2007-2008 Mazda3 Mazdaspeed Service & Repair Manual

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

2007

Mazda3

MAZDASPEED3

Workshop

Manual

FOREWORD

This manual contains on-vehicle service

and/or diagnosis procedures for the

Mazda3, MAZDASPEED3.

For proper repair and maintenance,

a thorough familiarization with this manual is

important, and it should always be kept in a

handy place for quick and easy reference.

All the contents of this manual, including

drawings and specifications, are the latest

available at the time of printing.

As modifications affecting repair or

maintenance occur, relevant information

supplementary to this volume will be made

available at Mazda dealers. This manual

should be kept up-to-date.

Mazda Motor Corporation reserves the right

to alter the specifications and contents of

this manual without obligation or advance

notice.

All rights reserved. No part of this book may

be reproduced or used in any form or by any

means, electronic or mechanical-including

photocopying and recording and the use of

any kind of information storage and retrieval

system-without permission in writing.

Mazda Motor Corporation

HIROSHIMA, JAPAN

APPLICATION:

This manual is applicable to vehicles

beginning with the Vehicle Identification

Numbers (VIN), and related materials

shown on the following page.

CONTENTS

Title

GENERAL INFORMATION

ENGINE

SUSPENSION

DRIVELINEIAXLE

BRAKES

TRANSMISSIONITRANSAXLE

STEERING

HEATER, VENTILATION &

AIR CONDITIONING HVAC

RESTRAINTS

BODY & ACCESSORIES

ALPHABETICAL INDEX

© 2006 Mazda Motor Corporation

PRINTED IN U.S.A., JULY 2006

Form No. 1886-1U-06G

Part No. 9999-95-0178-07

VEHICLE IDENTIFICATION NUMBERS (VIN)

JM1

JM1

JM1

JM1

JM1

JM1

JM1

JM1

JM1

JM1

JM1

JM1

JM1

JM1

..IM1

JM1

BK123*7#

BK124*7#

BK12F*7#

BK12G*7#

BK143*7#

BK144*7#

BK14L*7#

BK14M*7#

BK323*7#

BK324*7#

BK32F*7#

BK32G*7#

BK343*7#

BK344*7#

BK34L*7#

BK34M~i~7#

600001-

600001-

600001-

600001-

600001-

600001-

600001-

600001-

600001-

600001-

600001-

600001-

600001-

600001-

600001-

600001-

RELATED MATERIALS

I

Material Name MNAO Part No. Mazda Material No.

I

i 2004 Mazda3 Service Highlights 9999-95-064F-04 3385-1 U-031

I 200S Mazda3, Mazda MX-S Miata, Mazda MX-S, MAZDASPEED

9999-9S-MODL-OS 3400-1U-04H

MX-S, Mazda MPV, Mazda RX-8 Service Highlights

2006 Mazda3, Mazda MPV Service Highlights 9999-9S-M PV3-06 3408-1 U--0SG

2007 Mazda3, MAZDASPEED3, MazdaS, Mazda6,

9999-9S-MODL-07 3422-1 U-06G

MAZDASPEED6, Mazda MX-S, Mazda RX-8 Service Highlights

'1 99S. 1996, 1997, 1998, 1999,2000 08D-11 Service Highlights 9999-9S-08D2-00 3344-1U-99K

Engine Workshop Manual L3 WITH TC 9999-9S-0L3T-06 1833-1 U-OSH

Engine Workshop Manual LF, L3 9999-9S-LFL3-OS 1866-1U--0SH

Manual Transaxle Workshop Manual G3SM-R 9999-95-0G3S-03 17S6-1 U-021

Manual Transaxle and Transfer Workshop Manual A26M-R,

9999-9S-A26M-07 1898-1 U-06G

A26MX-R

i Automatic Transaxle Workshop Manual FN4A-EL 9999-9S-FN4A-04 1793-1 U-031

i Automatic Transaxle Workshop Manual FSSA-EL 9999-9S-FSSA-06 18S9-1U-OSF

2004 Mazda3 8odyshop Manual 9999-9S-036F-IJ4 3386-1 U-03J

2007 Mazda3 Wiring Diagram 9999-9S--019G--07 S677-1U-06G

~~G_E_NE_R_A_L_IN_F_O_R_M_AT_I_ON~~I~I~

GENERAL INFORMATION .... 00-00

00-00 GENERAL INFORMATION

VEHICLE IDENTIFICATION NUMBER Dynamometer 00-00-18

(VIN) CODE 00-00-2 SST 00-00-18

VEHICLE IDENTIFICATION INSTALLATION OF

NUMBER (VIN) 00-00-2 RADIO SySTEM '" 00-00-19

HOW TO USE THIS MANUAL 00-00-3 ELECTRICAL SYSTEM 00-00-19

Range of Topics 00-00-3 Electrical Parts 00-00-19

Service Procedure 00-00-3 Wiring Harness 00-00-19

Symbols 00-00-5 Connectors 00-00-20

Advisory Messages 00-00-5 Terminals 00-00-21

Troubleshooting Procedure 00-00-6 Sensors, Switches, and Relays 00-00-21

Procedures for Use 00-00-7 Wiring Harness 00-00-22

UNITS 00-00-12 Fuse 00-00-22

Conversion to SI Units Direction of View for Connector 00-00-22

(Systeme International d'Unites) 00-00-12 Electrical Troubleshooting Tools 00-00-23

