2012-2014 Mazda Mazda5 Service & Repair Manual

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

Title Section

GENERAL INFORMATION 00

BODY

STRUCTURE

BODY STRUCTURE 80A

PANEL REPLACEMENT 80B

WATER-PROOF AND RUST

PREVENTIVE

80C

DIMENSIONS 80D

PLASTIC BODY PARTS 80E

CONSTRUCTION

STANDARD VALVES

80F

CONTENTS

2012-present

Bodyshop

Manual

FOREWORD

This bodyshop manual is intended for

use by technicians of Authorized Mazda

Dealers to help them service and repair

Mazda vehicles. It can also be useful to

owners and operators of Mazda vehicles in

performing limited repair and maintenance

on Mazda vehicles.

For proper repair and maintenance, a

thorough familiarization with this manual is

important, and it should always be kept in a

handy place for quick and easy reference.

All the contents of this manual, including

drawings and specifications, are the latest

available at the time of printing.

As modifications affecting repair or

maintenance occur, relevant information

supplementary to this volume will be made

available at Mazda dealers. This manual

should be kept up-to-date.

Mazda Motor Corporation reserves the

right to alter the specifications and contents

of this manual without obligation or ad-

vance notice.

All rights reserved. No part of this book may

be reproduced or used in any form or

by any means, electronic or mechanical

including photocopying and recording and

the use of any kind of information storage

and retrieval system-without permission in

writing.

Mazda Motor Corporation

HIROSHIMA, JAPAN

APPLICATION:

This manual is applicable to vehicles beginning

with the Vehicle Identification Numbers (VIN),

shown on the following page.

© 2010 Mazda Motor Corporation

PRINTED IN U.S.A., OCTOBER 2010

Form No. 3494–1U–10J

Part No. 9999–95–030F–12

VEHICLE IDENTIFICATION NUMBERS (VIN)

