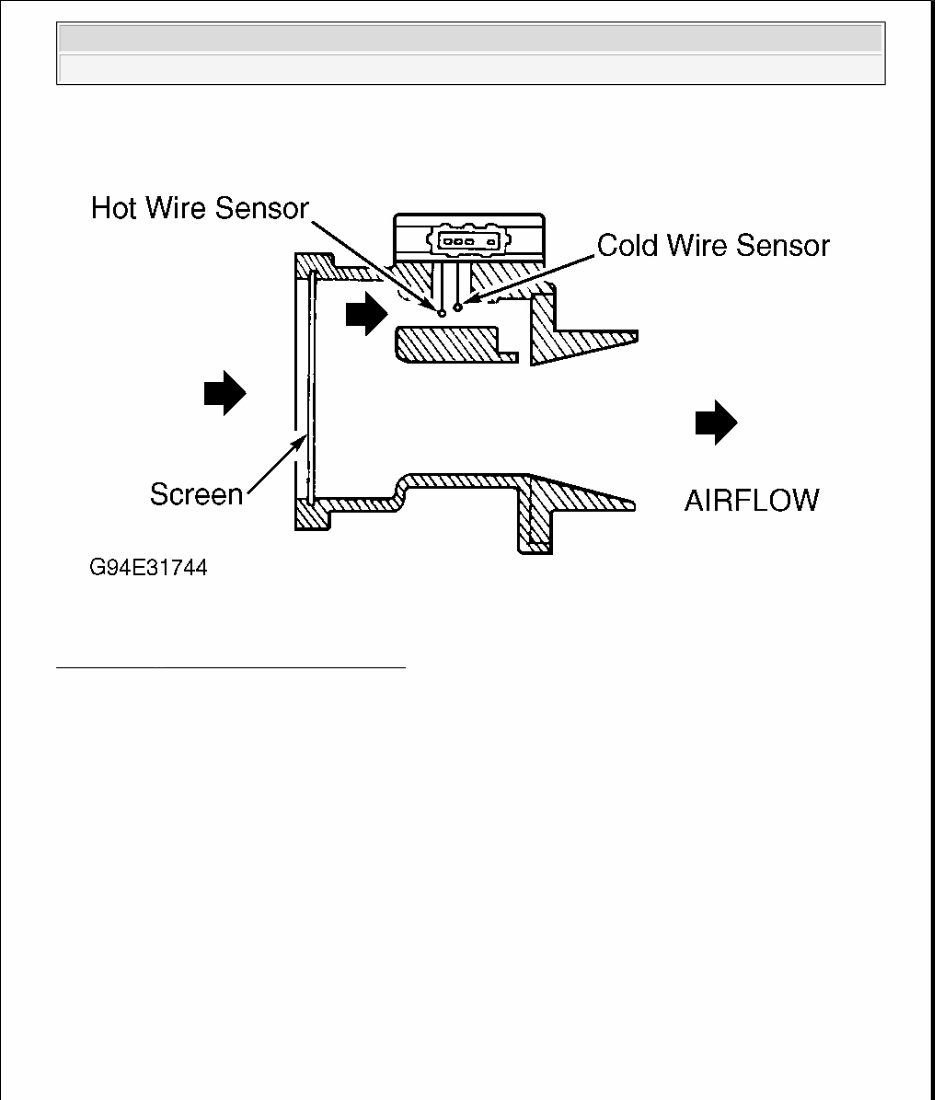

Mass Airflow (MAF) Sensor

MAF sensor uses a hot wire sensing element to measure amount of air entering the engine. Air passing over the

hot wire causes it to cool. The hot wire is maintained at 392°F (200°C) above ambient temperature, as measure

by a constant cold wire. See Fig. 2 .

The current required to maintain hot wire operating temperature is proportional to the intake air mass. The PCM

calculates the fuel injector pulse width in order to provide the desired air/fuel ratio.

1996 Ford Thunderbird LX

E - THEORY/OPERATION - 4.6L 1996 ENGINE PERFORMANCE Ford Motor Co. - Theory & Operation - EEC-V

Fig. 2: Cross - Sectional View Of MAF Sensor

Courtesy of FORD MOTOR CO.

Octane Adjust Shorting Bar

The octane adjust shorting bar is used to retard spark. A diagnostic trouble code will set if Octane Adjust

Shorting Bar is removed or, if an open circuit is present.

Output Shaft Speed (OSS) Sensor

The OSS sensor is a magnetic pick-up that sends a voltage signal to the PCM. This signal tells the PCM

transmission output shaft speed. Voltage is also used for shift schedules, modulated converter clutch control,

and determining EPC pressure.