Rounding Oft. 00-00-12 Precautions Before Welding 00-00-24

Upper and Lower Limits 00-00-12 JACKING POSITIONS, VEHICLE LIFT

SERVICE CAUTIONS 00-00-13 (2 SUPPORTS) AND SAFETY STAND

Injury/damage Prevention (RIGID RACK) POSITIONS 00-00-25

Precautions 00-00-13 Jacking Positions 00-00-25

Protection of the Vehicle 00-00-13 Vehicle Lift Positions 00-00-26

Preparation of Tools and Measuring Safety Stand Positions 00-00-26

Equipment. 00-00-13 TOWING 00-00-27

Special Service Tools 00-00-13 Towing 00-00-27

Malfunction Diagnosis System 00-00-13 Tiedown Hooks 00-00-28

Disconnection of the Negative TIEDOWN HOOK 00-00-29

Battery Cable 00-00-14 IDENTIFICATION NUMBER

Oil Leakage Inspection 00-00-14 LOCATIONS 00-00-30

Removal of Parts 00-00-14 Vehicle Identification Number

Disassembly 00-00-15 (VIN) 00-00-30

inspection During Removal, Engine Identification Number 00-00-30

Disassembly 00-00-15 SAE STANDARDS 00-00-31

Arrangement of Parts 00-00-15 ABBREVIATIONS 00-00-32

Cleaning of Parts 00-00-15 PRE-DELIVERY INSPECTION 00-00-32

Reassembly 00-00-16 Pre-Delivery Inspection Table 00-00-32

Adjustment 00-00-16 SCHEDULED MAINTENANCE 00-00-34

Rubber Parts and Tubing 00-00-16 Scheduled Maintenance Table for U.S.A.,

Hose Clamps 00-00-17 CANADA and Puerto Rico 00-00-34

Torque Formulas 00-00-17 Scheduled Maintenance

Vise 00-00-17 Table for Mexico 00-00-36

00-00-1

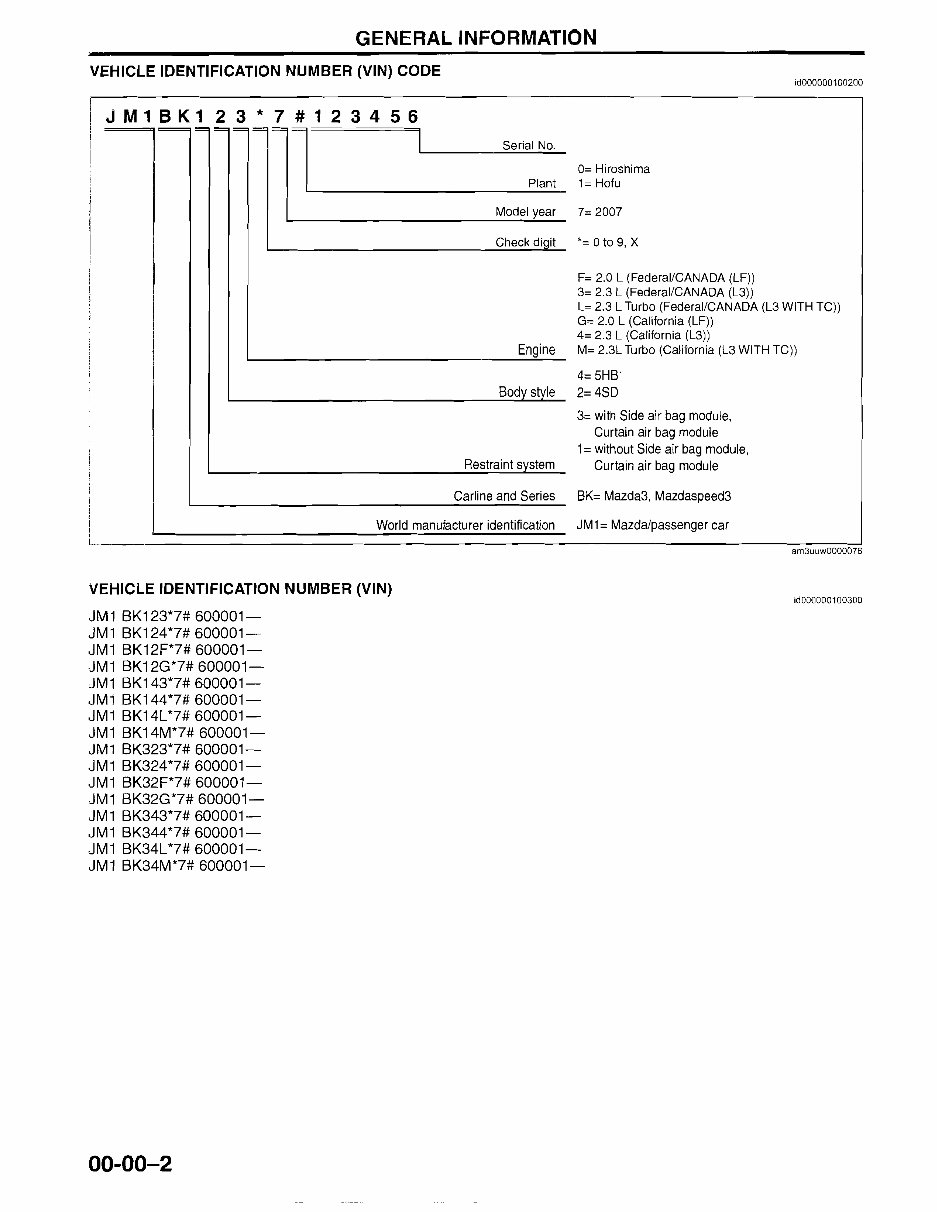

GENERAL INFORMATION

VEHICLE IDENTIFICATION NUMBER (VIN) CODE

id000000100200

JM1BK123*7#123456

'~~~~~'~l Serial No.

I

Plant

Model year

Check diqit

Engine

Body style

Restraint system

Carline and Series

World manufacturer identification

0= Hiroshima

1= Hofu

7= 2007

*= 0 to 9, X

F= 2.0 L (Federal/CANADA (LF))

3= 2.3 L (Federal/CANADA (L3))

L= 2.3 L Turbo (Federal/CANADA (L3 WITH TC))

G= 2.0 L (California (LF))

4= 2.3 L (California (L3))

M= 2.3L Turbo (California (L3 WITH TC))

4= 5HB

2= 4SD

3= with Side air bag module,

Curtain air bag module

1 = without Side air bag module,

Curtain air bag module

BK= Mazda3, Mazdaspeed3

J M1= Mazdalpassenger car

VEHICLE IDENTIFICATION NUMBER (VIN)