JM1 CW2✻L✻C# 100001—

00

GENERAL INFORMATION

00-00–1

SECTION

00-00

Toc of SCT

GENERAL INFORMATION . . . . 00-00

Toc of SCT

00-00 GENERAL INFORMATION

VEHICLE IDENTIFICATION NUMBER

(VIN) CODE . . . . . . . . . . . . . . . . . . . . . . 00-00–2

2012 Model Year . . . . . . . . . . . . . . . . . . 00-00–2

VEHICLE IDENTIFICATION NUMBERS

(VIN) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 00-00–2

2012 Model Year . . . . . . . . . . . . . . . . . . 00-00–2

HOW TO USE THIS MANUAL . . . . . . . . . 00-00–3

Efficient Replacement of

Body Panels . . . . . . . . . . . . . . . . . . . . 00-00–3

Symbols of Panel Replacement . . . . . . 00-00–3

Body Dimensions

(Flat-plane Dimensions) . . . . . . . . . . . 00-00–4

Body Dimensions

(Straight-line Dimensions) . . . . . . . . . . 00-00–6

Symbols of Body Dimensions . . . . . . . . 00-00–7

AIR BAG SYSTEM

SERVICE WARNINGS . . . . . . . . . . . . . . 00-00–8

Air Bag Module Inspection . . . . . . . . . . 00-00–8

Air Bag Module Handling . . . . . . . . . . . 00-00–8

Side Air Bag Module Handling . . . . . . . 00-00–8

SAS Control Module Handling . . . . . . . 00-00–9

Side Air Bag Sensor Handling. . . . . . . . 00-00–9

Pre-tensioner Seat Belt Inspection . . . . 00-00–9

Lap Pre-tensioner Seat Belt

Inspection . . . . . . . . . . . . . . . . . . . . . . 00-00–10

SERVICE PRECAUTIONS . . . . . . . . . . . . 00-00–10

Arrangement of Workshop . . . . . . . . . . 00-00–10

Safety Precautions . . . . . . . . . . . . . . . . 00-00–10

Vehicle Protection . . . . . . . . . . . . . . . . . 00-00–10

Remove Dangerous Articles . . . . . . . . . 00-00–10

Use of Pulling Equipment . . . . . . . . . . . 00-00–11

Prevent Short Circuits . . . . . . . . . . . . . . 00-00–11

EFFICIENT REMOVAL OF

BODY PANELS . . . . . . . . . . . . . . . . . . . . 00-00–11

Body Measurements . . . . . . . . . . . . . . 00-00–11

Prevention of Body Deformation. . . . . . 00-00–12

Selection of

Cut-and-join Locations . . . . . . . . . . . . 00-00–12

Removal of Associated Parts . . . . . . . . 00-00–12

Rough Cutting of Damaged Panel . . . . 00-00–12

EFFICIENT INSTALLATION OF

BODY PANELS . . . . . . . . . . . . . . . . . . . 00-00–12

Checking Preweld Measurements And

Watching . . . . . . . . . . . . . . . . . . . . . . 00-00–12

Welding Notes . . . . . . . . . . . . . . . . . . . 00-00–13

Spot Welding Notes . . . . . . . . . . . . . . . 00-00–13

Checking Weld Strength. . . . . . . . . . . . 00-00–14

INSTALLATION PREPARATIONS. . . . . . 00-00–15

Rough Cutting of New Parts . . . . . . . . . 00-00–15

Determination of Welding Method . . . . 00-00–15

Making Holes for CO

2

Arc Welding . . . 00-00–15

Application of Weld-through Primer . . . 00-00–16

ANTICORROSION, SOUND INSULATION,

AND VIBRATION INSULATION . . . . . . 00-00–16

Body Sealing . . . . . . . . . . . . . . . . . . . . 00-00–16

Application of Undercoating . . . . . . . . . 00-00–16

Application of Rust Inhibitor . . . . . . . . . 00-00–17

Application of Dumping Sheet . . . . . . . 00-00–17

ABBREVIATION . . . . . . . . . . . . . . . . . . . 00-00–17

BODY COLORS . . . . . . . . . . . . . . . . . . . . 00-00–17

Color Code and Color Name . . . . . . . . 00-00–17

Verification of Primary Color Mixture for

Body Color . . . . . . . . . . . . . . . . . . . . . 00-00–17

IDENTIFICATION NUMBER

LOCATIONS . . . . . . . . . . . . . . . . . . . . . 00-00–18

Vehicle Identification Number (VIN) . . . 00-00–18

Engine Identification Number . . . . . . . . 00-00–18

End of Toc

BM: GENERAL INFORMATION

GENERAL INFORMATION

00-00–2

VEHICLE IDENTIFICATION NUMBER (VIN) CODE

id000000600800

2012 Model Year

End Of Sie

VEHICLE IDENTIFICATION NUMBERS (VIN)

id000000600100

2012 Model Year

JM1 CW2*L*C# 100001—

End Of Sie

J M 1 C W 2 W L 0 C 0 1 2 3 4 5 6

Plant

Serial No.

0= Hiroshima

1= Hofu

Body style A, B, C, D, E, W= Wagon

World manufacturer identification

Model year

Engine

Carline and Series CW= Mazda5

JM1= Mazda/Passenger car/USA

L= 2.5 L (MZR 2.5) USA/Canada/Mexico

2= with Side Air bags, Front Wheel Drive

Check digit 0 to 9, X

C= 2012

Restraint system and Axle configuration

am5uuw0000360

GENERAL INFORMATION

00-00–3

00-00

HOW TO USE THIS MANUAL

id000000600900

Efficient Replacement of Body Panels

• This section contains information on the body panels in regard to the welding types, number of spot welds, and

cut-and-join locations that are necessary for panel removal and installation.

• The type of weld and position are indicated by symbols.

• Some sections have notes concerning the operation being performed. Thoroughly read and understand the

notes before carrying out any procedures.