OSS sensor is located on the rear of transmission case, on driver's side of vehicle. Control functions associated

with OSS sensor are limiting vehicle speed, converter clutch control and shift quality.

Park/Neutral Position (PNP) Switch

PNP switch is mounted on transmission selector lever. PNP indicates shift lever position by means of a variable

resistance signal. This signal is used by PCM to determine gear shift selector position.

Throttle Position (TP) Sensor

1996 Ford Thunderbird LX

E - THEORY/OPERATION - 4.6L 1996 ENGINE PERFORMANCE Ford Motor Co. - Theory & Operation - EEC-V

TP sensor is a rotary potentiometer. TP sensor monitors throttle plate opening. Its signal to the PCM is

proportional to throttle plate opening angle and rate of angle change. The TP sensor signal affects air/fuel ratio,

injector timing, idle speed, EGR flow and ignition timing. The TP sensor is mounted on throttle body, at throttle

plate rod.

Transmission Control Switch (TCS)

TCS position is controlled by vehicle operator. When equipped, the Transmission Control Indicator Light

(TCIL) will come on when the TCS is cycled to disengage overdrive.

Transmission Fluid Temperature (TFT) Sensor

TFT sensor is a thermistor that changes resistance as transmission fluid temperature changes. Sensor resistance

decreases as fluid temperature increases. Sensor resistance variation is converted into a voltage signal and sent

to the PCM. The PCM uses this input signal to determine transmission fluid temperature.

Vehicle Speed Sensor (VSS)

VSS is a variable reluctance sensor that generates a waveform with a frequency that is proportional to vehicle

speed. When vehicle is moving slowly, sensor produces a low frequency signal. As vehicle speed increases,

sensor produces a higher frequency signal. The PCM uses this signal to control fuel injection, ignition timing

and transmission shift points.

OUTPUT SIGNALS

A/C Cycle Switch (ACCS)

See MISCELLANEOUS CONTROLS .

A/C Pressure Switch (ACPSW)

See MISCELLANEOUS CONTROLS .

By-Pass Air (BPA) Valve

See IDLE SPEED under FUEL SYSTEM.

Canister Purge Valve

See FUEL EVAPORATIVE SYSTEM under EMISSION SYSTEMS.

Canister Purge Solenoid Valve

See FUEL EVAPORATIVE SYSTEM under EMISSION SYSTEMS.

NOTE: Vehicles are equipped with different combinations of computer-controlled

components. Not all components listed below are used on every vehicle. For

theory and operation on each output component, refer to system indicated after

component.

1996 Ford Thunderbird LX

E - THEORY/OPERATION - 4.6L 1996 ENGINE PERFORMANCE Ford Motor Co. - Theory & Operation - EEC-V

EGR System

See EGR SYSTEM under EMISSION SYSTEMS.

Fuel Injectors

See FUEL CONTROL under FUEL SYSTEM.

Fuel Pump

See FUEL DELIVERY under FUEL SYSTEM.

Fuel Pressure Regulator

See FUEL DELIVERY under FUEL SYSTEM.

Idle Air Control (IAC) Solenoid

See IDLE SPEED under FUEL SYSTEM.

Inertia Fuel Shutoff (IFS) Switch

See FUEL DELIVERY under FUEL SYSTEM.

Malfunction Indicator Light

See SELF - DIAGNOSTIC SYSTEM .

Transmission Solenoids

See MISCELLANEOUS CONTROLS .