JM1 BK123*7# 600001-

JM1 BK124*7# 600001-

JM1 BK12F*7# 600001-

JM1 BK12G*7# 600001-

JM1 BK143*7# 600001-

JM1 BK144*7# 600001-

JM 1 BK14L*7# 600001-

JM1 BK14M*7# 600001-

JM1 BK323*7# 600001-

JM1 BK324*7# 600001-

JM1 BK32F*7# 600001-

JM1 BK32G*7# 600001-

JM1 BK343*7# 600001-

JM1 BK344*7# 600001-

JM1 BK34L*7# 600001-

JM1 BK34M*7# 600001-

am3uuw0000076

id000000100300

00-00-2

GENERAL INFORMATION

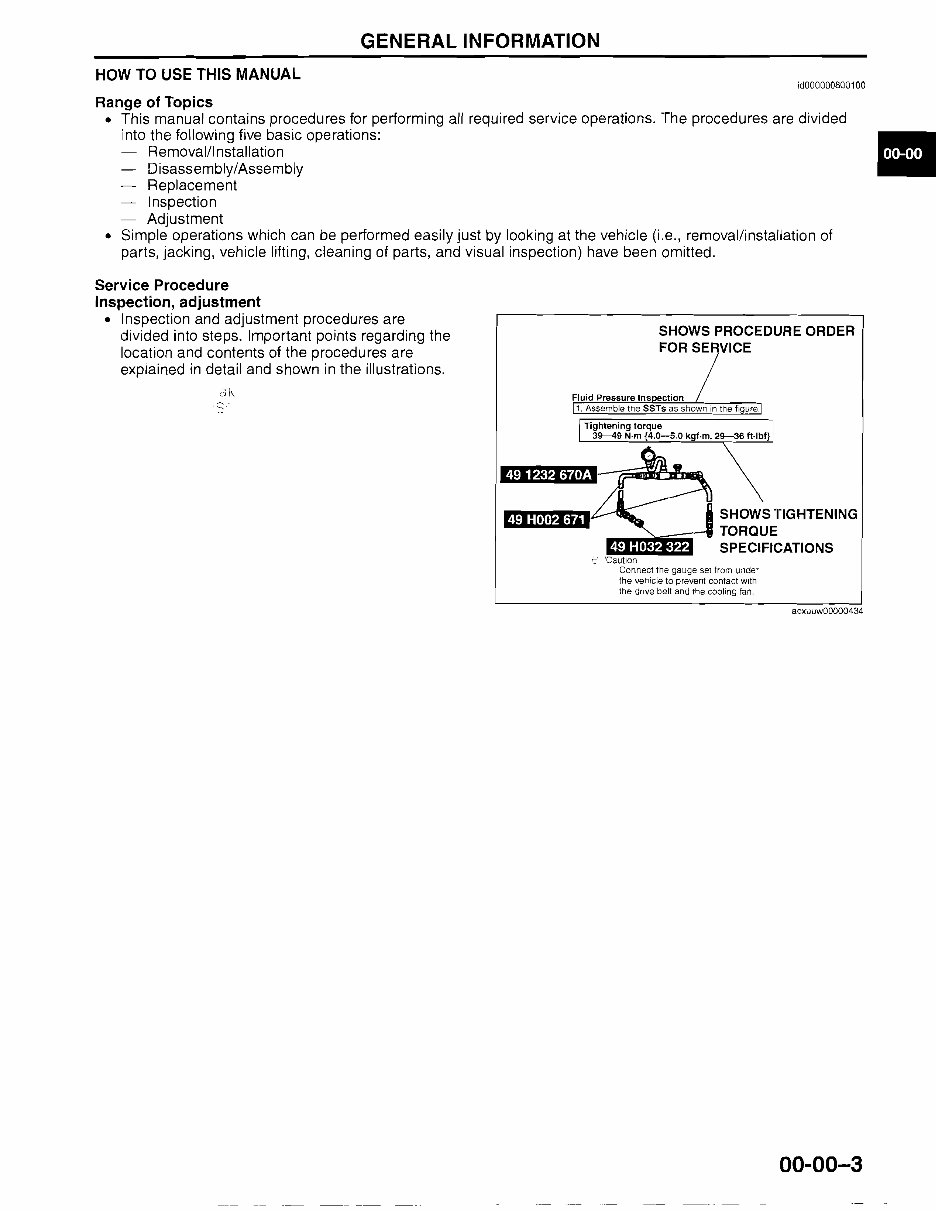

HOW TO USE THIS MANUAL

Range of Topics

id000000800100

• This manual contains procedures for performing all required service operations. The procedures are divided

into the following five basic operations:

Removal/I nstallation

Disassembly/Assembly

Replacement

•

Inspection

Adjustment

• Simple operations which can be performed easily just by looking at the vehicle (i.e., removal/installation of

parts, jacking, vehicle lifting, cleaning of parts, and visual inspection) have been omitted.

Service Procedure

Inspection, adjustment

• Inspection and adjustment procedures are

SHOWS PROCEDURE ORDER

divided into steps. Important points regarding the

FOR SERVICE

location and contents of the procedures are

explained in detail and shown in the illustrations.

SHOWS TIGHTENING

TORQUE

SPECIFICATIONS

~. 'Caution

Connect the gauge set from under

the vehicie to prevent contact with

the drive belt and the cooling fan.