Example

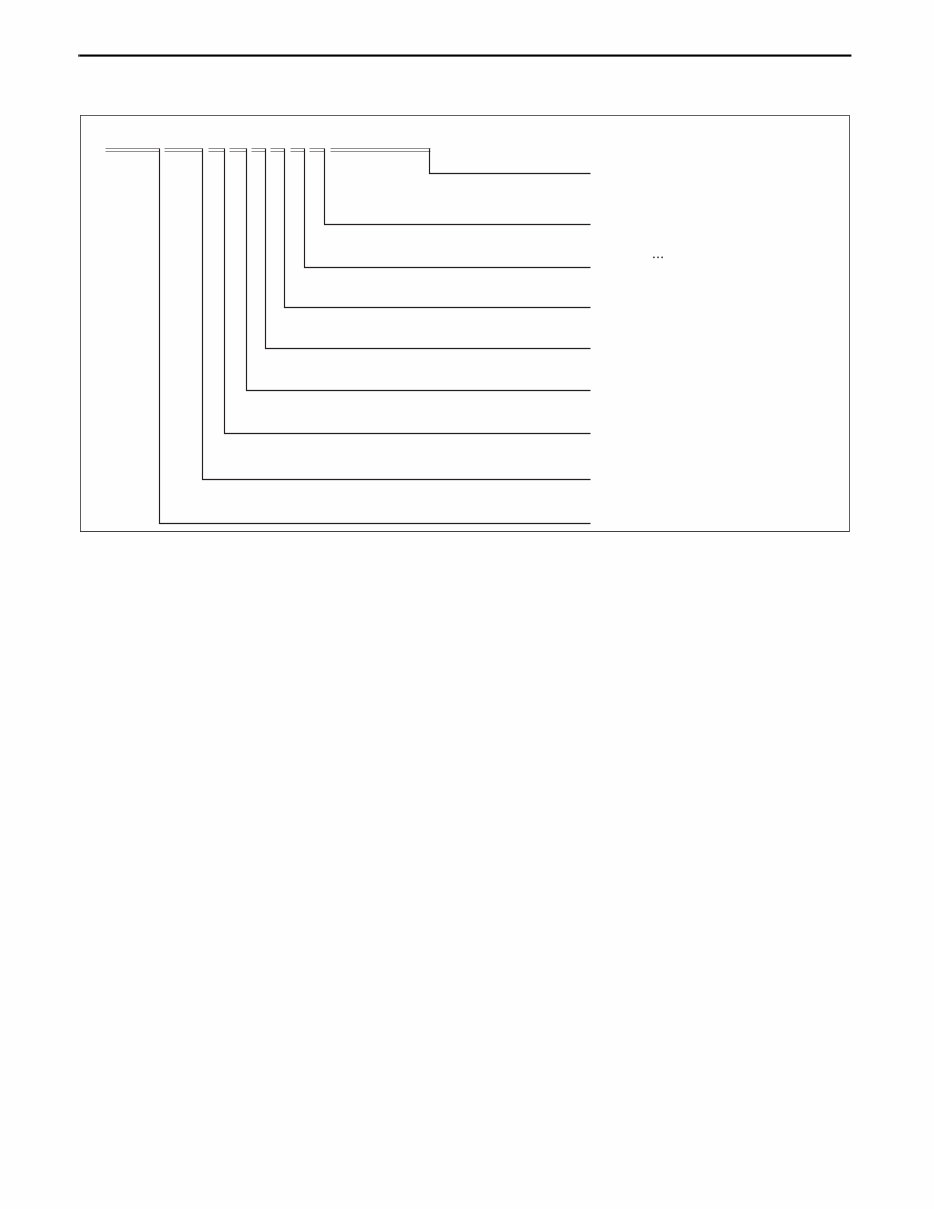

Symbols of Panel Replacement

• The following 6 symbols are used to indicate the type of weld that is used when replacing body panels.