FUEL SYSTEM

FUEL DELIVERY

Fuel Pump

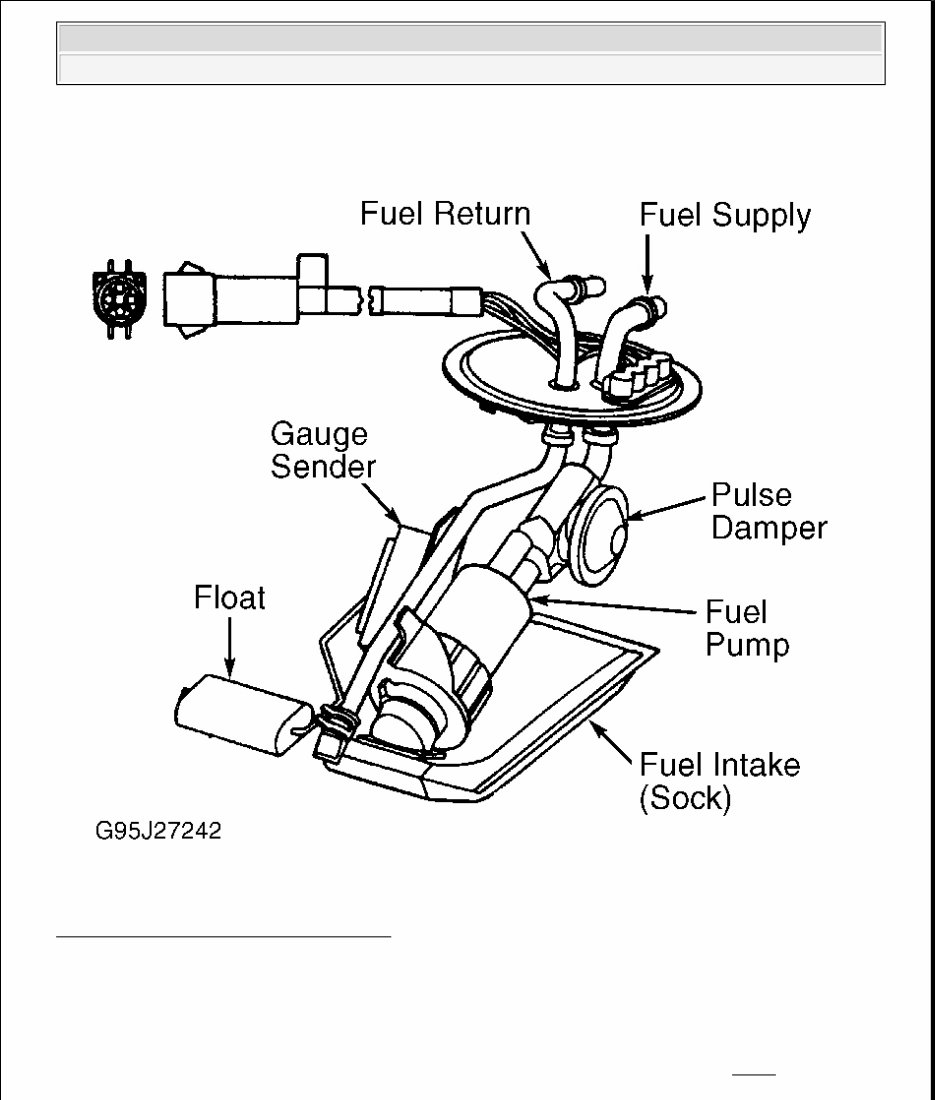

Fuel is supplied by an in-tank electric fuel pump. Pump also has a discharge check valve to maintain system

pressure during shutdowns and to minimize starting problems. See Fig. 3 .

Pump delivers fuel from fuel tank through fuel filter to fuel charging manifold assembly. Fuel charging

manifold assembly incorporates electrically actuated fuel injectors directly above each intake port. Injectors

spray metered quantity of fuel into intake airstream. Constant fuel pressure is maintained to injector nozzles by

fuel pressure regulator.

NOTE: For fuel pressure specifications, see FUEL PRESSURE SPECIFICATIONS

article.

1996 Ford Thunderbird LX

E - THEORY/OPERATION - 4.6L 1996 ENGINE PERFORMANCE Ford Motor Co. - Theory & Operation - EEC-V

Fig. 3: Identifying Fuel Pump Components

Courtesy of FORD MOTOR CO.