acxuuw00000434

00-00-3

GENERAL INFORMATION

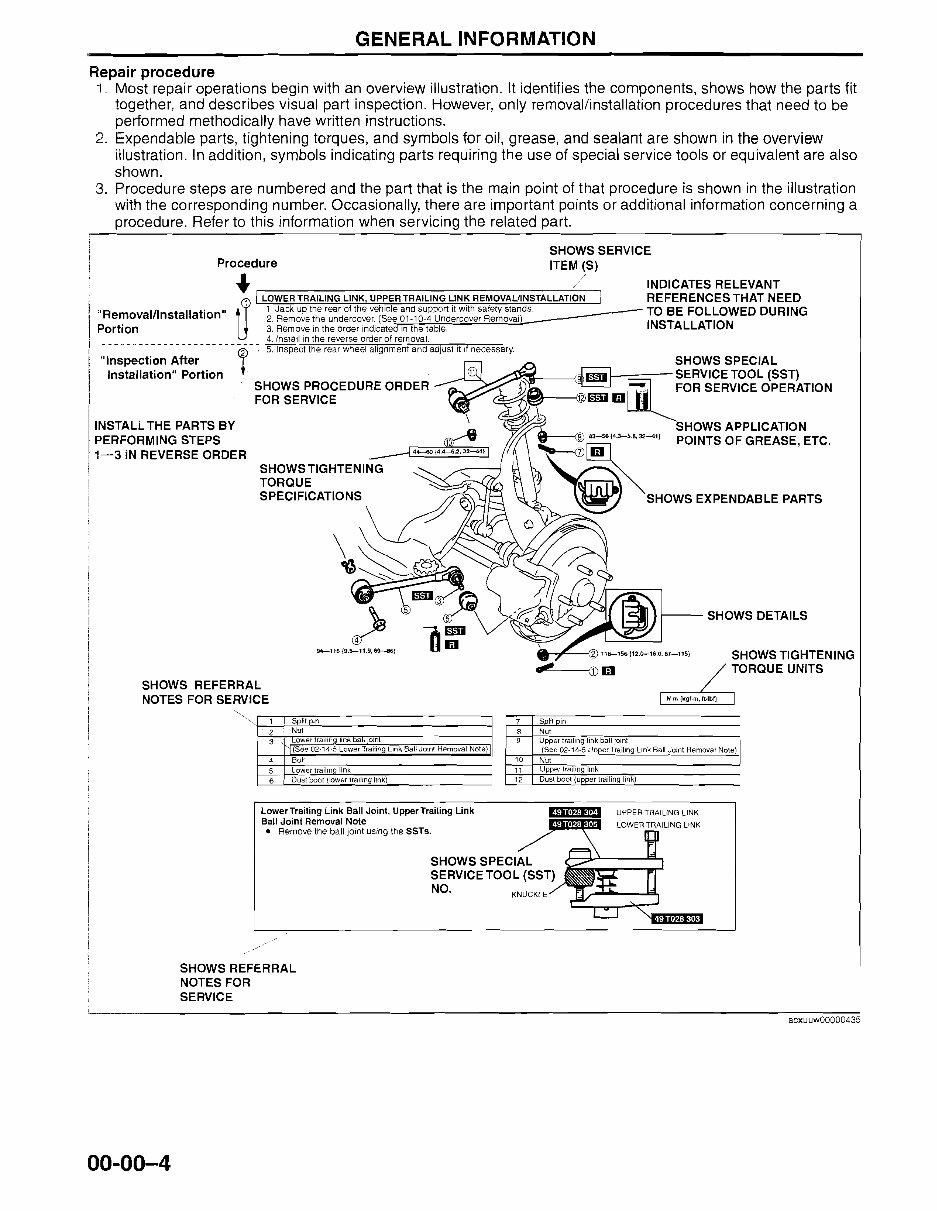

Repair procedure

1. Most repair operations begin with an overview illustration. It identifies the components, shows how the parts fit

together, and describes visual part inspection. However, only removal/installation procedures that need to be

performed methodically have written instructions.

2. Expendable parts, tightening torques, and symbols for oil, grease, and sealant are shown in the overview

illustration. In addition, symbols indicating parts requiring the use of special service tools or equivalent are also

shown.

3. Procedure steps are numbered and the part that is the main point of that procedure is shown in the illustration

with the corresponding number. Occasionally, there are important points or additional information concerning a

procedure. Refer to this information when servicing the related part.

SHOWS SERVICE

Procedure ITEM (S)

... / INDICATES RELEVANT

I LOWER TRAILING LINK, UPPER TRAILING LINK REMOVAUINSTALLATION I REFERENCES THAT NEED

"R III t II t'" 1.JaCkup therearotthevehlclea.ndsu

pp

ort. it with safely stands. __--- TO BE FOLLOWED DURING

emova ns a a Ion 2. Remove the undercover (See 01-10-4 Undercover Removal

Portion 3. Remove in the order indicated ,n the table INSTALLATION

U

4. Install in the reverse order of removal.

---- _.- ---------------- -~-.- ~ 5. Inspect the rear wheel alignment and adjust it if necessary.

SHOWS TIGHTENING

TORQUE UNITS

SHOWS DETAILS

94--116 {9.5-11.9, 69--a6}

SHOWS REFERRAL

NOTES FOR SERVICE

SHOWS TIGHTENING

TORQUE

SPECIFICATIONS

"Inspection After

Installation" Portion

INSTALL THE PARTS BY

PERFORMING STEPS

1-3 IN REVERSE ORDER

SHOWS PROCEDURE ORDER

FOR SERVICE

"'-.",. ,

Split pm

2 Nul

ower Iral In

'"

a jOint

(See O?-14-5 Lower Trailing Link Sal! Joint Removal Nole)

3

4 Bolt

Lower traihno link

Dust boot (lower trailing link)

5

6

7 50lit Din

8 Nul

9 Upper trailing link ball jOint

(See 02-14-5 Upper Trailing link Ball Joint Removal Note)

10 NUl

11 Upper trailing hnk

12 Dust boot (upper trailing link)

LowerTrailing Link Ball Joint, Upper Trailing Link

Ball Joint Removal Note

• Remove the ball jOint using the SSTs.

SHOWS SPECIAL

SERVICE TOOL (SST)

NO.