REAR FENDER PANEL REMOVAL

Shows operation section

Shows procedure, caution and note

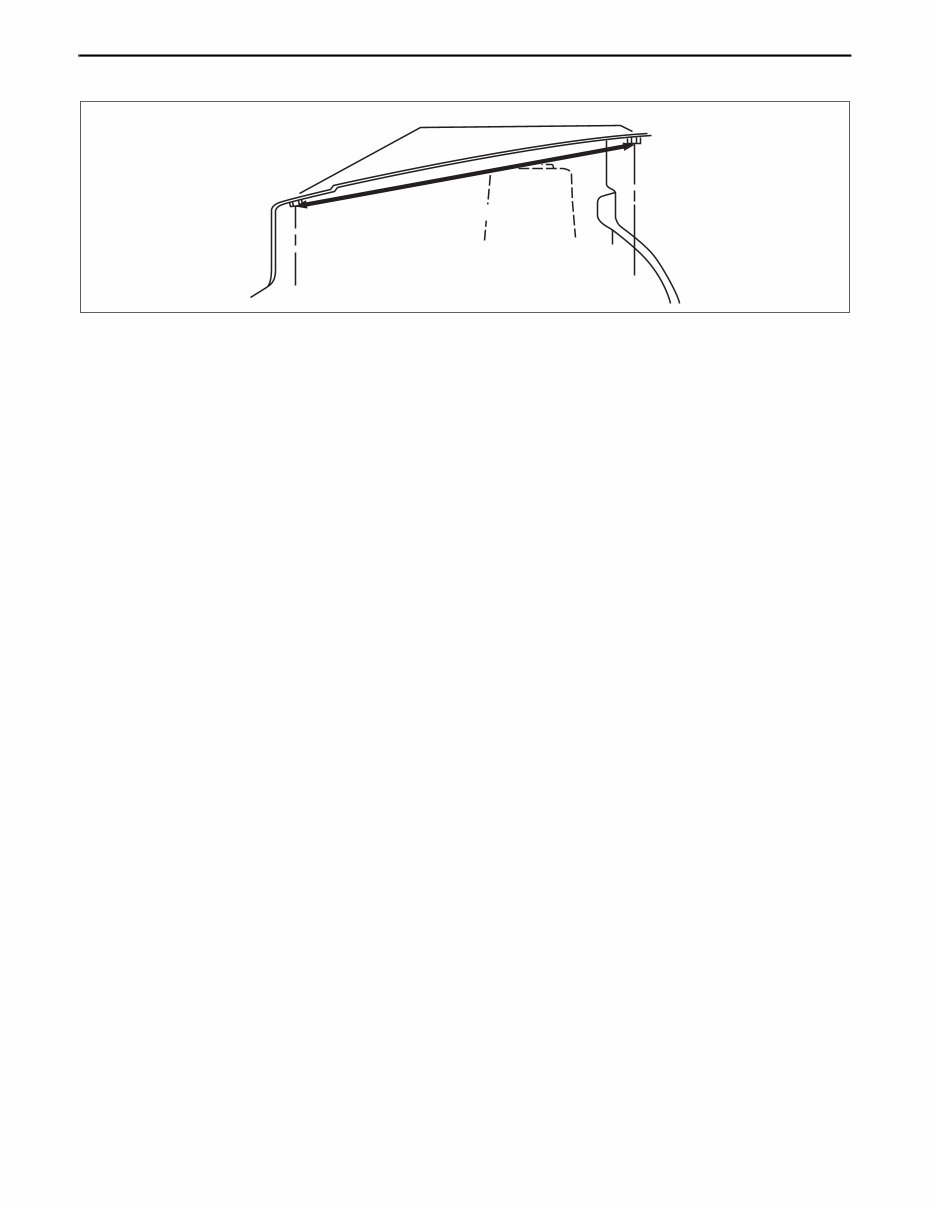

BRAZE WELDING

Shows welding region

Shows a cross

Shows a insulator

Avoid cutting with a flame as the insulator (shaded) is flammable.

1.The rear fender panel and wheel house are joined with glue at the wheel arch line.

Drill the 17 weld locations indicated by (A), from the room side.

Caution

NOTE

CUT-AND-JOINT LOCATION

ROUGH CUT LOCATION

Shows a dimensions

{9.84in}

250mm

A-A

30mm

{1.18in}

Shows number of weld

Shows a cross location

A A

(A)17

17

4

5

7 1

5

acxuub00000031

SYMBOL MEANING

Spot welding

CO

2

arc welding (plug welding)

CO

2

spot welding

SYMBOL MEANING

Continuous MIG welding (Cut-and-join location)

Braze welding

Rough cut location

acxuub00000032

GENERAL INFORMATION

00-00–4

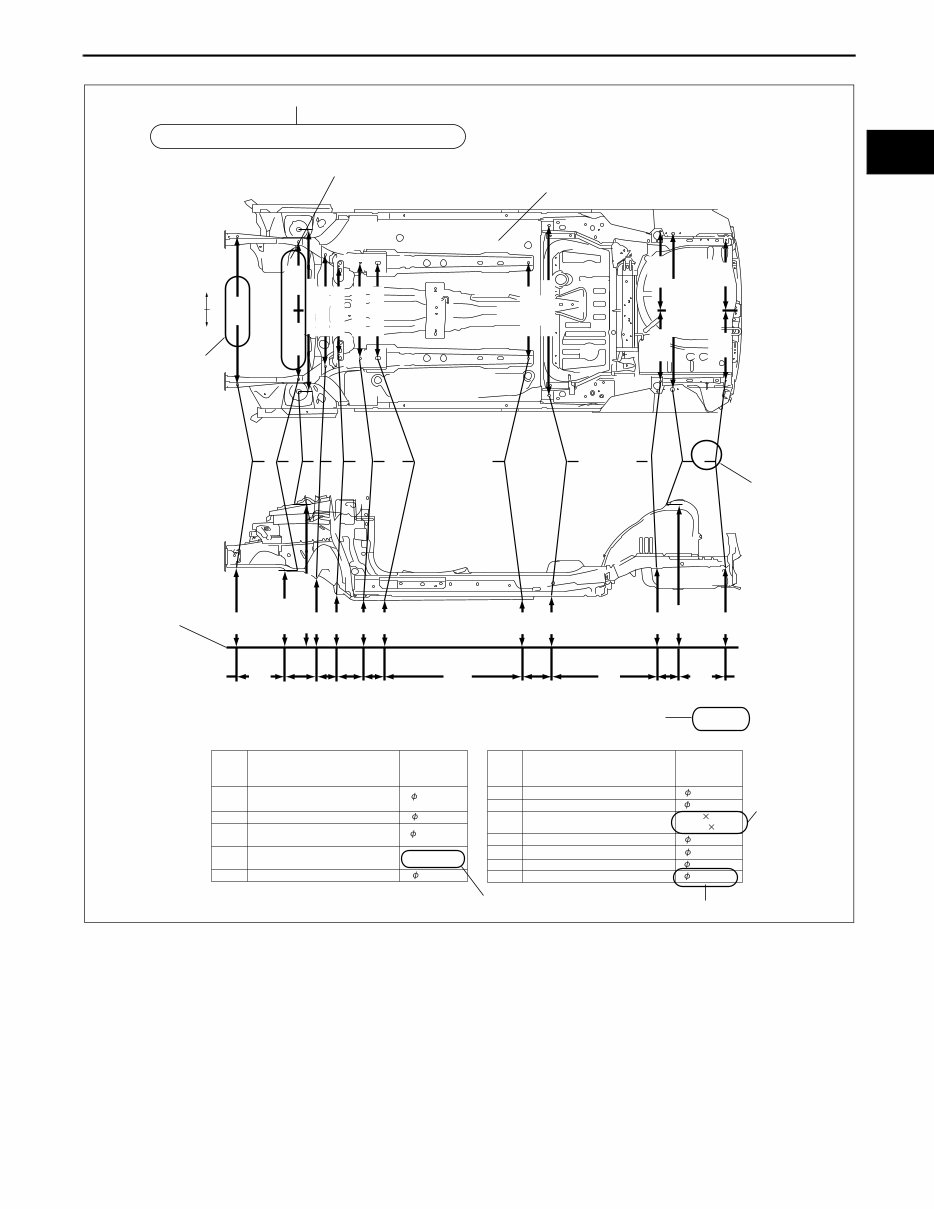

Body Dimensions (Flat-plane Dimensions)

• Flat-plane dimensions are the dimensions measured by projecting certain reference points onto a plane

surface.