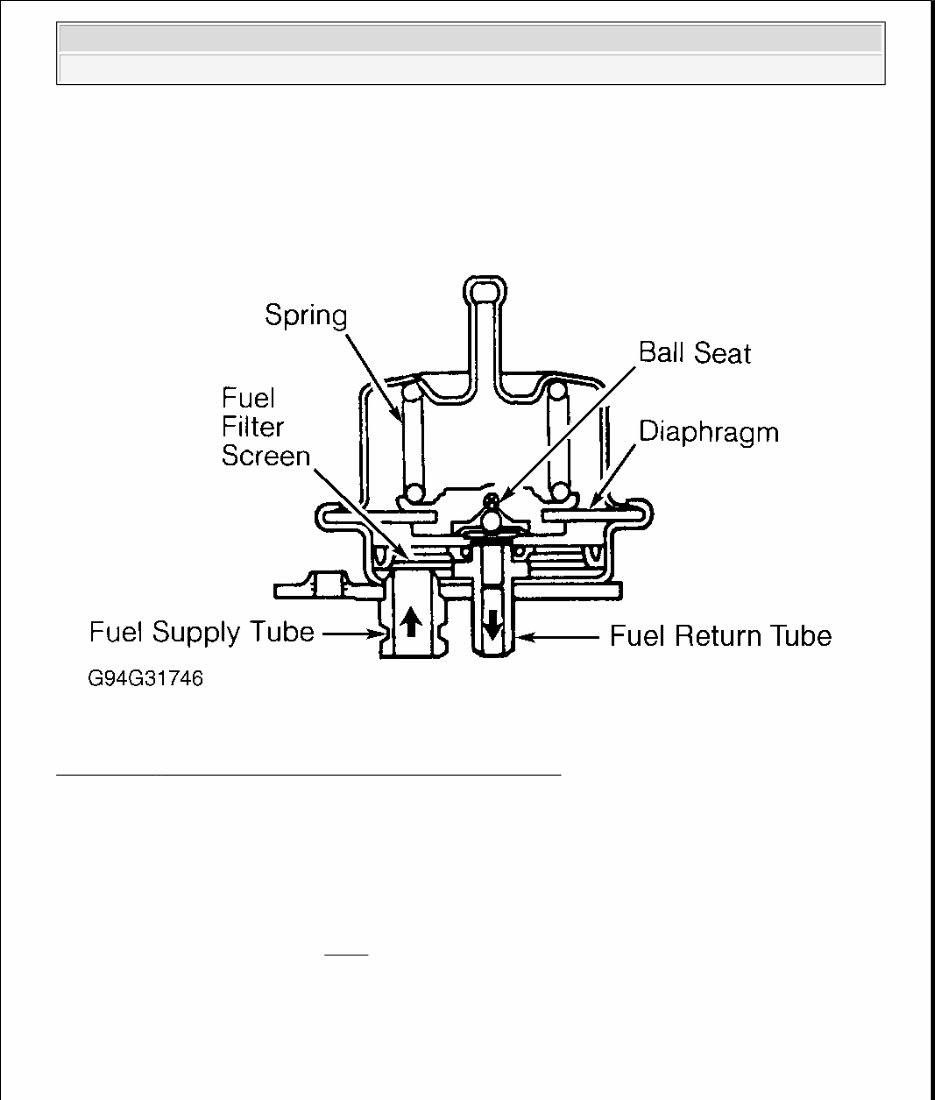

Fuel Pressure Regulator

Fuel pressure regulator controls fuel pressure supplied to injectors. Fuel pressure regulator is attached to fuel

supply manifold assembly, downstream of fuel injectors. Regulator is diaphragm operated. One side of

diaphragm senses fuel pressure, and other side is subjected to intake manifold pressure. See Fig. 4 .

1996 Ford Thunderbird LX

E - THEORY/OPERATION - 4.6L 1996 ENGINE PERFORMANCE Ford Motor Co. - Theory & Operation - EEC-V

Fuel pressure is controlled by spring preload applied to diaphragm. Balancing one side of diaphragm with

manifold pressure maintains constant fuel pressure at injectors. Excess fuel supplied by pump, but not

consumed by engine, passes through regulator and returns to fuel tank through fuel return line.

Fig. 4: Cross - Sectional View Of Pressure Regulator Components

Courtesy of FORD MOTOR CO.