KNUCKLE

'€i"f1:'ft§1

SHOWS REFERRAL

NOTES FOR

SERVICE

acxuuw00000435

00-00-4

GENERAL INFORMATION

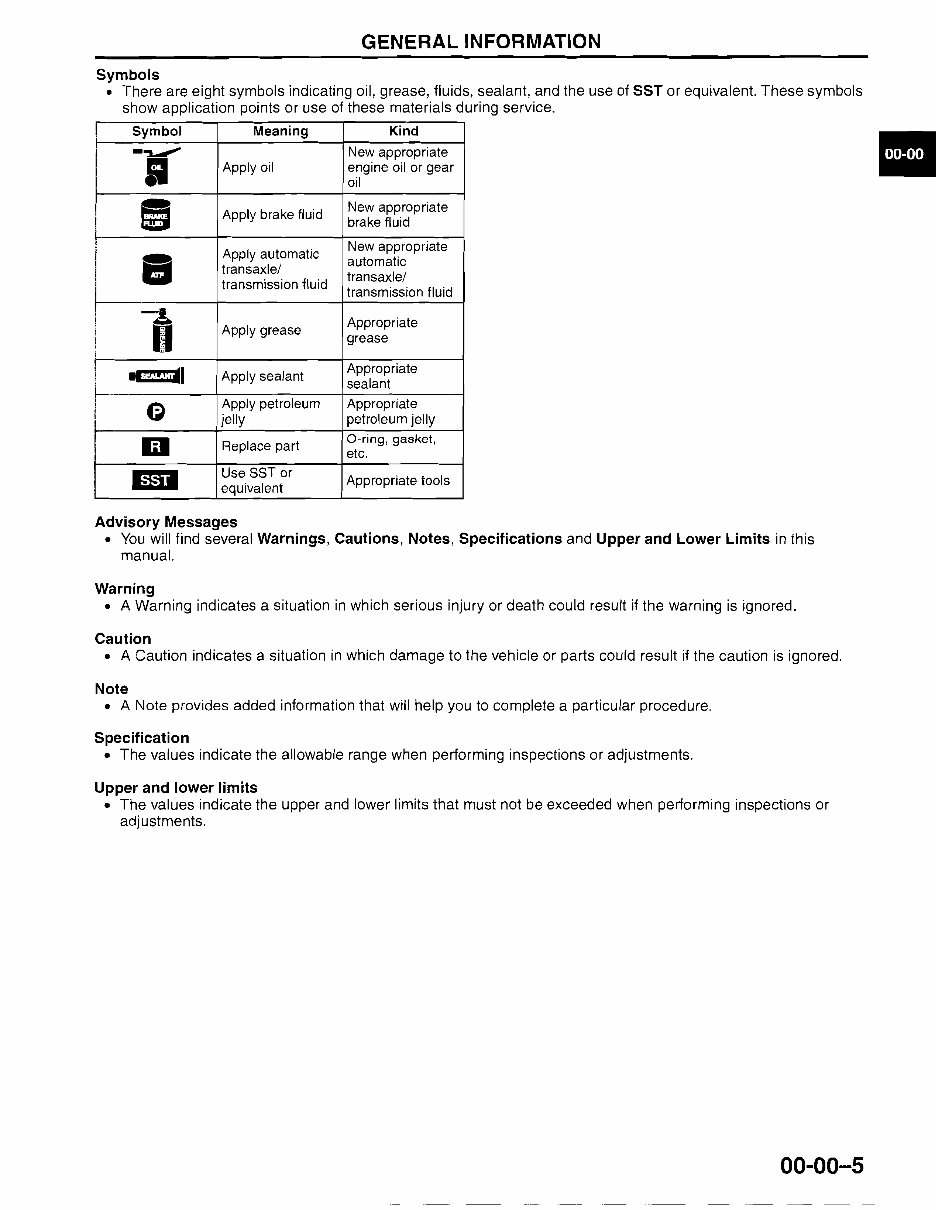

Symbols

• There are eight symbols indicating oil, grease, fluids, sealant, and the use of SST or equivalent. These symbols

show application points or use of these materials during service.

..

Symbol Meaning Kind

-~

I

Apply oil

New appropriate

engine oil or gear

oil

•

" .

Apply brake fluid

New appropriate

brake fluid

I

I

•

Apply automatic

transaxle/

transmission fluid

New appropriate

automatic

transaxle/

transmission fluid

I

I

,

i

-A

I

Apply grease

Appropriate

grease

I

! ~I

Apply sealant

Appropriate

sealant

e

Apply petroleum

jelly

Appropriate

petroleum jelly

iii

Replace part

O-ring, gasket,

etc.

lID

Use SST or

equivalent

Appropriate tools

Advisory Messages

• You will find several Warnings, Cautions, Notes, Specifications and Upper and Lower Limits in this

manual.

Warning

• A Warning indicates a situation in which serious injury or death could result if the warning is ignored.

Caution

• A Caution indicates a situation in which damage to the vehicle or parts could result if the caution is ignored.

Note

• A Note provides added information that will help you to complete a particular procedure.

Specification

• The values indicate the allowable range when performing inspections or adjustments.

Upper and lower limits

• The values indicate the upper and lower limits that must not be exceeded when performing inspections or

adjustments.