• When there are no specific indications, the standard points and dimensions are symmetrical in regard to the

center of the vehicle.

• The hypothetical lines may differ according to the vehicle model.

• The schematic diagram shows the vehicle as it is projected from the underbody.

810 {31.89}

FLAT-PLANE DIMENSIONS

FRONT FENDER INSTALLATION NUT

am5ezb0000017

GENERAL INFORMATION

00-00–5

00-00

Example

Shows vehicle section

Shows outline drawing

Shows dimension

Shows point

symbol

Crossmember No,1 standard hole

Front side frame standard hole

Front suspension mounting

block surface hole center

Front suspension mounting bolt

Front frame rear standard hole

Front frame rear standard hole

Rear side frame standard hole

Link bracket

Rear suspension housing

A

B

C

D

E

F

G

H

I

J

K

Rear side frame standard hole

Rear side frame standard hole

Shows bolt size

Shows hole diameter

mm {in}

UNDERBODY FLAT-PLANE DIMENSIONS

16 {0.62}

16 {0.62}

16 {0.62}

M14 {0.55}

80 {3.14}

16 {0.62}

31 {1.22}

12 {0.47}

Rear suspension housing

L 12 {0.47}

16 {0.62}

18 {0.62}

17 29.5

{0.66 1.16}

A B C D E F G H I J K L

182 93 144 120

{7.17} {3.66} {5.67} {4.72}

140 68

{5.51} {2.68}

LH

RH

1,016

{40.00}

469

{18.46}

455

{17.91}

1,106 {43.54}

760 {29.92}

605 {23.82}

650 {25.59}

650 {25.59}

650 {25.59}

1,164 {45.83}

543

{21.37}

484

{19.05}

1,073 {37.91}

485

{19.1}

478

{18.8}

The dimensions on the left and

right in regard to the center of

the vehicle are different.

Shows hypothetical

standard line

When there are no specific indications, all of

units are in millimeters (mm).