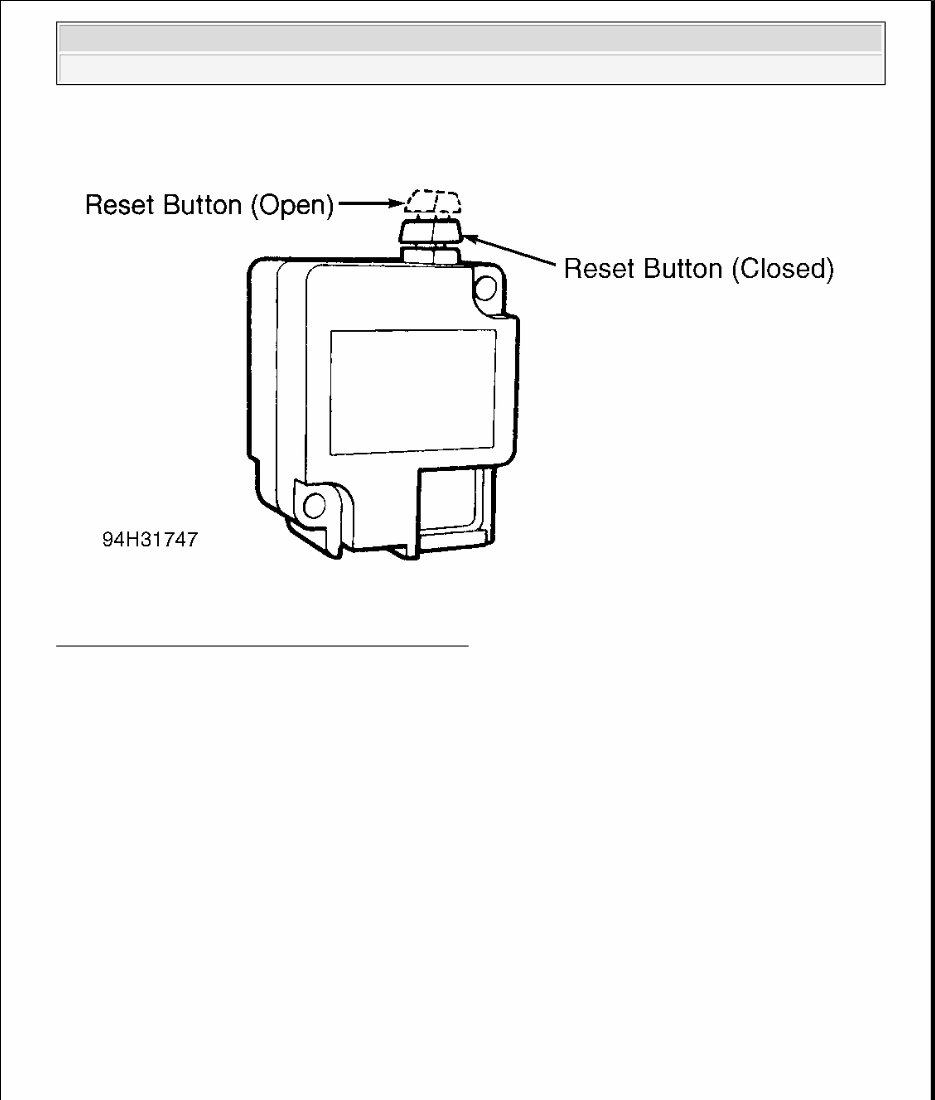

Inertia Fuel Shutoff (IFS) Switch

In the event of a collision or vehicle rollover, electrical contacts within the inertia switch trip open and voltage

supply to the electric fuel pump is shut off.

If the electrical circuit trips, it is not possible to restart the vehicle until the switch is reset. A reset button is

located on the switch assembly. See Fig. 5 .

WARNING: DO NOT reset IFS switch until complete fuel system has been inspected

for leaks.

1996 Ford Thunderbird LX

E - THEORY/OPERATION - 4.6L 1996 ENGINE PERFORMANCE Ford Motor Co. - Theory & Operation - EEC-V

Fig. 5: Identifying IFS Reset Button Switch Positions

Courtesy of FORD MOTOR CO.

FUEL CONTROL

Fuel Injectors

The PCM controls fuel injector ON time to meter fuel quantity into intake ports. The PCM receives inputs from

engine sensors to compute fuel flow necessary to maintain correct air/fuel ratio throughout entire engine

operating range. Injector ON time pulse width is the only controlled variable in fuel delivery system.

Each cylinder has a solenoid-operated injector that sprays fuel toward the back of each intake valve. Fuel

injector nozzles are solenoid-operated valves, which meter and atomize fuel delivered to engine. Each injector

receives battery voltage through an ignition switch circuit. The PCM-controlled ground circuit is used to

complete the circuit and energize the injector.

Injector bodies consist of solenoid-actuated pintle and needle valve assembly. Injector flow orifice is fixed and

fuel pressure at injector tip is constant. Fuel flow to engine is regulated according to length of time solenoid is

energized. This period is known as pulse width. Atomized spray pattern is obtained by shape of pintle.

IDLE SPEED

Idle Air Control (IAC) Valve Assembly

1996 Ford Thunderbird LX

E - THEORY/OPERATION - 4.6L 1996 ENGINE PERFORMANCE Ford Motor Co. - Theory & Operation - EEC-V

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

Viewed 41 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$36.99

Introducing the 1996 Mercury Cougar Service & Repair Manual Software.

Whether you are a professional mechanic or a DIY enthusiast, this software is essential for anyone looking to service and repair a 1996 Mercury Cougar. With step-by-step instructions, detailed illustrations, and comprehensive wiring diagrams, this manual software provides everything you need to efficiently and effectively maintain your vehicle.

Key Features:

- Complete coverage for all 1996 Mercury Cougar models:

- - Base Model

- - XR7

- - XR7 Anniversary Edition

- Highly detailed repair procedures

- Diagnostic codes and troubleshooting charts

- Electrical wiring diagrams

- Component location diagrams

- Exploded views and illustrations

- Torque specifications

- And much more!

Don't waste time and money on guesswork. Invest in the 1996 Mercury Cougar Service & Repair Manual Software today and keep your Cougar running at its best.