00-00-5

GENERAL INFORMATION

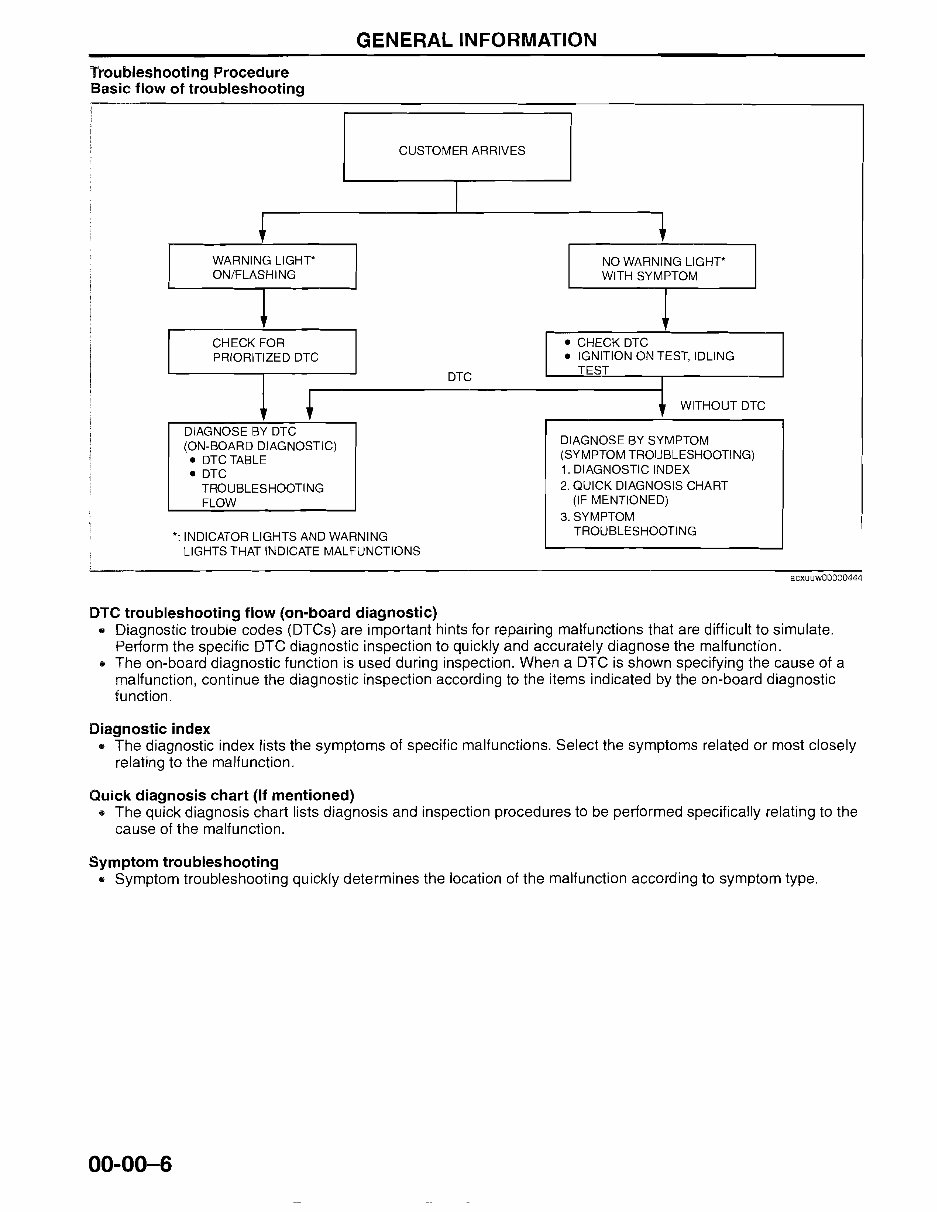

Troubleshooting Procedure

Basic flow of troubleshooting

WARNING L1GHT*

ON/FLASHING

CHECK FOR

PRIORITIZED DTC

DIAGNOSE BY DTC

•

(ON-BOARD DIAGNOSTIC)

.. DTCTABLE

.. DTC

TROUBLESHOOTING

FLOW

CUSTOMER ARRIVES

I

DTC

*: INDICATOR LIGHTS AND WARNING

LIGHTS THAT INDICATE MALFUNCTIONS

!

DTC troubleshooting flow (on-board diagnostic)

NO WARNING L1GHT*

WITH SYMPTOM

•

~

.. CHECK DTC

.. IGNITION ON TEST, IDLING

TEST

I

~ WITHOUT DTC

DIAGNOSE BY SYMPTOM

(SYMPTOM TROUBLESHOOTING)

1. DIAGNOSTIC INDEX

2. QUICK DIAGNOSIS CHART

(IF MENTIONED)

3. SYMPTOM

TROUBLESHOOTING

acxuuw00000444

.. Diagnostic trouble codes (DTCs) are important hints for repairing malfunctions that are difficult to simulate.

Periorm the specific DTC diagnostic inspection to quickly and accurately diagnose the malfunction.

.. The on-board diagnostic function is used during inspection. When a DTC is shown specifying the cause of a

malfunction, continue the diagnostic inspection according to the items indicated by the on-board diagnostic

function.

Diagnostic index

.. The diagnostic index lists the symptoms of specific malfunctions. Select the symptoms related or most closely

relating to the malfunction.

Quick diagnosis chart (If mentioned)

.. The quick diagnosis chart lists diagnosis and inspection procedures to be periormed specifically relating to the

cause of the malfunction.

Symptom troubleshooting

.. Symptom troubleshooting quickly determines the location of the malfunction according to symptom type.