Shows

slot

Designation

Point

symbol

Hole diameter

or bolt or nut

size mm {in}

Designation

Point

symbol

Hole diameter

or bolt or nut

size mm {in}

687

{27.05}

654

{25.75}

1,084 {42.84}

579

{22.80}

479

{18.86}

436

{17.17}

436

{17.17}

445

{17.52}

512

{20.16}

660

{25.98}

1,043

{41.06}

666

{26.22}

420

{16.54}

1,030

{40.55}

760

{29.92}

379

{14.92}

am5ezb0000017

GENERAL INFORMATION

00-00–6

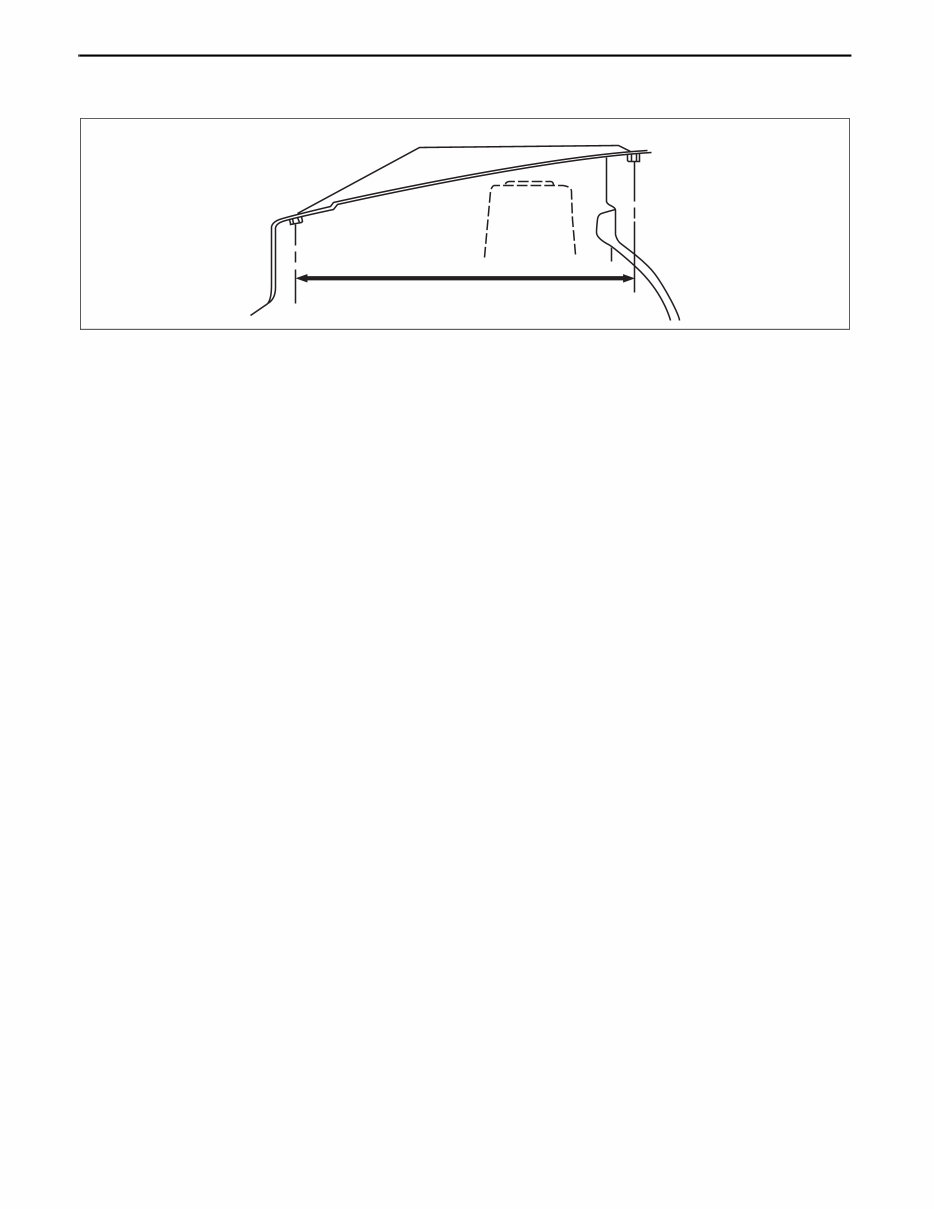

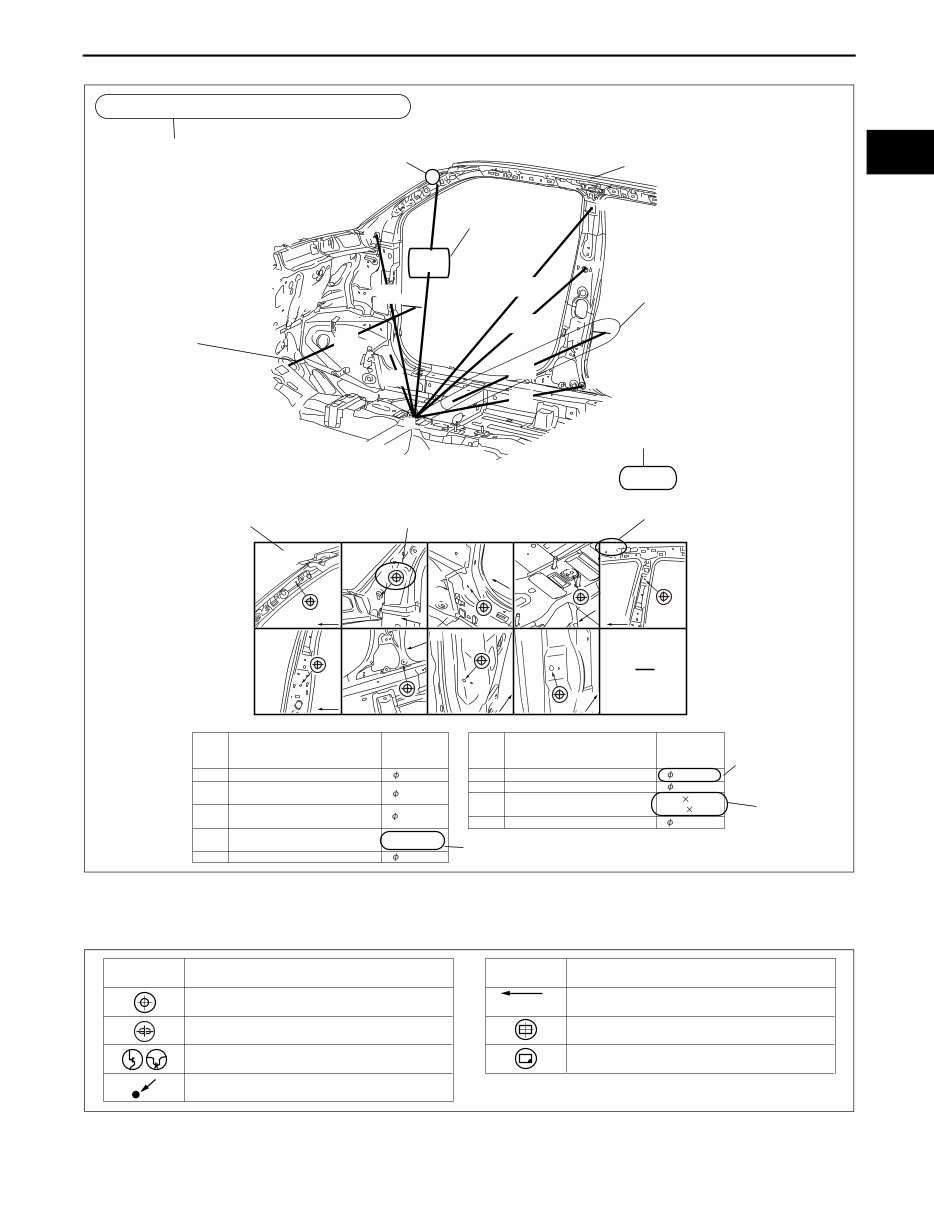

Body Dimensions (Straight-line Dimensions)

• Straight-line dimensions are the actual dimensions between two standard points.

• When there are no specific indications, the standard points and dimensions are symmetrical in regard to the

center of the vehicle.

817 {32.17}

FRONT FENDER INSTALLATION NUT

STRAIGHT-LINE DIMENSIONS

am5ezb0000017

GENERAL INFORMATION

00-00–7

00-00

Example

Symbols of Body Dimensions

• The following 8 symbols are used to indicate the standard points.

End Of Sie

A

B

C

H

D

I

E

F

G

A

F

G

B

H

I

C

D

E,E'

Fr

Fr Fr

Fr Fr

Fr

Fr

Fr

Fr

Front pillar inner designation

Front pillar inner designation

Front floor pan designation

