2.8L 6-CYL

Article Text

1994 Mercedes-Benz C280

For 1

Copyright © 1998 Mitchell Repair Information Company, LLC

Monday, March 19, 2012 12:22AM

ARTICLE BEGINNING

1994 ENGINES

Mercedes-Benz 2.8L 6-Cylinder

C280

* PLEASE READ THIS FIRST *

NOTE: For repair procedures not covered in this article, see

ENGINE OVERHAUL PROCEDURES - GENERAL INFORMATION

article in the GENERAL INFORMATION section.

ENGINE IDENTIFICATION

The engine family designation is shown on the emission

control information plate (attached to radiator crossmember). The 1st

character identifies the model year ("R" for 1994) while the 4th and

5th characters identify the engine displacement.

ENGINE IDENTIFICATION CODES TABLE

Application & (1) Engine Engine

Engine Size ID Code

C280 2.8L .............. 104.941 .......... RMB3.2VJGCEK

(1) - The engine identification number must be used when

ordering replacement parts. For certification reasons,

engines 104.942 and 104.941 fall into the 3.2L engine

family, even if actual engine displacement is 2.8L.

ADJUSTMENTS

VALVE CLEARANCE ADJUSTMENT

Hydraulic valve lifters are used, and valve clearance

adjustment is not necessary.

REMOVAL & INSTALLATION

NOTE: Removal and installation information for C280 model is not

available.

OVERHAUL

CYLINDER HEAD

Valve Springs

2.8L 6-CYL Article Text (p. 2)

1994 Mercedes-Benz C280For 1

Copyright © 1998 Mitchell Repair In

1) Remove camshafts. See CAMSHAFT. Install Supporting Bar

(104 589 01 59 00) onto cylinder head. Using a rubber removal tool,

remove bucket tappets. When removing bucket tappets, place in an order

easily identified for installation. Bucket tappets must be installed

at same point.

NOTE: DO NOT use a magnetic tool to remove bucket tappets. Small

iron particles can gather on magnetized sliding surfaces

causing damage to buckets and cams.

2) Using compressed air, blow out spark plug recesses. Remove

spark plugs. With respective cylinder at TDC, pressurize cylinder to

approximately 75 psi (5.2 bar) with compressed air. Using a valve

spring compressor, compress valve spring. Using a magnetic finger,

remove valve cone halves. Remove top valve spring retainer and valve

springs. To install, reverse removal procedure.

Valve Stem Oil Seals

Using pliers, remove old valve stem seals. Ensure no burrs

are present on valve stem. Install valve stem seals manually using

assembly sleeves included in repair kit.