00-00-6

GENERAL INFORMATION

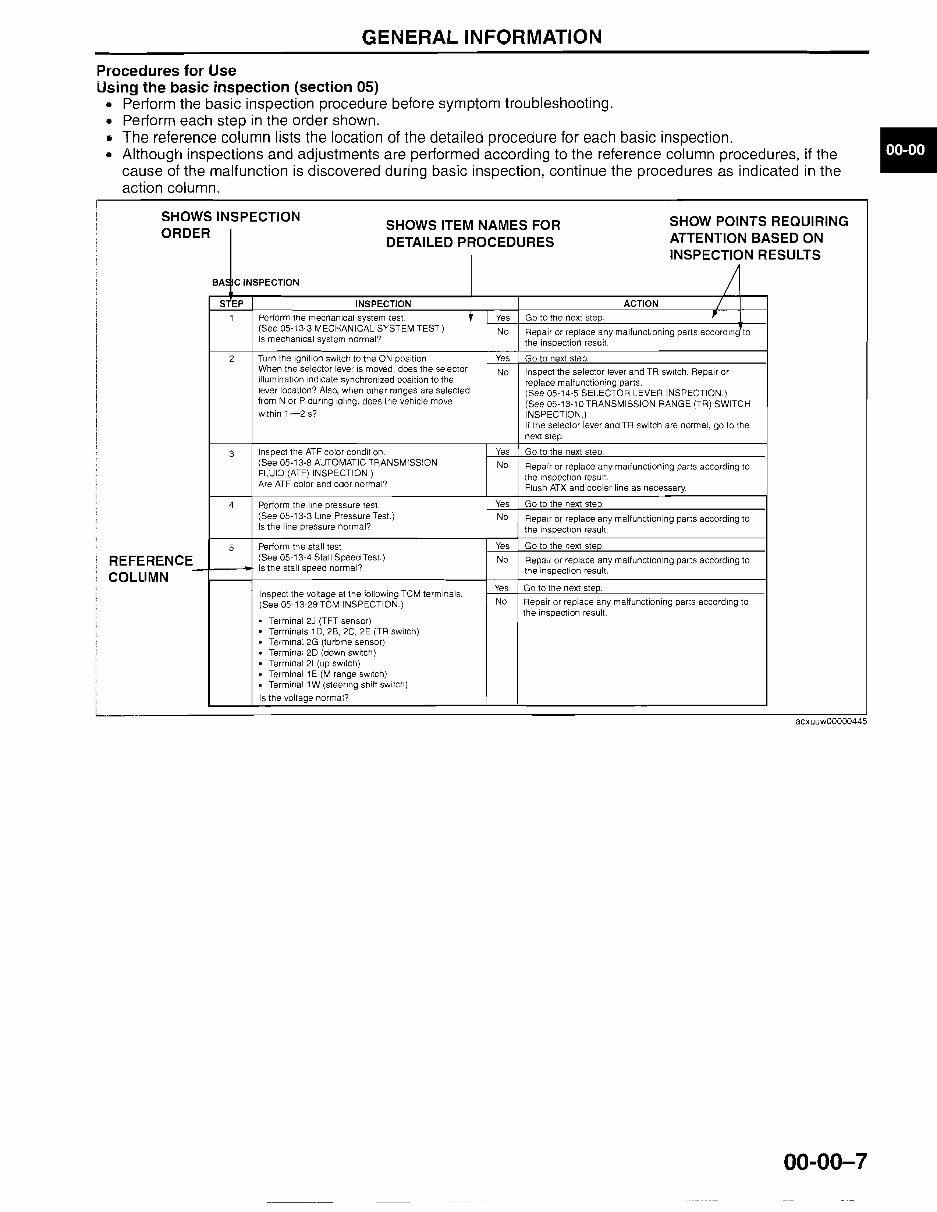

Procedures for Use

Using the basic inspection (section 05)

• Perform the basic inspection procedure before symptom troubleshooting.

• Perform each step in the order shown.

.. The reference column lists the location of the detailed procedure for each basic inspection.

• Although inspections and adjustments are performed according to the reference column procedures, if the

cause of the malfunction is discovered during basic inspection, continue the procedures as indicated in the

action column.

SHOWS INSPECTION

S EP INSPECTION

Perform the mecnanical system test. Yes

(See 05-13-3 MECHANICAL SYSTEM TEST.)

No Repair or replace any malfunctioning parts according to

Is mechanical system normal?

the inspection result.

2 Turn the Ignition switch to the ON position. Yes Go to next step.

When the selector lever is moved, does the selector

No Inspect the selector lever and TR sWitch. Repair or

illumination indicate synchronized position to the

replace malfunctioning parts.

lever location? Also, when other ranges are selected

(See 05-14-5 SELECTOR LEVER INSPECTION.)

from N or P during idling. does the vehicle move

(See 05-13-10TRANSMISSION RANGE (TR) SWITCH

within 1-2 s? INSPECTION.)

If the selector iever and TR switch are normal, go to the

next step.

3

Inspect the ATF color condition Yes Go to the next steD.

(See 05-13-8 AUTOMATIC TRANSMISSION

No Repair or replace any malfunctioning parts according to

FLUID (ATF) INSPECTION.)

The inspection resulT

Are ATF color and odor normal?

Flush ATX and cooler line as necessary.

4 Perform the line pressure test. Yes Go to the next step.

(See 05-13-3 Line Pressure Test.) No

Repair or replace any malfunctioning pans according to

Is the line pressure normal?

the inspection result

5 Perform the stall test. Yes Go to the next steD.

REFERENCE

(See 05-13-4 Stall Speed Test.)

No Repair or replace any malfunctioning parts according to

COLUMN

Is the stall speed normal?

the inspection result.

Inspect the voltage at the following TCM terminals.

Yes Go to the next step.

(See 05-13-29TCM INSPECTION.)

No

SHOW POINTS REQUIRING

SHOWS ITEM NAMES FOR

ORDER

ATTENTION BASED ON

DETAILED PROCEDURES

INSPECTION RESULTS

BA~ C INSPECTION

/

ACTION

/

,

Go to the next step. 1

Repair or replace any malfunctioning pans according to

the inspection result.

·

·

·

·

·

Terminal 2J (TFT sensor)

Terminals 1D, 26, 2C, 2E (TR switch)

Terminal 2G (turbine sensor)

Terminal 2D (down switch)

Terminal 21 (up sWitch)

Terminal 1E (M range switch)

Terminal 1W (steering shih switch)

Is the voltage normal?

[

..