Adjuster installation hole

Trim installation hole

Harness installation hole

Chaker bracket installation hole

Chaker bracket installation hole

A

B

C

D

E

F

G

H

I

16 {0.62} 18 {0.71}

16 {0.62}

Harness installation hole

Designation

Shows bolt size

Shows hole diameter

Shows

slot

16 {0.62}

M14 {0.55}

31 {1.22}

17 {0.67}

12 {0.47}

1,128

{44.41}

1,263

{49.72}

1,048

{41.26}

1,406

{55.35}

851

{33.50}

1,067

{42.01}

799

{31.46}

1,398

{55.04}

Point

symbol

Hole diameter

or bolt or nut

size mm {in}

Designation

Point

symbol

Hole diameter

or bolt or nut

size mm {in}

17 29.5

{0.66 1.16}

ROOM STRAIGHT-LINE DIMENSIONS (1)

Shows vehicle section

Shows dimension location

Shows outline drawing

Shows position and shape of the points

Shows dimension

mm {in}

No indication are shown

within the outline drawing.

Shows point

symbol

When there are no specific indications, all of

units are in millimeters (mm).

Shows point indication

Without apostrophe:RH

With apostrophe:LH

Shows details of the standard

point location

am5ezb0000017

SYMBOL MEANING SYMBOL MEANING

Center of circular hole

Center elliptical hole

Notch

Panel seam, bead, etc.

Bolt tip

(arrow only)