CYLINDER BLOCK ASSEMBLY

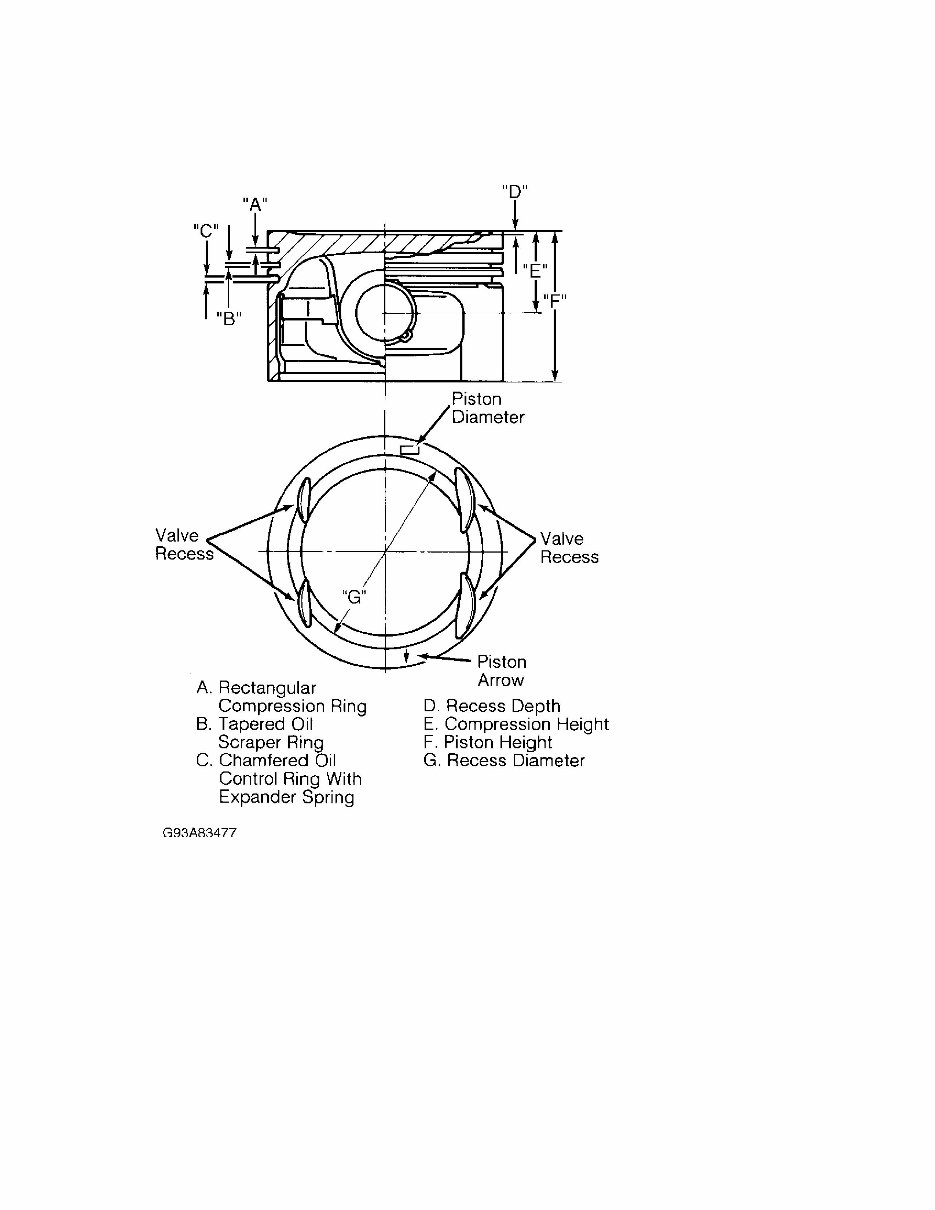

Piston & Rod Assembly

1) Piston must be installed in cylinder block with arrow on

top of piston toward front of engine. Piston and cylinder bores are

subdivided into 3 diameter groups. These group numbers are identified

as an "A", "X" or "B" stamped into top of piston and adjacent to

piston in cylinder block. When replacing pistons, replacement pistons

must have same group number as identified on cylinder block. See

Fig. 1.

CAUTION: Check connecting rod bearing cap bolts for excessive

stretching. Failure to replace stretched bolts may result

in bolts breaking.

2) Measure bolt length from bottom of bolt head to end of

bolt threads. If bolt length is not within specification, replace

stretch bolt. See CONNECTING ROD BEARING CAP BOLT SPECIFICATIONS

table.

CONNECTING ROD BEARING CAP BOLT SPECIFICATIONS TABLE

Application In. (mm)

Bolt Length

Standard ..................... 2.035-2.059 (51.70-52.30)

Maximum .................................... 2.08 (52.9)

2.8L 6-CYL Article Text (p. 3)

1994 Mercedes-Benz C280For 1

Copyright © 1998 Mitchell Repair Information Company, LLC

Fig. 1: Piston Identification

Courtesy of Mercedes-Benz of North America

ENGINE OILING

ENGINE LUBRICATION SYSTEM

Oil pump, located in oil pan, is chain driven by crankshaft

sprocket. Oil filter is located inside oil cooler.

Crankcase Capacity

Total oil capacity is 8.1 qts. (7.7L). Refill capacity is 7.9

qts. (7.5L) with a new filter.

TORQUE SPECIFICATIONS

2.8L 6-CYL Article Text (p. 4)

1994 Mercedes-Benz C280For 1

Copyright © 1998 Mitchell Repair Information Company, LLC

TORQUE SPECIFICATIONS TABLE

Application Ft. Lbs. (N.m)

Camshaft Bearing Cap Bolts ....................... 15 (21)

Camshaft Flange Shaft Bolt ....................... 13 (18)

Camshaft Flange Shaft Bolt (Torx Head) ........... 16 (22)

Camshaft Gear Nut ................................ 48 (65)

Chain Tensioner Housing (Nut) .................... 37 (50)

Chain Tensioner Housing Screw .................... 30 (40)

Crankshaft Pulley Bolts .......................... 24 (32)

Cylinder Head Bolts

Step 1 ......................................... 41 (55)

Step 2 ............................................. (1)

Step 3 ............................................. (1)