acxuuw00000445

00-00-7

GENERAL INFORMATION

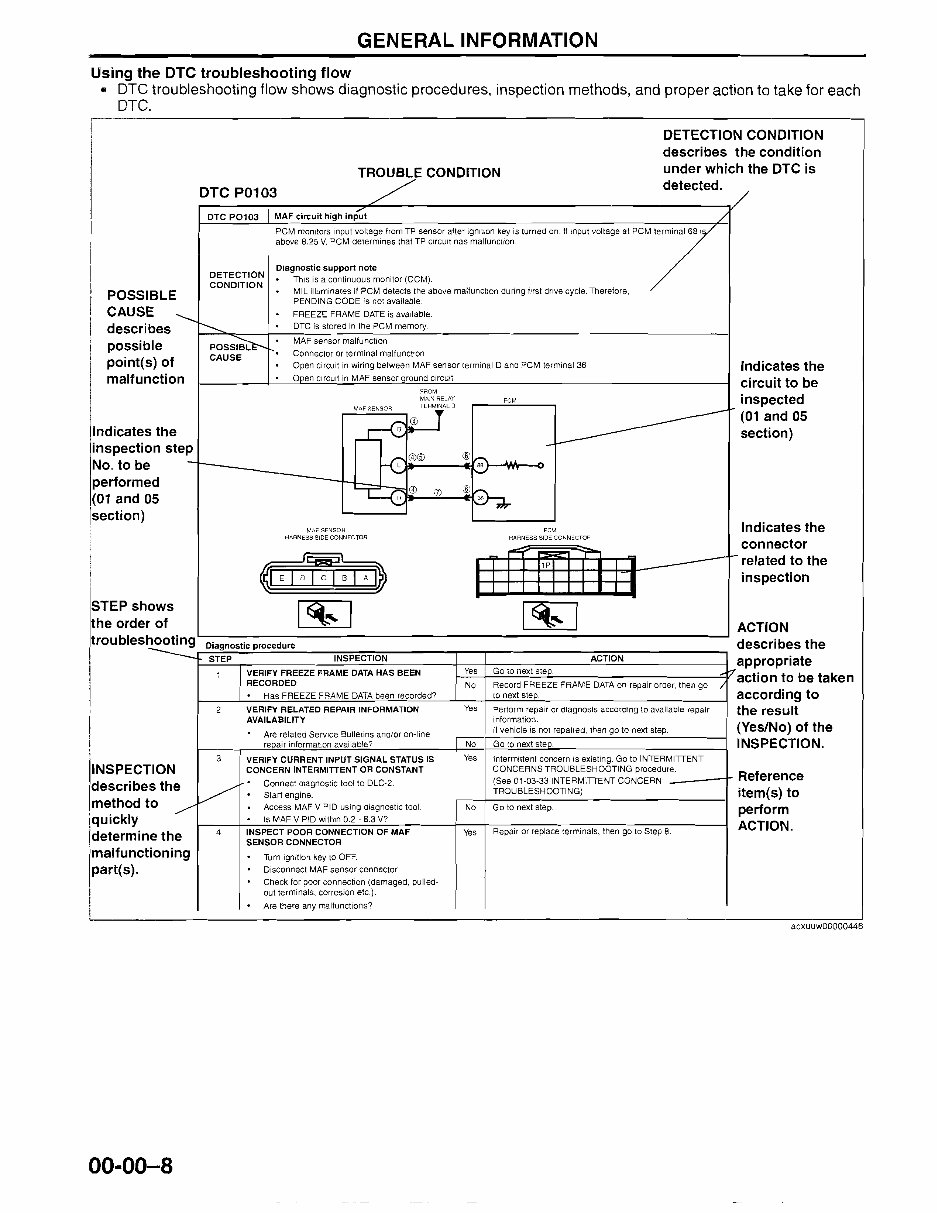

Using the DTC troubleshooting flow

• DTC troubleshooting flow shows diagnostic procedures, inspection methods, and proper action to take for each

DTC.

I

I

I

POSSIBLE

CAUSE

describes

possible

point(s) of

malfunction

I

Iindicates the

inspection step

No. to be

performed

(01 and 05

section)

STEP shows

the order of

troubleshooting

---..:..

INSPECTION

describe sthe

method t 0

/

quickly

Idetermin ethe

'malfunct ioning

part(s).

[

I

TROUBLE CONDITION

DTC P0103

DTC P0103 MAF circuit high input

DETECTION

CONDITION

Diagnostic support note

This is a continuous monitor (GeM).

MIL illuminates if PCM detects the above malfunction during first drive cycle. Therefore,

PENDING CODE is nor available

FREEZE FRAME DATE is available.

DTC is stored in the PCM memory.

PCM monitors input voltage from TP sensor after ignition key is turned on. If Input voltage at PCM terminal 68 !

above 8.25 V. PCM determines thai TP Circuit nas malfunccion

POSSIBL

CAUSE

MAF sensor malfunction

Connector or terminal malfunction

Open circuit in wiring between MAF sensor terminal 0 and PCM terminal 36

o en circuit in MAF sensor round circuit

lP

PCM

HARNESS SIDE COM~ECTOR

FROM

MAIN RELAY PCM

TERMINAL D

MAF SENSOR

HARNESS SIDE CONNECTOR

Diagnostic procedure describes the

STEP INSPECTION ACTION

appropriate

1

VERIFY FREEZE FRAME DATA HAS BEEN

RECORDED

Yes

No

Go to next step.

Record FREEZE FRAME DATA on repair order, then go

~

/

action to be taken

Has FREEZE FRAME DATA been recorded? to next step, according to

2 VERIFY RELATED REPAIR INFORMATION Yes Perform repair or diagnosis according to available repair

the result

AVAILABILITY

Are related Service Bullelins and/or on-line

information.

If vehicle is not repaired. then go to next step. (Yes/No) of the

repair information available? No Go to next steD. INSPECTION.

3 VERIFY CURRENT INPUT SIGNAL STATUS IS

Yes Intermittent concern is existing. Go to INTERMITTENT

CONCERN INTERMITIENT OR CONSTANT

/

Connect diagnostic tool to DLC-2.

Start engine.

Access MAF V PID using diagnostic tool. No

CONCERNS TROUBLESHOOTING procedure.

(See 01-03-33INTERMITIENT CONCERN _

TROUBLESHOOTING)

Go to next step.

Reference

item(s) to

perform

Is MAF V PID within 02 - 8.3 V?

4 INSPECT POOR CONNECTION OF MAF Yes Repair or replace terminals, then go to Step 8.

ACTION.

SENSOR CONNECTOR

Turn ignition key to OFF.

Disconnect MAF sensor connector

Check for poor connection (damaged, pulled-

out terminals, corrosion etc.).

Are there any malfunctions?

DETECTION CONDITION

describes the condition

under which the DTC is

detected.

Indicates the

circuit to be

inspected

(01 and 05

section)

Indicates the

connector

related to the

inspection

ACTION

acxuuw00000446

00-00-8

You're Reading a Preview

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

Viewed 80 Times Today

Loading...

Secure transaction

What's Included?

Fast Download Speeds

Online & Offline Access

Access PDF Contents & Bookmarks

Full Search Facility

Print one or all pages of your manual

$31.99

This manual is applicable to the 2007-2008 Mazda 3 and Mazdaspeed3 models.

It covers a comprehensive range of information, making it a valuable resource for both professional mechanics and DIY enthusiasts.

The manual is available in .PDF format, ensuring compatibility with all Windows versions, as well as Linux and Mac operating systems.

It is accessible for free and does not require shipping.