Center of rectangular-shaped hole

Edge of rectangular-shaped hole

acxuub00000037

GENERAL INFORMATION

00-00–8

AIR BAG SYSTEM SERVICE WARNINGS

id000000920000

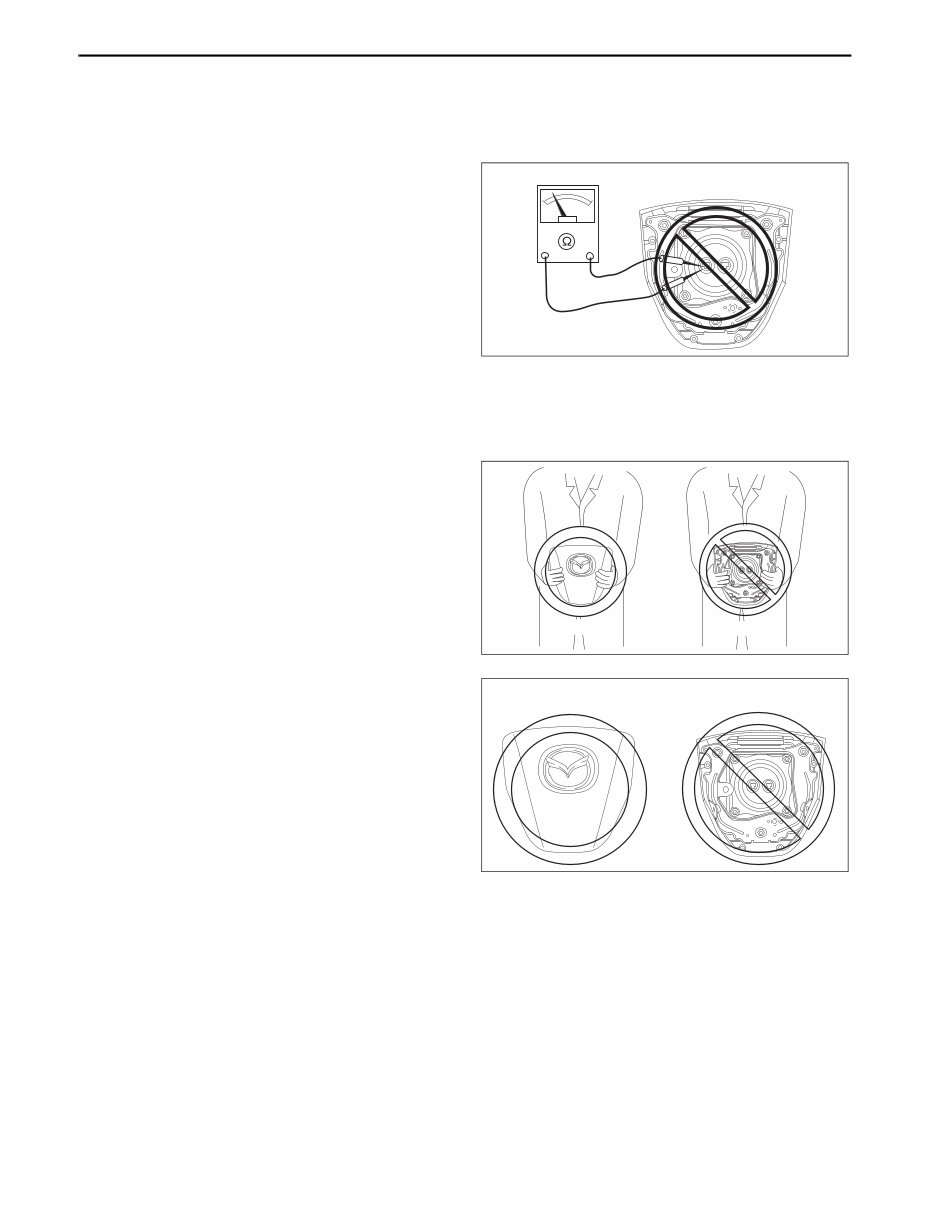

Air Bag Module Inspection

• Inspecting an air bag module using a tester can operate (deploy) the air bag module, which may cause

serious injury. Do not use a tester to inspect an air bag module. Always use the on-board diagnostic

function to diagnose the air bag module for malfunctions.

Air Bag Module Handling

• Before removing the air bag module or disconnecting the air bag module connector, always switch the

ignition to off, disconnect the negative battery cable, and then wait for 1 min or more to allow the

backup power supply of the SAS control module to deplete its stored power.

• Handling a live (undeployed) air bag module

that is pointed toward your body could result

in serious injury if the air bag module were to

accidentally operate (deploy). When carrying

a live (undeployed) air bag module, point the

deployment surface away from your body to

lessen the chance of injury in case it operates

(deploys).

• A live (undeployed) air bag module placed

with its deployment surface to ground is

dangerous. If the air bag module were to

accidentally operate (deploy), it could cause

serious injury. Always place a live

(undeployed) air bag module with its

deployment surface up.

Side Air Bag Module Handling

• Before removing the side air bag module or disconnecting the side air bag module connector, always

switch the ignition to off, disconnect the negative battery cable, and then wait for 1 min or more to

allow the backup power supply of the SAS control module to deplete its stored power.

• When a side air bag module operates (deploys) due to a collision, the interior of the seat back (pad,

frame, trim) may become damaged. If a side air bag does not operate (deploy) normally from a seat

back that has been reused, a serious accident may result. After a side air bag has operated (deployed),

always replace both the side air bag module and the seat back (pad, frame, trim) with new parts. After

servicing, verify that the seat operates normally and that the wiring harness is not caught.

NO GOOD

am3uuw0000368

GOOD NO GOOD

am3uuw0000368

NO GOOD GOOD

am3uuw0000369

You're Reading a Preview

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

Viewed 77 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Offline Viewing

Access Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$35.99

This manual is a comprehensive guide covering the Mazda 5 from 2012 to 2014, inclusive of both service and body manuals. It contains all the essential instructions required for vehicle repairs, from basic maintenance to extensive disassembly. Professional technicians and DIY enthusiasts alike can benefit from the accurate and concise text, accompanied by illustrations, which enable safe and straightforward servicing and repairs.

- Includes coverage for Mazda 5 2012, 2013, and 2014 models

- Encompasses service and body manuals

- Provides reliable information for routine maintenance and extensive repairs

- Comprehensive diagrams and in-depth illustrations

- Incorporates manufacturers' specifications and technical information

- Compatible with various operating systems: Windows (95, 98, ME, XP, 7), MAC, iPhone, iPad, iPod, LINUX