Drive Plate Bolts

Step 1 ......................................... 22 (30)

Step 2 ............................................. (1)

Drive Shaft Clamping Nut ................... 22-30 (30-40)

Front Engine Mount-To-Body ....................... 18 (25)

Oil Pump Bolts ................................... 18 (25)

Oil Pump Gear Bolt ............................... 24 (32)

Rear Engine Support Bracket-To-Body .............. 30 (40)

Rear Engine Mount-To-Engine ...................... 18 (25)

Top Front Cover Bolts ............................ 15 (21)

Two-Mass Flywheel Bolts

Step 1 ......................................... 30 (40)

Step 2 ............................................. (1)

Vibration Damper Bolt .......................... 295 (400)

INCH Lbs. (N.m)

Camshaft Holding Armature Bolt .................... 62 (7)

Crankshaft Shield Bolts .......................... 89 (10)

Front Timing Cover Bolts

6-mm ............................................ 80 (9)

8-mm ............................................... (2)

Oil Pan Bolts .................................... 89 (10)

(1) - Tighten an additional 90 degrees.

(2) - Tighten to 15 ft. lbs. (21 N.m).

ENGINE SPECIFICATIONS

GENERAL ENGINE SPECIFICATIONS

GENERAL ENGINE SPECIFICATIONS TABLE

Application Specification

2.8L

2.8L 6-CYL Article Text (p. 5)

1994 Mercedes-Benz C280For 1

Copyright © 1998 Mitchell Repair Information Compan

Displacement ...................... 171.1 Cu. In. (2.8L)

Bore ................................... 3.54" (89.9 mm)

Stroke ................................. 2.89" (73.5 mm)

Compression Ratio ................................. 10:1

Fuel System .................................... HFM-SFI

Horsepower @ RPM ............................ 194 @ 5500

Torque Ft. Lbs. @ RPM ....................... 199 @ 3750

PISTONS, PINS & RINGS SPECIFICATIONS

PISTONS, PINS & RINGS SPECIFICATIONS TABLE (1)

Application In. (mm)

Pistons

Diameter

Group A ................. 3.5394-3.5396 (89.900-89.906)

Group X ................. 3.5396-3.5398 (89.906-89.912)

Group B ................. 3.5398-3.5401 (89.912-89.918)

Recess Diameter ............................. 2.913 (74)

Recess Depth ................................ .051 (1.3)

Compression Height ......................... 1.22 (31.1)

Ring Side Clearance

1st Ring ........................ .060-.061 (1.52-1.55)

2nd Ring ........................ .069-.070 (1.75-1.77)

3rd Ring ........................ .118-.119 (3.00-3.02)

(1) - Information for piston pins and rings is not available

from manufacturer.

CYLINDER BLOCK SPECIFICATIONS

CYLINDER BLOCK SPECIFICATIONS TABLE

Application In. (mm)

Cylinder Bore

Standard Diameter ......................... 3.540 (89.9)

1st Repair Stage ......................... 3.550 (90.15)

2nd Repair Stage ......................... 3.560 (90.40)

VALVES & VALVE SPRINGS SPECIFICATIONS

VALVES & VALVE SPRINGS SPECIFICATIONS TABLE (1)

Application In. (mm)

Intake Valve

Stem Diameter .......................... .3132-.3138 (7)

2.8L 6-CYL Article Text (p. 6)

1994 Mercedes-Benz C280 For 1

Exhaust Valve

Stem Diameter .......................... .3518-.3527 (8)

(1) - Information on valve springs is not available from

manufacturer.

CYLINDER HEAD SPECIFICATIONS

CYLINDER HEAD SPECIFICATIONS TABLE

Application In. (mm)

Valve Guides

Inside Diameter

Intake ....................................... .276 (7)

Exhaust ...................................... .315 (8)

Length

Intake .................................... 1.40 (35.5)

Exhaust ................................... 1.50 (37.9)

CAMSHAFT SPECIFICATIONS

CAMSHAFT SPECIFICATIONS TABLE

Application In. (mm)

Bearing Diameter

Standard ................... 1.179-1.180 (29.947-29.960)

Repair Size ................ 1.159-1.160 (29.434-29.450)

Bearing Play

Radial ......................... .0016-.0030 (.040-.074)

Axial .......................... .0024-.0083 (.060-.210)

END OF ARTICLE

You're Reading a Preview

What's Included?

Lifetime Access

Access Contents & Bookmarks

Print one or all pages of your manual